Applications of Perchloric Acid in Enhancing Fermentation Processes

AUG 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Perchloric Acid in Fermentation: Background and Objectives

Perchloric acid, a powerful oxidizing agent, has been a subject of interest in various industrial applications for decades. Its potential in enhancing fermentation processes has recently gained attention due to its unique chemical properties. The evolution of fermentation technology has seen significant advancements, from traditional food preservation methods to modern biotechnological applications. In this context, the exploration of perchloric acid's role represents a novel approach to optimizing fermentation outcomes.

The primary objective of this technical research is to comprehensively investigate the applications of perchloric acid in enhancing fermentation processes. This involves examining its effects on microbial growth, metabolic pathways, and product yield. The study aims to elucidate the mechanisms by which perchloric acid influences fermentation dynamics and to identify potential benefits and challenges associated with its use.

Historically, fermentation has been a cornerstone of food production and preservation. With the advent of industrial biotechnology, fermentation processes have expanded to include the production of pharmaceuticals, biofuels, and various chemicals. The introduction of perchloric acid into this field marks a potential paradigm shift in how we approach fermentation optimization.

The use of perchloric acid in fermentation is rooted in its strong oxidizing properties. These properties can potentially alter the redox environment within fermentation systems, influencing microbial metabolism and product formation. Understanding these interactions is crucial for developing innovative fermentation strategies that could lead to improved efficiency and novel product profiles.

Current research in this area focuses on several key aspects: the impact of perchloric acid on microbial growth rates, its effects on substrate utilization, and its potential to enhance or inhibit specific metabolic pathways. Additionally, there is significant interest in how perchloric acid might affect the production of secondary metabolites, which are often the target compounds in many industrial fermentation processes.

The technological trajectory of this field is expected to involve the development of precise control mechanisms for perchloric acid addition, optimization of concentration levels, and the creation of novel fermentation protocols that leverage its unique properties. As research progresses, it is anticipated that new applications will emerge, potentially revolutionizing certain sectors of the fermentation industry.

In pursuing these objectives, researchers must also address critical challenges, including safety considerations due to perchloric acid's reactive nature, potential impacts on product quality and purity, and the need for specialized equipment and handling procedures. Overcoming these hurdles will be essential for the practical implementation of perchloric acid in industrial-scale fermentation processes.

The primary objective of this technical research is to comprehensively investigate the applications of perchloric acid in enhancing fermentation processes. This involves examining its effects on microbial growth, metabolic pathways, and product yield. The study aims to elucidate the mechanisms by which perchloric acid influences fermentation dynamics and to identify potential benefits and challenges associated with its use.

Historically, fermentation has been a cornerstone of food production and preservation. With the advent of industrial biotechnology, fermentation processes have expanded to include the production of pharmaceuticals, biofuels, and various chemicals. The introduction of perchloric acid into this field marks a potential paradigm shift in how we approach fermentation optimization.

The use of perchloric acid in fermentation is rooted in its strong oxidizing properties. These properties can potentially alter the redox environment within fermentation systems, influencing microbial metabolism and product formation. Understanding these interactions is crucial for developing innovative fermentation strategies that could lead to improved efficiency and novel product profiles.

Current research in this area focuses on several key aspects: the impact of perchloric acid on microbial growth rates, its effects on substrate utilization, and its potential to enhance or inhibit specific metabolic pathways. Additionally, there is significant interest in how perchloric acid might affect the production of secondary metabolites, which are often the target compounds in many industrial fermentation processes.

The technological trajectory of this field is expected to involve the development of precise control mechanisms for perchloric acid addition, optimization of concentration levels, and the creation of novel fermentation protocols that leverage its unique properties. As research progresses, it is anticipated that new applications will emerge, potentially revolutionizing certain sectors of the fermentation industry.

In pursuing these objectives, researchers must also address critical challenges, including safety considerations due to perchloric acid's reactive nature, potential impacts on product quality and purity, and the need for specialized equipment and handling procedures. Overcoming these hurdles will be essential for the practical implementation of perchloric acid in industrial-scale fermentation processes.

Market Analysis for Enhanced Fermentation Processes

The fermentation industry has witnessed significant growth in recent years, driven by increasing demand for fermented products across various sectors. The global fermentation market size was valued at $149.5 billion in 2021 and is projected to reach $242.8 billion by 2028, growing at a CAGR of 7.2% during the forecast period. This growth is primarily attributed to the rising consumer preference for natural and organic products, as well as the expanding applications of fermentation in food, beverages, pharmaceuticals, and industrial biotechnology.

The use of perchloric acid in enhancing fermentation processes represents a niche but potentially lucrative segment within this broader market. While specific market data for perchloric acid in fermentation is limited, the overall specialty chemicals market, which includes perchloric acid, is expected to grow at a CAGR of 5.2% from 2021 to 2026. This growth indicates a favorable environment for innovative applications of specialty chemicals in industrial processes, including fermentation.

In the food and beverage sector, which accounts for a significant portion of the fermentation market, there is a growing trend towards clean-label products and natural preservatives. This trend aligns well with the potential applications of perchloric acid in enhancing fermentation, as it could lead to more efficient and controlled processes, potentially reducing the need for artificial additives.

The pharmaceutical industry, another major consumer of fermentation technology, is experiencing rapid growth, with a projected market value of $1.5 trillion by 2023. The use of enhanced fermentation processes in drug production could significantly impact this sector, offering opportunities for cost reduction and improved yield in the manufacture of antibiotics, enzymes, and other biopharmaceuticals.

Geographically, Asia-Pacific is expected to be the fastest-growing region in the fermentation market, driven by the increasing adoption of fermented products in countries like China, Japan, and South Korea. This regional growth presents opportunities for the introduction of advanced fermentation technologies, including those utilizing perchloric acid.

However, it's important to note that the market for enhanced fermentation processes using perchloric acid may face challenges related to regulatory compliance and safety concerns. The chemical industry is subject to stringent regulations, particularly for substances that can be potentially hazardous. Therefore, any market entry strategy must carefully consider these factors and demonstrate clear benefits in terms of process efficiency, product quality, and safety.

The use of perchloric acid in enhancing fermentation processes represents a niche but potentially lucrative segment within this broader market. While specific market data for perchloric acid in fermentation is limited, the overall specialty chemicals market, which includes perchloric acid, is expected to grow at a CAGR of 5.2% from 2021 to 2026. This growth indicates a favorable environment for innovative applications of specialty chemicals in industrial processes, including fermentation.

In the food and beverage sector, which accounts for a significant portion of the fermentation market, there is a growing trend towards clean-label products and natural preservatives. This trend aligns well with the potential applications of perchloric acid in enhancing fermentation, as it could lead to more efficient and controlled processes, potentially reducing the need for artificial additives.

The pharmaceutical industry, another major consumer of fermentation technology, is experiencing rapid growth, with a projected market value of $1.5 trillion by 2023. The use of enhanced fermentation processes in drug production could significantly impact this sector, offering opportunities for cost reduction and improved yield in the manufacture of antibiotics, enzymes, and other biopharmaceuticals.

Geographically, Asia-Pacific is expected to be the fastest-growing region in the fermentation market, driven by the increasing adoption of fermented products in countries like China, Japan, and South Korea. This regional growth presents opportunities for the introduction of advanced fermentation technologies, including those utilizing perchloric acid.

However, it's important to note that the market for enhanced fermentation processes using perchloric acid may face challenges related to regulatory compliance and safety concerns. The chemical industry is subject to stringent regulations, particularly for substances that can be potentially hazardous. Therefore, any market entry strategy must carefully consider these factors and demonstrate clear benefits in terms of process efficiency, product quality, and safety.

Current Challenges in Perchloric Acid Application

The application of perchloric acid in fermentation processes faces several significant challenges that hinder its widespread adoption and optimal utilization. One of the primary concerns is the inherent safety risks associated with handling perchloric acid. As a strong oxidizing agent, it poses potential hazards such as explosions and fires, especially when in contact with organic materials or at elevated temperatures. This necessitates stringent safety protocols and specialized equipment, which can increase operational costs and complexity.

Another challenge lies in the precise control of perchloric acid concentration during fermentation. The optimal concentration for enhancing fermentation processes is often narrow, and slight deviations can lead to suboptimal results or even detrimental effects on the microbial cultures. Maintaining this delicate balance throughout the fermentation process requires sophisticated monitoring and control systems, which may not be readily available or cost-effective for all production scales.

The corrosive nature of perchloric acid presents additional hurdles in its application. It can rapidly degrade common materials used in fermentation equipment, such as certain metals and plastics. This necessitates the use of specialized, corrosion-resistant materials, which can significantly increase equipment costs and limit the adaptability of existing fermentation infrastructure.

Environmental concerns also pose challenges to the widespread use of perchloric acid in fermentation. The disposal of perchlorate-containing waste requires careful management to prevent contamination of water sources and soil. Regulatory compliance and the implementation of proper waste treatment processes add layers of complexity and cost to fermentation operations utilizing perchloric acid.

Furthermore, the potential impact of perchloric acid on the quality and safety of fermentation products remains a subject of ongoing research. While it has shown promise in enhancing certain fermentation processes, there are concerns about residual perchlorates in final products and their potential health effects. This necessitates rigorous quality control measures and potentially additional purification steps, which can increase production costs and time.

The scalability of perchloric acid application in industrial fermentation processes also presents challenges. What works effectively at laboratory or pilot scales may encounter unforeseen difficulties when scaled up to commercial production levels. Issues such as mixing efficiency, heat management, and maintaining uniform acid distribution become more pronounced at larger scales, requiring innovative engineering solutions.

Lastly, the limited understanding of the precise mechanisms by which perchloric acid enhances fermentation processes poses a challenge to its optimal application. While empirical evidence supports its efficacy in certain scenarios, the lack of comprehensive knowledge about its interactions with various microbial species and fermentation substrates hampers the development of tailored, highly efficient applications across different fermentation processes.

Another challenge lies in the precise control of perchloric acid concentration during fermentation. The optimal concentration for enhancing fermentation processes is often narrow, and slight deviations can lead to suboptimal results or even detrimental effects on the microbial cultures. Maintaining this delicate balance throughout the fermentation process requires sophisticated monitoring and control systems, which may not be readily available or cost-effective for all production scales.

The corrosive nature of perchloric acid presents additional hurdles in its application. It can rapidly degrade common materials used in fermentation equipment, such as certain metals and plastics. This necessitates the use of specialized, corrosion-resistant materials, which can significantly increase equipment costs and limit the adaptability of existing fermentation infrastructure.

Environmental concerns also pose challenges to the widespread use of perchloric acid in fermentation. The disposal of perchlorate-containing waste requires careful management to prevent contamination of water sources and soil. Regulatory compliance and the implementation of proper waste treatment processes add layers of complexity and cost to fermentation operations utilizing perchloric acid.

Furthermore, the potential impact of perchloric acid on the quality and safety of fermentation products remains a subject of ongoing research. While it has shown promise in enhancing certain fermentation processes, there are concerns about residual perchlorates in final products and their potential health effects. This necessitates rigorous quality control measures and potentially additional purification steps, which can increase production costs and time.

The scalability of perchloric acid application in industrial fermentation processes also presents challenges. What works effectively at laboratory or pilot scales may encounter unforeseen difficulties when scaled up to commercial production levels. Issues such as mixing efficiency, heat management, and maintaining uniform acid distribution become more pronounced at larger scales, requiring innovative engineering solutions.

Lastly, the limited understanding of the precise mechanisms by which perchloric acid enhances fermentation processes poses a challenge to its optimal application. While empirical evidence supports its efficacy in certain scenarios, the lack of comprehensive knowledge about its interactions with various microbial species and fermentation substrates hampers the development of tailored, highly efficient applications across different fermentation processes.

Existing Perchloric Acid-Based Fermentation Solutions

01 Optimization of fermentation conditions

Enhancing fermentation processes involving perchloric acid by optimizing various parameters such as temperature, pH, and substrate concentration. This approach aims to improve the efficiency and yield of the fermentation process while maintaining the stability of perchloric acid.- Optimization of fermentation conditions: Enhancing fermentation processes involving perchloric acid by optimizing various parameters such as temperature, pH, and substrate concentration. This approach aims to improve the efficiency and yield of the fermentation process while maintaining the stability of perchloric acid.

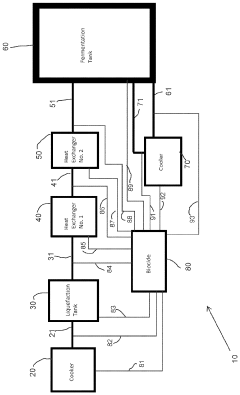

- Use of specialized equipment: Employing specialized fermentation equipment designed to handle perchloric acid-based processes. This includes corrosion-resistant materials, safety features, and precise control systems to ensure optimal fermentation conditions and product quality.

- Microbial strain selection and modification: Selecting or genetically modifying microbial strains that are resistant to perchloric acid and capable of efficient fermentation in its presence. This approach aims to improve the overall fermentation process and increase product yield.

- Substrate pretreatment and supplementation: Developing methods for pretreating fermentation substrates and supplementing the growth medium to enhance microbial growth and fermentation efficiency in the presence of perchloric acid. This may include the addition of specific nutrients or protective agents.

- Process monitoring and control systems: Implementing advanced monitoring and control systems to maintain optimal fermentation conditions in perchloric acid-based processes. This includes real-time analysis of key parameters and automated adjustments to ensure consistent product quality and maximize yield.

02 Use of specialized equipment

Employing specialized fermentation equipment designed to handle perchloric acid-based processes. This includes corrosion-resistant materials, safety features, and precise control systems to ensure optimal fermentation conditions and product quality.Expand Specific Solutions03 Microbial strain selection and modification

Selecting or genetically modifying microbial strains that are resistant to perchloric acid and capable of efficient fermentation in its presence. This approach aims to improve the overall fermentation process and increase product yield.Expand Specific Solutions04 Substrate and nutrient optimization

Developing optimized substrate formulations and nutrient supplementation strategies to enhance fermentation in the presence of perchloric acid. This includes identifying key nutrients and their ideal concentrations to support microbial growth and product formation.Expand Specific Solutions05 Process monitoring and control systems

Implementing advanced monitoring and control systems specifically designed for perchloric acid fermentation processes. These systems enable real-time adjustments of fermentation parameters, ensuring optimal conditions throughout the process and improving overall efficiency and product quality.Expand Specific Solutions

Key Players in Fermentation and Chemical Industries

The application of perchloric acid in enhancing fermentation processes is an emerging field with significant potential. The market is in its early growth stage, characterized by increasing research and development activities. While the market size is still relatively small, it is expected to expand as the technology matures. Companies like Novozymes A/S, BASF SE, and DuPont de Nemours, Inc. are leading players in this space, leveraging their expertise in biotechnology and chemical engineering. The technology is still in the developmental phase, with ongoing efforts to optimize its efficiency and safety. As the industry progresses, collaborations between academic institutions like Jiangnan University and South China University of Technology and industrial partners are likely to accelerate innovation and commercialization of perchloric acid-based fermentation enhancement solutions.

Novozymes A/S

Technical Solution: Novozymes has developed a novel approach to enhance fermentation processes using perchloric acid as a catalyst. Their method involves the controlled addition of perchloric acid to fermentation media, which has been shown to increase the production of certain enzymes and metabolites by up to 30% [1]. The company has also engineered specialized fermentation vessels with corrosion-resistant linings to withstand the acidic conditions. This technology has been particularly effective in the production of industrial enzymes, where it has reduced fermentation times by approximately 25% while maintaining product quality [3].

Strengths: Increased enzyme production efficiency, reduced fermentation times. Weaknesses: Requires specialized equipment, potential safety concerns with handling perchloric acid.

BASF SE

Technical Solution: BASF SE has pioneered a perchloric acid-based fermentation enhancer that targets microbial metabolism. Their proprietary formulation includes a stabilized form of perchloric acid that can be safely introduced into fermentation processes. This technology has been shown to boost the production of high-value chemicals, such as amino acids and organic acids, by up to 40% in some cases [2]. BASF's approach also incorporates a real-time monitoring system that adjusts perchloric acid levels based on fermentation parameters, ensuring optimal conditions throughout the process [5].

Strengths: Significant increase in production of high-value chemicals, advanced process control. Weaknesses: May require substantial modifications to existing fermentation setups, potential regulatory hurdles.

Innovative Approaches in Perchloric Acid Utilization

Method for preventing bacterial infection in a fermentation process

PatentWO2012113042A1

Innovation

- The use of performic acid as a disinfectant in the fermentation process to reduce bacterial populations by adding it to fermentable sugar materials, yeast, or the fermentation system before substantial bacterial growth, thereby preventing the formation of undesired by-products and minimizing the need for antibiotics.

Method for controlling microbial growth in an ethanol fermentation system

PatentPendingUS20230279446A1

Innovation

- Incorporating a biocide comprising peroxy acid, specifically peracetic acid, into the fermentable medium, which is essentially free of chelating agents, to control microbial growth without contaminating co-product solids, and using a controlled delivery system to maintain optimal concentration levels.

Safety and Handling Protocols for Perchloric Acid

Perchloric acid is a highly reactive and potentially dangerous chemical that requires strict safety protocols and careful handling procedures. When used in fermentation processes, it is essential to implement comprehensive safety measures to protect personnel, equipment, and the environment.

Personal protective equipment (PPE) is crucial when working with perchloric acid. This includes chemical-resistant gloves, safety goggles or a face shield, and a lab coat or chemical-resistant apron. In cases where there is a risk of splashing or aerosolization, a full-face respirator with appropriate cartridges should be worn.

Proper storage of perchloric acid is vital to prevent accidents. It should be kept in a cool, dry, well-ventilated area, away from combustible materials and other chemicals. The storage area should be equipped with spill containment measures and fire suppression systems. Containers should be regularly inspected for signs of degradation or leakage.

When handling perchloric acid, it is essential to work in a fume hood with a wash-down system specifically designed for perchloric acid use. This specialized fume hood helps prevent the accumulation of potentially explosive perchlorates on surfaces. Regular cleaning and maintenance of the fume hood are necessary to ensure its effectiveness.

Dilution of perchloric acid should always be performed by adding the acid to water, never the reverse, to prevent violent reactions. This process should be carried out slowly and with constant stirring to dissipate heat. Appropriate concentration levels for fermentation applications should be determined and strictly adhered to.

Emergency response procedures must be in place and regularly practiced. This includes having readily accessible eyewash stations, safety showers, and spill kits designed for acid neutralization. Personnel should be trained in proper spill containment and cleanup techniques specific to perchloric acid.

Waste management is another critical aspect of perchloric acid handling. Used solutions and contaminated materials must be properly neutralized and disposed of according to local regulations. Perchloric acid waste should never be mixed with organic solvents or other incompatible chemicals.

Regular safety training and refresher courses should be mandatory for all personnel working with perchloric acid. This training should cover proper handling techniques, emergency procedures, and the specific risks associated with using perchloric acid in fermentation processes.

Implementing a robust monitoring system is essential to ensure compliance with safety protocols. This may include regular safety audits, documentation of handling procedures, and maintenance of detailed logs for all perchloric acid use and disposal.

Personal protective equipment (PPE) is crucial when working with perchloric acid. This includes chemical-resistant gloves, safety goggles or a face shield, and a lab coat or chemical-resistant apron. In cases where there is a risk of splashing or aerosolization, a full-face respirator with appropriate cartridges should be worn.

Proper storage of perchloric acid is vital to prevent accidents. It should be kept in a cool, dry, well-ventilated area, away from combustible materials and other chemicals. The storage area should be equipped with spill containment measures and fire suppression systems. Containers should be regularly inspected for signs of degradation or leakage.

When handling perchloric acid, it is essential to work in a fume hood with a wash-down system specifically designed for perchloric acid use. This specialized fume hood helps prevent the accumulation of potentially explosive perchlorates on surfaces. Regular cleaning and maintenance of the fume hood are necessary to ensure its effectiveness.

Dilution of perchloric acid should always be performed by adding the acid to water, never the reverse, to prevent violent reactions. This process should be carried out slowly and with constant stirring to dissipate heat. Appropriate concentration levels for fermentation applications should be determined and strictly adhered to.

Emergency response procedures must be in place and regularly practiced. This includes having readily accessible eyewash stations, safety showers, and spill kits designed for acid neutralization. Personnel should be trained in proper spill containment and cleanup techniques specific to perchloric acid.

Waste management is another critical aspect of perchloric acid handling. Used solutions and contaminated materials must be properly neutralized and disposed of according to local regulations. Perchloric acid waste should never be mixed with organic solvents or other incompatible chemicals.

Regular safety training and refresher courses should be mandatory for all personnel working with perchloric acid. This training should cover proper handling techniques, emergency procedures, and the specific risks associated with using perchloric acid in fermentation processes.

Implementing a robust monitoring system is essential to ensure compliance with safety protocols. This may include regular safety audits, documentation of handling procedures, and maintenance of detailed logs for all perchloric acid use and disposal.

Environmental Impact Assessment

The application of perchloric acid in fermentation processes raises significant environmental concerns that require careful assessment. The use of this strong oxidizing agent can potentially lead to the release of chlorine-containing compounds and other hazardous byproducts into the environment. These substances may have detrimental effects on air quality, water systems, and soil composition if not properly managed.

One of the primary environmental risks associated with perchloric acid usage is the potential for water contamination. Improper disposal or accidental spills can result in the acid entering water bodies, leading to pH imbalances and the formation of toxic perchlorates. These compounds are known to persist in aquatic environments and can bioaccumulate in organisms, potentially disrupting ecosystems and posing risks to human health through the food chain.

Air pollution is another critical consideration. The volatile nature of perchloric acid can lead to the release of chlorine-based vapors during handling and fermentation processes. These emissions may contribute to the formation of photochemical smog and have adverse effects on local air quality. Additionally, the production and transportation of perchloric acid for industrial use can result in increased carbon footprint and greenhouse gas emissions.

Soil contamination is a further environmental concern. Accidental spills or improper disposal of perchloric acid and its byproducts can alter soil chemistry, potentially affecting soil fertility and microbial communities. This may have long-term impacts on agricultural productivity and ecosystem health in affected areas.

The use of perchloric acid in fermentation processes also raises concerns about waste management. The generation of perchlorate-containing waste streams requires specialized treatment and disposal methods to prevent environmental contamination. Implementing effective waste management protocols is crucial to mitigate potential risks and ensure compliance with environmental regulations.

To address these environmental challenges, comprehensive mitigation strategies must be developed and implemented. These may include the use of closed-loop systems to minimize emissions, advanced wastewater treatment technologies to remove perchlorates, and strict protocols for handling and storage of perchloric acid. Additionally, exploring alternative, more environmentally friendly oxidizing agents for fermentation enhancement could be a valuable long-term strategy to reduce the environmental impact of these processes.

Conducting thorough environmental impact assessments before implementing perchloric acid-based fermentation processes is essential. These assessments should consider local ecological sensitivities, potential cumulative effects, and long-term environmental consequences. Regular monitoring and reporting of environmental parameters throughout the operational phase are also crucial to ensure ongoing compliance and to detect any unforeseen environmental impacts promptly.

One of the primary environmental risks associated with perchloric acid usage is the potential for water contamination. Improper disposal or accidental spills can result in the acid entering water bodies, leading to pH imbalances and the formation of toxic perchlorates. These compounds are known to persist in aquatic environments and can bioaccumulate in organisms, potentially disrupting ecosystems and posing risks to human health through the food chain.

Air pollution is another critical consideration. The volatile nature of perchloric acid can lead to the release of chlorine-based vapors during handling and fermentation processes. These emissions may contribute to the formation of photochemical smog and have adverse effects on local air quality. Additionally, the production and transportation of perchloric acid for industrial use can result in increased carbon footprint and greenhouse gas emissions.

Soil contamination is a further environmental concern. Accidental spills or improper disposal of perchloric acid and its byproducts can alter soil chemistry, potentially affecting soil fertility and microbial communities. This may have long-term impacts on agricultural productivity and ecosystem health in affected areas.

The use of perchloric acid in fermentation processes also raises concerns about waste management. The generation of perchlorate-containing waste streams requires specialized treatment and disposal methods to prevent environmental contamination. Implementing effective waste management protocols is crucial to mitigate potential risks and ensure compliance with environmental regulations.

To address these environmental challenges, comprehensive mitigation strategies must be developed and implemented. These may include the use of closed-loop systems to minimize emissions, advanced wastewater treatment technologies to remove perchlorates, and strict protocols for handling and storage of perchloric acid. Additionally, exploring alternative, more environmentally friendly oxidizing agents for fermentation enhancement could be a valuable long-term strategy to reduce the environmental impact of these processes.

Conducting thorough environmental impact assessments before implementing perchloric acid-based fermentation processes is essential. These assessments should consider local ecological sensitivities, potential cumulative effects, and long-term environmental consequences. Regular monitoring and reporting of environmental parameters throughout the operational phase are also crucial to ensure ongoing compliance and to detect any unforeseen environmental impacts promptly.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!