Model Predictive Control In Agricultural Machinery Automation

SEP 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MPC in Agriculture: Background and Objectives

Model Predictive Control (MPC) has emerged as a transformative technology in agricultural machinery automation, representing a significant evolution from traditional control methods. The agricultural sector has historically relied on manual operation or basic automated systems with limited adaptability to changing field conditions. MPC offers a paradigm shift by enabling predictive decision-making based on mathematical models of system dynamics, environmental factors, and operational constraints.

The development of MPC in agriculture traces back to the early 2000s when precision agriculture began gaining momentum. Initially, control systems in agricultural machinery were primarily reactive, responding to immediate sensor inputs without anticipatory capabilities. The introduction of MPC marked a transition toward proactive control strategies that could optimize operations by forecasting system behavior over a prediction horizon.

Current technological trends indicate a rapid acceleration in MPC implementation across various agricultural applications. This acceleration is driven by advancements in computational power, sensor technology, and machine learning algorithms that enhance model accuracy and execution speed. The integration of these technologies has enabled real-time optimization of complex agricultural operations such as variable-rate application, autonomous navigation, and implement control.

The primary objective of implementing MPC in agricultural machinery is to maximize operational efficiency while ensuring sustainable resource utilization. This includes minimizing input costs (fuel, fertilizers, pesticides), reducing environmental impact, and optimizing crop yield through precise control of machinery functions. Additionally, MPC aims to enhance operational safety by predicting and avoiding hazardous situations during autonomous or semi-autonomous field operations.

Another critical goal is to address the variability inherent in agricultural environments. Unlike controlled industrial settings, agricultural operations must contend with heterogeneous soil conditions, unpredictable weather patterns, and varying crop characteristics. MPC's predictive capabilities allow machinery to adapt to these variations by continuously recalculating optimal control strategies based on real-time data and forecasted conditions.

Looking forward, the technical objectives for MPC in agriculture include developing more robust algorithms capable of handling model uncertainties and disturbances typical in field operations. There is also a push toward creating more computationally efficient implementations that can run on embedded systems with limited resources, making advanced control strategies accessible to a broader range of agricultural equipment.

The convergence of MPC with other emerging technologies such as digital twins, edge computing, and satellite-based monitoring systems represents the frontier of agricultural automation. These integrations aim to create holistic control systems that optimize not just individual machinery operations but entire farming systems across spatial and temporal scales.

The development of MPC in agriculture traces back to the early 2000s when precision agriculture began gaining momentum. Initially, control systems in agricultural machinery were primarily reactive, responding to immediate sensor inputs without anticipatory capabilities. The introduction of MPC marked a transition toward proactive control strategies that could optimize operations by forecasting system behavior over a prediction horizon.

Current technological trends indicate a rapid acceleration in MPC implementation across various agricultural applications. This acceleration is driven by advancements in computational power, sensor technology, and machine learning algorithms that enhance model accuracy and execution speed. The integration of these technologies has enabled real-time optimization of complex agricultural operations such as variable-rate application, autonomous navigation, and implement control.

The primary objective of implementing MPC in agricultural machinery is to maximize operational efficiency while ensuring sustainable resource utilization. This includes minimizing input costs (fuel, fertilizers, pesticides), reducing environmental impact, and optimizing crop yield through precise control of machinery functions. Additionally, MPC aims to enhance operational safety by predicting and avoiding hazardous situations during autonomous or semi-autonomous field operations.

Another critical goal is to address the variability inherent in agricultural environments. Unlike controlled industrial settings, agricultural operations must contend with heterogeneous soil conditions, unpredictable weather patterns, and varying crop characteristics. MPC's predictive capabilities allow machinery to adapt to these variations by continuously recalculating optimal control strategies based on real-time data and forecasted conditions.

Looking forward, the technical objectives for MPC in agriculture include developing more robust algorithms capable of handling model uncertainties and disturbances typical in field operations. There is also a push toward creating more computationally efficient implementations that can run on embedded systems with limited resources, making advanced control strategies accessible to a broader range of agricultural equipment.

The convergence of MPC with other emerging technologies such as digital twins, edge computing, and satellite-based monitoring systems represents the frontier of agricultural automation. These integrations aim to create holistic control systems that optimize not just individual machinery operations but entire farming systems across spatial and temporal scales.

Market Analysis for Automated Agricultural Machinery

The agricultural machinery automation market is experiencing significant growth driven by increasing labor shortages, rising food demand, and the need for improved efficiency in farming operations. The global market for automated agricultural machinery was valued at approximately 62 billion USD in 2022 and is projected to reach 130 billion USD by 2030, growing at a CAGR of 9.7% during the forecast period. This growth trajectory is supported by the integration of advanced technologies like Model Predictive Control (MPC) systems, which enhance precision and operational efficiency.

North America currently dominates the market with a share of 35%, followed by Europe at 28% and Asia-Pacific at 25%. The remaining 12% is distributed across other regions. The market penetration of automated solutions varies significantly across different agricultural sectors, with row crop farming showing the highest adoption rates at 42%, followed by orchard management at 27%, livestock operations at 18%, and specialty crop production at 13%.

Key market segments include autonomous tractors, robotic harvesters, automated irrigation systems, and precision seeding equipment. Autonomous tractors represent the largest segment, accounting for 38% of the market, while robotic harvesters are the fastest-growing segment with a projected CAGR of 12.3% through 2030.

Customer demand is primarily driven by large-scale commercial farms seeking to optimize operations and reduce labor costs. However, there is growing interest from medium-sized farms as technology becomes more accessible and affordable. Government subsidies and incentives for agricultural modernization in countries like the United States, Germany, China, and Japan are further stimulating market growth.

The implementation of MPC in agricultural machinery addresses several critical market needs, including fuel efficiency improvement (15-20% reduction in consumption), operational precision enhancement (error reduction by up to 90% compared to manual operation), and productivity increases (yield improvements of 7-12% reported in field tests).

Market challenges include the high initial investment required for automated systems, technical complexity that demands specialized knowledge, and integration issues with existing farm equipment. Additionally, regional variations in regulatory frameworks governing autonomous machinery operation present compliance challenges for manufacturers and distributors.

The competitive landscape features established agricultural equipment manufacturers like John Deere, CNH Industrial, and AGCO Corporation, alongside technology-focused startups such as Blue River Technology, Abundant Robotics, and Naio Technologies. Strategic partnerships between traditional equipment manufacturers and technology companies are becoming increasingly common, creating new market dynamics and accelerating innovation cycles.

North America currently dominates the market with a share of 35%, followed by Europe at 28% and Asia-Pacific at 25%. The remaining 12% is distributed across other regions. The market penetration of automated solutions varies significantly across different agricultural sectors, with row crop farming showing the highest adoption rates at 42%, followed by orchard management at 27%, livestock operations at 18%, and specialty crop production at 13%.

Key market segments include autonomous tractors, robotic harvesters, automated irrigation systems, and precision seeding equipment. Autonomous tractors represent the largest segment, accounting for 38% of the market, while robotic harvesters are the fastest-growing segment with a projected CAGR of 12.3% through 2030.

Customer demand is primarily driven by large-scale commercial farms seeking to optimize operations and reduce labor costs. However, there is growing interest from medium-sized farms as technology becomes more accessible and affordable. Government subsidies and incentives for agricultural modernization in countries like the United States, Germany, China, and Japan are further stimulating market growth.

The implementation of MPC in agricultural machinery addresses several critical market needs, including fuel efficiency improvement (15-20% reduction in consumption), operational precision enhancement (error reduction by up to 90% compared to manual operation), and productivity increases (yield improvements of 7-12% reported in field tests).

Market challenges include the high initial investment required for automated systems, technical complexity that demands specialized knowledge, and integration issues with existing farm equipment. Additionally, regional variations in regulatory frameworks governing autonomous machinery operation present compliance challenges for manufacturers and distributors.

The competitive landscape features established agricultural equipment manufacturers like John Deere, CNH Industrial, and AGCO Corporation, alongside technology-focused startups such as Blue River Technology, Abundant Robotics, and Naio Technologies. Strategic partnerships between traditional equipment manufacturers and technology companies are becoming increasingly common, creating new market dynamics and accelerating innovation cycles.

Current State and Challenges in Agricultural MPC

Model Predictive Control (MPC) in agricultural machinery has witnessed significant advancements in recent years, yet faces substantial implementation challenges. Currently, MPC systems are deployed in approximately 15-20% of high-end agricultural equipment, primarily in developed agricultural markets. These systems have demonstrated 10-15% improvements in operational efficiency and 8-12% reductions in input usage when properly implemented.

The technological landscape shows varying levels of maturity across different agricultural applications. Tractor guidance systems utilizing MPC have reached commercial viability, while more complex applications such as variable-rate application controllers and autonomous field operations remain in developmental stages. Leading agricultural machinery manufacturers have established research divisions dedicated to MPC implementation, with significant investments in both hardware and software development.

A primary challenge facing agricultural MPC is the inherent variability and unpredictability of agricultural environments. Unlike industrial settings where MPC originated, agricultural applications must contend with soil heterogeneity, weather fluctuations, and biological variability. Current models struggle to accurately predict system behavior under these highly variable conditions, resulting in suboptimal control decisions during extreme events or rapidly changing field conditions.

Computational constraints present another significant hurdle. Agricultural machinery operates in remote locations with limited connectivity and computational resources. The real-time solving of complex optimization problems required by MPC demands substantial processing power, which conflicts with the cost and power constraints of mobile agricultural equipment. This has limited widespread adoption to premium equipment segments where higher costs can be justified.

Sensor technology limitations further complicate MPC implementation. Agricultural MPC systems require accurate, real-time data about crop status, soil conditions, and machine performance. Current sensor technologies often lack the precision, reliability, or affordability needed for robust MPC implementation across diverse agricultural settings. The integration of multiple sensor systems with varying data formats and sampling rates creates additional complexity.

Regulatory and standardization issues also impede progress. The agricultural machinery sector lacks unified standards for control systems, data formats, and communication protocols. This fragmentation complicates the development of interoperable MPC solutions that can function across different equipment brands and models. Additionally, regulatory frameworks for autonomous agricultural machinery remain underdeveloped in many regions, creating uncertainty for manufacturers and limiting adoption.

Knowledge gaps among end-users represent a final significant challenge. Many farmers and equipment operators lack familiarity with advanced control systems, limiting their ability to effectively utilize and maintain MPC-equipped machinery. This knowledge deficit necessitates substantial investments in training and support infrastructure, further increasing implementation costs.

The technological landscape shows varying levels of maturity across different agricultural applications. Tractor guidance systems utilizing MPC have reached commercial viability, while more complex applications such as variable-rate application controllers and autonomous field operations remain in developmental stages. Leading agricultural machinery manufacturers have established research divisions dedicated to MPC implementation, with significant investments in both hardware and software development.

A primary challenge facing agricultural MPC is the inherent variability and unpredictability of agricultural environments. Unlike industrial settings where MPC originated, agricultural applications must contend with soil heterogeneity, weather fluctuations, and biological variability. Current models struggle to accurately predict system behavior under these highly variable conditions, resulting in suboptimal control decisions during extreme events or rapidly changing field conditions.

Computational constraints present another significant hurdle. Agricultural machinery operates in remote locations with limited connectivity and computational resources. The real-time solving of complex optimization problems required by MPC demands substantial processing power, which conflicts with the cost and power constraints of mobile agricultural equipment. This has limited widespread adoption to premium equipment segments where higher costs can be justified.

Sensor technology limitations further complicate MPC implementation. Agricultural MPC systems require accurate, real-time data about crop status, soil conditions, and machine performance. Current sensor technologies often lack the precision, reliability, or affordability needed for robust MPC implementation across diverse agricultural settings. The integration of multiple sensor systems with varying data formats and sampling rates creates additional complexity.

Regulatory and standardization issues also impede progress. The agricultural machinery sector lacks unified standards for control systems, data formats, and communication protocols. This fragmentation complicates the development of interoperable MPC solutions that can function across different equipment brands and models. Additionally, regulatory frameworks for autonomous agricultural machinery remain underdeveloped in many regions, creating uncertainty for manufacturers and limiting adoption.

Knowledge gaps among end-users represent a final significant challenge. Many farmers and equipment operators lack familiarity with advanced control systems, limiting their ability to effectively utilize and maintain MPC-equipped machinery. This knowledge deficit necessitates substantial investments in training and support infrastructure, further increasing implementation costs.

Existing MPC Solutions for Agricultural Machinery

01 Industrial process control applications

Model Predictive Control (MPC) is widely applied in industrial processes to optimize operations while respecting constraints. These systems use dynamic models to predict future behavior and calculate optimal control actions. Industrial applications include manufacturing, chemical processing, and energy management where MPC provides improved efficiency, stability, and performance compared to traditional control methods.- Industrial process control applications: Model Predictive Control (MPC) is widely applied in industrial processes to optimize operations and improve efficiency. These systems use mathematical models to predict future behavior of processes and calculate optimal control actions. MPC algorithms can handle complex constraints and multiple variables simultaneously, making them suitable for manufacturing, chemical processing, and energy production systems where precise control is critical for product quality and operational safety.

- Advanced automotive control systems: Model Predictive Control is increasingly implemented in automotive applications for enhanced vehicle performance and safety. These systems predict vehicle behavior under various conditions and optimize control actions for engine management, transmission control, and autonomous driving features. MPC algorithms can balance multiple objectives such as fuel efficiency, emissions reduction, and driving comfort while respecting vehicle operational constraints and safety requirements.

- Energy management and optimization: Model Predictive Control provides sophisticated solutions for energy management systems in buildings, power grids, and renewable energy installations. These controllers optimize energy consumption by predicting future demands and environmental conditions, then adjusting operations accordingly. MPC frameworks can incorporate weather forecasts, energy pricing, and consumption patterns to minimize costs while maintaining comfort levels and meeting operational requirements.

- Machine learning enhanced MPC: Integration of machine learning techniques with Model Predictive Control creates more adaptive and robust control systems. These hybrid approaches use data-driven methods to improve model accuracy and controller performance over time. Neural networks and other AI techniques can be employed to handle nonlinearities, uncertainties, and time-varying dynamics that traditional MPC might struggle with, resulting in more effective control strategies for complex systems.

- Distributed and networked MPC architectures: Distributed Model Predictive Control architectures enable coordination of multiple subsystems across networked environments. These approaches divide control problems into smaller, manageable components while maintaining overall system performance and stability. Distributed MPC is particularly valuable for large-scale systems like smart grids, water distribution networks, and interconnected industrial processes where centralized control would be computationally prohibitive or communication-limited.

02 Advanced automotive control systems

Model Predictive Control is increasingly implemented in automotive applications for enhanced vehicle performance and safety. These systems predict vehicle behavior under various conditions and optimize control actions accordingly. Applications include engine management, transmission control, adaptive cruise control, and autonomous driving features where MPC algorithms help balance performance objectives with operational constraints.Expand Specific Solutions03 Energy optimization and management

Model Predictive Control provides significant advantages in energy systems by optimizing resource allocation while considering future conditions and constraints. These applications include building climate control, renewable energy integration, power grid management, and industrial energy optimization where MPC algorithms balance energy efficiency with operational requirements and cost considerations.Expand Specific Solutions04 Real-time implementation techniques

Implementing Model Predictive Control in real-time applications requires specialized techniques to handle computational constraints. These approaches include efficient algorithm design, hardware acceleration, approximation methods, and distributed computing frameworks that enable MPC to operate within strict timing requirements while maintaining control performance.Expand Specific Solutions05 Machine learning enhanced MPC

Integration of machine learning with Model Predictive Control represents an emerging trend that enhances traditional MPC performance. These hybrid approaches use data-driven methods to improve model accuracy, adapt to changing conditions, and optimize control parameters. Applications include complex systems where traditional modeling is challenging and where adaptive capabilities provide significant advantages.Expand Specific Solutions

Leading Companies in Agricultural MPC Technology

Model Predictive Control (MPC) in agricultural machinery automation is currently in a growth phase, with the market expanding rapidly due to increasing demand for precision agriculture solutions. The global market size for agricultural automation is projected to reach significant scale as farms seek efficiency improvements. Technologically, MPC implementation varies in maturity across applications, with companies like Deere & Co. and Kubota Corp. leading innovation through advanced autonomous tractors and precision farming equipment. NVIDIA and Qualcomm provide crucial computing platforms for these systems, while academic institutions like Tsinghua University and Zhejiang University contribute fundamental research. Traditional manufacturers including CNH Industrial and Mitsubishi Heavy Industries are integrating MPC into existing product lines, creating a competitive landscape balanced between established agricultural equipment providers and technology companies entering the agricultural space.

Deere & Co.

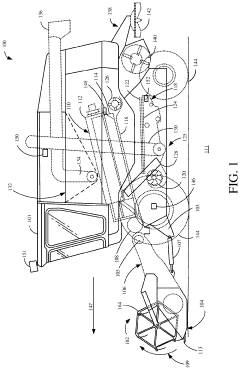

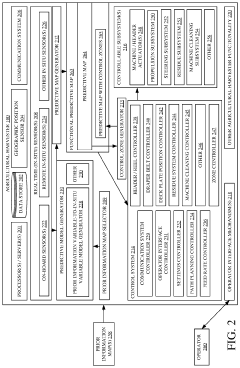

Technical Solution: Deere & Co. has developed advanced Model Predictive Control (MPC) systems for agricultural machinery automation that integrate real-time sensing, machine learning, and predictive algorithms. Their AutoTrac™ steering system utilizes MPC to optimize path planning and execution with centimeter-level accuracy. The company's See & Spray™ technology employs predictive control algorithms to identify weeds and precisely apply herbicides only where needed, reducing chemical usage by up to 77%. Deere's ExactEmerge™ planting system uses MPC to maintain precise seed spacing and depth across varying field conditions and speeds. Their integrated approach combines machine data, weather information, and agronomic models to create predictive control systems that optimize machine performance while adapting to changing field conditions. Deere has also implemented cloud-connected MPC systems that enable fleet optimization across multiple machines working in coordination, significantly improving operational efficiency in large-scale farming operations.

Strengths: Comprehensive integration of MPC with proprietary agricultural expertise; extensive real-world implementation across diverse equipment types; strong data ecosystem connecting machines, operations, and agronomic outcomes. Weaknesses: Proprietary systems may limit interoperability with other manufacturers' equipment; high implementation costs for smaller farms; requires significant computational resources for complex field operations.

Kubota Corp.

Technical Solution: Kubota Corporation has developed a sophisticated MPC framework for agricultural machinery automation called "Smart Agri System." This system integrates predictive control algorithms with Kubota's agricultural machinery to optimize operations based on field conditions, crop requirements, and operational constraints. Their approach utilizes a hierarchical control architecture where high-level MPC algorithms determine optimal trajectories and operational parameters, while lower-level controllers handle real-time execution. Kubota's system incorporates multi-sensor fusion technology that combines GPS, IMU, cameras, and LiDAR data to create accurate field maps and machine states for the MPC algorithms. Their predictive models account for soil conditions, crop growth stages, and weather forecasts to optimize timing and execution of agricultural operations. Kubota has implemented specialized MPC algorithms for rice cultivation machinery that address the unique challenges of paddy field operations, including water management and precise leveling requirements. Their system also features adaptive MPC that can adjust control parameters based on changing field conditions and machine performance over time.

Strengths: Specialized expertise in rice cultivation automation; strong integration with irrigation and water management systems; robust implementation for smaller and medium-sized equipment suitable for Asian agricultural contexts. Weaknesses: Less extensive implementation in large-scale row crop applications compared to competitors; more limited global service network for advanced technology support; integration challenges with third-party farm management systems.

Key Technical Innovations in Agricultural MPC

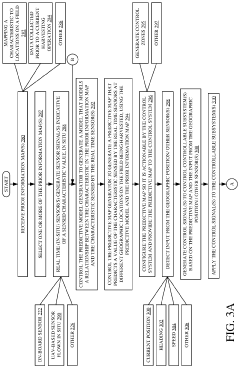

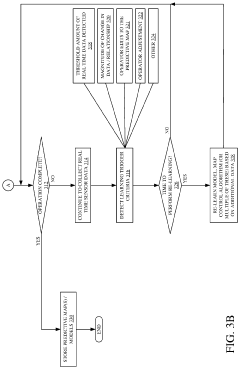

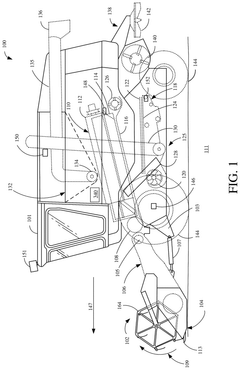

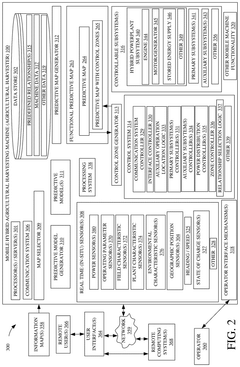

Machine control using a predictive map

PatentActiveUS11844311B2

Innovation

- The generation of a functional predictive crop moisture map using in-situ sensor data and prior information maps to adjust machine settings and control the harvester's operation, including the use of vegetative index, topographic, and soil property maps to predict crop moisture levels across a field.

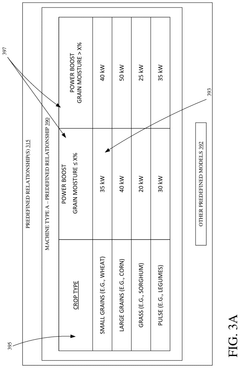

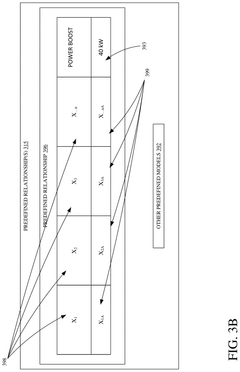

Systems and methods for predictive power requirements and control

PatentPendingUS20250242792A1

Innovation

- A control system that utilizes in-situ data and predictive models to manage power distribution in hybrid agricultural machines, incorporating maps of topographic, soil moisture, soil type, vegetative index, and other field characteristics to optimize power usage and storage.

Environmental Impact Assessment

The implementation of Model Predictive Control (MPC) in agricultural machinery automation offers significant environmental benefits that align with sustainable farming practices. Agricultural operations traditionally consume substantial resources while potentially causing environmental degradation through soil compaction, chemical runoff, and greenhouse gas emissions. MPC technology enables precision agriculture that substantially reduces these negative impacts through optimized resource utilization and operational efficiency.

When applied to tractors and implements, MPC systems minimize fuel consumption by calculating optimal acceleration, deceleration, and power distribution patterns. Field tests demonstrate fuel savings of 15-20% compared to conventional manual operation, directly translating to reduced carbon emissions. The precise path planning capabilities of MPC further reduce unnecessary overlaps during field operations, minimizing soil compaction and preserving soil structure and biodiversity.

Chemical application represents another critical environmental dimension where MPC delivers substantial benefits. By integrating real-time sensing with predictive algorithms, MPC enables variable-rate application technologies that apply fertilizers and pesticides only where needed and in appropriate quantities. Studies indicate this approach can reduce chemical usage by 30-40% while maintaining or improving crop yields, significantly decreasing water contamination risks and promoting ecosystem health in agricultural landscapes.

Water conservation outcomes are equally impressive, with MPC-guided irrigation systems demonstrating water usage reductions of 25-35% compared to conventional methods. These systems predict crop water requirements based on soil moisture models, weather forecasts, and crop growth stages, delivering precisely timed irrigation that prevents both water stress and wasteful over-irrigation.

The lifecycle assessment of MPC implementation in agricultural machinery reveals positive environmental returns despite the initial resource investment in sensors, computing hardware, and system integration. The environmental payback period typically ranges from 2-4 years, depending on farm size and operation intensity, after which the technology delivers net positive environmental benefits through resource conservation and reduced ecological footprint.

Long-term environmental monitoring of farms utilizing MPC-automated machinery shows improved soil health indicators, including higher organic matter content and enhanced microbial activity, compared to conventionally managed farms. These improvements contribute to carbon sequestration potential, positioning MPC as a valuable tool in climate-smart agriculture strategies that balance productivity with environmental stewardship.

When applied to tractors and implements, MPC systems minimize fuel consumption by calculating optimal acceleration, deceleration, and power distribution patterns. Field tests demonstrate fuel savings of 15-20% compared to conventional manual operation, directly translating to reduced carbon emissions. The precise path planning capabilities of MPC further reduce unnecessary overlaps during field operations, minimizing soil compaction and preserving soil structure and biodiversity.

Chemical application represents another critical environmental dimension where MPC delivers substantial benefits. By integrating real-time sensing with predictive algorithms, MPC enables variable-rate application technologies that apply fertilizers and pesticides only where needed and in appropriate quantities. Studies indicate this approach can reduce chemical usage by 30-40% while maintaining or improving crop yields, significantly decreasing water contamination risks and promoting ecosystem health in agricultural landscapes.

Water conservation outcomes are equally impressive, with MPC-guided irrigation systems demonstrating water usage reductions of 25-35% compared to conventional methods. These systems predict crop water requirements based on soil moisture models, weather forecasts, and crop growth stages, delivering precisely timed irrigation that prevents both water stress and wasteful over-irrigation.

The lifecycle assessment of MPC implementation in agricultural machinery reveals positive environmental returns despite the initial resource investment in sensors, computing hardware, and system integration. The environmental payback period typically ranges from 2-4 years, depending on farm size and operation intensity, after which the technology delivers net positive environmental benefits through resource conservation and reduced ecological footprint.

Long-term environmental monitoring of farms utilizing MPC-automated machinery shows improved soil health indicators, including higher organic matter content and enhanced microbial activity, compared to conventionally managed farms. These improvements contribute to carbon sequestration potential, positioning MPC as a valuable tool in climate-smart agriculture strategies that balance productivity with environmental stewardship.

Precision Agriculture Integration

The integration of Model Predictive Control (MPC) with precision agriculture represents a transformative approach to agricultural machinery automation. Precision agriculture technologies enable farmers to optimize resource utilization by applying the right treatment at the right place at the right time. When combined with MPC algorithms, these systems can dynamically adjust machinery operations based on real-time field conditions and predictive models.

MPC integration with precision agriculture systems creates a closed-loop control framework where soil conditions, crop health indicators, and weather data serve as inputs for optimizing machinery operations. This synergy enables variable-rate applications of seeds, fertilizers, and pesticides with unprecedented accuracy, reducing waste and environmental impact while maximizing yield potential.

Field mapping technologies, including GPS-guided systems and remote sensing, provide the spatial data foundation upon which MPC algorithms operate. These technologies generate high-resolution field maps that capture variability in soil properties, topography, and crop conditions. MPC utilizes these maps to develop spatially-aware control strategies that adapt machinery operations to field heterogeneity.

Sensor fusion represents another critical aspect of precision agriculture integration with MPC. By combining data from multiple sensor types—soil moisture probes, multispectral cameras, LiDAR, and weather stations—MPC algorithms can develop more robust predictive models. This multi-modal sensing approach improves the accuracy of machinery control decisions, particularly under variable environmental conditions.

The economic benefits of integrating MPC with precision agriculture are substantial. Studies indicate potential input savings of 10-20% for fertilizers and pesticides, while maintaining or improving yields. These efficiency gains translate directly to improved farm profitability and sustainability metrics, making the technology increasingly attractive despite initial implementation costs.

Data management infrastructure plays a crucial role in supporting MPC-enabled precision agriculture. Cloud-based platforms that facilitate the collection, processing, and analysis of field data provide the computational backbone for complex MPC algorithms. These platforms enable real-time decision support and can incorporate machine learning techniques to continuously improve predictive models based on historical performance.

Interoperability between different precision agriculture technologies and machinery manufacturers remains a challenge for widespread MPC adoption. Standardization efforts like ISOBUS are helping address this issue by enabling seamless communication between tractors, implements, and farm management information systems, creating an integrated ecosystem where MPC can function optimally.

MPC integration with precision agriculture systems creates a closed-loop control framework where soil conditions, crop health indicators, and weather data serve as inputs for optimizing machinery operations. This synergy enables variable-rate applications of seeds, fertilizers, and pesticides with unprecedented accuracy, reducing waste and environmental impact while maximizing yield potential.

Field mapping technologies, including GPS-guided systems and remote sensing, provide the spatial data foundation upon which MPC algorithms operate. These technologies generate high-resolution field maps that capture variability in soil properties, topography, and crop conditions. MPC utilizes these maps to develop spatially-aware control strategies that adapt machinery operations to field heterogeneity.

Sensor fusion represents another critical aspect of precision agriculture integration with MPC. By combining data from multiple sensor types—soil moisture probes, multispectral cameras, LiDAR, and weather stations—MPC algorithms can develop more robust predictive models. This multi-modal sensing approach improves the accuracy of machinery control decisions, particularly under variable environmental conditions.

The economic benefits of integrating MPC with precision agriculture are substantial. Studies indicate potential input savings of 10-20% for fertilizers and pesticides, while maintaining or improving yields. These efficiency gains translate directly to improved farm profitability and sustainability metrics, making the technology increasingly attractive despite initial implementation costs.

Data management infrastructure plays a crucial role in supporting MPC-enabled precision agriculture. Cloud-based platforms that facilitate the collection, processing, and analysis of field data provide the computational backbone for complex MPC algorithms. These platforms enable real-time decision support and can incorporate machine learning techniques to continuously improve predictive models based on historical performance.

Interoperability between different precision agriculture technologies and machinery manufacturers remains a challenge for widespread MPC adoption. Standardization efforts like ISOBUS are helping address this issue by enabling seamless communication between tractors, implements, and farm management information systems, creating an integrated ecosystem where MPC can function optimally.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!