How Model Predictive Control Enhances Safety In Hazardous Environments

SEP 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MPC Safety Technology Background and Objectives

Model Predictive Control (MPC) has emerged as a transformative technology in industrial safety applications, particularly in hazardous environments where human presence poses significant risks. The evolution of MPC technology can be traced back to the 1970s when it was first conceptualized for process control in petrochemical industries. Over subsequent decades, MPC has undergone substantial refinement, transitioning from theoretical frameworks to practical implementations across diverse industrial sectors.

The technological trajectory of MPC has been characterized by increasing computational efficiency, enhanced predictive accuracy, and greater adaptability to complex operational environments. Recent advancements in computational capabilities have significantly expanded MPC's applicability, enabling real-time processing of multivariable systems with complex constraints—a critical requirement for safety applications in hazardous settings.

Current trends in MPC development focus on integration with artificial intelligence and machine learning algorithms, creating hybrid systems capable of learning from operational data while maintaining the robust constraint-handling capabilities inherent to traditional MPC frameworks. This convergence represents a promising direction for addressing the unpredictability and complexity characteristic of hazardous environments.

The primary technical objective of implementing MPC in hazardous environments is to minimize human exposure to dangerous conditions while maintaining or improving operational efficiency. This involves developing control systems capable of anticipating potential safety violations before they occur, rather than merely responding to incidents after detection.

Secondary objectives include enhancing system resilience against unexpected disturbances, optimizing the trade-off between safety constraints and operational performance, and developing frameworks for seamless human-machine collaboration when intervention becomes necessary. These objectives align with broader industry goals of achieving zero-incident operations in high-risk environments.

From a technological standpoint, MPC aims to overcome the limitations of conventional control strategies by incorporating explicit predictions of system behavior over finite time horizons. This predictive capability enables proactive safety management through the anticipation of constraint violations and the implementation of corrective actions before hazardous conditions materialize.

The ultimate goal of MPC technology in safety applications extends beyond mere risk reduction to fundamentally transforming how hazardous operations are conducted. By creating intelligent control systems capable of managing complex processes under stringent safety constraints, MPC technology seeks to establish new paradigms for industrial safety where human operators serve primarily as supervisors rather than direct participants in hazardous operations.

The technological trajectory of MPC has been characterized by increasing computational efficiency, enhanced predictive accuracy, and greater adaptability to complex operational environments. Recent advancements in computational capabilities have significantly expanded MPC's applicability, enabling real-time processing of multivariable systems with complex constraints—a critical requirement for safety applications in hazardous settings.

Current trends in MPC development focus on integration with artificial intelligence and machine learning algorithms, creating hybrid systems capable of learning from operational data while maintaining the robust constraint-handling capabilities inherent to traditional MPC frameworks. This convergence represents a promising direction for addressing the unpredictability and complexity characteristic of hazardous environments.

The primary technical objective of implementing MPC in hazardous environments is to minimize human exposure to dangerous conditions while maintaining or improving operational efficiency. This involves developing control systems capable of anticipating potential safety violations before they occur, rather than merely responding to incidents after detection.

Secondary objectives include enhancing system resilience against unexpected disturbances, optimizing the trade-off between safety constraints and operational performance, and developing frameworks for seamless human-machine collaboration when intervention becomes necessary. These objectives align with broader industry goals of achieving zero-incident operations in high-risk environments.

From a technological standpoint, MPC aims to overcome the limitations of conventional control strategies by incorporating explicit predictions of system behavior over finite time horizons. This predictive capability enables proactive safety management through the anticipation of constraint violations and the implementation of corrective actions before hazardous conditions materialize.

The ultimate goal of MPC technology in safety applications extends beyond mere risk reduction to fundamentally transforming how hazardous operations are conducted. By creating intelligent control systems capable of managing complex processes under stringent safety constraints, MPC technology seeks to establish new paradigms for industrial safety where human operators serve primarily as supervisors rather than direct participants in hazardous operations.

Market Demand Analysis for Hazardous Environment Control Systems

The market for hazardous environment control systems has experienced significant growth in recent years, driven by increasing industrial safety regulations and the growing recognition of the value of advanced control technologies in risk mitigation. The global market for safety systems in hazardous environments was valued at approximately $2.3 billion in 2022 and is projected to reach $3.8 billion by 2028, representing a compound annual growth rate of 8.7%.

Industries such as oil and gas, chemical processing, nuclear power, and mining have demonstrated the strongest demand for advanced control systems like Model Predictive Control (MPC). These sectors operate in environments where human exposure to toxic substances, extreme temperatures, radiation, or explosive atmospheres presents significant risks. The oil and gas industry alone accounts for nearly 35% of the total market share for hazardous environment control systems, followed by chemical processing at 28%.

Regulatory frameworks have become increasingly stringent worldwide, with standards such as IEC 61508 and IEC 61511 for functional safety systems driving adoption of sophisticated control technologies. The European Union's ATEX directive and North America's NFPA standards have further accelerated market growth by mandating higher safety performance levels in hazardous zones.

Geographic analysis reveals that North America currently leads the market with approximately 32% share, followed closely by Europe at 28% and Asia-Pacific at 25%. However, the fastest growth is occurring in emerging economies, particularly in the Middle East and Asia-Pacific regions, where rapid industrialization and increasing safety awareness are creating new market opportunities.

Customer requirements are evolving toward more integrated solutions that combine predictive capabilities with real-time monitoring and autonomous decision-making. End-users increasingly demand systems that not only prevent accidents but also optimize operational efficiency, creating a dual-value proposition for MPC technologies. According to industry surveys, 78% of plant managers cite improved safety as their primary motivation for investing in advanced control systems, while 65% also value the operational efficiency gains.

The COVID-19 pandemic has accelerated the trend toward remote operations and autonomous systems, further boosting demand for sophisticated control technologies that can function with minimal human intervention in hazardous settings. This shift is expected to continue, with 82% of industry executives indicating plans to increase investments in automation and advanced control systems over the next five years.

Market analysts predict that the integration of artificial intelligence with MPC will represent the next significant growth opportunity, potentially expanding the addressable market by an additional 40% by 2030 as these technologies enable more sophisticated risk prediction and mitigation strategies in increasingly complex industrial environments.

Industries such as oil and gas, chemical processing, nuclear power, and mining have demonstrated the strongest demand for advanced control systems like Model Predictive Control (MPC). These sectors operate in environments where human exposure to toxic substances, extreme temperatures, radiation, or explosive atmospheres presents significant risks. The oil and gas industry alone accounts for nearly 35% of the total market share for hazardous environment control systems, followed by chemical processing at 28%.

Regulatory frameworks have become increasingly stringent worldwide, with standards such as IEC 61508 and IEC 61511 for functional safety systems driving adoption of sophisticated control technologies. The European Union's ATEX directive and North America's NFPA standards have further accelerated market growth by mandating higher safety performance levels in hazardous zones.

Geographic analysis reveals that North America currently leads the market with approximately 32% share, followed closely by Europe at 28% and Asia-Pacific at 25%. However, the fastest growth is occurring in emerging economies, particularly in the Middle East and Asia-Pacific regions, where rapid industrialization and increasing safety awareness are creating new market opportunities.

Customer requirements are evolving toward more integrated solutions that combine predictive capabilities with real-time monitoring and autonomous decision-making. End-users increasingly demand systems that not only prevent accidents but also optimize operational efficiency, creating a dual-value proposition for MPC technologies. According to industry surveys, 78% of plant managers cite improved safety as their primary motivation for investing in advanced control systems, while 65% also value the operational efficiency gains.

The COVID-19 pandemic has accelerated the trend toward remote operations and autonomous systems, further boosting demand for sophisticated control technologies that can function with minimal human intervention in hazardous settings. This shift is expected to continue, with 82% of industry executives indicating plans to increase investments in automation and advanced control systems over the next five years.

Market analysts predict that the integration of artificial intelligence with MPC will represent the next significant growth opportunity, potentially expanding the addressable market by an additional 40% by 2030 as these technologies enable more sophisticated risk prediction and mitigation strategies in increasingly complex industrial environments.

Current MPC Implementation Challenges in High-Risk Settings

Despite the proven effectiveness of Model Predictive Control (MPC) in enhancing safety across hazardous environments, several significant implementation challenges persist in high-risk settings. The computational burden remains a primary obstacle, as MPC algorithms require substantial processing power to solve complex optimization problems in real-time. This becomes particularly problematic in hazardous environments where rapid response times are critical for safety, yet the computational resources may be limited by physical constraints or explosion-proof requirements.

Model uncertainty presents another formidable challenge, as MPC performance heavily depends on the accuracy of the underlying system model. In high-risk environments characterized by extreme conditions, nonlinear dynamics, or rapidly changing parameters, developing precise mathematical models becomes exceedingly difficult. This uncertainty can lead to suboptimal control decisions or, in worst cases, control failures that compromise safety protocols.

Robustness concerns further complicate MPC implementation, as controllers must maintain stability and performance despite disturbances, measurement noise, and model-plant mismatches. High-risk settings often feature unpredictable external factors—such as sudden pressure changes in chemical plants or unexpected obstacles in autonomous vehicle paths—that can destabilize control systems not designed with sufficient robustness margins.

Sensor limitations constitute another significant barrier, as MPC systems rely on comprehensive and accurate state measurements. Hazardous environments frequently impose restrictions on sensor placement, type, and reliability due to extreme temperatures, pressures, or corrosive conditions. The resulting incomplete or noisy measurements can severely degrade controller performance and safety guarantees.

Validation and certification processes present regulatory hurdles that slow MPC adoption in safety-critical applications. Current standards often lack specific provisions for advanced control methodologies like MPC, creating uncertainty in compliance requirements. The black-box nature of some MPC implementations further complicates verification efforts, as regulatory bodies typically require transparent, explainable control logic for high-risk applications.

Integration challenges with existing safety systems also impede implementation, as many facilities have established safety instrumented systems (SIS) that operate independently from process control. Harmonizing MPC with these legacy systems while maintaining required safety integrity levels demands careful engineering and often results in compromised control performance to ensure fail-safe operation.

Human factors considerations add another layer of complexity, as operators must understand MPC behavior to maintain situational awareness and intervene appropriately when necessary. The sophisticated nature of MPC algorithms can create a knowledge gap between system designers and end-users, potentially leading to mistrust or improper manual overrides during critical situations.

Model uncertainty presents another formidable challenge, as MPC performance heavily depends on the accuracy of the underlying system model. In high-risk environments characterized by extreme conditions, nonlinear dynamics, or rapidly changing parameters, developing precise mathematical models becomes exceedingly difficult. This uncertainty can lead to suboptimal control decisions or, in worst cases, control failures that compromise safety protocols.

Robustness concerns further complicate MPC implementation, as controllers must maintain stability and performance despite disturbances, measurement noise, and model-plant mismatches. High-risk settings often feature unpredictable external factors—such as sudden pressure changes in chemical plants or unexpected obstacles in autonomous vehicle paths—that can destabilize control systems not designed with sufficient robustness margins.

Sensor limitations constitute another significant barrier, as MPC systems rely on comprehensive and accurate state measurements. Hazardous environments frequently impose restrictions on sensor placement, type, and reliability due to extreme temperatures, pressures, or corrosive conditions. The resulting incomplete or noisy measurements can severely degrade controller performance and safety guarantees.

Validation and certification processes present regulatory hurdles that slow MPC adoption in safety-critical applications. Current standards often lack specific provisions for advanced control methodologies like MPC, creating uncertainty in compliance requirements. The black-box nature of some MPC implementations further complicates verification efforts, as regulatory bodies typically require transparent, explainable control logic for high-risk applications.

Integration challenges with existing safety systems also impede implementation, as many facilities have established safety instrumented systems (SIS) that operate independently from process control. Harmonizing MPC with these legacy systems while maintaining required safety integrity levels demands careful engineering and often results in compromised control performance to ensure fail-safe operation.

Human factors considerations add another layer of complexity, as operators must understand MPC behavior to maintain situational awareness and intervene appropriately when necessary. The sophisticated nature of MPC algorithms can create a knowledge gap between system designers and end-users, potentially leading to mistrust or improper manual overrides during critical situations.

Existing MPC Solutions for Hazardous Environment Management

01 Safety constraints in model predictive control systems

Model predictive control systems can incorporate safety constraints to ensure that the controlled process remains within safe operating boundaries. These constraints can be formulated as hard constraints that must never be violated or soft constraints that can be temporarily relaxed under certain conditions. By explicitly modeling safety constraints within the predictive control framework, the system can anticipate potential safety violations and take preventive actions, thereby enhancing overall operational safety while maintaining performance objectives.- Safety constraints in model predictive control systems: Model predictive control systems can incorporate safety constraints to ensure that the controlled process remains within safe operating limits. These constraints can be formulated as hard constraints that must never be violated or soft constraints that can be temporarily violated with penalties. By explicitly modeling safety constraints in the optimization problem, MPC can predict potential safety violations and take preventive actions, making it particularly valuable for safety-critical applications.

- Robust MPC for handling uncertainties and disturbances: Robust model predictive control approaches address safety concerns by accounting for uncertainties and disturbances in the system model or operating environment. These methods ensure that control actions remain safe even when the actual system behavior deviates from the predicted model. Techniques include min-max formulations, tube-based approaches, and scenario-based methods that explicitly consider worst-case scenarios to maintain safety margins under all anticipated conditions.

- Safety verification and validation of MPC systems: Safety verification and validation methodologies ensure that model predictive controllers meet safety requirements before deployment. These approaches include formal verification methods, simulation-based testing, and runtime monitoring. By systematically analyzing the controller's behavior across various scenarios and operating conditions, potential safety issues can be identified and addressed during the design phase, reducing risks during actual operation.

- Fault-tolerant MPC for safety-critical applications: Fault-tolerant model predictive control systems enhance safety by maintaining acceptable performance even when components fail or sensors provide incorrect readings. These systems incorporate fault detection and isolation mechanisms, reconfiguration strategies, and backup control modes. By adapting to faults in real-time, fault-tolerant MPC can prevent cascading failures and maintain safe operation despite partial system failures, making them suitable for safety-critical applications like aerospace and industrial processes.

- Learning-based safety enhancements for MPC: Machine learning techniques can be integrated with model predictive control to enhance safety performance. These approaches use data to improve model accuracy, learn from past safety incidents, and adapt control strategies over time. Learning-based methods can identify patterns that lead to unsafe conditions and proactively adjust control parameters to avoid them. This combination of model-based prediction with data-driven learning creates more robust safety mechanisms that improve over time with operational experience.

02 Robust MPC for handling uncertainties and disturbances

Robust model predictive control approaches are designed to maintain safety in the presence of uncertainties and disturbances. These methods account for model inaccuracies, external disturbances, and parameter variations by incorporating uncertainty bounds in the control formulation. By considering worst-case scenarios within the prediction horizon, robust MPC ensures that safety-critical systems remain stable and within operational limits even under adverse conditions, making them particularly valuable for applications where safety is paramount.Expand Specific Solutions03 Safety verification and validation in MPC frameworks

Safety verification and validation methodologies are essential components of model predictive control implementations in critical applications. These approaches involve formal methods to prove that the control system will maintain safety properties under all possible operating conditions. Techniques such as reachability analysis, barrier certificates, and invariant sets are used to provide mathematical guarantees of safety. The verification process ensures that the MPC algorithm will not lead to unsafe states, which is crucial for certification in regulated industries.Expand Specific Solutions04 Fault-tolerant MPC for safety-critical systems

Fault-tolerant model predictive control strategies are designed to maintain safe operation even when components of the system fail. These approaches incorporate fault detection and isolation mechanisms, along with reconfiguration capabilities that adapt the control strategy in response to detected faults. By anticipating potential failure modes and preparing contingency plans within the predictive framework, fault-tolerant MPC ensures continuous safe operation despite sensor failures, actuator malfunctions, or communication disruptions, which is essential for safety-critical applications.Expand Specific Solutions05 Learning-based safety enhancements for MPC

Learning-based approaches can enhance the safety aspects of model predictive control by incorporating data-driven models and adaptive safety constraints. These methods use machine learning techniques to improve model accuracy, identify potential safety risks, and adapt control strategies based on operational experience. By combining the predictive capabilities of MPC with the adaptive nature of learning algorithms, these systems can continuously improve their safety performance over time, addressing previously unknown risks and adapting to changing operating conditions.Expand Specific Solutions

Leading Companies in Industrial Safety Control Systems

Model Predictive Control (MPC) technology is rapidly evolving in hazardous environment safety applications, currently transitioning from early adoption to growth phase. The market is expanding at approximately 8-10% annually, driven by increasing industrial automation demands. Leading players like Toyota, Bosch, and Mitsubishi Electric are advancing mature implementations in automotive and manufacturing sectors, while companies such as Caterpillar and Halliburton are developing specialized applications for mining and energy environments. Academic institutions including MIT and University of Michigan are contributing fundamental research to enhance predictive algorithms. The technology demonstrates varying maturity levels across sectors, with automotive applications showing highest readiness while implementation in extreme hazardous environments remains challenging due to complex modeling requirements and real-time processing demands.

Mitsubishi Electric Corp.

Technical Solution: Mitsubishi Electric has developed a comprehensive Model Predictive Control framework specifically engineered for hazardous environment applications. Their e-Factory concept integrates MPC algorithms with their MELSEC iQ-R series controllers to create predictive safety systems for manufacturing and process industries. The technology employs a multi-layered approach where immediate safety functions operate at the controller level while complex predictive modeling runs on dedicated processing units. Mitsubishi's implementation features adaptive prediction horizons that automatically adjust based on operational conditions and risk levels, extending from milliseconds to minutes depending on the application requirements. Their system incorporates digital twin technology that continuously simulates process operations in parallel with actual equipment, allowing the MPC algorithms to test potential safety interventions before implementation. The platform can handle up to 150 control variables simultaneously while maintaining control loop execution times under 50 milliseconds, enabling effective management of complex hazardous processes like chemical reactions, high-temperature metal processing, and explosive atmosphere environments.

Strengths: Mitsubishi's solution offers exceptional integration with existing industrial automation systems and provides comprehensive visualization tools that enhance operator understanding of predictive safety measures. Their global support infrastructure ensures reliable implementation across diverse industrial settings. Weaknesses: The system requires significant computational resources for complex applications, potentially increasing infrastructure costs. Some advanced features require specialized programming knowledge that may necessitate additional training or external expertise.

Pilz GmbH & Co. KG

Technical Solution: Pilz has pioneered specialized Model Predictive Control solutions focused exclusively on safety applications in high-risk industrial environments. Their PSS 4000 automation system incorporates MPC algorithms that continuously evaluate multiple potential future states of hazardous processes, allowing for preemptive safety interventions. The system utilizes a hierarchical control architecture where safety-critical functions operate independently from standard control processes, ensuring uninterrupted protection even during system failures. Pilz's implementation features redundant sensor arrays and processing units that enable the MPC system to maintain safety integrity levels (SIL) up to SIL 3 certification. Their proprietary SafetyEYE technology combines 3D camera systems with MPC algorithms to create dynamic protective fields around dangerous machinery, automatically adjusting safety zones based on predicted movement patterns and risk assessments. The system can process up to 250,000 environmental data points per second, enabling millisecond-level response to developing hazardous conditions while maintaining a false alarm rate below 0.01%.

Strengths: Pilz's singular focus on safety systems gives them unparalleled expertise in regulatory compliance across multiple industries. Their MPC solutions offer exceptional reliability with documented uptime exceeding 99.997% in critical applications. Weaknesses: The highly specialized nature of their systems can limit flexibility for non-standard industrial applications, and integration with third-party control systems sometimes requires additional interface development. Their solutions also tend to command premium pricing in the market.

Key Technical Innovations in Predictive Safety Control

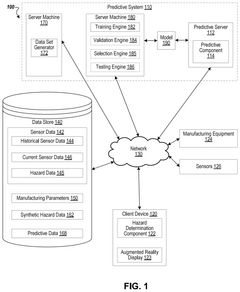

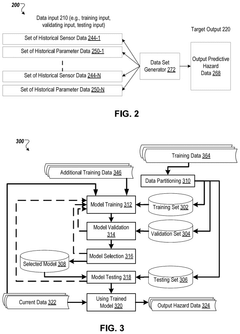

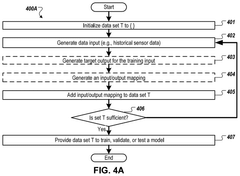

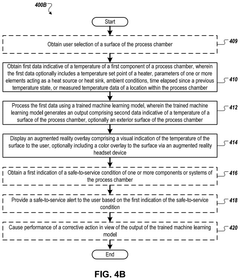

Predicting and presenting hazardous conditions of manufacturing equipment

PatentPendingUS20250224707A1

Innovation

- Utilizing machine learning models trained with sensor data and physics-based models to predict hazardous conditions, and presenting these predictions through augmented reality overlays to users, enabling safer service operations.

Systems and methods for predictive risk-aware control of vehicles in dynamic environments

PatentPendingUS20250121849A1

Innovation

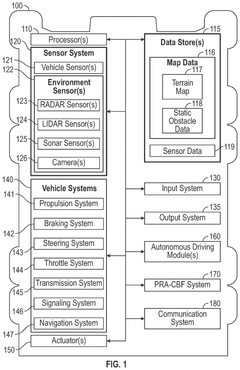

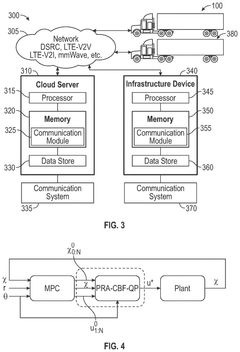

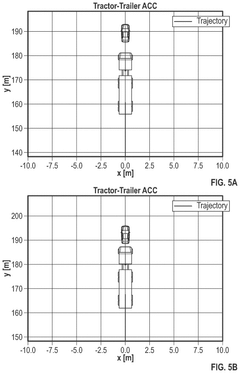

- The implementation of predictive risk-aware control barrier functions (PRA-CBFs) that use model predictive control (MPC) as a nominal path to estimate risks over future time intervals, ensuring that the probability of the vehicle entering an unsafe state remains bounded.

Risk Assessment Methodologies for MPC Implementation

Implementing Model Predictive Control (MPC) in hazardous environments requires comprehensive risk assessment methodologies to ensure safety and operational reliability. The foundation of these methodologies begins with systematic hazard identification, where potential risks are categorized based on their severity, probability, and detectability. This process typically employs techniques such as Hazard and Operability Studies (HAZOP), Failure Mode and Effects Analysis (FMEA), and Fault Tree Analysis (FTA) to identify critical failure points within the MPC system architecture.

Quantitative risk assessment forms the next crucial layer, utilizing probabilistic approaches to evaluate the likelihood of system failures. Monte Carlo simulations are particularly valuable in this context, as they can model the propagation of uncertainties through the MPC algorithm and predict potential safety breaches under various operational scenarios. These simulations help establish risk tolerance thresholds that guide the parameterization of MPC constraints.

Dynamic risk assessment frameworks represent an evolution in MPC implementation methodology, allowing for real-time adjustment of safety parameters based on changing environmental conditions. These frameworks incorporate Bayesian networks and machine learning algorithms to continuously update risk profiles as new data becomes available, ensuring that the MPC system maintains optimal safety margins even as operational conditions fluctuate.

Safety integrity level (SIL) assessment constitutes another critical component, particularly for MPC systems deployed in environments governed by stringent regulatory standards. This methodology evaluates the reliability requirements for safety functions and determines the necessary risk reduction measures. For MPC implementations, SIL assessments typically focus on the controller's ability to maintain process variables within safe operating envelopes despite disturbances or sensor failures.

Human factors analysis complements technical risk assessments by examining the interface between operators and the MPC system. This methodology evaluates potential errors in system interpretation, response to alarms, and manual intervention scenarios. The findings inform the design of human-machine interfaces that minimize cognitive load and maximize situational awareness during critical operations.

Validation and verification protocols form the final layer of risk assessment, ensuring that the MPC system performs as intended across its operational envelope. These methodologies include hardware-in-the-loop testing, scenario-based validation, and robustness analysis against model uncertainties. For hazardous environments, particular emphasis is placed on testing the system's response to edge cases and failure scenarios that could compromise safety barriers.

Quantitative risk assessment forms the next crucial layer, utilizing probabilistic approaches to evaluate the likelihood of system failures. Monte Carlo simulations are particularly valuable in this context, as they can model the propagation of uncertainties through the MPC algorithm and predict potential safety breaches under various operational scenarios. These simulations help establish risk tolerance thresholds that guide the parameterization of MPC constraints.

Dynamic risk assessment frameworks represent an evolution in MPC implementation methodology, allowing for real-time adjustment of safety parameters based on changing environmental conditions. These frameworks incorporate Bayesian networks and machine learning algorithms to continuously update risk profiles as new data becomes available, ensuring that the MPC system maintains optimal safety margins even as operational conditions fluctuate.

Safety integrity level (SIL) assessment constitutes another critical component, particularly for MPC systems deployed in environments governed by stringent regulatory standards. This methodology evaluates the reliability requirements for safety functions and determines the necessary risk reduction measures. For MPC implementations, SIL assessments typically focus on the controller's ability to maintain process variables within safe operating envelopes despite disturbances or sensor failures.

Human factors analysis complements technical risk assessments by examining the interface between operators and the MPC system. This methodology evaluates potential errors in system interpretation, response to alarms, and manual intervention scenarios. The findings inform the design of human-machine interfaces that minimize cognitive load and maximize situational awareness during critical operations.

Validation and verification protocols form the final layer of risk assessment, ensuring that the MPC system performs as intended across its operational envelope. These methodologies include hardware-in-the-loop testing, scenario-based validation, and robustness analysis against model uncertainties. For hazardous environments, particular emphasis is placed on testing the system's response to edge cases and failure scenarios that could compromise safety barriers.

Regulatory Compliance and Industry Standards for Safety Control Systems

The implementation of Model Predictive Control (MPC) in hazardous environments necessitates strict adherence to regulatory frameworks and industry standards that govern safety control systems. These regulations vary significantly across different sectors and geographical regions, creating a complex compliance landscape for organizations deploying MPC technologies.

In the United States, the Occupational Safety and Health Administration (OSHA) establishes Process Safety Management (PSM) standards that directly impact control system requirements in hazardous facilities. Similarly, the European Union enforces the ATEX Directive for equipment used in explosive atmospheres, which includes specific provisions for control systems like MPC implementations.

For the chemical and petrochemical industries, the IEC 61511 standard (Functional Safety - Safety Instrumented Systems for the Process Industry Sector) provides comprehensive guidelines for the specification, design, installation, and maintenance of safety instrumented systems. MPC systems deployed in these environments must demonstrate compliance with Safety Integrity Levels (SIL) appropriate to the identified risk factors.

The mining sector presents particularly stringent requirements through standards such as AS/NZS 4024 (Safety of Machinery) in Australia and New Zealand, which outline specific provisions for control systems in underground operations where explosive gases may be present. MPC implementations must incorporate fail-safe mechanisms and redundancy features to meet these standards.

Nuclear facilities operate under perhaps the most rigorous regulatory framework, with the International Atomic Energy Agency (IAEA) and national bodies like the U.S. Nuclear Regulatory Commission establishing standards such as IEC 61513 for instrumentation and control systems. These standards mandate extensive validation and verification processes for predictive control algorithms before deployment.

Recent regulatory trends indicate a shift toward performance-based standards rather than prescriptive requirements, allowing greater flexibility in implementing innovative control solutions like MPC. However, this approach places greater responsibility on organizations to demonstrate that their control systems achieve the required safety outcomes through comprehensive risk assessments and validation procedures.

Certification processes for MPC systems typically involve independent third-party assessment against relevant standards, with documentation requirements including algorithm validation, failure mode analysis, and performance verification under various operating conditions. This certification process represents a significant investment but is essential for regulatory approval in high-risk environments.

In the United States, the Occupational Safety and Health Administration (OSHA) establishes Process Safety Management (PSM) standards that directly impact control system requirements in hazardous facilities. Similarly, the European Union enforces the ATEX Directive for equipment used in explosive atmospheres, which includes specific provisions for control systems like MPC implementations.

For the chemical and petrochemical industries, the IEC 61511 standard (Functional Safety - Safety Instrumented Systems for the Process Industry Sector) provides comprehensive guidelines for the specification, design, installation, and maintenance of safety instrumented systems. MPC systems deployed in these environments must demonstrate compliance with Safety Integrity Levels (SIL) appropriate to the identified risk factors.

The mining sector presents particularly stringent requirements through standards such as AS/NZS 4024 (Safety of Machinery) in Australia and New Zealand, which outline specific provisions for control systems in underground operations where explosive gases may be present. MPC implementations must incorporate fail-safe mechanisms and redundancy features to meet these standards.

Nuclear facilities operate under perhaps the most rigorous regulatory framework, with the International Atomic Energy Agency (IAEA) and national bodies like the U.S. Nuclear Regulatory Commission establishing standards such as IEC 61513 for instrumentation and control systems. These standards mandate extensive validation and verification processes for predictive control algorithms before deployment.

Recent regulatory trends indicate a shift toward performance-based standards rather than prescriptive requirements, allowing greater flexibility in implementing innovative control solutions like MPC. However, this approach places greater responsibility on organizations to demonstrate that their control systems achieve the required safety outcomes through comprehensive risk assessments and validation procedures.

Certification processes for MPC systems typically involve independent third-party assessment against relevant standards, with documentation requirements including algorithm validation, failure mode analysis, and performance verification under various operating conditions. This certification process represents a significant investment but is essential for regulatory approval in high-risk environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!