Model Predictive Control For Collaborative Robotics

SEP 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MPC in Collaborative Robotics: Background and Objectives

Model Predictive Control (MPC) has emerged as a pivotal control methodology in the evolution of collaborative robotics, representing a significant advancement from traditional control techniques. The trajectory of MPC development began in the 1970s with its initial applications in process industries, gradually expanding into more complex domains including robotics by the early 2000s. This evolution has been characterized by increasing computational efficiency and algorithm sophistication, enabling real-time implementation in dynamic environments.

In collaborative robotics specifically, MPC offers unique advantages due to its predictive nature and constraint-handling capabilities. The integration of MPC into collaborative robots (cobots) began gaining momentum around 2010, with significant acceleration in the past five years as computing power has increased and algorithm efficiency has improved. This technological progression has enabled cobots to operate safely alongside humans while maintaining optimal performance.

The fundamental objective of implementing MPC in collaborative robotics is to achieve precise motion control while simultaneously ensuring human safety through predictive collision avoidance. This dual requirement presents a complex optimization challenge that traditional reactive control systems struggle to address effectively. MPC's ability to anticipate future states and proactively adjust robot behavior makes it particularly well-suited for human-robot collaboration scenarios.

Current technical goals in this field include reducing computational overhead to enable faster sampling rates, improving the accuracy of human motion prediction models, and developing more robust methods for handling uncertainty in dynamic environments. Researchers are also focusing on enhancing MPC frameworks to accommodate varying levels of human-robot interaction, from simple co-existence to direct physical collaboration.

The technological trajectory indicates a move toward more adaptive and learning-based MPC approaches, where control parameters can be adjusted based on accumulated experience. This represents a convergence of classical control theory with modern machine learning techniques, potentially leading to more intuitive and responsive collaborative robotic systems.

Industry objectives for MPC in collaborative robotics include increasing deployment flexibility across manufacturing environments, reducing implementation complexity for non-experts, and improving energy efficiency during operation. There is also significant interest in developing standardized MPC frameworks that can be easily integrated into existing robotic systems, thereby lowering the barrier to adoption for small and medium enterprises.

In collaborative robotics specifically, MPC offers unique advantages due to its predictive nature and constraint-handling capabilities. The integration of MPC into collaborative robots (cobots) began gaining momentum around 2010, with significant acceleration in the past five years as computing power has increased and algorithm efficiency has improved. This technological progression has enabled cobots to operate safely alongside humans while maintaining optimal performance.

The fundamental objective of implementing MPC in collaborative robotics is to achieve precise motion control while simultaneously ensuring human safety through predictive collision avoidance. This dual requirement presents a complex optimization challenge that traditional reactive control systems struggle to address effectively. MPC's ability to anticipate future states and proactively adjust robot behavior makes it particularly well-suited for human-robot collaboration scenarios.

Current technical goals in this field include reducing computational overhead to enable faster sampling rates, improving the accuracy of human motion prediction models, and developing more robust methods for handling uncertainty in dynamic environments. Researchers are also focusing on enhancing MPC frameworks to accommodate varying levels of human-robot interaction, from simple co-existence to direct physical collaboration.

The technological trajectory indicates a move toward more adaptive and learning-based MPC approaches, where control parameters can be adjusted based on accumulated experience. This represents a convergence of classical control theory with modern machine learning techniques, potentially leading to more intuitive and responsive collaborative robotic systems.

Industry objectives for MPC in collaborative robotics include increasing deployment flexibility across manufacturing environments, reducing implementation complexity for non-experts, and improving energy efficiency during operation. There is also significant interest in developing standardized MPC frameworks that can be easily integrated into existing robotic systems, thereby lowering the barrier to adoption for small and medium enterprises.

Market Analysis for Collaborative Robotics Control Systems

The collaborative robotics market is experiencing significant growth, driven by increasing demand for automation solutions that can safely work alongside humans. The global collaborative robot market was valued at approximately $1.2 billion in 2021 and is projected to reach $10.5 billion by 2028, growing at a CAGR of over 30%. This remarkable growth trajectory underscores the expanding adoption of collaborative robots across various industries.

Manufacturing remains the primary adopter of collaborative robotics, accounting for nearly 55% of the market share. Within this sector, automotive and electronics manufacturing lead implementation, followed by food and beverage, pharmaceuticals, and consumer goods industries. The healthcare sector is emerging as a rapidly growing market segment, with applications in surgical assistance, rehabilitation, and patient care.

Control systems, particularly those utilizing Model Predictive Control (MPC), represent a critical component of the collaborative robotics ecosystem. The market for advanced control systems for collaborative robots is estimated at $350 million in 2022, with projections to reach $2.1 billion by 2027. This specialized segment is growing faster than the overall robotics market due to increasing demands for more sophisticated human-robot interaction capabilities.

Regional analysis reveals that North America and Europe currently dominate the collaborative robotics control systems market, collectively accounting for approximately 60% of global revenue. However, the Asia-Pacific region, particularly China, Japan, and South Korea, is experiencing the fastest growth rate at 35-40% annually, driven by aggressive manufacturing automation initiatives and government support programs.

Key market drivers include labor shortages in developed economies, increasing labor costs, growing emphasis on workplace safety, and the need for flexible manufacturing systems capable of handling product customization demands. The COVID-19 pandemic has accelerated adoption as companies seek to ensure operational continuity during health crises while maintaining social distancing protocols.

Customer requirements are evolving toward more intuitive interfaces, enhanced safety features, and greater adaptability. End-users increasingly demand control systems that enable robots to respond dynamically to changing environments and human behaviors without extensive reprogramming. This has created a market premium for MPC-based solutions that can predict and optimize robot behavior based on real-time environmental feedback.

Market challenges include high implementation costs, technical complexity requiring specialized expertise, and integration difficulties with existing systems. Additionally, regulatory frameworks governing human-robot collaboration continue to evolve, creating uncertainty for manufacturers and end-users alike.

Manufacturing remains the primary adopter of collaborative robotics, accounting for nearly 55% of the market share. Within this sector, automotive and electronics manufacturing lead implementation, followed by food and beverage, pharmaceuticals, and consumer goods industries. The healthcare sector is emerging as a rapidly growing market segment, with applications in surgical assistance, rehabilitation, and patient care.

Control systems, particularly those utilizing Model Predictive Control (MPC), represent a critical component of the collaborative robotics ecosystem. The market for advanced control systems for collaborative robots is estimated at $350 million in 2022, with projections to reach $2.1 billion by 2027. This specialized segment is growing faster than the overall robotics market due to increasing demands for more sophisticated human-robot interaction capabilities.

Regional analysis reveals that North America and Europe currently dominate the collaborative robotics control systems market, collectively accounting for approximately 60% of global revenue. However, the Asia-Pacific region, particularly China, Japan, and South Korea, is experiencing the fastest growth rate at 35-40% annually, driven by aggressive manufacturing automation initiatives and government support programs.

Key market drivers include labor shortages in developed economies, increasing labor costs, growing emphasis on workplace safety, and the need for flexible manufacturing systems capable of handling product customization demands. The COVID-19 pandemic has accelerated adoption as companies seek to ensure operational continuity during health crises while maintaining social distancing protocols.

Customer requirements are evolving toward more intuitive interfaces, enhanced safety features, and greater adaptability. End-users increasingly demand control systems that enable robots to respond dynamically to changing environments and human behaviors without extensive reprogramming. This has created a market premium for MPC-based solutions that can predict and optimize robot behavior based on real-time environmental feedback.

Market challenges include high implementation costs, technical complexity requiring specialized expertise, and integration difficulties with existing systems. Additionally, regulatory frameworks governing human-robot collaboration continue to evolve, creating uncertainty for manufacturers and end-users alike.

Current MPC Implementation Challenges in Cobot Applications

Despite the promising potential of Model Predictive Control (MPC) in collaborative robotics, several significant implementation challenges persist that hinder its widespread adoption. One primary obstacle is the computational complexity associated with solving optimization problems in real-time. Collaborative robots (cobots) require control decisions within milliseconds to ensure safe human-robot interaction, yet traditional MPC algorithms often demand substantial computational resources that exceed the onboard processing capabilities of most cobots.

The nonlinear dynamics inherent in robotic systems further complicate MPC implementation. While linear MPC is well-established, many cobot applications involve complex nonlinear behaviors, especially during physical human-robot interaction. Nonlinear MPC formulations significantly increase computational burden and may not converge to optimal solutions within the required time constraints, creating a fundamental tension between model accuracy and computational feasibility.

Uncertainty management represents another critical challenge. Collaborative environments are inherently unpredictable due to human behavior variability. Current MPC frameworks struggle to effectively incorporate stochastic elements and robust formulations that can handle these uncertainties while maintaining computational tractability. This limitation often forces developers to implement overly conservative safety constraints that restrict cobot performance and responsiveness.

The multi-objective nature of collaborative robotics also presents implementation difficulties. MPC controllers must simultaneously optimize for task performance, energy efficiency, safety constraints, and human comfort. Balancing these competing objectives within a unified control framework remains problematic, particularly when objectives have different priorities that may shift dynamically during operation.

Hardware limitations constitute a significant practical barrier. Many commercial cobots utilize relatively modest onboard computing platforms to maintain cost-effectiveness and energy efficiency. Implementing complex MPC algorithms on these platforms requires substantial optimization and often compromises on model fidelity or prediction horizon length, reducing control performance.

Tuning and parameter selection for MPC controllers in collaborative applications presents another challenge. The performance of MPC heavily depends on appropriate weighting matrices, prediction horizons, and constraint formulations. Current practices largely rely on heuristic approaches and expert knowledge rather than systematic methodologies, making implementation time-consuming and results inconsistent across different applications.

Finally, the integration of MPC with higher-level planning systems and safety monitoring frameworks remains underdeveloped. Ensuring seamless coordination between trajectory planning, obstacle avoidance, and low-level MPC control requires sophisticated software architectures that are not yet standardized in the industry, creating implementation barriers for system integrators and end-users.

The nonlinear dynamics inherent in robotic systems further complicate MPC implementation. While linear MPC is well-established, many cobot applications involve complex nonlinear behaviors, especially during physical human-robot interaction. Nonlinear MPC formulations significantly increase computational burden and may not converge to optimal solutions within the required time constraints, creating a fundamental tension between model accuracy and computational feasibility.

Uncertainty management represents another critical challenge. Collaborative environments are inherently unpredictable due to human behavior variability. Current MPC frameworks struggle to effectively incorporate stochastic elements and robust formulations that can handle these uncertainties while maintaining computational tractability. This limitation often forces developers to implement overly conservative safety constraints that restrict cobot performance and responsiveness.

The multi-objective nature of collaborative robotics also presents implementation difficulties. MPC controllers must simultaneously optimize for task performance, energy efficiency, safety constraints, and human comfort. Balancing these competing objectives within a unified control framework remains problematic, particularly when objectives have different priorities that may shift dynamically during operation.

Hardware limitations constitute a significant practical barrier. Many commercial cobots utilize relatively modest onboard computing platforms to maintain cost-effectiveness and energy efficiency. Implementing complex MPC algorithms on these platforms requires substantial optimization and often compromises on model fidelity or prediction horizon length, reducing control performance.

Tuning and parameter selection for MPC controllers in collaborative applications presents another challenge. The performance of MPC heavily depends on appropriate weighting matrices, prediction horizons, and constraint formulations. Current practices largely rely on heuristic approaches and expert knowledge rather than systematic methodologies, making implementation time-consuming and results inconsistent across different applications.

Finally, the integration of MPC with higher-level planning systems and safety monitoring frameworks remains underdeveloped. Ensuring seamless coordination between trajectory planning, obstacle avoidance, and low-level MPC control requires sophisticated software architectures that are not yet standardized in the industry, creating implementation barriers for system integrators and end-users.

State-of-the-Art MPC Solutions for Human-Robot Interaction

01 Industrial Process Control Applications

Model Predictive Control (MPC) is widely applied in industrial processes to optimize operations and improve efficiency. These systems use mathematical models to predict future behavior of processes and calculate optimal control actions. MPC algorithms can handle complex constraints and multiple variables simultaneously, making them particularly valuable in manufacturing, chemical processing, and energy production where precise control is critical for product quality and operational safety.- Industrial Process Control Applications: Model Predictive Control (MPC) is widely applied in industrial processes to optimize operations and improve efficiency. These systems use mathematical models to predict future process behavior and calculate optimal control actions. MPC algorithms can handle complex constraints and multiple variables simultaneously, making them suitable for manufacturing, chemical processing, and energy production systems where precise control is critical for product quality and operational safety.

- Advanced Vehicle Control Systems: Model Predictive Control is increasingly implemented in automotive and transportation applications for enhanced vehicle dynamics and autonomous driving capabilities. These systems predict vehicle behavior based on current states and environmental conditions to optimize trajectory planning, stability control, and energy management. MPC frameworks enable vehicles to navigate complex scenarios while maintaining safety constraints and improving fuel efficiency or battery usage in electric vehicles.

- Energy Management and Optimization: Model Predictive Control strategies are employed for energy management in buildings, power grids, and renewable energy systems. These controllers optimize energy consumption by predicting future demand patterns and environmental conditions while considering operational constraints. MPC algorithms can balance multiple objectives such as minimizing energy costs, reducing carbon emissions, and maintaining comfort levels by coordinating various energy sources and storage systems.

- Real-time Implementation and Computational Efficiency: Advancements in computational methods for Model Predictive Control focus on improving execution speed and efficiency for real-time applications. These innovations include specialized algorithms that reduce computational complexity, hardware acceleration techniques, and approximation methods that maintain control performance while decreasing processing requirements. Such developments enable MPC implementation on embedded systems with limited resources and applications requiring high-frequency control updates.

- Robust and Adaptive MPC Frameworks: Robust and adaptive Model Predictive Control frameworks address uncertainties in system models and changing operating conditions. These advanced controllers incorporate techniques to handle model inaccuracies, disturbances, and parameter variations while maintaining stability and performance. Adaptive MPC systems can automatically update their internal models based on observed system behavior, enabling effective control even when the controlled process changes over time or operates in unpredictable environments.

02 Advanced Vehicle Control Systems

Model Predictive Control is increasingly implemented in automotive applications for enhanced vehicle performance and safety. These systems predict vehicle behavior based on current states and environmental conditions to optimize driving dynamics. MPC algorithms can manage complex vehicle subsystems including powertrain control, autonomous driving features, and adaptive cruise control, allowing for smoother operation and improved fuel efficiency while maintaining safety constraints.Expand Specific Solutions03 Energy Management Optimization

Model Predictive Control provides significant advantages in energy management systems by optimizing resource allocation and consumption patterns. These controllers can forecast energy demands and adjust operations accordingly, balancing multiple objectives such as cost reduction, efficiency improvement, and emissions control. MPC frameworks are particularly valuable in smart grid applications, building energy management, and renewable energy integration where they can adapt to changing conditions while maintaining system constraints.Expand Specific Solutions04 Computational Methods and Algorithm Improvements

Research in Model Predictive Control focuses on developing more efficient computational methods and algorithm improvements to enhance performance and applicability. These advancements include faster solving techniques for optimization problems, distributed MPC architectures for large-scale systems, and robust MPC formulations that can handle uncertainties and disturbances. Innovations in this area aim to reduce computational complexity while maintaining or improving control performance for real-time applications.Expand Specific Solutions05 Adaptive and Learning-Based MPC

Adaptive and learning-based Model Predictive Control represents an evolution of traditional MPC by incorporating machine learning techniques and adaptive mechanisms. These systems can automatically update their internal models based on observed data, improving prediction accuracy and control performance over time. By combining MPC with artificial intelligence approaches, these controllers can handle complex nonlinear systems, adapt to changing conditions, and improve their performance through operational experience.Expand Specific Solutions

Leading Companies and Research Institutions in MPC Robotics

Model Predictive Control for Collaborative Robotics is currently in a growth phase, with an expanding market driven by increasing demand for human-robot collaboration in manufacturing. The global market is estimated to reach significant scale as industries adopt smart factory concepts. Technologically, the field shows varying maturity levels across players. Academic institutions like Politecnico di Milano and Vanderbilt University are advancing theoretical frameworks, while established industrial players such as FANUC, Intel, and NVIDIA are developing commercial applications. Companies like Dexterity and Neuromeka are creating specialized collaborative robot solutions incorporating MPC techniques. Google and Bosch are investing in integrating AI with MPC for enhanced robot adaptability, indicating the technology's transition from research to practical implementation.

FANUC Corp.

Technical Solution: FANUC's collaborative robotics MPC solution integrates real-time trajectory optimization with advanced safety protocols. Their system employs hierarchical MPC architecture that separates high-level task planning from low-level motion control, enabling millisecond-level response times. The CRX series collaborative robots utilize this technology with a dual-processor system: one dedicated to safety monitoring and another for predictive control calculations. FANUC's implementation includes adaptive friction compensation and dynamic parameter identification that continuously updates the robot's internal model during operation. Their Learning Vibration Control (LVC) technology further enhances MPC performance by identifying and compensating for resonance frequencies in real-time, reducing settling time by up to 65% compared to conventional controllers.

Strengths: Industry-leading computational efficiency allowing MPC implementation on standard robot controllers without specialized hardware; extensive industrial deployment experience across various manufacturing sectors. Weaknesses: Proprietary ecosystem limits integration flexibility with third-party systems; higher implementation costs compared to conventional control approaches.

OMRON Corp.

Technical Solution: OMRON has developed a distributed MPC framework specifically for collaborative robotics applications that emphasizes human-robot interaction safety. Their TM series collaborative robots implement a multi-layered MPC approach where the control horizon is dynamically adjusted based on human proximity detected through their proprietary vision systems. OMRON's solution incorporates real-time constraint handling that allows for smooth trajectory adjustments when humans enter the workspace. The system utilizes a unique "soft constraint" formulation that prioritizes safety constraints while maintaining task performance when possible. Their implementation includes specialized hardware accelerators that solve quadratic programming problems in under 2ms, enabling control frequencies of up to 500Hz. OMRON has also integrated their MPC controllers with their Sysmac automation platform, allowing for factory-wide coordination of collaborative robots.

Strengths: Exceptional human-safety integration with vision systems; seamless integration with broader factory automation systems. Weaknesses: Limited customization options for advanced users; higher computational requirements than traditional control methods.

Key Patents and Research in Predictive Control for Cobots

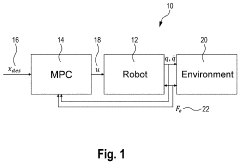

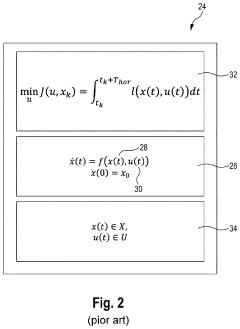

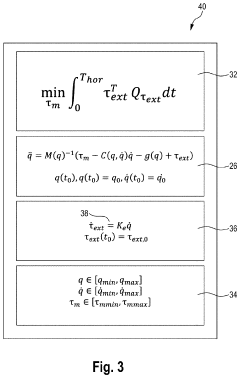

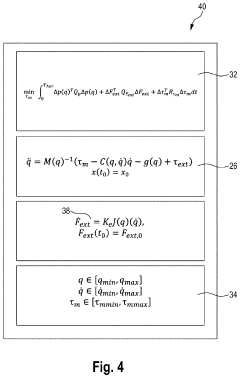

Robot Control Using Model-Predictive Interaction

PatentInactiveUS20210138652A1

Innovation

- The method integrates interaction dynamics into model predictive control, allowing for the consideration of forces that arise during human-robot interaction, enabling a unified approach for yield, force, and motion control through an optimization problem that weights interaction forces and adapts to different applications.

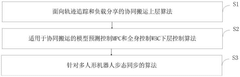

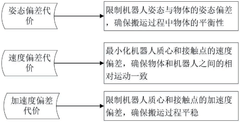

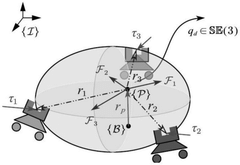

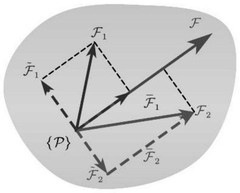

Multi-humanoid robot distributed collaborative carrying method based on model predictive control

PatentPendingCN119847023A

Innovation

- A multi-human robot distributed load sharing collaborative handling control method is adopted based on model predictive control (MPC), including upper-level collaborative handling algorithm, lower-level MPC and full-body control (WBC) algorithm, and multi-human robot gait synchronization algorithm. Active load sharing and gait synchronization are achieved through distributed communication networks and distributed consistency terms.

Safety Standards and Compliance for Collaborative Robots

The integration of Model Predictive Control (MPC) in collaborative robotics necessitates strict adherence to established safety standards and compliance frameworks. ISO/TS 15066, specifically designed for collaborative robots, outlines four primary safety modes: safety-rated monitored stop, hand guiding, speed and separation monitoring, and power and force limiting. These standards are particularly relevant when implementing MPC algorithms that must predict and respond to human movements within shared workspaces.

The IEC 61508 standard for functional safety of electrical/electronic/programmable electronic safety-related systems provides a framework for ensuring that MPC implementations meet required safety integrity levels (SIL). For collaborative robots utilizing predictive control, achieving SIL-2 or SIL-3 certification is typically necessary, requiring extensive validation of the control algorithms' reliability and failure response mechanisms.

ANSI/RIA R15.06 and ISO 10218-1/2 establish comprehensive safety requirements for industrial robots, including collaborative applications. These standards mandate risk assessment procedures that must account for the dynamic nature of MPC systems, particularly their ability to adapt trajectories based on real-time human position prediction.

Risk assessment methodologies for MPC-based collaborative robots must follow ISO 12100 principles, with special consideration for the predictive nature of the control system. This includes analyzing potential failure modes where prediction accuracy might degrade or computational delays could impact safety response times.

Safety certification for MPC algorithms in collaborative robotics presents unique challenges due to their adaptive and predictive nature. Certification bodies increasingly require formal verification methods to prove that the control system maintains safety constraints under all foreseeable operating conditions. Techniques such as reachability analysis and barrier certificates are becoming standard requirements for demonstrating the robustness of MPC safety implementations.

Regional variations in safety requirements must also be considered. The EU Machinery Directive 2006/42/EC imposes additional requirements for collaborative robots in European markets, while OSHA regulations in the United States focus more on workplace implementation aspects. These regional differences necessitate adaptable MPC frameworks that can be configured to meet varying compliance requirements.

Emerging standards specifically addressing AI and machine learning components in safety-critical systems, such as ISO/IEC TR 24028:2020, are increasingly relevant as MPC algorithms incorporate more sophisticated prediction models. These standards emphasize explainability and transparency in decision-making processes, requiring MPC implementations to provide clear justification for control actions, especially during human-robot interaction scenarios.

The IEC 61508 standard for functional safety of electrical/electronic/programmable electronic safety-related systems provides a framework for ensuring that MPC implementations meet required safety integrity levels (SIL). For collaborative robots utilizing predictive control, achieving SIL-2 or SIL-3 certification is typically necessary, requiring extensive validation of the control algorithms' reliability and failure response mechanisms.

ANSI/RIA R15.06 and ISO 10218-1/2 establish comprehensive safety requirements for industrial robots, including collaborative applications. These standards mandate risk assessment procedures that must account for the dynamic nature of MPC systems, particularly their ability to adapt trajectories based on real-time human position prediction.

Risk assessment methodologies for MPC-based collaborative robots must follow ISO 12100 principles, with special consideration for the predictive nature of the control system. This includes analyzing potential failure modes where prediction accuracy might degrade or computational delays could impact safety response times.

Safety certification for MPC algorithms in collaborative robotics presents unique challenges due to their adaptive and predictive nature. Certification bodies increasingly require formal verification methods to prove that the control system maintains safety constraints under all foreseeable operating conditions. Techniques such as reachability analysis and barrier certificates are becoming standard requirements for demonstrating the robustness of MPC safety implementations.

Regional variations in safety requirements must also be considered. The EU Machinery Directive 2006/42/EC imposes additional requirements for collaborative robots in European markets, while OSHA regulations in the United States focus more on workplace implementation aspects. These regional differences necessitate adaptable MPC frameworks that can be configured to meet varying compliance requirements.

Emerging standards specifically addressing AI and machine learning components in safety-critical systems, such as ISO/IEC TR 24028:2020, are increasingly relevant as MPC algorithms incorporate more sophisticated prediction models. These standards emphasize explainability and transparency in decision-making processes, requiring MPC implementations to provide clear justification for control actions, especially during human-robot interaction scenarios.

Human Factors in Cobot Control System Design

Human factors in collaborative robot control systems represent a critical dimension that bridges technological capabilities with user needs and safety requirements. The integration of Model Predictive Control (MPC) in collaborative robotics necessitates careful consideration of the human operator's cognitive load, physical capabilities, and psychological comfort. Effective human-robot collaboration requires control systems that can anticipate human behavior while remaining intuitive and responsive to human inputs.

The design of MPC algorithms for cobots must incorporate human reaction times, which typically range from 200-300 milliseconds for simple tasks but can extend to seconds for complex decision-making. This temporal constraint influences the prediction horizon and control frequency parameters within MPC frameworks, ensuring that robot movements remain synchronized with human partners without causing delays or safety hazards.

Ergonomic considerations play a substantial role in cobot control system design. MPC systems must account for human biomechanical limitations, adapting force profiles and movement trajectories to complement human capabilities rather than forcing operators to adapt to rigid robotic patterns. This adaptation includes variable impedance control that adjusts stiffness based on task requirements and human fatigue levels.

Trust development between humans and collaborative robots represents another crucial factor. MPC systems that provide transparent decision-making processes and predictable behavior patterns foster greater operator confidence. Research indicates that humans develop trust in automated systems primarily through consistent performance and clear communication of intent, which can be facilitated through MPC's predictive visualization capabilities.

Cognitive ergonomics must be addressed through intuitive interfaces that present relevant information without overwhelming the operator. MPC's predictive nature allows for proactive display of future robot states, enabling operators to anticipate movements rather than merely react to them. Studies show that predictive displays can reduce mental workload by up to 30% in complex collaborative tasks.

Safety perception significantly influences human comfort and productivity when working alongside cobots. MPC systems can enhance safety perception by maintaining appropriate proximity thresholds that dynamically adjust based on movement speed and task context. These adaptive safety boundaries, calculated through real-time risk assessment algorithms within the MPC framework, help maintain operator confidence while maximizing collaborative efficiency.

Skill acquisition and learning curves must be considered when implementing MPC-based control systems. Training protocols should progressively introduce operators to the predictive capabilities of the system, allowing for gradual development of mental models that accurately reflect the cobot's behavior patterns and decision-making processes.

The design of MPC algorithms for cobots must incorporate human reaction times, which typically range from 200-300 milliseconds for simple tasks but can extend to seconds for complex decision-making. This temporal constraint influences the prediction horizon and control frequency parameters within MPC frameworks, ensuring that robot movements remain synchronized with human partners without causing delays or safety hazards.

Ergonomic considerations play a substantial role in cobot control system design. MPC systems must account for human biomechanical limitations, adapting force profiles and movement trajectories to complement human capabilities rather than forcing operators to adapt to rigid robotic patterns. This adaptation includes variable impedance control that adjusts stiffness based on task requirements and human fatigue levels.

Trust development between humans and collaborative robots represents another crucial factor. MPC systems that provide transparent decision-making processes and predictable behavior patterns foster greater operator confidence. Research indicates that humans develop trust in automated systems primarily through consistent performance and clear communication of intent, which can be facilitated through MPC's predictive visualization capabilities.

Cognitive ergonomics must be addressed through intuitive interfaces that present relevant information without overwhelming the operator. MPC's predictive nature allows for proactive display of future robot states, enabling operators to anticipate movements rather than merely react to them. Studies show that predictive displays can reduce mental workload by up to 30% in complex collaborative tasks.

Safety perception significantly influences human comfort and productivity when working alongside cobots. MPC systems can enhance safety perception by maintaining appropriate proximity thresholds that dynamically adjust based on movement speed and task context. These adaptive safety boundaries, calculated through real-time risk assessment algorithms within the MPC framework, help maintain operator confidence while maximizing collaborative efficiency.

Skill acquisition and learning curves must be considered when implementing MPC-based control systems. Training protocols should progressively introduce operators to the predictive capabilities of the system, allowing for gradual development of mental models that accurately reflect the cobot's behavior patterns and decision-making processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!