Borosilicate Glass Integration in Microelectromechanical Systems

JUL 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MEMS Borosilicate Glass Background and Objectives

Borosilicate glass has emerged as a crucial material in the field of Microelectromechanical Systems (MEMS), offering unique properties that enhance the performance and reliability of these miniature devices. The integration of borosilicate glass in MEMS technology represents a significant advancement in the ongoing quest for improved functionality and durability in microsystems.

The development of MEMS technology dates back to the 1960s, with the invention of the resonant gate transistor. However, it wasn't until the 1990s that MEMS devices began to gain widespread commercial adoption. Throughout this evolution, silicon has been the dominant material in MEMS fabrication due to its well-established processing techniques and excellent mechanical properties.

In recent years, the limitations of silicon-based MEMS have become increasingly apparent, particularly in applications requiring high thermal stability, chemical resistance, and optical transparency. This has led researchers and engineers to explore alternative materials, with borosilicate glass emerging as a promising candidate.

Borosilicate glass, first developed by Otto Schott in the late 19th century, is known for its low thermal expansion coefficient, high chemical durability, and excellent optical properties. These characteristics make it an ideal material for various MEMS applications, including microfluidics, optical MEMS, and sensors operating in harsh environments.

The integration of borosilicate glass in MEMS aims to address several key objectives. Firstly, it seeks to improve the thermal stability of MEMS devices, allowing for operation across a wider temperature range without compromising performance. Secondly, the chemical inertness of borosilicate glass enables the development of MEMS devices capable of functioning in corrosive or chemically aggressive environments.

Another critical objective is to enhance the optical properties of MEMS devices. Borosilicate glass's high transparency and low autofluorescence make it particularly suitable for optical MEMS applications, such as micro-mirrors, optical switches, and lab-on-a-chip devices.

Furthermore, the integration of borosilicate glass in MEMS technology aims to facilitate the development of hybrid devices that combine the benefits of both glass and silicon. This approach allows for the creation of more complex and versatile MEMS structures, leveraging the strengths of each material.

As research in this field progresses, the overarching goal is to expand the capabilities of MEMS technology, enabling new applications and improving the performance of existing devices. The successful integration of borosilicate glass in MEMS has the potential to revolutionize various industries, from healthcare and environmental monitoring to telecommunications and aerospace.

The development of MEMS technology dates back to the 1960s, with the invention of the resonant gate transistor. However, it wasn't until the 1990s that MEMS devices began to gain widespread commercial adoption. Throughout this evolution, silicon has been the dominant material in MEMS fabrication due to its well-established processing techniques and excellent mechanical properties.

In recent years, the limitations of silicon-based MEMS have become increasingly apparent, particularly in applications requiring high thermal stability, chemical resistance, and optical transparency. This has led researchers and engineers to explore alternative materials, with borosilicate glass emerging as a promising candidate.

Borosilicate glass, first developed by Otto Schott in the late 19th century, is known for its low thermal expansion coefficient, high chemical durability, and excellent optical properties. These characteristics make it an ideal material for various MEMS applications, including microfluidics, optical MEMS, and sensors operating in harsh environments.

The integration of borosilicate glass in MEMS aims to address several key objectives. Firstly, it seeks to improve the thermal stability of MEMS devices, allowing for operation across a wider temperature range without compromising performance. Secondly, the chemical inertness of borosilicate glass enables the development of MEMS devices capable of functioning in corrosive or chemically aggressive environments.

Another critical objective is to enhance the optical properties of MEMS devices. Borosilicate glass's high transparency and low autofluorescence make it particularly suitable for optical MEMS applications, such as micro-mirrors, optical switches, and lab-on-a-chip devices.

Furthermore, the integration of borosilicate glass in MEMS technology aims to facilitate the development of hybrid devices that combine the benefits of both glass and silicon. This approach allows for the creation of more complex and versatile MEMS structures, leveraging the strengths of each material.

As research in this field progresses, the overarching goal is to expand the capabilities of MEMS technology, enabling new applications and improving the performance of existing devices. The successful integration of borosilicate glass in MEMS has the potential to revolutionize various industries, from healthcare and environmental monitoring to telecommunications and aerospace.

Market Analysis for MEMS with Borosilicate Glass

The integration of borosilicate glass in Microelectromechanical Systems (MEMS) has opened up new opportunities in the MEMS market. The unique properties of borosilicate glass, including its low thermal expansion coefficient, high chemical resistance, and excellent optical transparency, make it an attractive material for various MEMS applications.

The global MEMS market is experiencing significant growth, with a projected Compound Annual Growth Rate (CAGR) of over 8% from 2021 to 2026. Within this market, the demand for MEMS devices incorporating borosilicate glass is expected to increase substantially, driven by the growing need for high-performance sensors and actuators in industries such as automotive, consumer electronics, and healthcare.

In the automotive sector, borosilicate glass-based MEMS devices are gaining traction for applications like pressure sensors, inertial measurement units, and microfluidic systems. The automotive industry's shift towards electric and autonomous vehicles is further fueling the demand for advanced MEMS sensors, creating a favorable market environment for borosilicate glass integration.

The consumer electronics industry represents another significant market for MEMS devices with borosilicate glass. Smartphones, wearables, and smart home devices increasingly rely on MEMS sensors for functions such as motion sensing, environmental monitoring, and optical sensing. The superior performance and reliability offered by borosilicate glass-based MEMS components are driving their adoption in these applications.

In the healthcare sector, the market for MEMS devices with borosilicate glass is expanding rapidly. Applications include lab-on-a-chip devices, biosensors, and microfluidic systems for point-of-care diagnostics. The biocompatibility and chemical inertness of borosilicate glass make it particularly suitable for these sensitive medical applications.

The Asia-Pacific region is expected to dominate the MEMS market, including devices with borosilicate glass integration. This is primarily due to the presence of major semiconductor and electronics manufacturers in countries like China, Japan, and South Korea. North America and Europe also represent significant markets, driven by technological advancements and research activities in MEMS technology.

Key market players in the MEMS industry are increasingly focusing on developing innovative products that leverage the advantages of borosilicate glass. This trend is expected to drive further market growth and technological advancements in the coming years. However, challenges such as high initial production costs and complex manufacturing processes may impact the market adoption rate of borosilicate glass-based MEMS devices in certain applications.

The global MEMS market is experiencing significant growth, with a projected Compound Annual Growth Rate (CAGR) of over 8% from 2021 to 2026. Within this market, the demand for MEMS devices incorporating borosilicate glass is expected to increase substantially, driven by the growing need for high-performance sensors and actuators in industries such as automotive, consumer electronics, and healthcare.

In the automotive sector, borosilicate glass-based MEMS devices are gaining traction for applications like pressure sensors, inertial measurement units, and microfluidic systems. The automotive industry's shift towards electric and autonomous vehicles is further fueling the demand for advanced MEMS sensors, creating a favorable market environment for borosilicate glass integration.

The consumer electronics industry represents another significant market for MEMS devices with borosilicate glass. Smartphones, wearables, and smart home devices increasingly rely on MEMS sensors for functions such as motion sensing, environmental monitoring, and optical sensing. The superior performance and reliability offered by borosilicate glass-based MEMS components are driving their adoption in these applications.

In the healthcare sector, the market for MEMS devices with borosilicate glass is expanding rapidly. Applications include lab-on-a-chip devices, biosensors, and microfluidic systems for point-of-care diagnostics. The biocompatibility and chemical inertness of borosilicate glass make it particularly suitable for these sensitive medical applications.

The Asia-Pacific region is expected to dominate the MEMS market, including devices with borosilicate glass integration. This is primarily due to the presence of major semiconductor and electronics manufacturers in countries like China, Japan, and South Korea. North America and Europe also represent significant markets, driven by technological advancements and research activities in MEMS technology.

Key market players in the MEMS industry are increasingly focusing on developing innovative products that leverage the advantages of borosilicate glass. This trend is expected to drive further market growth and technological advancements in the coming years. However, challenges such as high initial production costs and complex manufacturing processes may impact the market adoption rate of borosilicate glass-based MEMS devices in certain applications.

Current Challenges in Borosilicate Glass MEMS Integration

The integration of borosilicate glass in Microelectromechanical Systems (MEMS) presents several significant challenges that researchers and engineers are actively working to overcome. One of the primary obstacles is the difficulty in achieving precise and reliable bonding between borosilicate glass and other materials commonly used in MEMS, such as silicon or metals. The mismatch in thermal expansion coefficients between these materials can lead to stress and potential failure during thermal cycling or operation.

Another major challenge lies in the microfabrication processes for borosilicate glass. Traditional MEMS fabrication techniques, optimized for silicon, are not always directly applicable to glass substrates. Etching borosilicate glass with high aspect ratios and smooth sidewalls remains a complex task, often requiring specialized equipment and processes. This limitation can restrict the design possibilities and miniaturization of MEMS devices incorporating borosilicate glass.

The integration of electrical components and conductive pathways on or through borosilicate glass also poses significant technical hurdles. Creating reliable electrical connections and maintaining their integrity during device operation is crucial for many MEMS applications. However, the insulating nature of glass and its chemical composition make it challenging to deposit and pattern conductive materials effectively.

Hermeticity and packaging represent another set of challenges in borosilicate glass MEMS integration. While glass offers excellent hermeticity, creating reliable seals between glass and other materials, especially at the microscale, can be problematic. Ensuring long-term stability and preventing contamination or degradation of the MEMS device over its lifetime requires innovative packaging solutions.

The mechanical properties of borosilicate glass, while advantageous in many respects, also present challenges in MEMS design and fabrication. The brittleness of glass can lead to issues with device reliability, especially in applications involving high stress or impact. Balancing the mechanical strength requirements with the desired optical and electrical properties often necessitates complex design trade-offs.

Lastly, the cost and scalability of borosilicate glass MEMS production remain significant hurdles for widespread adoption. The specialized equipment and processes required for glass microfabrication can be more expensive compared to traditional silicon-based MEMS manufacturing. Developing cost-effective, high-volume production methods that maintain the precision and quality required for MEMS devices is an ongoing challenge for the industry.

Another major challenge lies in the microfabrication processes for borosilicate glass. Traditional MEMS fabrication techniques, optimized for silicon, are not always directly applicable to glass substrates. Etching borosilicate glass with high aspect ratios and smooth sidewalls remains a complex task, often requiring specialized equipment and processes. This limitation can restrict the design possibilities and miniaturization of MEMS devices incorporating borosilicate glass.

The integration of electrical components and conductive pathways on or through borosilicate glass also poses significant technical hurdles. Creating reliable electrical connections and maintaining their integrity during device operation is crucial for many MEMS applications. However, the insulating nature of glass and its chemical composition make it challenging to deposit and pattern conductive materials effectively.

Hermeticity and packaging represent another set of challenges in borosilicate glass MEMS integration. While glass offers excellent hermeticity, creating reliable seals between glass and other materials, especially at the microscale, can be problematic. Ensuring long-term stability and preventing contamination or degradation of the MEMS device over its lifetime requires innovative packaging solutions.

The mechanical properties of borosilicate glass, while advantageous in many respects, also present challenges in MEMS design and fabrication. The brittleness of glass can lead to issues with device reliability, especially in applications involving high stress or impact. Balancing the mechanical strength requirements with the desired optical and electrical properties often necessitates complex design trade-offs.

Lastly, the cost and scalability of borosilicate glass MEMS production remain significant hurdles for widespread adoption. The specialized equipment and processes required for glass microfabrication can be more expensive compared to traditional silicon-based MEMS manufacturing. Developing cost-effective, high-volume production methods that maintain the precision and quality required for MEMS devices is an ongoing challenge for the industry.

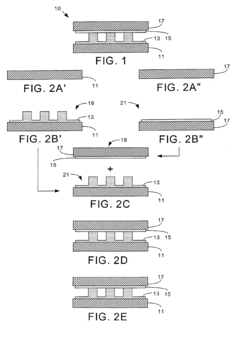

Existing Borosilicate Glass Integration Techniques for MEMS

01 Composition and properties of borosilicate glass

Borosilicate glass is a type of glass with silica and boron trioxide as the main glass-forming constituents. It is known for its low thermal expansion coefficient, high chemical resistance, and excellent thermal shock resistance. These properties make it suitable for various applications in laboratory equipment, cookware, and industrial uses.- Composition and properties of borosilicate glass: Borosilicate glass is a type of glass with silica and boron trioxide as the main glass-forming constituents. It is known for its low thermal expansion coefficient, high chemical resistance, and excellent thermal shock resistance. These properties make it suitable for various applications in laboratory equipment, cookware, and industrial uses.

- Manufacturing processes for borosilicate glass: Various manufacturing processes are employed to produce borosilicate glass, including melting, forming, and annealing. Advanced techniques such as float glass production and precision molding are used to create different forms of borosilicate glass products. The manufacturing process can be optimized to enhance specific properties of the glass.

- Applications of borosilicate glass in laboratory and industrial settings: Borosilicate glass is widely used in laboratory glassware, such as beakers, test tubes, and pipettes, due to its chemical resistance and thermal stability. In industrial applications, it is used for sight glasses, process vessels, and piping systems in chemical and pharmaceutical industries. Its durability and transparency make it ideal for these demanding environments.

- Borosilicate glass in consumer products: Borosilicate glass is increasingly used in consumer products such as cookware, bakeware, and food storage containers. Its heat resistance and durability make it suitable for oven-to-table use. Additionally, it is used in high-end lighting fixtures, solar collectors, and smartphone screen protectors due to its optical clarity and scratch resistance.

- Innovations and modifications in borosilicate glass: Ongoing research focuses on improving the properties of borosilicate glass through composition modifications and surface treatments. This includes developing ultra-thin borosilicate glass for electronic displays, enhancing its strength through ion-exchange processes, and creating specialty borosilicate glasses for specific applications such as radiation shielding or optical components.

02 Manufacturing processes for borosilicate glass

Various manufacturing processes are employed to produce borosilicate glass, including melting, forming, and annealing. Advanced techniques such as float glass production and precision molding are used to create different forms of borosilicate glass products. The manufacturing process often involves careful control of temperature and composition to achieve desired properties.Expand Specific Solutions03 Applications of borosilicate glass in laboratory and scientific equipment

Borosilicate glass is widely used in laboratory and scientific equipment due to its chemical inertness and thermal stability. It is commonly used in beakers, test tubes, pipettes, and other laboratory glassware. The material's resistance to thermal shock makes it ideal for applications involving rapid temperature changes.Expand Specific Solutions04 Use of borosilicate glass in optical and lighting applications

Borosilicate glass finds applications in optical and lighting industries due to its excellent light transmission properties and durability. It is used in the production of lenses, mirrors, and other optical components. In lighting, it is employed in the manufacture of high-quality light bulbs and fixtures that require resistance to heat and thermal shock.Expand Specific Solutions05 Innovations in borosilicate glass for specialized applications

Ongoing research and development in borosilicate glass technology have led to innovations for specialized applications. These include the development of borosilicate glass with enhanced properties for use in solar panels, high-temperature industrial processes, and advanced medical devices. New formulations and processing techniques are being explored to expand the range of applications for this versatile material.Expand Specific Solutions

Key Players in MEMS and Borosilicate Glass Industry

The integration of borosilicate glass in Microelectromechanical Systems (MEMS) is in a growth phase, with increasing market size due to expanding applications in electronics, automotive, and medical industries. The technology's maturity is advancing, driven by key players like Corning, SCHOTT AG, and Applied Materials. These companies are leveraging their expertise in specialty glass and semiconductor manufacturing to develop innovative MEMS solutions. Other significant contributors include Samsung Electro-Mechanics and Infineon Technologies, focusing on miniaturization and performance enhancement. The competitive landscape is characterized by a mix of established glass manufacturers and semiconductor industry leaders, indicating a convergence of technologies and expertise in this field.

Corning, Inc.

Technical Solution: Corning has developed advanced borosilicate glass formulations specifically tailored for MEMS applications. Their HPFS® (High Purity Fused Silica) and Pyrex® borosilicate glasses offer excellent thermal stability, low thermal expansion, and high chemical durability[1]. Corning's glass integration process involves precision micromachining techniques, such as deep reactive ion etching (DRIE) and anodic bonding, to create complex microstructures and hermetic seals[2]. They have also pioneered the use of glass frit bonding for MEMS packaging, which provides robust hermeticity and electrical isolation[3]. Corning's borosilicate glass solutions enable the fabrication of high-performance inertial sensors, microfluidic devices, and RF MEMS with improved reliability and longevity[4].

Strengths: Industry-leading expertise in specialty glass formulations, established manufacturing processes for high-volume production, and extensive intellectual property portfolio. Weaknesses: Higher cost compared to some alternative materials, potential limitations in extreme high-temperature applications.

SCHOTT AG

Technical Solution: SCHOTT AG has developed a range of borosilicate glass solutions for MEMS integration, focusing on their BOROFLOAT® glass series. Their approach involves precision glass wafer manufacturing with tight thickness tolerances and surface quality[1]. SCHOTT's borosilicate glasses offer excellent thermal and chemical stability, making them suitable for a wide range of MEMS applications[2]. They have developed specialized bonding techniques, including anodic bonding and glass frit bonding, to create hermetic seals between glass and silicon substrates[3]. SCHOTT has also introduced innovative glass structuring methods, such as precision etching and laser processing, to create complex 3D microstructures in borosilicate glass for MEMS devices[4]. Their glass solutions have been successfully implemented in various MEMS applications, including microfluidics, optical MEMS, and inertial sensors[5].

Strengths: Wide range of specialized glass compositions, advanced manufacturing capabilities for high-precision glass wafers, and expertise in glass-to-silicon bonding techniques. Weaknesses: Potential challenges in scaling down certain glass structures to nanometer levels, limited flexibility in customizing glass properties compared to some emerging materials.

Core Innovations in Borosilicate Glass MEMS Fabrication

Borosilicate glass compositions and uses therof

PatentInactiveEP1426345A1

Innovation

- A borosilicate glass composition with silicon dioxide, boric oxide, aluminum oxide, and at least one alkali oxide, which resists devitrification and maintains a suitable coefficient of thermal expansion without the need for inhibitor oxides, ensuring mechanical strength and chemical durability.

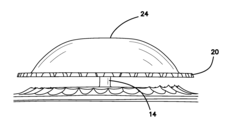

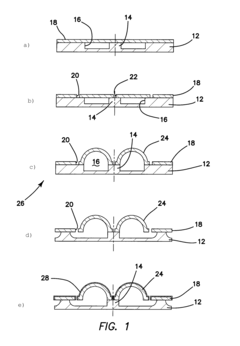

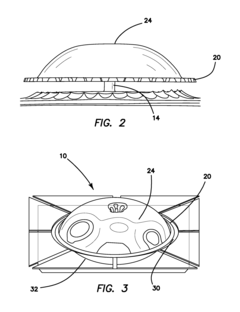

Method of fabricating micro-glassblown gyroscopes

PatentActiveUS20170016742A1

Innovation

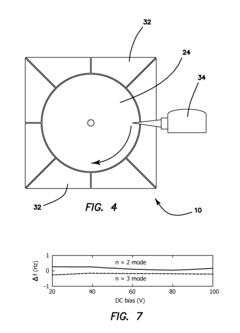

- A wafer-level micro-glassblowing process is developed for fabricating high Q-factor fused silica micro-hemispherical resonators with integrated out-of-plane electrodes, enabling batch-scale production of three-dimensional Coriolis vibratory gyroscopes with improved structural symmetry and transduction efficiency.

Environmental Impact of Borosilicate Glass in MEMS

The integration of borosilicate glass in Microelectromechanical Systems (MEMS) has significant environmental implications that warrant careful consideration. Borosilicate glass, known for its low thermal expansion coefficient and excellent chemical resistance, offers several environmental benefits when used in MEMS devices.

One of the primary environmental advantages of borosilicate glass in MEMS is its durability and longevity. The material's resistance to thermal shock and chemical corrosion contributes to extended device lifespans, reducing the frequency of replacements and, consequently, electronic waste generation. This durability aligns with sustainable design principles and supports the circular economy by minimizing resource consumption and waste production over time.

Furthermore, the manufacturing process of borosilicate glass for MEMS applications generally requires lower temperatures compared to some alternative materials, potentially reducing energy consumption during production. This energy efficiency can translate to a lower carbon footprint for MEMS devices incorporating borosilicate glass components.

However, the environmental impact of borosilicate glass in MEMS is not without challenges. The production of borosilicate glass involves the use of boron compounds, which can have environmental implications if not properly managed. Boron mining and processing can lead to habitat disruption and potential water contamination if strict environmental controls are not in place.

Recycling of MEMS devices containing borosilicate glass presents both opportunities and challenges. While glass is generally recyclable, the complex integration of materials in MEMS devices can make separation and recycling more difficult. Developing effective end-of-life strategies for these devices is crucial to maximize material recovery and minimize environmental impact.

The use of borosilicate glass in MEMS can also contribute to miniaturization trends in electronics. Smaller, more efficient devices typically consume less power during operation, leading to reduced energy consumption over their lifetime. This indirect environmental benefit can be significant when considering the large-scale deployment of MEMS devices in various applications.

In terms of toxicity, borosilicate glass is generally considered inert and non-toxic, making it a safer choice for both human health and environmental exposure compared to some alternative materials used in MEMS. This characteristic is particularly important for MEMS devices used in medical or environmental monitoring applications.

As the adoption of MEMS technology continues to grow, the environmental impact of materials like borosilicate glass becomes increasingly important. Future research and development efforts should focus on optimizing the environmental performance of borosilicate glass in MEMS, including improving manufacturing efficiency, enhancing recyclability, and exploring bio-based or more sustainable alternatives where possible.

One of the primary environmental advantages of borosilicate glass in MEMS is its durability and longevity. The material's resistance to thermal shock and chemical corrosion contributes to extended device lifespans, reducing the frequency of replacements and, consequently, electronic waste generation. This durability aligns with sustainable design principles and supports the circular economy by minimizing resource consumption and waste production over time.

Furthermore, the manufacturing process of borosilicate glass for MEMS applications generally requires lower temperatures compared to some alternative materials, potentially reducing energy consumption during production. This energy efficiency can translate to a lower carbon footprint for MEMS devices incorporating borosilicate glass components.

However, the environmental impact of borosilicate glass in MEMS is not without challenges. The production of borosilicate glass involves the use of boron compounds, which can have environmental implications if not properly managed. Boron mining and processing can lead to habitat disruption and potential water contamination if strict environmental controls are not in place.

Recycling of MEMS devices containing borosilicate glass presents both opportunities and challenges. While glass is generally recyclable, the complex integration of materials in MEMS devices can make separation and recycling more difficult. Developing effective end-of-life strategies for these devices is crucial to maximize material recovery and minimize environmental impact.

The use of borosilicate glass in MEMS can also contribute to miniaturization trends in electronics. Smaller, more efficient devices typically consume less power during operation, leading to reduced energy consumption over their lifetime. This indirect environmental benefit can be significant when considering the large-scale deployment of MEMS devices in various applications.

In terms of toxicity, borosilicate glass is generally considered inert and non-toxic, making it a safer choice for both human health and environmental exposure compared to some alternative materials used in MEMS. This characteristic is particularly important for MEMS devices used in medical or environmental monitoring applications.

As the adoption of MEMS technology continues to grow, the environmental impact of materials like borosilicate glass becomes increasingly important. Future research and development efforts should focus on optimizing the environmental performance of borosilicate glass in MEMS, including improving manufacturing efficiency, enhancing recyclability, and exploring bio-based or more sustainable alternatives where possible.

Reliability and Longevity of Glass-Integrated MEMS Devices

The reliability and longevity of glass-integrated MEMS devices are critical factors in their widespread adoption and long-term performance. Borosilicate glass, known for its excellent thermal, mechanical, and chemical properties, offers significant advantages in enhancing the durability of MEMS devices. However, the integration of glass with other materials in MEMS structures presents unique challenges that must be addressed to ensure long-term reliability.

One of the primary concerns in glass-integrated MEMS devices is the thermal mismatch between glass and other materials, such as silicon or metals. This mismatch can lead to residual stresses and potential delamination or cracking over time, especially under thermal cycling conditions. To mitigate these issues, researchers have developed advanced bonding techniques and stress-relief structures that accommodate thermal expansion differences.

The hermeticity of glass-integrated MEMS devices is another crucial aspect of their reliability. Borosilicate glass provides excellent sealing properties, protecting sensitive components from environmental factors such as moisture and contaminants. However, maintaining this hermetic seal over extended periods requires careful consideration of interface materials and bonding processes to prevent degradation or leakage pathways.

Mechanical stability is a key factor in the longevity of glass-integrated MEMS devices. The brittleness of glass can make it susceptible to fracture under high stress or impact. To address this, designers have implemented innovative structural designs and protective packaging solutions that distribute stress and absorb shock, enhancing the overall robustness of the devices.

Chemical resistance is another advantage of borosilicate glass in MEMS applications. Its inertness to many chemicals ensures that the devices can maintain their performance in harsh environments or when exposed to various analytes. This property is particularly valuable in sensing and biomedical applications, where long-term stability in the presence of diverse chemical species is essential.

The aging behavior of glass-integrated MEMS devices is an area of ongoing research. While borosilicate glass is known for its stability, long-term exposure to certain conditions, such as high humidity or radiation, can potentially alter its properties. Understanding and mitigating these aging effects is crucial for predicting and extending the operational lifespan of MEMS devices.

To enhance reliability and longevity, advanced characterization techniques and accelerated testing methods have been developed specifically for glass-integrated MEMS devices. These include non-destructive imaging, in-situ stress measurements, and environmental stress testing protocols that simulate long-term use conditions. Such methods allow for more accurate prediction of device lifetimes and identification of potential failure modes.

One of the primary concerns in glass-integrated MEMS devices is the thermal mismatch between glass and other materials, such as silicon or metals. This mismatch can lead to residual stresses and potential delamination or cracking over time, especially under thermal cycling conditions. To mitigate these issues, researchers have developed advanced bonding techniques and stress-relief structures that accommodate thermal expansion differences.

The hermeticity of glass-integrated MEMS devices is another crucial aspect of their reliability. Borosilicate glass provides excellent sealing properties, protecting sensitive components from environmental factors such as moisture and contaminants. However, maintaining this hermetic seal over extended periods requires careful consideration of interface materials and bonding processes to prevent degradation or leakage pathways.

Mechanical stability is a key factor in the longevity of glass-integrated MEMS devices. The brittleness of glass can make it susceptible to fracture under high stress or impact. To address this, designers have implemented innovative structural designs and protective packaging solutions that distribute stress and absorb shock, enhancing the overall robustness of the devices.

Chemical resistance is another advantage of borosilicate glass in MEMS applications. Its inertness to many chemicals ensures that the devices can maintain their performance in harsh environments or when exposed to various analytes. This property is particularly valuable in sensing and biomedical applications, where long-term stability in the presence of diverse chemical species is essential.

The aging behavior of glass-integrated MEMS devices is an area of ongoing research. While borosilicate glass is known for its stability, long-term exposure to certain conditions, such as high humidity or radiation, can potentially alter its properties. Understanding and mitigating these aging effects is crucial for predicting and extending the operational lifespan of MEMS devices.

To enhance reliability and longevity, advanced characterization techniques and accelerated testing methods have been developed specifically for glass-integrated MEMS devices. These include non-destructive imaging, in-situ stress measurements, and environmental stress testing protocols that simulate long-term use conditions. Such methods allow for more accurate prediction of device lifetimes and identification of potential failure modes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!