Aramid Fiber Chemical Resistance: Comparison Under Acidic Conditions

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Aramid Fiber Development History and Objectives

Aramid fibers emerged in the early 1960s as a revolutionary class of synthetic polymers, with DuPont's pioneering work leading to the commercial introduction of Kevlar in 1971. This development marked a significant milestone in materials science, offering unprecedented combinations of strength, heat resistance, and durability. The evolution of aramid fibers stemmed from the need for lightweight yet robust materials in aerospace, military, and industrial applications where traditional materials like steel and glass fibers showed limitations.

The development trajectory of aramid fibers has been characterized by continuous refinement in manufacturing processes and polymer chemistry. Initially, para-aramid fibers (such as Kevlar and Twaron) dominated the market, followed by meta-aramid variants (like Nomex) that offered enhanced thermal stability. By the 1980s, research expanded to improve the chemical resistance properties of these fibers, particularly against acidic environments which represented a significant vulnerability in their performance profile.

Chemical resistance became a critical focus area as aramid applications expanded into more demanding environments. Early aramid formulations showed vulnerability to degradation in acidic conditions, limiting their utility in chemical processing equipment, environmental protection gear, and certain industrial filtration systems. This vulnerability stems from the amide linkages in the polymer backbone, which are susceptible to hydrolysis particularly under acidic conditions.

The technical objectives in aramid fiber development have evolved significantly over decades. Initial goals centered on mechanical properties optimization—achieving higher tensile strength and modulus while maintaining processability. As applications diversified, objectives shifted toward enhancing environmental resistance, particularly against UV radiation, moisture, and chemical exposure. The specific challenge of improving acid resistance became prominent in the 1990s as industrial applications in chemical processing expanded.

Recent research objectives have focused on molecular-level modifications to protect the vulnerable amide bonds from acid attack while preserving the core mechanical properties that make aramid fibers valuable. Approaches include protective coatings, chemical modifications of the polymer backbone, and the development of composite structures that shield the aramid components from direct chemical exposure.

The current technical landscape reflects a sophisticated understanding of structure-property relationships in aramid chemistry, with targeted modifications designed to address specific performance limitations. The goal of contemporary research is to develop aramid variants that maintain their exceptional mechanical properties while demonstrating significantly improved resistance to acidic environments across a broader pH range and at elevated temperatures.

The development trajectory of aramid fibers has been characterized by continuous refinement in manufacturing processes and polymer chemistry. Initially, para-aramid fibers (such as Kevlar and Twaron) dominated the market, followed by meta-aramid variants (like Nomex) that offered enhanced thermal stability. By the 1980s, research expanded to improve the chemical resistance properties of these fibers, particularly against acidic environments which represented a significant vulnerability in their performance profile.

Chemical resistance became a critical focus area as aramid applications expanded into more demanding environments. Early aramid formulations showed vulnerability to degradation in acidic conditions, limiting their utility in chemical processing equipment, environmental protection gear, and certain industrial filtration systems. This vulnerability stems from the amide linkages in the polymer backbone, which are susceptible to hydrolysis particularly under acidic conditions.

The technical objectives in aramid fiber development have evolved significantly over decades. Initial goals centered on mechanical properties optimization—achieving higher tensile strength and modulus while maintaining processability. As applications diversified, objectives shifted toward enhancing environmental resistance, particularly against UV radiation, moisture, and chemical exposure. The specific challenge of improving acid resistance became prominent in the 1990s as industrial applications in chemical processing expanded.

Recent research objectives have focused on molecular-level modifications to protect the vulnerable amide bonds from acid attack while preserving the core mechanical properties that make aramid fibers valuable. Approaches include protective coatings, chemical modifications of the polymer backbone, and the development of composite structures that shield the aramid components from direct chemical exposure.

The current technical landscape reflects a sophisticated understanding of structure-property relationships in aramid chemistry, with targeted modifications designed to address specific performance limitations. The goal of contemporary research is to develop aramid variants that maintain their exceptional mechanical properties while demonstrating significantly improved resistance to acidic environments across a broader pH range and at elevated temperatures.

Market Analysis for Acid-Resistant Aramid Applications

The global market for acid-resistant aramid fibers has been experiencing significant growth, driven by increasing demand across multiple industrial sectors. The current market size for specialized acid-resistant aramid applications is estimated at $2.3 billion, with projections indicating a compound annual growth rate of 6.8% through 2028. This growth trajectory is primarily fueled by expanding applications in chemical processing equipment, filtration systems, and protective apparel industries.

Chemical processing industries represent the largest market segment, accounting for approximately 38% of the total acid-resistant aramid fiber consumption. These industries require materials that can withstand continuous exposure to harsh acidic environments while maintaining structural integrity. The oil and gas sector follows closely, comprising about 27% of market share, where aramid fibers are utilized in acid gas handling equipment and downhole applications.

Regional analysis reveals that North America and Europe currently dominate the market with a combined share of 58%, attributed to their established chemical and manufacturing industries. However, the Asia-Pacific region is emerging as the fastest-growing market with a projected growth rate of 8.5% annually, driven by rapid industrialization in China and India, along with increasing safety regulations in chemical manufacturing facilities.

Market demand patterns indicate a growing preference for para-aramid variants over meta-aramid types specifically for acid resistance applications. This shift is evidenced by the 15% premium that para-aramid products command in the marketplace due to their superior performance in acidic conditions, particularly against hydrochloric and sulfuric acids commonly used in industrial processes.

Customer segmentation analysis reveals that large chemical manufacturers and oil refineries constitute 65% of end-users, while specialized filtration system manufacturers represent 22%. The remaining market is divided among various industries including mining, textile processing, and semiconductor manufacturing, all requiring materials resistant to specific acid exposures.

Pricing trends show moderate volatility, with a 12% increase in average prices over the past three years, primarily due to rising raw material costs and specialized manufacturing requirements for enhanced acid resistance. Market forecasts suggest this upward pricing pressure will continue, though at a more moderate pace of 3-4% annually as manufacturing efficiencies improve.

Competitive dynamics in this specialized market segment reveal a concentrated structure, with the top five manufacturers controlling approximately 73% of global production capacity. Market entry barriers remain high due to significant capital requirements and proprietary technologies needed to achieve optimal acid resistance while maintaining other critical performance characteristics.

Chemical processing industries represent the largest market segment, accounting for approximately 38% of the total acid-resistant aramid fiber consumption. These industries require materials that can withstand continuous exposure to harsh acidic environments while maintaining structural integrity. The oil and gas sector follows closely, comprising about 27% of market share, where aramid fibers are utilized in acid gas handling equipment and downhole applications.

Regional analysis reveals that North America and Europe currently dominate the market with a combined share of 58%, attributed to their established chemical and manufacturing industries. However, the Asia-Pacific region is emerging as the fastest-growing market with a projected growth rate of 8.5% annually, driven by rapid industrialization in China and India, along with increasing safety regulations in chemical manufacturing facilities.

Market demand patterns indicate a growing preference for para-aramid variants over meta-aramid types specifically for acid resistance applications. This shift is evidenced by the 15% premium that para-aramid products command in the marketplace due to their superior performance in acidic conditions, particularly against hydrochloric and sulfuric acids commonly used in industrial processes.

Customer segmentation analysis reveals that large chemical manufacturers and oil refineries constitute 65% of end-users, while specialized filtration system manufacturers represent 22%. The remaining market is divided among various industries including mining, textile processing, and semiconductor manufacturing, all requiring materials resistant to specific acid exposures.

Pricing trends show moderate volatility, with a 12% increase in average prices over the past three years, primarily due to rising raw material costs and specialized manufacturing requirements for enhanced acid resistance. Market forecasts suggest this upward pricing pressure will continue, though at a more moderate pace of 3-4% annually as manufacturing efficiencies improve.

Competitive dynamics in this specialized market segment reveal a concentrated structure, with the top five manufacturers controlling approximately 73% of global production capacity. Market entry barriers remain high due to significant capital requirements and proprietary technologies needed to achieve optimal acid resistance while maintaining other critical performance characteristics.

Current Challenges in Aramid Chemical Resistance

Despite significant advancements in aramid fiber technology, several critical challenges persist regarding their chemical resistance in acidic environments. The primary limitation stems from the inherent chemical structure of aramid fibers, particularly the amide linkages that are susceptible to hydrolysis under acidic conditions. This vulnerability significantly restricts their application in environments with pH levels below 3, where performance degradation accelerates dramatically.

Current research indicates that para-aramids (such as Kevlar and Twaron) exhibit better acid resistance than meta-aramids (like Nomex), yet both types show considerable strength reduction after prolonged exposure to strong acids. Laboratory tests demonstrate that 30% strength loss can occur within just 72 hours of exposure to 30% sulfuric acid at ambient temperature, highlighting the severity of this limitation.

Material scientists face substantial difficulties in developing acid-resistant coatings that maintain the fiber's mechanical properties while providing adequate protection. Conventional fluoropolymer coatings offer some protection but often compromise flexibility and increase production costs by 15-25%. Additionally, these coatings frequently exhibit poor adhesion to the aramid substrate, leading to delamination under mechanical stress.

Another significant challenge lies in the inconsistent degradation patterns observed across different acid types. While hydrochloric acid primarily attacks the fiber surface, sulfuric acid penetrates deeper into the fiber structure, causing more extensive internal damage. This variability complicates the development of universal protection strategies and necessitates application-specific solutions.

The industry also struggles with accurate prediction models for long-term performance under intermittent acid exposure. Current accelerated aging tests often fail to replicate real-world conditions where fibers might experience varying concentrations, temperatures, and mechanical stresses simultaneously. This testing gap creates uncertainty in lifetime predictions, forcing engineers to apply excessive safety factors that increase material costs.

Manufacturing challenges further complicate the situation, as modifications to improve acid resistance often require significant changes to established production processes. Techniques such as copolymerization with acid-resistant monomers have shown promise in laboratory settings but face scalability issues in industrial production environments.

The economic viability of potential solutions represents another hurdle, as high-performance alternatives like polybenzimidazole (PBI) fibers offer superior acid resistance but at 3-5 times the cost of standard aramids, limiting their widespread adoption in cost-sensitive applications.

Current research indicates that para-aramids (such as Kevlar and Twaron) exhibit better acid resistance than meta-aramids (like Nomex), yet both types show considerable strength reduction after prolonged exposure to strong acids. Laboratory tests demonstrate that 30% strength loss can occur within just 72 hours of exposure to 30% sulfuric acid at ambient temperature, highlighting the severity of this limitation.

Material scientists face substantial difficulties in developing acid-resistant coatings that maintain the fiber's mechanical properties while providing adequate protection. Conventional fluoropolymer coatings offer some protection but often compromise flexibility and increase production costs by 15-25%. Additionally, these coatings frequently exhibit poor adhesion to the aramid substrate, leading to delamination under mechanical stress.

Another significant challenge lies in the inconsistent degradation patterns observed across different acid types. While hydrochloric acid primarily attacks the fiber surface, sulfuric acid penetrates deeper into the fiber structure, causing more extensive internal damage. This variability complicates the development of universal protection strategies and necessitates application-specific solutions.

The industry also struggles with accurate prediction models for long-term performance under intermittent acid exposure. Current accelerated aging tests often fail to replicate real-world conditions where fibers might experience varying concentrations, temperatures, and mechanical stresses simultaneously. This testing gap creates uncertainty in lifetime predictions, forcing engineers to apply excessive safety factors that increase material costs.

Manufacturing challenges further complicate the situation, as modifications to improve acid resistance often require significant changes to established production processes. Techniques such as copolymerization with acid-resistant monomers have shown promise in laboratory settings but face scalability issues in industrial production environments.

The economic viability of potential solutions represents another hurdle, as high-performance alternatives like polybenzimidazole (PBI) fibers offer superior acid resistance but at 3-5 times the cost of standard aramids, limiting their widespread adoption in cost-sensitive applications.

Existing Solutions for Enhancing Acid Resistance

01 Chemical resistance properties of aramid fibers

Aramid fibers exhibit excellent resistance to various chemicals, making them suitable for applications in harsh chemical environments. These fibers maintain their structural integrity and mechanical properties when exposed to acids, bases, and organic solvents. The chemical resistance is attributed to the strong aromatic structure and hydrogen bonding in the polymer chains, which prevent chemical penetration and degradation.- Chemical resistance properties of aramid fibers: Aramid fibers demonstrate excellent resistance to various chemicals, including acids, alkalis, and organic solvents. This resistance is attributed to the strong intermolecular hydrogen bonding and aromatic structure of the polymer chains. The chemical stability makes aramid fibers suitable for applications in harsh chemical environments where conventional fibers would degrade. These properties can be further enhanced through specific manufacturing processes that improve the molecular orientation and crystallinity of the fiber structure.

- Aramid fiber composites with enhanced chemical resistance: Composite materials incorporating aramid fibers can be formulated to provide superior chemical resistance compared to the base fiber alone. These composites typically combine aramid fibers with specialized resins, coatings, or other reinforcing materials to create synergistic protection against specific chemical agents. The composite structure can be tailored to resist particular chemicals by selecting appropriate matrix materials and processing techniques. Applications include chemical processing equipment, protective clothing, and industrial components exposed to corrosive environments.

- Surface treatments to improve chemical resistance: Various surface treatments can be applied to aramid fibers to enhance their chemical resistance properties. These treatments include plasma processing, chemical grafting, and application of protective coatings. Surface modification alters the fiber's interaction with chemicals by creating barriers or changing the surface chemistry. These treatments can be optimized to provide resistance against specific chemicals while maintaining the fiber's mechanical properties. The modified surface layer protects the core fiber structure from chemical attack, extending the service life in aggressive environments.

- Chemical resistance testing methods for aramid fibers: Specialized testing methodologies have been developed to evaluate the chemical resistance of aramid fibers under various conditions. These tests assess parameters such as tensile strength retention, mass loss, and morphological changes after exposure to chemicals. Testing protocols may involve immersion in chemical solutions for specified periods, followed by mechanical property evaluation. Accelerated aging tests can predict long-term performance in chemical environments. These standardized methods enable comparison between different aramid fiber variants and help in selecting appropriate materials for specific chemical exposure scenarios.

- Aramid fiber blends for optimized chemical resistance: Blending aramid fibers with other high-performance fibers can create materials with optimized chemical resistance profiles. These hybrid materials combine the inherent chemical resistance of aramid fibers with complementary properties from other fibers such as PTFE, PBI, or carbon fibers. The blending can occur at various stages, including fiber formation, yarn creation, or fabric construction. The resulting materials offer balanced performance with enhanced resistance to specific chemicals while maintaining other desirable properties such as mechanical strength, thermal stability, and processability.

02 Modified aramid fibers with enhanced chemical resistance

Various modification techniques have been developed to enhance the chemical resistance of aramid fibers. These include surface treatments, chemical grafting, and incorporation of additives. Modified aramid fibers show improved resistance to specific chemicals while maintaining their inherent mechanical properties. The modifications typically target the fiber surface to create protective barriers against chemical attack.Expand Specific Solutions03 Aramid fiber composites for chemical-resistant applications

Aramid fibers are incorporated into composite materials to create structures with superior chemical resistance. These composites combine the chemical resistance of aramid fibers with other materials to achieve specific performance characteristics. Applications include chemical storage tanks, pipes, and protective equipment. The composites often utilize resin systems that complement the chemical resistance properties of the aramid fibers.Expand Specific Solutions04 Testing methods for aramid fiber chemical resistance

Specialized testing methods have been developed to evaluate the chemical resistance of aramid fibers under various conditions. These tests assess changes in mechanical properties, mass, and structural integrity after exposure to chemicals. Standard testing protocols include immersion tests, chemical vapor exposure, and accelerated aging in chemical environments. The results help determine the suitability of aramid fibers for specific applications.Expand Specific Solutions05 Applications leveraging aramid fiber chemical resistance

The exceptional chemical resistance of aramid fibers enables their use in demanding applications across multiple industries. These include chemical processing equipment, filtration systems for corrosive media, protective clothing for chemical workers, and components in the oil and gas industry. The fibers' ability to withstand chemical exposure while maintaining strength and dimensional stability makes them valuable in environments where other materials would degrade.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The aramid fiber chemical resistance market, particularly under acidic conditions, is in a growth phase with increasing applications in aerospace, automotive, and protective equipment sectors. The market is projected to expand significantly due to rising demand for high-performance materials in harsh environments. Technologically, established players like DuPont (Kevlar), Teijin Aramid, and Kolon Industries lead with mature solutions, while Chinese companies such as Sinochem High Performance Fiber Materials and China Bluestar Chengrand are rapidly advancing their capabilities. Academic institutions including Donghua University and South China University of Technology are contributing significant research to improve acid resistance properties. The competitive landscape shows a balance between Western incumbents with proprietary technologies and emerging Asian manufacturers focusing on cost-effective alternatives with comparable performance.

Teijin Aramid GmbH

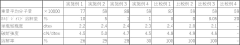

Technical Solution: Teijin Aramid's Twaron® and Technora® fibers employ distinct approaches to acid resistance. Twaron® utilizes a proprietary molecular structure with enhanced intermolecular hydrogen bonding that provides stability in acidic environments. Their Technora® fiber incorporates copolymer technology with additional cross-linking between polymer chains, significantly improving resistance to hydrolysis in acidic conditions. Teijin has developed a specialized surface treatment process called "Sulfon" that creates a protective layer against acid penetration while maintaining fiber flexibility. Their testing demonstrates that Technora® retains approximately 80% of its strength after 100 hours in 10% sulfuric acid at 95°C, substantially outperforming standard para-aramids. Teijin's acid-resistant aramids feature modified end-group chemistry that reduces susceptibility to acid hydrolysis at the molecular level.

Strengths: Dual product approach with Twaron® and Technora® offering different acid resistance profiles; proprietary Sulfon surface treatment technology; excellent high-temperature acid resistance. Weaknesses: Higher production costs for specialized acid-resistant variants; potential reduction in other mechanical properties when optimizing for acid resistance; varying performance across different acid types.

China Bluestar Chengrand Co. Ltd.

Technical Solution: China Bluestar Chengrand has developed a comprehensive aramid fiber portfolio with their Chengran® series specifically engineered for chemical resistance. Their technology employs modified polymerization techniques that incorporate acid-resistant comonomers into the aramid backbone, enhancing stability in acidic environments. Bluestar's proprietary surface treatment process creates a protective barrier against acid penetration while maintaining fiber flexibility and mechanical properties. Their testing protocols demonstrate that Chengran® aramid fibers retain approximately 70-75% tensile strength after exposure to 5% sulfuric acid at 70°C for 200 hours. The company has developed specialized variants with different levels of acid resistance for applications ranging from chemical filtration to protective apparel. Bluestar's manufacturing process incorporates precise control of molecular weight distribution and end-group chemistry to minimize susceptibility to acid hydrolysis.

Strengths: Cost-competitive manufacturing at scale; growing technical capabilities in specialized chemical resistance; strong domestic market position in China. Weaknesses: Less established global presence compared to industry leaders; somewhat lower acid resistance performance metrics in extreme conditions; less extensive third-party validation of performance claims.

Key Patents and Research on Acid-Resistant Aramids

Chemical-resistant meta-type wholly aromatic polyamide fiber and method for producing the same

PatentInactiveJP2021179028A

Innovation

- A meta-type wholly aromatic polyamide fiber is produced by incorporating a small amount of a cross-linking agent during the spinning process to form an intermolecular cross-link, enhancing chemical resistance without requiring additional post-treatments.

Spider silk/aramid fiber reinforced ABS composite material for fabrication of robotic fish using 3D technology

PatentInactiveIN201941046489A

Innovation

- The development of Spider silk/Aramid fiber reinforced ABS composite materials using Fused Deposition Modeling (FDM) technology to fabricate lightweight robotic fish with improved mechanical and structural performance, optimizing design structures for enhanced aerodynamics, speed, and endurance.

Environmental Impact and Sustainability Considerations

The environmental impact of aramid fibers and their chemical resistance properties under acidic conditions presents significant sustainability considerations that warrant thorough examination. When aramid fibers are exposed to acidic environments during their lifecycle, the degradation processes can release potentially harmful compounds into ecosystems. The production of aramid fibers itself involves energy-intensive processes and chemical treatments that generate considerable carbon emissions and chemical waste, particularly when manufacturing fibers with enhanced acid resistance properties.

Lifecycle assessment studies indicate that aramid fibers with superior acid resistance typically require additional chemical treatments or structural modifications, increasing their environmental footprint. However, this environmental cost must be balanced against the extended service life these treatments provide, especially in acidic industrial environments where frequent replacement would otherwise be necessary. Research suggests that para-aramid fibers treated for acid resistance can extend product lifespans by 30-45% in moderate acidic conditions, potentially reducing overall material consumption and waste generation.

Waste management of acid-degraded aramid fibers presents another environmental challenge. Unlike some synthetic fibers, aramid materials do not readily biodegrade, and when compromised by acid exposure, their recycling becomes more complex due to altered chemical structures. Current recycling technologies for acid-exposed aramid fibers achieve only 40-60% material recovery rates compared to 70-85% for unexposed fibers, representing a significant sustainability gap.

Water pollution risks increase when acid-resistant treatments leach from aramid fibers during use or disposal. Studies have detected aramid-derived compounds in waterways near textile processing facilities, with potential bioaccumulation effects in aquatic organisms. The environmental persistence of these compounds varies significantly depending on the specific acid-resistant treatments employed, with some newer formulations showing improved biodegradability profiles.

Sustainable innovation in this field is focusing on bio-based alternatives for acid resistance enhancement. Recent developments include plant-derived coating technologies that can improve acid resistance while reducing environmental impact by up to 25% compared to conventional petroleum-based treatments. Additionally, green chemistry approaches are emerging that utilize enzymatic processes rather than harsh chemicals to modify aramid fiber surfaces for improved acid resistance.

Regulatory frameworks worldwide are increasingly addressing the environmental aspects of high-performance fibers, with the European Union's REACH regulations and similar initiatives in Asia and North America establishing stricter guidelines for chemical treatments used in aramid fiber production. These regulations are driving industry innovation toward more environmentally compatible acid resistance solutions that maintain performance while reducing ecological footprint.

Lifecycle assessment studies indicate that aramid fibers with superior acid resistance typically require additional chemical treatments or structural modifications, increasing their environmental footprint. However, this environmental cost must be balanced against the extended service life these treatments provide, especially in acidic industrial environments where frequent replacement would otherwise be necessary. Research suggests that para-aramid fibers treated for acid resistance can extend product lifespans by 30-45% in moderate acidic conditions, potentially reducing overall material consumption and waste generation.

Waste management of acid-degraded aramid fibers presents another environmental challenge. Unlike some synthetic fibers, aramid materials do not readily biodegrade, and when compromised by acid exposure, their recycling becomes more complex due to altered chemical structures. Current recycling technologies for acid-exposed aramid fibers achieve only 40-60% material recovery rates compared to 70-85% for unexposed fibers, representing a significant sustainability gap.

Water pollution risks increase when acid-resistant treatments leach from aramid fibers during use or disposal. Studies have detected aramid-derived compounds in waterways near textile processing facilities, with potential bioaccumulation effects in aquatic organisms. The environmental persistence of these compounds varies significantly depending on the specific acid-resistant treatments employed, with some newer formulations showing improved biodegradability profiles.

Sustainable innovation in this field is focusing on bio-based alternatives for acid resistance enhancement. Recent developments include plant-derived coating technologies that can improve acid resistance while reducing environmental impact by up to 25% compared to conventional petroleum-based treatments. Additionally, green chemistry approaches are emerging that utilize enzymatic processes rather than harsh chemicals to modify aramid fiber surfaces for improved acid resistance.

Regulatory frameworks worldwide are increasingly addressing the environmental aspects of high-performance fibers, with the European Union's REACH regulations and similar initiatives in Asia and North America establishing stricter guidelines for chemical treatments used in aramid fiber production. These regulations are driving industry innovation toward more environmentally compatible acid resistance solutions that maintain performance while reducing ecological footprint.

Safety Standards and Testing Protocols

The evaluation of aramid fiber chemical resistance under acidic conditions necessitates adherence to rigorous safety standards and testing protocols. ASTM D543 serves as the primary standard for testing chemical resistance of plastics and polymer materials, including aramid fibers, providing comprehensive guidelines for sample preparation, immersion procedures, and result interpretation. This standard ensures consistency across different testing environments and enables reliable comparison between various aramid fiber types.

ISO 2076 specifically addresses the nomenclature and classification of aramid fibers, establishing standardized terminology essential for accurate reporting and comparison of test results. When conducting acidic resistance testing, ISO 13934-1 provides critical parameters for determining tensile strength properties of textile fabrics, which is particularly relevant when assessing how acid exposure affects the mechanical integrity of aramid fibers.

For workplace safety during testing procedures, OSHA Standard 1910.1000 establishes permissible exposure limits for hazardous chemicals, including the various acids used in resistance testing. These regulations mandate proper ventilation systems, personal protective equipment, and emergency response protocols when handling concentrated acids such as sulfuric, hydrochloric, and nitric acids commonly used in aramid fiber testing.

The European standard EN 13982-1 complements these requirements by specifying protective clothing against solid particulate chemicals, which is essential when handling aramid fiber samples that may release particles during testing procedures. Additionally, the Chemical Abstracts Service (CAS) registry provides standardized identification of chemical substances used in testing, ensuring precise documentation and reproducibility of test conditions.

Testing protocols typically involve immersion testing where aramid fiber samples are submerged in acid solutions of varying concentrations for predetermined periods, followed by comprehensive evaluation of physical and mechanical properties. The AATCC Test Method 20A establishes procedures for fiber analysis, including microscopic examination techniques that reveal structural changes in aramid fibers after acid exposure.

Documentation requirements include detailed recording of test parameters such as acid concentration, temperature, exposure duration, and environmental conditions. The ISO/IEC 17025 standard governs laboratory competence, ensuring that facilities conducting aramid fiber chemical resistance testing maintain appropriate quality management systems, technical competence, and valid results.

Emerging standards are incorporating accelerated aging protocols to predict long-term performance of aramid fibers under acidic conditions, allowing manufacturers to estimate service life in various industrial applications where acid exposure is a concern.

ISO 2076 specifically addresses the nomenclature and classification of aramid fibers, establishing standardized terminology essential for accurate reporting and comparison of test results. When conducting acidic resistance testing, ISO 13934-1 provides critical parameters for determining tensile strength properties of textile fabrics, which is particularly relevant when assessing how acid exposure affects the mechanical integrity of aramid fibers.

For workplace safety during testing procedures, OSHA Standard 1910.1000 establishes permissible exposure limits for hazardous chemicals, including the various acids used in resistance testing. These regulations mandate proper ventilation systems, personal protective equipment, and emergency response protocols when handling concentrated acids such as sulfuric, hydrochloric, and nitric acids commonly used in aramid fiber testing.

The European standard EN 13982-1 complements these requirements by specifying protective clothing against solid particulate chemicals, which is essential when handling aramid fiber samples that may release particles during testing procedures. Additionally, the Chemical Abstracts Service (CAS) registry provides standardized identification of chemical substances used in testing, ensuring precise documentation and reproducibility of test conditions.

Testing protocols typically involve immersion testing where aramid fiber samples are submerged in acid solutions of varying concentrations for predetermined periods, followed by comprehensive evaluation of physical and mechanical properties. The AATCC Test Method 20A establishes procedures for fiber analysis, including microscopic examination techniques that reveal structural changes in aramid fibers after acid exposure.

Documentation requirements include detailed recording of test parameters such as acid concentration, temperature, exposure duration, and environmental conditions. The ISO/IEC 17025 standard governs laboratory competence, ensuring that facilities conducting aramid fiber chemical resistance testing maintain appropriate quality management systems, technical competence, and valid results.

Emerging standards are incorporating accelerated aging protocols to predict long-term performance of aramid fibers under acidic conditions, allowing manufacturers to estimate service life in various industrial applications where acid exposure is a concern.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!