Ultrathin Borosilicate Glass Sheets for Flexible Electronics

JUL 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ultrathin Glass Evolution

The evolution of ultrathin glass for flexible electronics represents a significant technological advancement in materials science. This journey began in the early 2000s when researchers first recognized the potential of thin glass as a substrate for flexible devices. Initially, glass sheets with thicknesses of around 100 micrometers were considered thin, but rapid advancements in manufacturing techniques have pushed this boundary to unprecedented levels.

By the mid-2010s, major breakthroughs in glass forming and processing allowed for the production of glass sheets as thin as 25 micrometers. This milestone marked a turning point in the field, as it opened up new possibilities for integrating glass into flexible and foldable electronic devices. The reduction in thickness was accompanied by improvements in flexibility and durability, addressing key challenges that had previously limited the use of glass in such applications.

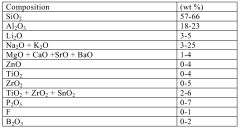

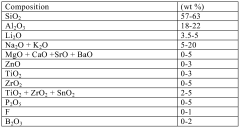

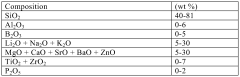

The period between 2015 and 2020 saw intense research focused on optimizing the composition of borosilicate glass for ultrathin applications. Scientists experimented with various ratios of silica, boron oxide, and other additives to enhance the glass's mechanical properties while maintaining its transparency and chemical stability. This era also witnessed the development of novel manufacturing processes, such as the down-draw method, which enabled the production of large-area ultrathin glass sheets with consistent quality.

Recent years have seen a push towards even thinner glass, with some manufacturers achieving thicknesses below 10 micrometers. This ultra-ultrathin glass presents new challenges in handling and integration but offers unprecedented flexibility and conformability. Researchers are now exploring hybrid structures that combine ultrathin glass with polymer layers to create composite materials that leverage the best properties of both.

The evolution of ultrathin glass has been closely tied to advancements in flexible electronics. As display technologies progressed from rigid LCDs to flexible OLEDs, the demand for suitable substrate materials grew. Ultrathin glass emerged as a promising candidate due to its excellent barrier properties against moisture and oxygen, high temperature stability, and superior optical clarity compared to plastic alternatives.

Looking forward, the trajectory of ultrathin glass development is aimed at further reducing thickness while enhancing strength and flexibility. Researchers are investigating nanostructured glass surfaces and edge treatments to improve durability and reduce the risk of fracture. Additionally, efforts are underway to develop roll-to-roll manufacturing processes for ultrathin glass, which could significantly reduce production costs and enable large-scale adoption in consumer electronics and other industries.

By the mid-2010s, major breakthroughs in glass forming and processing allowed for the production of glass sheets as thin as 25 micrometers. This milestone marked a turning point in the field, as it opened up new possibilities for integrating glass into flexible and foldable electronic devices. The reduction in thickness was accompanied by improvements in flexibility and durability, addressing key challenges that had previously limited the use of glass in such applications.

The period between 2015 and 2020 saw intense research focused on optimizing the composition of borosilicate glass for ultrathin applications. Scientists experimented with various ratios of silica, boron oxide, and other additives to enhance the glass's mechanical properties while maintaining its transparency and chemical stability. This era also witnessed the development of novel manufacturing processes, such as the down-draw method, which enabled the production of large-area ultrathin glass sheets with consistent quality.

Recent years have seen a push towards even thinner glass, with some manufacturers achieving thicknesses below 10 micrometers. This ultra-ultrathin glass presents new challenges in handling and integration but offers unprecedented flexibility and conformability. Researchers are now exploring hybrid structures that combine ultrathin glass with polymer layers to create composite materials that leverage the best properties of both.

The evolution of ultrathin glass has been closely tied to advancements in flexible electronics. As display technologies progressed from rigid LCDs to flexible OLEDs, the demand for suitable substrate materials grew. Ultrathin glass emerged as a promising candidate due to its excellent barrier properties against moisture and oxygen, high temperature stability, and superior optical clarity compared to plastic alternatives.

Looking forward, the trajectory of ultrathin glass development is aimed at further reducing thickness while enhancing strength and flexibility. Researchers are investigating nanostructured glass surfaces and edge treatments to improve durability and reduce the risk of fracture. Additionally, efforts are underway to develop roll-to-roll manufacturing processes for ultrathin glass, which could significantly reduce production costs and enable large-scale adoption in consumer electronics and other industries.

Flexible Electronics Market

The flexible electronics market has been experiencing significant growth and transformation in recent years, driven by the increasing demand for lightweight, portable, and bendable electronic devices. This market encompasses a wide range of applications, including flexible displays, wearable devices, flexible sensors, and flexible solar cells. The adoption of flexible electronics is rapidly expanding across various industries, such as consumer electronics, healthcare, automotive, and aerospace.

One of the key factors driving the growth of the flexible electronics market is the rising consumer preference for compact and portable devices. As consumers seek more versatile and user-friendly products, manufacturers are increasingly incorporating flexible components into their designs. This trend is particularly evident in the smartphone and wearable technology sectors, where flexible displays and sensors are becoming more prevalent.

The healthcare industry is another major contributor to the flexible electronics market's expansion. Flexible sensors and wearable devices are revolutionizing patient monitoring and diagnostics, enabling continuous and non-invasive health tracking. These technologies are proving invaluable in managing chronic conditions and promoting preventive healthcare practices.

In the automotive sector, flexible electronics are being integrated into vehicle interiors, enhancing both functionality and aesthetics. Curved displays, touch-sensitive controls, and flexible lighting solutions are becoming more common in modern vehicles, improving the overall user experience and safety features.

The energy sector is also benefiting from advancements in flexible electronics, particularly in the development of flexible solar cells. These lightweight and bendable photovoltaic modules offer new possibilities for integrating solar power generation into various surfaces and structures, potentially revolutionizing renewable energy deployment.

Market analysts project substantial growth for the flexible electronics industry in the coming years. Factors such as technological advancements, increasing investments in research and development, and the growing adoption of Internet of Things (IoT) devices are expected to fuel this expansion. Additionally, the development of new materials and manufacturing processes is likely to reduce production costs and improve the performance of flexible electronic components, further driving market growth.

However, the flexible electronics market also faces certain challenges. These include the need for improved durability and reliability of flexible components, as well as the development of more efficient manufacturing processes to scale up production. Overcoming these hurdles will be crucial for the widespread adoption of flexible electronics across various applications and industries.

One of the key factors driving the growth of the flexible electronics market is the rising consumer preference for compact and portable devices. As consumers seek more versatile and user-friendly products, manufacturers are increasingly incorporating flexible components into their designs. This trend is particularly evident in the smartphone and wearable technology sectors, where flexible displays and sensors are becoming more prevalent.

The healthcare industry is another major contributor to the flexible electronics market's expansion. Flexible sensors and wearable devices are revolutionizing patient monitoring and diagnostics, enabling continuous and non-invasive health tracking. These technologies are proving invaluable in managing chronic conditions and promoting preventive healthcare practices.

In the automotive sector, flexible electronics are being integrated into vehicle interiors, enhancing both functionality and aesthetics. Curved displays, touch-sensitive controls, and flexible lighting solutions are becoming more common in modern vehicles, improving the overall user experience and safety features.

The energy sector is also benefiting from advancements in flexible electronics, particularly in the development of flexible solar cells. These lightweight and bendable photovoltaic modules offer new possibilities for integrating solar power generation into various surfaces and structures, potentially revolutionizing renewable energy deployment.

Market analysts project substantial growth for the flexible electronics industry in the coming years. Factors such as technological advancements, increasing investments in research and development, and the growing adoption of Internet of Things (IoT) devices are expected to fuel this expansion. Additionally, the development of new materials and manufacturing processes is likely to reduce production costs and improve the performance of flexible electronic components, further driving market growth.

However, the flexible electronics market also faces certain challenges. These include the need for improved durability and reliability of flexible components, as well as the development of more efficient manufacturing processes to scale up production. Overcoming these hurdles will be crucial for the widespread adoption of flexible electronics across various applications and industries.

Borosilicate Glass Challenges

The development of ultrathin borosilicate glass sheets for flexible electronics faces several significant challenges. One of the primary obstacles is achieving the required thinness while maintaining the glass's structural integrity and mechanical properties. Borosilicate glass, known for its excellent thermal and chemical resistance, becomes increasingly brittle as it is thinned down to the micro and nanometer scale. This brittleness can lead to cracking and breakage during manufacturing processes and in end-use applications, limiting its practical implementation in flexible electronic devices.

Another major challenge lies in the production process itself. Traditional glass manufacturing techniques are not well-suited for creating ultrathin sheets with consistent thickness and surface quality. Developing new manufacturing methods that can produce large-area, uniform, and defect-free ultrathin borosilicate glass sheets at scale remains a significant hurdle. These methods must also be cost-effective to make the technology commercially viable for mass production of flexible electronics.

The integration of ultrathin borosilicate glass with other materials in flexible electronic devices presents additional challenges. Creating robust and reliable interfaces between the glass and other components, such as electrodes, semiconductors, and protective layers, is crucial for device performance and longevity. The difference in thermal expansion coefficients between glass and other materials can lead to stress and potential delamination during thermal cycling, which is common in electronic devices.

Furthermore, the handling and processing of ultrathin glass sheets in manufacturing environments pose unique difficulties. The extreme thinness makes the glass susceptible to damage from mechanical stresses during transport, cleaning, and device assembly. Developing specialized handling equipment and processes that can work with these delicate materials without causing damage or contamination is essential for successful integration into production lines.

Lastly, ensuring the long-term reliability and durability of flexible electronic devices incorporating ultrathin borosilicate glass is a significant challenge. The glass must maintain its properties and performance under repeated bending, folding, and environmental stresses such as temperature fluctuations and humidity. Developing appropriate testing methodologies and standards to evaluate the long-term behavior of these materials in real-world conditions is crucial for their adoption in commercial products.

Another major challenge lies in the production process itself. Traditional glass manufacturing techniques are not well-suited for creating ultrathin sheets with consistent thickness and surface quality. Developing new manufacturing methods that can produce large-area, uniform, and defect-free ultrathin borosilicate glass sheets at scale remains a significant hurdle. These methods must also be cost-effective to make the technology commercially viable for mass production of flexible electronics.

The integration of ultrathin borosilicate glass with other materials in flexible electronic devices presents additional challenges. Creating robust and reliable interfaces between the glass and other components, such as electrodes, semiconductors, and protective layers, is crucial for device performance and longevity. The difference in thermal expansion coefficients between glass and other materials can lead to stress and potential delamination during thermal cycling, which is common in electronic devices.

Furthermore, the handling and processing of ultrathin glass sheets in manufacturing environments pose unique difficulties. The extreme thinness makes the glass susceptible to damage from mechanical stresses during transport, cleaning, and device assembly. Developing specialized handling equipment and processes that can work with these delicate materials without causing damage or contamination is essential for successful integration into production lines.

Lastly, ensuring the long-term reliability and durability of flexible electronic devices incorporating ultrathin borosilicate glass is a significant challenge. The glass must maintain its properties and performance under repeated bending, folding, and environmental stresses such as temperature fluctuations and humidity. Developing appropriate testing methodologies and standards to evaluate the long-term behavior of these materials in real-world conditions is crucial for their adoption in commercial products.

Current Ultrathin Glass Tech

01 Ultra-thin borosilicate glass sheet production

Methods for producing ultra-thin borosilicate glass sheets with thicknesses ranging from a few micrometers to several hundred micrometers. These techniques often involve specialized drawing or etching processes to achieve the desired thinness while maintaining the glass's structural integrity and optical properties.- Ultra-thin borosilicate glass sheet manufacturing: Advanced manufacturing techniques are employed to produce ultra-thin borosilicate glass sheets. These methods often involve precision drawing or rolling processes to achieve thicknesses in the micrometer range while maintaining the desirable properties of borosilicate glass, such as thermal resistance and chemical durability.

- Thickness range of ultra-thin borosilicate glass sheets: Ultra-thin borosilicate glass sheets typically range from a few micrometers to several hundred micrometers in thickness. The specific thickness can be tailored to meet various application requirements, balancing factors such as flexibility, strength, and optical properties.

- Applications of ultra-thin borosilicate glass sheets: Ultra-thin borosilicate glass sheets find applications in various fields, including electronics, optics, and medical devices. Their thinness, combined with the inherent properties of borosilicate glass, makes them suitable for use in displays, sensors, and protective covers for electronic devices.

- Surface treatment and coating of ultra-thin borosilicate glass: Various surface treatments and coatings can be applied to ultra-thin borosilicate glass sheets to enhance their properties. These treatments may improve scratch resistance, reduce reflectivity, or add functionalities such as anti-fingerprint or hydrophobic characteristics.

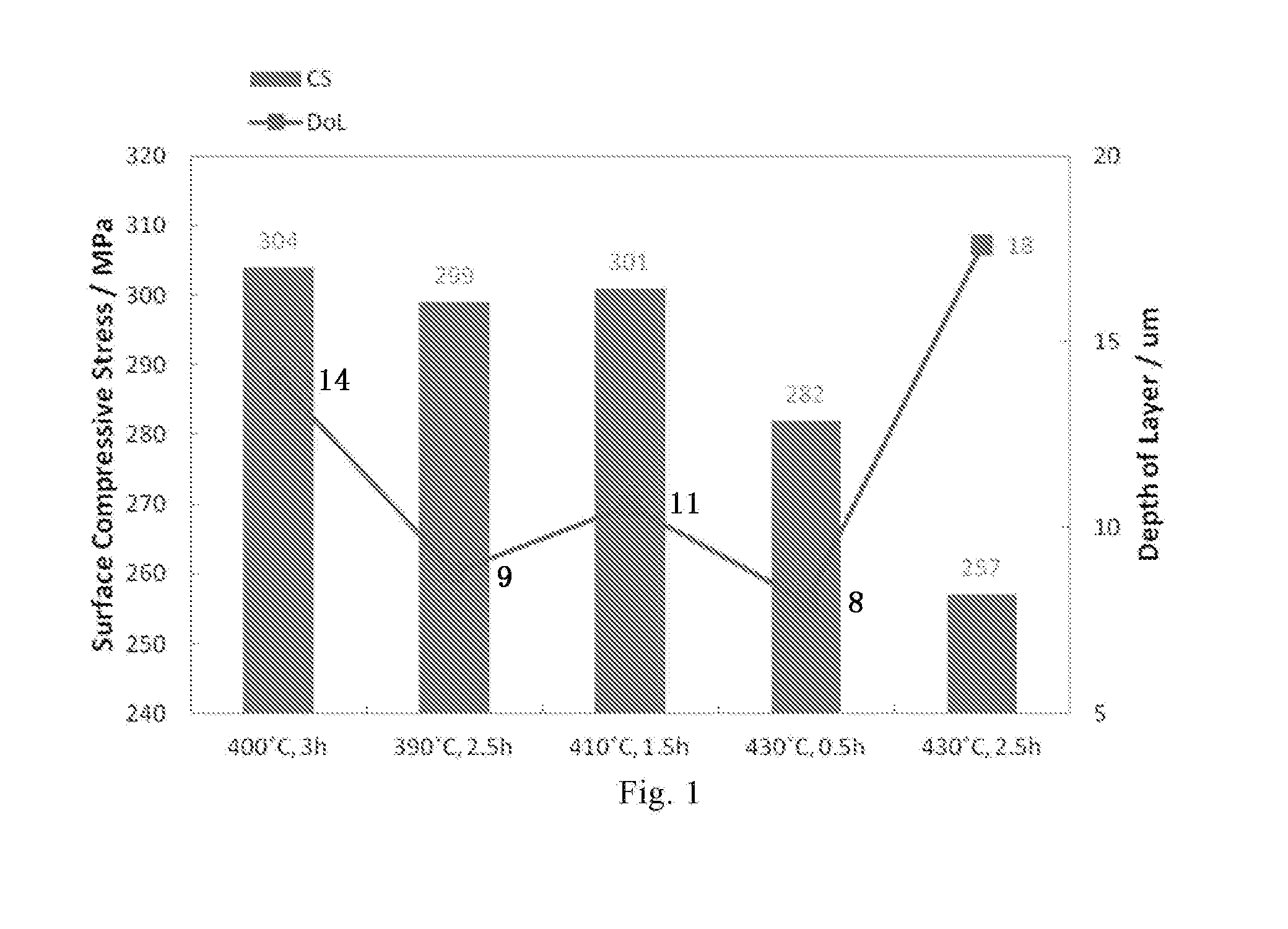

- Strengthening techniques for ultra-thin borosilicate glass: To improve the mechanical strength of ultra-thin borosilicate glass sheets, various strengthening techniques are employed. These may include chemical tempering, ion exchange processes, or the application of protective layers, allowing the glass to maintain its thinness while increasing its durability and resistance to breakage.

02 Thickness control and measurement

Techniques for precisely controlling and measuring the thickness of ultra-thin borosilicate glass sheets. This may include advanced optical measurement systems, real-time monitoring during production, and feedback control mechanisms to ensure consistent thickness across the sheet.Expand Specific Solutions03 Applications of ultra-thin borosilicate glass

Various applications for ultra-thin borosilicate glass sheets, including use in electronic devices, display panels, solar cells, and optical components. The thinness of these sheets allows for flexibility, improved light transmission, and reduced weight in final products.Expand Specific Solutions04 Surface treatment and coating

Methods for treating and coating ultra-thin borosilicate glass sheets to enhance their properties. This may include anti-reflective coatings, strengthening treatments, or functionalization for specific applications, all while maintaining the ultra-thin profile of the glass.Expand Specific Solutions05 Mechanical properties and handling

Techniques for improving the mechanical properties of ultra-thin borosilicate glass sheets and methods for handling these delicate materials during production and integration into devices. This includes strategies to enhance flexibility, reduce brittleness, and prevent damage during manufacturing processes.Expand Specific Solutions

Key Manufacturers Analysis

The research on ultrathin borosilicate glass sheets for flexible electronics is in a rapidly evolving phase, with significant market potential and technological advancements. The industry is transitioning from early-stage development to commercial applications, driven by the growing demand for flexible and durable electronic devices. Major players like SCHOTT AG, Corning, Inc., and Nippon Electric Glass Co., Ltd. are at the forefront of this technology, investing heavily in R&D and production capabilities. The market size is expanding, fueled by applications in smartphones, wearables, and emerging flexible display technologies. While the technology is progressing, it is not yet fully mature, with ongoing challenges in mass production and integration into consumer products.

SCHOTT AG

Technical Solution: SCHOTT AG has developed ultra-thin flexible glass sheets as thin as 25 microns for flexible electronics applications[1]. Their technology involves a down-draw process to produce borosilicate glass with high flexibility and durability. The glass sheets maintain excellent optical properties and can withstand repeated bending cycles without damage[2]. SCHOTT's ultra-thin glass provides a hermetic barrier against moisture and oxygen, making it ideal for OLED displays and other sensitive electronic components[3]. The company has also developed special coating techniques to enhance the glass's scratch resistance and reduce reflections[4].

Strengths: Superior barrier properties, high flexibility, and excellent optical quality. Weaknesses: Higher production costs compared to plastic substrates, potential for brittle fracture if bent beyond limits.

Corning, Inc.

Technical Solution: Corning has pioneered Willow Glass, an ultra-thin, flexible glass substrate as thin as 100 microns for use in flexible electronics[5]. The glass is produced using a proprietary fusion process that creates atomically smooth surfaces. Willow Glass can withstand processing temperatures up to 500°C, allowing for the fabrication of high-performance electronics directly on the glass substrate[6]. Corning has also developed roll-to-roll processing techniques for Willow Glass, enabling cost-effective, large-scale production of flexible electronic devices[7]. The company has demonstrated the use of Willow Glass in flexible OLED displays, solar cells, and touch sensors[8].

Strengths: High-temperature processing capability, smooth surface for high-quality electronics, roll-to-roll manufacturing potential. Weaknesses: Thicker than some competing ultra-thin glass products, may require special handling during device assembly.

Borosilicate Innovations

Chemically Toughened Flexible Ultrathin Glass

PatentActiveUS20160002103A1

Innovation

- Development of a chemically toughened ultrathin glass with a thickness of less than 500 μm, featuring a shallow ion exchange layer (≤30 μm) and low compressive stress (≤120 MPa), made from alkali-containing glasses like alkali silicate or borosilicate, which are processed using techniques like down drawing or special float methods to enhance mechanical strength and flexibility.

Chemically toughened flexible ultrathin glass

PatentWO2014139147A1

Innovation

- Development of a chemically toughened ultrathin glass with a thickness less than 500 μm, featuring a shallow ion-exchange layer (≤30 μm) and low compressive stress (≤120 MPa), made from alkaline-containing glasses like alkali silicate or borosilicate, with controlled composition and processing to enhance flexibility and thermal shock resistance, suitable for roll-to-roll processing and integration with conductive coatings or antimicrobial functions.

Environmental Impact

The development and adoption of ultrathin borosilicate glass sheets for flexible electronics have significant environmental implications that warrant careful consideration. These innovative materials offer potential benefits in terms of resource efficiency and waste reduction, but also present challenges related to production processes and end-of-life management.

One of the primary environmental advantages of ultrathin borosilicate glass sheets is their potential to reduce material consumption. By utilizing thinner glass substrates, manufacturers can significantly decrease the amount of raw materials required for electronic devices. This reduction in material usage translates to lower energy consumption during production and transportation, thereby reducing the overall carbon footprint of the electronics industry.

Furthermore, the durability and flexibility of these glass sheets may contribute to extended product lifespans. Devices incorporating this technology are likely to be more resistant to damage from bending or impact, potentially reducing the frequency of replacements and, consequently, electronic waste generation. This longevity aspect aligns well with circular economy principles and sustainable product design.

However, the production of ultrathin borosilicate glass sheets involves complex manufacturing processes that may have their own environmental impacts. The high temperatures required for glass production and the specialized equipment needed for achieving ultrathin dimensions could result in increased energy consumption and associated greenhouse gas emissions. It is crucial for manufacturers to optimize these processes and explore renewable energy sources to mitigate these effects.

The use of boron in borosilicate glass also raises environmental concerns. Boron mining and processing can have negative impacts on ecosystems and water resources. Responsible sourcing and efficient use of boron compounds are essential to minimize these environmental risks. Additionally, the potential for boron leaching from discarded electronic devices must be carefully evaluated to prevent soil and water contamination.

End-of-life management of electronics incorporating ultrathin borosilicate glass sheets presents both opportunities and challenges. While the glass itself is recyclable, the integration with other electronic components may complicate the recycling process. Developing effective separation and recycling techniques for these composite materials will be crucial to maximize resource recovery and minimize waste.

In conclusion, the environmental impact of ultrathin borosilicate glass sheets in flexible electronics is multifaceted. While offering promising benefits in terms of material efficiency and product durability, careful attention must be paid to production processes, raw material sourcing, and end-of-life management to ensure that the technology contributes positively to environmental sustainability in the electronics industry.

One of the primary environmental advantages of ultrathin borosilicate glass sheets is their potential to reduce material consumption. By utilizing thinner glass substrates, manufacturers can significantly decrease the amount of raw materials required for electronic devices. This reduction in material usage translates to lower energy consumption during production and transportation, thereby reducing the overall carbon footprint of the electronics industry.

Furthermore, the durability and flexibility of these glass sheets may contribute to extended product lifespans. Devices incorporating this technology are likely to be more resistant to damage from bending or impact, potentially reducing the frequency of replacements and, consequently, electronic waste generation. This longevity aspect aligns well with circular economy principles and sustainable product design.

However, the production of ultrathin borosilicate glass sheets involves complex manufacturing processes that may have their own environmental impacts. The high temperatures required for glass production and the specialized equipment needed for achieving ultrathin dimensions could result in increased energy consumption and associated greenhouse gas emissions. It is crucial for manufacturers to optimize these processes and explore renewable energy sources to mitigate these effects.

The use of boron in borosilicate glass also raises environmental concerns. Boron mining and processing can have negative impacts on ecosystems and water resources. Responsible sourcing and efficient use of boron compounds are essential to minimize these environmental risks. Additionally, the potential for boron leaching from discarded electronic devices must be carefully evaluated to prevent soil and water contamination.

End-of-life management of electronics incorporating ultrathin borosilicate glass sheets presents both opportunities and challenges. While the glass itself is recyclable, the integration with other electronic components may complicate the recycling process. Developing effective separation and recycling techniques for these composite materials will be crucial to maximize resource recovery and minimize waste.

In conclusion, the environmental impact of ultrathin borosilicate glass sheets in flexible electronics is multifaceted. While offering promising benefits in terms of material efficiency and product durability, careful attention must be paid to production processes, raw material sourcing, and end-of-life management to ensure that the technology contributes positively to environmental sustainability in the electronics industry.

Durability and Reliability

The durability and reliability of ultrathin borosilicate glass sheets are critical factors in their application for flexible electronics. These properties determine the long-term performance and viability of devices incorporating this material. Borosilicate glass, known for its excellent thermal and chemical resistance, presents unique challenges when reduced to ultrathin dimensions for flexible applications.

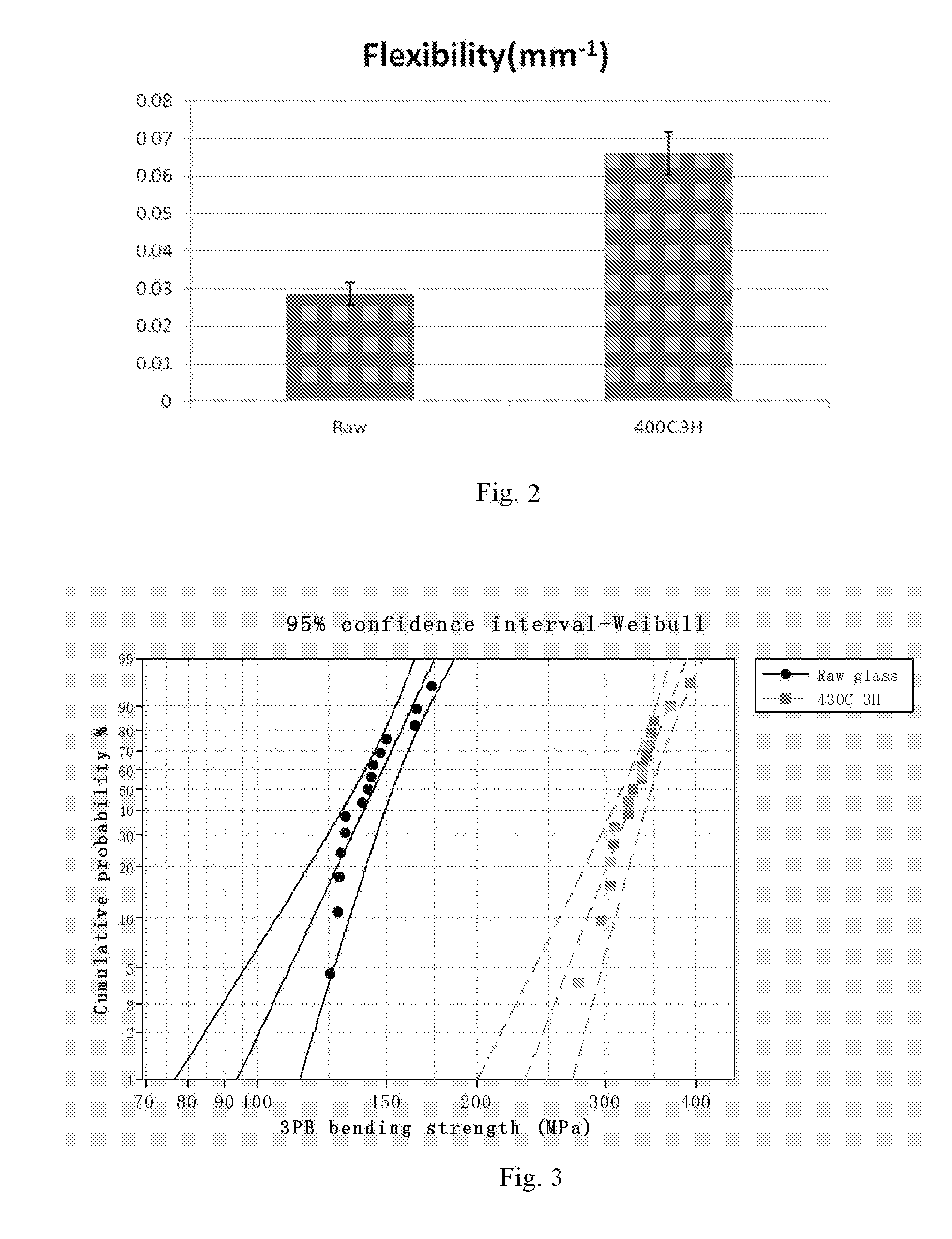

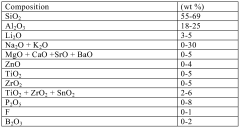

One of the primary concerns in the durability of ultrathin borosilicate glass is its resistance to mechanical stress. While bulk borosilicate glass is relatively strong, ultrathin sheets may be more susceptible to cracking or shattering under bending or impact forces. Research has shown that the flexibility of these sheets increases as thickness decreases, but this comes at the cost of reduced mechanical strength. Efforts to enhance durability have focused on surface treatments and lamination techniques to improve impact resistance without compromising flexibility.

Chemical durability is another crucial aspect of ultrathin borosilicate glass sheets. The material's inherent resistance to chemical attack is generally maintained in thin formats, but prolonged exposure to certain environments may lead to surface degradation over time. Studies have investigated the effects of various chemical agents on the glass surface, with particular attention to those commonly encountered in electronic manufacturing processes and end-use environments.

Thermal reliability is a key consideration, especially in electronic applications where heat generation is common. Ultrathin borosilicate glass sheets must maintain their structural integrity and optical properties across a wide temperature range. Research has shown that these sheets exhibit good thermal stability, with minimal warping or dimensional changes under typical operating conditions. However, extreme temperature fluctuations or prolonged exposure to high temperatures may still pose challenges to long-term reliability.

The optical properties of ultrathin borosilicate glass sheets are also subject to durability concerns. Maintaining transparency and preventing yellowing or clouding over time is essential for many flexible electronic applications, particularly in display technologies. Studies have focused on developing coatings and surface treatments to enhance scratch resistance and maintain optical clarity under various environmental conditions.

Long-term stability under cyclic mechanical stress is a critical area of research for flexible electronics. Repeated bending and flexing of ultrathin glass sheets can lead to fatigue and eventual failure. Investigations into the fatigue behavior of these materials have employed accelerated testing methods to simulate years of use in a shorter timeframe. Results have been promising, showing that properly engineered ultrathin borosilicate glass can withstand thousands of bending cycles without significant degradation in performance.

In conclusion, while ultrathin borosilicate glass sheets offer exciting possibilities for flexible electronics, ensuring their durability and reliability remains an ongoing challenge. Continued research in this area is essential to develop robust solutions that can meet the demanding requirements of next-generation flexible electronic devices.

One of the primary concerns in the durability of ultrathin borosilicate glass is its resistance to mechanical stress. While bulk borosilicate glass is relatively strong, ultrathin sheets may be more susceptible to cracking or shattering under bending or impact forces. Research has shown that the flexibility of these sheets increases as thickness decreases, but this comes at the cost of reduced mechanical strength. Efforts to enhance durability have focused on surface treatments and lamination techniques to improve impact resistance without compromising flexibility.

Chemical durability is another crucial aspect of ultrathin borosilicate glass sheets. The material's inherent resistance to chemical attack is generally maintained in thin formats, but prolonged exposure to certain environments may lead to surface degradation over time. Studies have investigated the effects of various chemical agents on the glass surface, with particular attention to those commonly encountered in electronic manufacturing processes and end-use environments.

Thermal reliability is a key consideration, especially in electronic applications where heat generation is common. Ultrathin borosilicate glass sheets must maintain their structural integrity and optical properties across a wide temperature range. Research has shown that these sheets exhibit good thermal stability, with minimal warping or dimensional changes under typical operating conditions. However, extreme temperature fluctuations or prolonged exposure to high temperatures may still pose challenges to long-term reliability.

The optical properties of ultrathin borosilicate glass sheets are also subject to durability concerns. Maintaining transparency and preventing yellowing or clouding over time is essential for many flexible electronic applications, particularly in display technologies. Studies have focused on developing coatings and surface treatments to enhance scratch resistance and maintain optical clarity under various environmental conditions.

Long-term stability under cyclic mechanical stress is a critical area of research for flexible electronics. Repeated bending and flexing of ultrathin glass sheets can lead to fatigue and eventual failure. Investigations into the fatigue behavior of these materials have employed accelerated testing methods to simulate years of use in a shorter timeframe. Results have been promising, showing that properly engineered ultrathin borosilicate glass can withstand thousands of bending cycles without significant degradation in performance.

In conclusion, while ultrathin borosilicate glass sheets offer exciting possibilities for flexible electronics, ensuring their durability and reliability remains an ongoing challenge. Continued research in this area is essential to develop robust solutions that can meet the demanding requirements of next-generation flexible electronic devices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!