Aramid Fiber vs Carbon Fiber: Performance in Impact Scenarios

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Aramid and Carbon Fiber Evolution and Objectives

The evolution of high-performance fibers has revolutionized material science over the past five decades, with aramid and carbon fibers emerging as two dominant materials in impact-resistant applications. Aramid fibers, first commercially introduced by DuPont under the Kevlar brand in 1971, represented a breakthrough in polymer science with their exceptional tensile strength-to-weight ratio. The development pathway began with research into aromatic polyamides in the 1960s, leading to materials that offered unprecedented resistance to impacts while maintaining flexibility.

Carbon fiber technology traces its origins to the late 1950s, with significant commercial development occurring in the 1970s. Unlike aramid fibers, carbon fibers evolved from precursor materials such as polyacrylonitrile (PAN), rayon, or pitch, which undergo carbonization at extremely high temperatures. This evolution has resulted in materials with extraordinary stiffness and strength characteristics, though with different impact response profiles compared to aramid fibers.

The technological trajectories of these materials have been shaped by distinct performance objectives. Aramid fibers were primarily developed to provide exceptional tensile strength, heat resistance, and impact absorption capabilities, making them ideal for ballistic protection and safety applications. Their molecular structure, characterized by strong intermolecular hydrogen bonds and rigid para-oriented aromatic rings, enables remarkable energy dissipation during impact events.

Carbon fibers, conversely, were developed with objectives centered on achieving maximum stiffness-to-weight ratios and compressive strength. Their graphitic microstructure, with aligned carbon atoms in crystalline arrangements, delivers superior performance in applications requiring structural rigidity and resistance to deformation under load.

Recent technological advancements have focused on hybridization strategies, combining aramid and carbon fibers to leverage complementary properties. This evolution reflects a growing understanding that impact scenarios involve complex mechanical interactions requiring tailored material responses. Modern research objectives include developing multi-functional composites that can simultaneously address multiple performance parameters including impact resistance, post-impact structural integrity, and damage visualization capabilities.

The current technological frontier involves nanoscale modifications to both fiber types, with research objectives targeting improved interfacial bonding in composite structures, enhanced energy absorption mechanisms, and reduced manufacturing costs. Computational modeling has become increasingly important in predicting performance in varied impact scenarios, allowing for accelerated development cycles and more precise material optimization for specific applications.

Carbon fiber technology traces its origins to the late 1950s, with significant commercial development occurring in the 1970s. Unlike aramid fibers, carbon fibers evolved from precursor materials such as polyacrylonitrile (PAN), rayon, or pitch, which undergo carbonization at extremely high temperatures. This evolution has resulted in materials with extraordinary stiffness and strength characteristics, though with different impact response profiles compared to aramid fibers.

The technological trajectories of these materials have been shaped by distinct performance objectives. Aramid fibers were primarily developed to provide exceptional tensile strength, heat resistance, and impact absorption capabilities, making them ideal for ballistic protection and safety applications. Their molecular structure, characterized by strong intermolecular hydrogen bonds and rigid para-oriented aromatic rings, enables remarkable energy dissipation during impact events.

Carbon fibers, conversely, were developed with objectives centered on achieving maximum stiffness-to-weight ratios and compressive strength. Their graphitic microstructure, with aligned carbon atoms in crystalline arrangements, delivers superior performance in applications requiring structural rigidity and resistance to deformation under load.

Recent technological advancements have focused on hybridization strategies, combining aramid and carbon fibers to leverage complementary properties. This evolution reflects a growing understanding that impact scenarios involve complex mechanical interactions requiring tailored material responses. Modern research objectives include developing multi-functional composites that can simultaneously address multiple performance parameters including impact resistance, post-impact structural integrity, and damage visualization capabilities.

The current technological frontier involves nanoscale modifications to both fiber types, with research objectives targeting improved interfacial bonding in composite structures, enhanced energy absorption mechanisms, and reduced manufacturing costs. Computational modeling has become increasingly important in predicting performance in varied impact scenarios, allowing for accelerated development cycles and more precise material optimization for specific applications.

Market Analysis for Impact-Resistant Materials

The impact-resistant materials market is experiencing robust growth, driven by increasing safety requirements across multiple industries. The global market for these materials was valued at approximately $12.5 billion in 2022 and is projected to reach $18.7 billion by 2028, representing a compound annual growth rate of 6.9%. This growth trajectory is particularly evident in automotive, aerospace, defense, and sporting goods sectors where high-performance impact protection is critical.

Aramid fibers, dominated by brands like Kevlar and Twaron, hold approximately 35% of the impact-resistant materials market. Their exceptional tensile strength-to-weight ratio and superior energy absorption capabilities have established them as the preferred choice for ballistic protection applications. The aramid fiber segment has shown steady growth at 5.8% annually, with particularly strong demand in personal protective equipment and military applications.

Carbon fiber materials account for approximately 28% of the impact-resistant materials market, with a higher growth rate of 7.3% annually. This accelerated growth is primarily attributed to the automotive and aerospace industries' increasing adoption of lightweight yet strong materials to improve fuel efficiency while maintaining safety standards. The premium pricing of carbon fiber materials has historically limited broader market penetration, but recent manufacturing innovations are gradually reducing production costs.

Regional analysis reveals that North America dominates the market with a 38% share, followed by Europe (31%) and Asia-Pacific (24%). However, the Asia-Pacific region is demonstrating the fastest growth rate at 8.2% annually, driven by rapid industrialization, increasing automotive production, and growing defense expenditures in countries like China and India.

End-user segmentation shows that automotive applications constitute the largest market share at 32%, followed by aerospace and defense (28%), sporting goods (18%), and industrial applications (14%). The remaining 8% is distributed across various other applications including consumer electronics and medical devices.

Price sensitivity varies significantly across application segments. Defense and aerospace sectors demonstrate low price sensitivity due to performance-critical requirements, while consumer goods and automotive mass-market applications show higher price sensitivity, creating distinct market dynamics for aramid and carbon fiber materials.

Market trends indicate growing demand for hybrid solutions that combine aramid and carbon fibers to optimize performance characteristics for specific impact scenarios. Additionally, sustainability concerns are driving research into bio-based alternatives and recycling technologies for both material types, with several major manufacturers investing in circular economy initiatives to address end-of-life considerations for these advanced materials.

Aramid fibers, dominated by brands like Kevlar and Twaron, hold approximately 35% of the impact-resistant materials market. Their exceptional tensile strength-to-weight ratio and superior energy absorption capabilities have established them as the preferred choice for ballistic protection applications. The aramid fiber segment has shown steady growth at 5.8% annually, with particularly strong demand in personal protective equipment and military applications.

Carbon fiber materials account for approximately 28% of the impact-resistant materials market, with a higher growth rate of 7.3% annually. This accelerated growth is primarily attributed to the automotive and aerospace industries' increasing adoption of lightweight yet strong materials to improve fuel efficiency while maintaining safety standards. The premium pricing of carbon fiber materials has historically limited broader market penetration, but recent manufacturing innovations are gradually reducing production costs.

Regional analysis reveals that North America dominates the market with a 38% share, followed by Europe (31%) and Asia-Pacific (24%). However, the Asia-Pacific region is demonstrating the fastest growth rate at 8.2% annually, driven by rapid industrialization, increasing automotive production, and growing defense expenditures in countries like China and India.

End-user segmentation shows that automotive applications constitute the largest market share at 32%, followed by aerospace and defense (28%), sporting goods (18%), and industrial applications (14%). The remaining 8% is distributed across various other applications including consumer electronics and medical devices.

Price sensitivity varies significantly across application segments. Defense and aerospace sectors demonstrate low price sensitivity due to performance-critical requirements, while consumer goods and automotive mass-market applications show higher price sensitivity, creating distinct market dynamics for aramid and carbon fiber materials.

Market trends indicate growing demand for hybrid solutions that combine aramid and carbon fibers to optimize performance characteristics for specific impact scenarios. Additionally, sustainability concerns are driving research into bio-based alternatives and recycling technologies for both material types, with several major manufacturers investing in circular economy initiatives to address end-of-life considerations for these advanced materials.

Technical Limitations and Challenges in Impact Applications

Despite the impressive properties of both aramid and carbon fibers, significant technical challenges persist when applying these materials in impact scenarios. The fundamental limitation of carbon fiber lies in its inherent brittleness. While carbon fiber reinforced polymers (CFRPs) exhibit exceptional strength-to-weight ratios and stiffness, they typically fail catastrophically under impact loads without significant energy absorption. This brittle failure mode severely limits their effectiveness in applications requiring progressive energy dissipation during impact events.

Aramid fibers, though more ductile than carbon fibers, face challenges related to moisture absorption. When exposed to humid environments, aramid fibers can absorb up to 4-6% moisture by weight, potentially compromising their mechanical properties and dimensional stability over time. This hygroscopic nature necessitates additional protective measures in many applications, increasing complexity and cost.

Both materials exhibit anisotropic behavior, performing exceptionally well along fiber orientation but showing significantly reduced properties in transverse directions. This directional dependency creates substantial design challenges when multi-directional impact resistance is required. Engineers must carefully optimize fiber architecture and layup sequences to address potential weak points in the material system.

Manufacturing consistency presents another significant hurdle. Achieving uniform fiber distribution, consistent fiber volume fractions, and void-free composites remains technically challenging, particularly in complex geometries. These manufacturing variations can create unpredictable weak points that may fail prematurely under impact conditions.

Interface adhesion between fibers and matrix materials represents a critical technical limitation. Poor fiber-matrix bonding can lead to delamination and premature failure during impact events. This challenge is particularly pronounced with aramid fibers, which have chemically inert surfaces that resist strong bonding with many polymer matrices.

Temperature sensitivity further complicates the application of these materials. Carbon fiber composites typically maintain their properties across a wider temperature range than aramid composites, but both materials can experience significant property degradation at temperature extremes. This thermal sensitivity limits their application in environments with wide temperature fluctuations.

Cost considerations also present practical challenges. Both materials, particularly carbon fiber, remain significantly more expensive than conventional materials like steel or aluminum. This cost premium restricts widespread adoption in many potential applications where impact resistance is desired but not critical enough to justify the substantial price difference.

Aramid fibers, though more ductile than carbon fibers, face challenges related to moisture absorption. When exposed to humid environments, aramid fibers can absorb up to 4-6% moisture by weight, potentially compromising their mechanical properties and dimensional stability over time. This hygroscopic nature necessitates additional protective measures in many applications, increasing complexity and cost.

Both materials exhibit anisotropic behavior, performing exceptionally well along fiber orientation but showing significantly reduced properties in transverse directions. This directional dependency creates substantial design challenges when multi-directional impact resistance is required. Engineers must carefully optimize fiber architecture and layup sequences to address potential weak points in the material system.

Manufacturing consistency presents another significant hurdle. Achieving uniform fiber distribution, consistent fiber volume fractions, and void-free composites remains technically challenging, particularly in complex geometries. These manufacturing variations can create unpredictable weak points that may fail prematurely under impact conditions.

Interface adhesion between fibers and matrix materials represents a critical technical limitation. Poor fiber-matrix bonding can lead to delamination and premature failure during impact events. This challenge is particularly pronounced with aramid fibers, which have chemically inert surfaces that resist strong bonding with many polymer matrices.

Temperature sensitivity further complicates the application of these materials. Carbon fiber composites typically maintain their properties across a wider temperature range than aramid composites, but both materials can experience significant property degradation at temperature extremes. This thermal sensitivity limits their application in environments with wide temperature fluctuations.

Cost considerations also present practical challenges. Both materials, particularly carbon fiber, remain significantly more expensive than conventional materials like steel or aluminum. This cost premium restricts widespread adoption in many potential applications where impact resistance is desired but not critical enough to justify the substantial price difference.

Current Impact Resistance Solutions Comparison

01 Mechanical properties of aramid and carbon fiber composites

Aramid and carbon fibers exhibit exceptional mechanical properties when used in composite materials. Aramid fibers provide excellent tensile strength and impact resistance, while carbon fibers contribute superior stiffness and strength-to-weight ratio. When combined in hybrid composites, these materials can achieve an optimal balance of properties including enhanced flexural strength, improved fracture toughness, and better vibration damping characteristics compared to single-fiber composites.- Mechanical properties comparison between aramid and carbon fibers: Aramid fibers and carbon fibers exhibit different mechanical properties that make them suitable for various applications. Aramid fibers generally have excellent tensile strength, impact resistance, and flexibility, while carbon fibers offer superior stiffness, compressive strength, and lower weight. The comparison of these properties helps in selecting the appropriate fiber for specific applications where strength-to-weight ratio is critical.

- Hybrid composites combining aramid and carbon fibers: Hybrid composites that combine aramid and carbon fibers leverage the complementary properties of both materials. These hybrids often demonstrate improved impact resistance from aramid fibers while maintaining the high stiffness and strength of carbon fibers. The synergistic effect results in composites with balanced mechanical properties, enhanced damage tolerance, and better vibration damping characteristics compared to single-fiber composites.

- Thermal and chemical resistance characteristics: Aramid and carbon fibers exhibit distinct thermal and chemical resistance properties. Aramid fibers typically offer excellent heat resistance up to certain temperatures and good chemical resistance to many solvents and acids. Carbon fibers provide superior thermal stability at higher temperatures and are generally inert to most chemicals. These characteristics determine their suitability for applications in extreme environments such as aerospace, automotive, and industrial settings.

- Manufacturing processes and their effect on fiber performance: The manufacturing processes for aramid and carbon fibers significantly influence their final performance characteristics. For aramid fibers, the spinning and heat treatment processes affect crystallinity and orientation, which determine tensile properties. For carbon fibers, precursor selection and carbonization conditions impact the resulting strength and modulus. Process innovations such as surface treatments and sizing applications further enhance fiber-matrix adhesion in composite applications.

- Application-specific performance in protective and structural components: Aramid and carbon fibers demonstrate different performance characteristics in specific applications. Aramid fibers excel in ballistic protection, cut-resistant gear, and applications requiring high impact resistance due to their energy absorption capabilities. Carbon fibers are preferred in structural components where high stiffness, dimensional stability, and fatigue resistance are required, such as in aerospace structures, sporting goods, and high-performance automotive parts.

02 Thermal and electrical performance characteristics

Aramid and carbon fibers display distinct thermal and electrical behaviors that influence their application domains. Carbon fibers offer excellent thermal stability, low thermal expansion, and high electrical conductivity, making them suitable for applications requiring heat dissipation or electromagnetic shielding. Aramid fibers provide good thermal insulation and flame resistance but lack electrical conductivity. These complementary properties allow for tailored solutions in aerospace, automotive, and electronics industries.Expand Specific Solutions03 Processing techniques and surface treatments

Various processing techniques and surface treatments can significantly enhance the performance of aramid and carbon fibers. Surface modifications such as plasma treatment, chemical functionalization, and sizing application improve fiber-matrix adhesion and interfacial properties. Advanced manufacturing methods including pultrusion, filament winding, and automated fiber placement optimize fiber orientation and distribution, resulting in composites with superior mechanical integrity and durability for high-performance applications.Expand Specific Solutions04 Hybrid and reinforcement applications

Combining aramid and carbon fibers in hybrid structures leverages the complementary strengths of both materials. Aramid fibers contribute toughness, impact resistance, and vibration damping, while carbon fibers provide stiffness, strength, and lightweight characteristics. These hybrid composites find applications in aerospace components, automotive structures, sporting goods, and protective equipment where balanced mechanical properties are required. The synergistic effect of the two fibers often results in superior performance compared to single-fiber reinforced composites.Expand Specific Solutions05 Environmental durability and aging characteristics

Aramid and carbon fibers exhibit different responses to environmental factors and aging. Carbon fibers demonstrate excellent resistance to moisture, chemicals, and UV radiation but can be susceptible to galvanic corrosion when in contact with certain metals. Aramid fibers offer good chemical resistance but may degrade under prolonged UV exposure and moisture absorption. Understanding these durability characteristics is crucial for designing composites with appropriate protective measures for specific environmental conditions and service life requirements.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The aramid fiber versus carbon fiber impact performance market is in a growth phase, with increasing demand across automotive, aerospace, and defense sectors. The global market for high-performance fibers is expanding at approximately 8-10% annually, driven by lightweight material requirements in transportation and protective applications. Technologically, carbon fiber dominates in strength-to-weight applications while aramid excels in impact resistance. Key players demonstrate varying technological maturity: established manufacturers like Teijin Aramid, Toray Industries, and Kolon Industries lead with comprehensive aramid portfolios, while companies such as Lyten and Resonac are advancing innovative composite solutions. Research institutions including Jiangsu University and IIT Kanpur are developing next-generation hybrid materials combining both fibers' properties for optimized impact performance.

Kolon Industries, Inc.

Technical Solution: Kolon Industries has developed specialized aramid fiber technologies focused on impact performance. Their Heracron® aramid fiber demonstrates exceptional tensile strength (3.2 GPa) and energy absorption capabilities, making it particularly effective in impact scenarios. Kolon's research has shown that their aramid composites can absorb up to 50% more impact energy than comparable carbon fiber structures before failure. Their proprietary fiber processing techniques create optimized microstructures that enhance energy dissipation during impact events. Kolon has developed specialized surface treatments that improve fiber-matrix adhesion while maintaining the flexibility critical for impact performance. Their hybrid composite solutions combine aramid's superior impact resistance with complementary materials to create tailored solutions for specific applications. Kolon's testing has demonstrated that their aramid-based composites exhibit significantly better damage tolerance after impact compared to carbon fiber alternatives, retaining up to 40% more residual strength after equivalent impact events.

Strengths: Excellent energy absorption capabilities, superior damage tolerance after impact, and cost-effective manufacturing processes compared to some competitors. Weaknesses: Lower stiffness than carbon fiber alternatives and reduced performance in compression loading scenarios.

Toray Industries, Inc.

Technical Solution: Toray has developed advanced carbon fiber composite technologies specifically designed for impact resistance applications. Their T1100G carbon fiber offers exceptional tensile strength (7.0 GPa) and modulus (324 GPa), making it ideal for applications requiring high impact resistance. For impact scenarios, Toray employs a multi-scale approach combining nano, micro, and macro structural engineering to optimize energy absorption. Their proprietary resin systems feature modified toughening agents that enhance interlaminar strength by up to 30% compared to standard systems. Toray's research has demonstrated that their carbon fiber composites can absorb 40-50% more energy during impact events than conventional materials, while maintaining structural integrity. They've also developed hybrid solutions incorporating both carbon and aramid fibers to leverage the complementary properties of both materials - carbon fiber's stiffness and aramid's superior impact resistance and damage tolerance.

Strengths: Industry-leading tensile properties, proprietary resin systems enhancing impact performance, and extensive R&D capabilities in composite materials. Weaknesses: Higher production costs compared to aramid solutions, and carbon fiber's inherent brittleness requiring careful design considerations for pure impact applications.

Key Patents and Research in Fiber Impact Performance

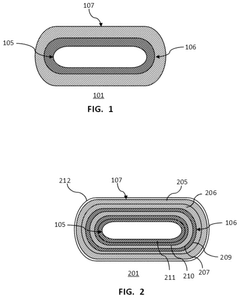

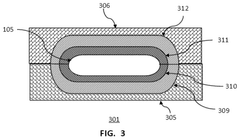

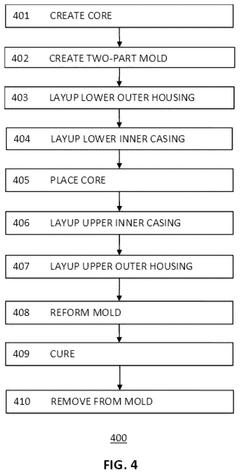

High Strength Composite Structure and Method of Production

PatentPendingUS20250277454A1

Innovation

- A composite structure is created by enclosing a lightweight polymer core with an inner casing of resin-impregnated carbon fiber fabric and an outer housing of resin-impregnated aramid fabric, optionally interspersing aramid layers between carbon fiber layers, and applying a protective outer layer to enhance impact resistance and environmental protection.

Spider silk/aramid fiber reinforced ABS composite material for fabrication of robotic fish using 3D technology

PatentInactiveIN201941046489A

Innovation

- The development of Spider silk/Aramid fiber reinforced ABS composite materials using Fused Deposition Modeling (FDM) technology to fabricate lightweight robotic fish with improved mechanical and structural performance, optimizing design structures for enhanced aerodynamics, speed, and endurance.

Sustainability and Lifecycle Assessment

The sustainability profiles of aramid and carbon fibers differ significantly, with important implications for their environmental impact throughout their lifecycle. Aramid fibers generally demonstrate a lower carbon footprint during production compared to carbon fibers, which require energy-intensive manufacturing processes involving temperatures exceeding 1000°C. Life cycle assessment (LCA) studies indicate that carbon fiber production generates approximately 20-25 kg CO2 equivalent per kilogram of material, while aramid fiber production typically results in 10-15 kg CO2 equivalent.

Water consumption presents another critical sustainability factor. Carbon fiber manufacturing demands substantial water resources for cooling processes, whereas aramid fiber production generally requires less water input. However, aramid fiber production involves more chemical processing, potentially leading to greater chemical waste management challenges.

End-of-life considerations reveal distinct differences between these materials. Carbon fiber presents significant recycling challenges due to its thermoset matrix systems, with most carbon fiber composites currently ending up in landfills. Recent technological advances have improved carbon fiber reclamation processes, though these remain energy-intensive. Aramid fibers offer somewhat better recyclability prospects, with established mechanical recycling methods allowing for material recovery in certain applications.

In impact scenarios, the durability and longevity of both materials contribute positively to their sustainability profiles. Components made from either fiber type typically demonstrate extended service lives compared to conventional materials, reducing replacement frequency and associated environmental impacts. Aramid's superior impact resistance may provide sustainability advantages in applications where damage resistance extends product lifespan.

The raw material sourcing also differs substantially. Carbon fiber relies primarily on polyacrylonitrile (PAN) precursors derived from petrochemical sources, while aramid fibers utilize aromatic polyamide chemistry, also petroleum-based but with different resource requirements and environmental implications. Neither material currently offers significant bio-based alternatives at commercial scale, though research into sustainable precursors continues.

When considering total environmental impact across the entire lifecycle, the application context becomes crucial. In transportation applications where weight reduction leads to fuel savings, carbon fiber's lighter weight may offset its higher production footprint through use-phase benefits. Conversely, aramid's lower production impact and potentially easier end-of-life management may prove advantageous in applications where weight differences are less critical.

Water consumption presents another critical sustainability factor. Carbon fiber manufacturing demands substantial water resources for cooling processes, whereas aramid fiber production generally requires less water input. However, aramid fiber production involves more chemical processing, potentially leading to greater chemical waste management challenges.

End-of-life considerations reveal distinct differences between these materials. Carbon fiber presents significant recycling challenges due to its thermoset matrix systems, with most carbon fiber composites currently ending up in landfills. Recent technological advances have improved carbon fiber reclamation processes, though these remain energy-intensive. Aramid fibers offer somewhat better recyclability prospects, with established mechanical recycling methods allowing for material recovery in certain applications.

In impact scenarios, the durability and longevity of both materials contribute positively to their sustainability profiles. Components made from either fiber type typically demonstrate extended service lives compared to conventional materials, reducing replacement frequency and associated environmental impacts. Aramid's superior impact resistance may provide sustainability advantages in applications where damage resistance extends product lifespan.

The raw material sourcing also differs substantially. Carbon fiber relies primarily on polyacrylonitrile (PAN) precursors derived from petrochemical sources, while aramid fibers utilize aromatic polyamide chemistry, also petroleum-based but with different resource requirements and environmental implications. Neither material currently offers significant bio-based alternatives at commercial scale, though research into sustainable precursors continues.

When considering total environmental impact across the entire lifecycle, the application context becomes crucial. In transportation applications where weight reduction leads to fuel savings, carbon fiber's lighter weight may offset its higher production footprint through use-phase benefits. Conversely, aramid's lower production impact and potentially easier end-of-life management may prove advantageous in applications where weight differences are less critical.

Cost-Performance Analysis for Various Industries

When comparing aramid fibers and carbon fibers in impact scenarios, cost considerations become a critical factor for implementation across various industries. The cost-performance ratio varies significantly depending on the specific application requirements and industry standards.

In the automotive sector, carbon fiber components typically cost 5-10 times more than conventional materials, while aramid fiber solutions generally fall in the middle price range. However, the weight reduction achieved with carbon fiber (up to 70% compared to steel) translates to fuel efficiency improvements of approximately 7-10% for every 10% weight reduction. Aramid fibers, while offering less weight reduction (40-50% compared to steel), provide superior impact resistance at approximately 60-70% of carbon fiber's cost.

For aerospace applications, the initial investment in carbon fiber structures can be 8-12 times higher than traditional aluminum constructions, but the lifetime fuel savings can exceed 20-30% due to the significant weight advantages. Aramid fiber components cost approximately 30-40% less than carbon fiber alternatives while still delivering excellent vibration damping and impact resistance, making them particularly valuable for aircraft interior components and ballistic protection systems.

The sporting goods industry presents a different cost-performance landscape. Carbon fiber tennis rackets, bicycles, and golf clubs command premium prices (typically 200-300% higher than standard materials) but deliver performance enhancements that professional athletes consider essential. Aramid fiber alternatives offer approximately 70-80% of the performance benefits at 50-60% of the cost, making them attractive for mid-range consumer products.

In protective equipment applications, aramid fibers demonstrate superior cost-effectiveness. Body armor made from aramid fibers costs approximately 30-40% less than comparable carbon fiber solutions while providing better performance against ballistic threats. The energy absorption capacity of aramid fibers in impact scenarios translates to approximately 15-20% better protection per dollar invested compared to carbon fiber alternatives.

Manufacturing considerations further influence the cost-performance equation. Carbon fiber production requires more energy-intensive processes and specialized equipment, contributing to its higher cost structure. Aramid fiber manufacturing, while still specialized, involves fewer extreme processing conditions, resulting in lower production costs and potentially more sustainable manufacturing practices when evaluated on a lifecycle basis.

In the automotive sector, carbon fiber components typically cost 5-10 times more than conventional materials, while aramid fiber solutions generally fall in the middle price range. However, the weight reduction achieved with carbon fiber (up to 70% compared to steel) translates to fuel efficiency improvements of approximately 7-10% for every 10% weight reduction. Aramid fibers, while offering less weight reduction (40-50% compared to steel), provide superior impact resistance at approximately 60-70% of carbon fiber's cost.

For aerospace applications, the initial investment in carbon fiber structures can be 8-12 times higher than traditional aluminum constructions, but the lifetime fuel savings can exceed 20-30% due to the significant weight advantages. Aramid fiber components cost approximately 30-40% less than carbon fiber alternatives while still delivering excellent vibration damping and impact resistance, making them particularly valuable for aircraft interior components and ballistic protection systems.

The sporting goods industry presents a different cost-performance landscape. Carbon fiber tennis rackets, bicycles, and golf clubs command premium prices (typically 200-300% higher than standard materials) but deliver performance enhancements that professional athletes consider essential. Aramid fiber alternatives offer approximately 70-80% of the performance benefits at 50-60% of the cost, making them attractive for mid-range consumer products.

In protective equipment applications, aramid fibers demonstrate superior cost-effectiveness. Body armor made from aramid fibers costs approximately 30-40% less than comparable carbon fiber solutions while providing better performance against ballistic threats. The energy absorption capacity of aramid fibers in impact scenarios translates to approximately 15-20% better protection per dollar invested compared to carbon fiber alternatives.

Manufacturing considerations further influence the cost-performance equation. Carbon fiber production requires more energy-intensive processes and specialized equipment, contributing to its higher cost structure. Aramid fiber manufacturing, while still specialized, involves fewer extreme processing conditions, resulting in lower production costs and potentially more sustainable manufacturing practices when evaluated on a lifecycle basis.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!