Fused Borosilicate Glass Microchannel Development

JUL 3, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Borosilicate Glass Microchannel Background and Objectives

Borosilicate glass microchannels have emerged as a critical technology in various fields, including microfluidics, lab-on-a-chip devices, and miniaturized chemical reactors. The development of these microchannels represents a convergence of materials science, microfabrication techniques, and fluid dynamics. The journey of this technology began in the late 20th century, driven by the need for miniaturization and increased efficiency in chemical and biological processes.

The evolution of borosilicate glass microchannel technology has been marked by significant advancements in fabrication methods, design optimization, and application diversification. Initially, these microchannels were primarily used in simple microfluidic devices. However, as the technology matured, its potential for more complex applications became apparent, leading to its adoption in areas such as point-of-care diagnostics, environmental monitoring, and drug discovery.

One of the key drivers behind the development of borosilicate glass microchannels has been the unique properties of borosilicate glass itself. This material offers excellent thermal stability, chemical resistance, and optical transparency, making it ideal for a wide range of applications. These properties have allowed researchers and engineers to push the boundaries of microchannel design and functionality, enabling the creation of increasingly sophisticated devices.

The objectives of research in this field are multifaceted. Primarily, there is a focus on improving fabrication techniques to achieve higher precision, better reproducibility, and increased complexity in microchannel designs. This includes developing methods for creating three-dimensional structures, integrating multiple functionalities within a single device, and scaling up production for commercial applications.

Another key objective is to enhance the performance of borosilicate glass microchannels in specific applications. This involves optimizing channel geometries, surface treatments, and integration with other materials to improve fluid flow characteristics, reaction efficiencies, and detection sensitivities. Researchers are also exploring ways to functionalize the microchannel surfaces to enable new applications in areas such as biosensing and catalysis.

As the field progresses, there is an increasing emphasis on sustainability and cost-effectiveness. This has led to research into more efficient fabrication processes, the use of recycled materials, and the development of reusable microchannel devices. Additionally, there is a growing interest in combining borosilicate glass microchannels with other emerging technologies, such as 3D printing and nanotechnology, to create hybrid systems with enhanced capabilities.

The future trajectory of borosilicate glass microchannel technology points towards greater integration with digital technologies, including artificial intelligence and the Internet of Things. This convergence is expected to lead to the development of smart, autonomous microfluidic systems capable of complex decision-making and real-time data analysis, opening up new frontiers in fields like personalized medicine and environmental monitoring.

The evolution of borosilicate glass microchannel technology has been marked by significant advancements in fabrication methods, design optimization, and application diversification. Initially, these microchannels were primarily used in simple microfluidic devices. However, as the technology matured, its potential for more complex applications became apparent, leading to its adoption in areas such as point-of-care diagnostics, environmental monitoring, and drug discovery.

One of the key drivers behind the development of borosilicate glass microchannels has been the unique properties of borosilicate glass itself. This material offers excellent thermal stability, chemical resistance, and optical transparency, making it ideal for a wide range of applications. These properties have allowed researchers and engineers to push the boundaries of microchannel design and functionality, enabling the creation of increasingly sophisticated devices.

The objectives of research in this field are multifaceted. Primarily, there is a focus on improving fabrication techniques to achieve higher precision, better reproducibility, and increased complexity in microchannel designs. This includes developing methods for creating three-dimensional structures, integrating multiple functionalities within a single device, and scaling up production for commercial applications.

Another key objective is to enhance the performance of borosilicate glass microchannels in specific applications. This involves optimizing channel geometries, surface treatments, and integration with other materials to improve fluid flow characteristics, reaction efficiencies, and detection sensitivities. Researchers are also exploring ways to functionalize the microchannel surfaces to enable new applications in areas such as biosensing and catalysis.

As the field progresses, there is an increasing emphasis on sustainability and cost-effectiveness. This has led to research into more efficient fabrication processes, the use of recycled materials, and the development of reusable microchannel devices. Additionally, there is a growing interest in combining borosilicate glass microchannels with other emerging technologies, such as 3D printing and nanotechnology, to create hybrid systems with enhanced capabilities.

The future trajectory of borosilicate glass microchannel technology points towards greater integration with digital technologies, including artificial intelligence and the Internet of Things. This convergence is expected to lead to the development of smart, autonomous microfluidic systems capable of complex decision-making and real-time data analysis, opening up new frontiers in fields like personalized medicine and environmental monitoring.

Market Analysis for Microfluidic Devices

The microfluidic devices market has experienced significant growth in recent years, driven by advancements in technology and increasing applications across various industries. The global market for microfluidic devices is projected to reach $32.7 billion by 2025, with a compound annual growth rate (CAGR) of 22.6% from 2020 to 2025. This robust growth is attributed to the rising demand for point-of-care testing, drug discovery and development, and personalized medicine.

The healthcare sector remains the largest consumer of microfluidic devices, accounting for approximately 60% of the market share. Within healthcare, diagnostics and drug discovery are the primary applications driving demand. The ability of microfluidic devices to handle small sample volumes, reduce reagent consumption, and provide rapid results has made them invaluable in clinical diagnostics and pharmaceutical research.

In the field of diagnostics, there is a growing trend towards miniaturization and integration of multiple functions onto a single chip. This has led to the development of lab-on-a-chip devices, which are compact, portable, and capable of performing complex analytical tasks. The COVID-19 pandemic has further accelerated the adoption of microfluidic-based diagnostic tools, particularly for rapid testing and disease monitoring.

The pharmaceutical industry is another major driver of the microfluidic devices market. Drug discovery and development processes benefit from microfluidic technologies through improved screening efficiency, reduced costs, and the ability to mimic in vivo conditions more accurately. Organ-on-a-chip devices, which replicate the physiological functions of human organs on a microscale, are gaining traction in drug testing and toxicology studies.

Geographically, North America dominates the microfluidic devices market, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by increasing healthcare expenditure, growing research activities, and rising adoption of advanced technologies in countries like China and India.

The market for microfluidic devices based on fused borosilicate glass is particularly promising. Borosilicate glass offers several advantages over polymer-based materials, including superior optical properties, chemical resistance, and thermal stability. These characteristics make it ideal for applications requiring high-resolution imaging, precise temperature control, or exposure to harsh chemicals.

As the demand for more sophisticated and reliable microfluidic devices continues to grow, the development of fused borosilicate glass microchannels is likely to play a crucial role in advancing the field. The ability to create complex, three-dimensional structures in glass through techniques like selective laser-induced etching (SLE) opens up new possibilities for device design and functionality.

The healthcare sector remains the largest consumer of microfluidic devices, accounting for approximately 60% of the market share. Within healthcare, diagnostics and drug discovery are the primary applications driving demand. The ability of microfluidic devices to handle small sample volumes, reduce reagent consumption, and provide rapid results has made them invaluable in clinical diagnostics and pharmaceutical research.

In the field of diagnostics, there is a growing trend towards miniaturization and integration of multiple functions onto a single chip. This has led to the development of lab-on-a-chip devices, which are compact, portable, and capable of performing complex analytical tasks. The COVID-19 pandemic has further accelerated the adoption of microfluidic-based diagnostic tools, particularly for rapid testing and disease monitoring.

The pharmaceutical industry is another major driver of the microfluidic devices market. Drug discovery and development processes benefit from microfluidic technologies through improved screening efficiency, reduced costs, and the ability to mimic in vivo conditions more accurately. Organ-on-a-chip devices, which replicate the physiological functions of human organs on a microscale, are gaining traction in drug testing and toxicology studies.

Geographically, North America dominates the microfluidic devices market, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by increasing healthcare expenditure, growing research activities, and rising adoption of advanced technologies in countries like China and India.

The market for microfluidic devices based on fused borosilicate glass is particularly promising. Borosilicate glass offers several advantages over polymer-based materials, including superior optical properties, chemical resistance, and thermal stability. These characteristics make it ideal for applications requiring high-resolution imaging, precise temperature control, or exposure to harsh chemicals.

As the demand for more sophisticated and reliable microfluidic devices continues to grow, the development of fused borosilicate glass microchannels is likely to play a crucial role in advancing the field. The ability to create complex, three-dimensional structures in glass through techniques like selective laser-induced etching (SLE) opens up new possibilities for device design and functionality.

Current Challenges in Fused Glass Microchannel Fabrication

The development of fused borosilicate glass microchannels faces several significant challenges that hinder their widespread adoption and commercialization. One of the primary obstacles is the complexity of the fabrication process, which requires precise control over multiple parameters to achieve the desired microchannel structures.

The high melting point of borosilicate glass, typically around 800°C, necessitates specialized equipment and energy-intensive processes. This not only increases production costs but also limits the scalability of manufacturing. Additionally, the thermal expansion mismatch between the glass and other materials used in the fabrication process can lead to residual stresses and potential device failure.

Another critical challenge lies in achieving consistent and uniform channel dimensions across the entire device. The viscous nature of molten glass makes it difficult to maintain precise control over channel geometry, especially for complex designs with varying cross-sections or intricate networks. This issue is particularly pronounced when attempting to create high-aspect-ratio channels or ultra-small features below 10 micrometers.

Surface roughness and optical clarity present further complications. The etching and bonding processes used in microchannel fabrication can introduce surface imperfections, affecting both fluid flow characteristics and optical performance. Achieving optically smooth surfaces while maintaining the desired channel geometry remains a significant hurdle.

The integration of additional functionalities, such as electrodes or sensors, within the glass microchannels poses another set of challenges. The high processing temperatures and chemical inertness of borosilicate glass limit the range of compatible materials and integration techniques, often requiring innovative approaches to incorporate these elements without compromising the integrity of the microfluidic structure.

Bonding and sealing of glass microchannels represent a critical step in device fabrication. Traditional methods like thermal bonding can lead to channel deformation or collapse, especially for shallow channels. Alternative techniques such as anodic bonding or adhesive bonding each come with their own set of limitations in terms of bond strength, chemical compatibility, and process complexity.

Lastly, the characterization and quality control of fused glass microchannels remain challenging due to the transparent nature of the material and the small scale of the features. Non-destructive inspection techniques capable of detecting defects or variations in channel dimensions are limited, making it difficult to ensure consistent performance across manufactured devices.

Addressing these challenges requires interdisciplinary approaches, combining advances in materials science, fabrication technologies, and characterization methods. Overcoming these hurdles is crucial for realizing the full potential of fused borosilicate glass microchannels in various applications, from lab-on-a-chip devices to advanced analytical systems.

The high melting point of borosilicate glass, typically around 800°C, necessitates specialized equipment and energy-intensive processes. This not only increases production costs but also limits the scalability of manufacturing. Additionally, the thermal expansion mismatch between the glass and other materials used in the fabrication process can lead to residual stresses and potential device failure.

Another critical challenge lies in achieving consistent and uniform channel dimensions across the entire device. The viscous nature of molten glass makes it difficult to maintain precise control over channel geometry, especially for complex designs with varying cross-sections or intricate networks. This issue is particularly pronounced when attempting to create high-aspect-ratio channels or ultra-small features below 10 micrometers.

Surface roughness and optical clarity present further complications. The etching and bonding processes used in microchannel fabrication can introduce surface imperfections, affecting both fluid flow characteristics and optical performance. Achieving optically smooth surfaces while maintaining the desired channel geometry remains a significant hurdle.

The integration of additional functionalities, such as electrodes or sensors, within the glass microchannels poses another set of challenges. The high processing temperatures and chemical inertness of borosilicate glass limit the range of compatible materials and integration techniques, often requiring innovative approaches to incorporate these elements without compromising the integrity of the microfluidic structure.

Bonding and sealing of glass microchannels represent a critical step in device fabrication. Traditional methods like thermal bonding can lead to channel deformation or collapse, especially for shallow channels. Alternative techniques such as anodic bonding or adhesive bonding each come with their own set of limitations in terms of bond strength, chemical compatibility, and process complexity.

Lastly, the characterization and quality control of fused glass microchannels remain challenging due to the transparent nature of the material and the small scale of the features. Non-destructive inspection techniques capable of detecting defects or variations in channel dimensions are limited, making it difficult to ensure consistent performance across manufactured devices.

Addressing these challenges requires interdisciplinary approaches, combining advances in materials science, fabrication technologies, and characterization methods. Overcoming these hurdles is crucial for realizing the full potential of fused borosilicate glass microchannels in various applications, from lab-on-a-chip devices to advanced analytical systems.

Existing Fused Glass Microchannel Fabrication Methods

01 Fabrication of fused borosilicate glass microchannels

Techniques for creating microchannels in borosilicate glass through fusion processes. This may involve precise heating and cooling methods to form intricate channel structures within the glass substrate. The process allows for the creation of complex microfluidic devices with high chemical and thermal resistance.- Fabrication of fused borosilicate glass microchannels: Techniques for creating microchannels in borosilicate glass through fusion processes. This may involve precise heating and cooling methods to form intricate channel structures within the glass substrate, allowing for the development of microfluidic devices with high chemical resistance and optical clarity.

- Applications in microfluidic devices: Utilization of fused borosilicate glass microchannels in various microfluidic applications. These may include lab-on-a-chip devices, chemical reactors, and analytical instruments that benefit from the material's properties such as thermal stability, chemical inertness, and transparency.

- Surface modification of borosilicate glass microchannels: Methods for altering the surface properties of fused borosilicate glass microchannels. This can involve treatments to modify hydrophobicity, improve bonding capabilities, or enhance specific chemical interactions within the channels for improved performance in various applications.

- Integration with other materials and components: Techniques for integrating fused borosilicate glass microchannels with other materials or components. This may include bonding methods, interfacing with electrodes or sensors, or creating hybrid systems that combine the advantages of glass with other materials for enhanced functionality.

- Specialized manufacturing processes: Advanced manufacturing techniques specific to creating complex microchannel structures in fused borosilicate glass. This could involve laser processing, etching methods, or novel fusion techniques that allow for the creation of intricate three-dimensional channel networks within the glass substrate.

02 Applications in microfluidic devices

Fused borosilicate glass microchannels are utilized in various microfluidic applications. These include lab-on-a-chip devices, chemical reactors, and analytical instruments. The glass properties provide excellent optical clarity and compatibility with biological samples, making them ideal for biomedical research and diagnostics.Expand Specific Solutions03 Surface modification of microchannels

Methods for modifying the surface properties of fused borosilicate glass microchannels. This can involve chemical treatments, plasma processing, or coating techniques to alter the hydrophobicity, reactivity, or other characteristics of the channel walls. Such modifications can enhance the performance of microfluidic devices for specific applications.Expand Specific Solutions04 Integration with other materials

Techniques for integrating fused borosilicate glass microchannels with other materials such as polymers, metals, or semiconductors. This can involve bonding methods, encapsulation techniques, or hybrid fabrication processes to create multi-material microfluidic systems with enhanced functionality.Expand Specific Solutions05 Specialized borosilicate glass compositions

Development of specialized borosilicate glass compositions tailored for microchannel applications. These may include adjustments to the glass chemistry to optimize properties such as thermal expansion, chemical durability, or optical transmission. Such customized compositions can improve the performance and reliability of microfluidic devices.Expand Specific Solutions

Key Players in Microfluidic Device Industry

The research on fused borosilicate glass microchannel development is in a growth phase, with increasing market demand driven by applications in microfluidics, lab-on-a-chip devices, and miniaturized analytical systems. The global market for microfluidic devices is projected to reach significant value in the coming years, indicating substantial potential for this technology. Key players like SCHOTT AG, Corning, Inc., and Nippon Electric Glass Co., Ltd. are at the forefront of innovation, leveraging their expertise in specialty glass manufacturing to develop advanced microchannel solutions. The technology's maturity is progressing, with ongoing research focused on improving fabrication techniques, enhancing channel uniformity, and expanding application areas. Collaborations between industry leaders and research institutions are accelerating technological advancements in this field.

SCHOTT AG

Technical Solution: SCHOTT AG has developed advanced fused borosilicate glass microchannel technology for various applications. Their approach involves precision glass drawing and etching techniques to create microchannels with high aspect ratios and smooth surfaces. SCHOTT's process allows for the fabrication of complex microchannel networks with precise control over channel dimensions, typically ranging from 10 to 500 micrometers in width[1]. The company utilizes proprietary glass compositions optimized for specific applications, such as microfluidics and lab-on-a-chip devices. SCHOTT's technology incorporates thermal bonding methods to create sealed microchannel structures, ensuring high pressure resistance and chemical inertness[2]. Additionally, they have developed surface modification techniques to control the wettability and functionality of the microchannel walls, enhancing their performance in various analytical and biomedical applications[3].

Strengths: High precision and reproducibility, excellent optical properties, chemical resistance, and thermal stability. Weaknesses: Higher production costs compared to polymer-based alternatives, limited flexibility in channel geometry modifications post-fabrication.

Corning, Inc.

Technical Solution: Corning, Inc. has pioneered innovative approaches in fused borosilicate glass microchannel development. Their technology utilizes a combination of photolithography and wet etching processes to create microchannels with high aspect ratios and smooth surfaces. Corning's method allows for the fabrication of microchannels with widths ranging from 5 to 1000 micrometers and depths up to several hundred micrometers[4]. The company has developed proprietary glass formulations that offer enhanced chemical resistance and thermal stability, making them suitable for a wide range of applications, including microreactors and high-throughput screening devices. Corning's process incorporates advanced bonding techniques, such as fusion bonding, to create hermetically sealed microchannel structures capable of withstanding high pressures and temperatures[5]. Furthermore, they have developed surface functionalization methods to tailor the surface properties of the microchannels for specific applications, such as improved cell adhesion or reduced protein adsorption[6].

Strengths: Excellent optical clarity, high chemical resistance, and thermal stability. Ability to create complex 3D microchannel networks. Weaknesses: Higher initial tooling costs, limited flexibility for rapid prototyping compared to some polymer-based alternatives.

Innovations in Borosilicate Glass Microchannel Development

Microfluidic system with surface coating

PatentInactiveEP2146201A1

Innovation

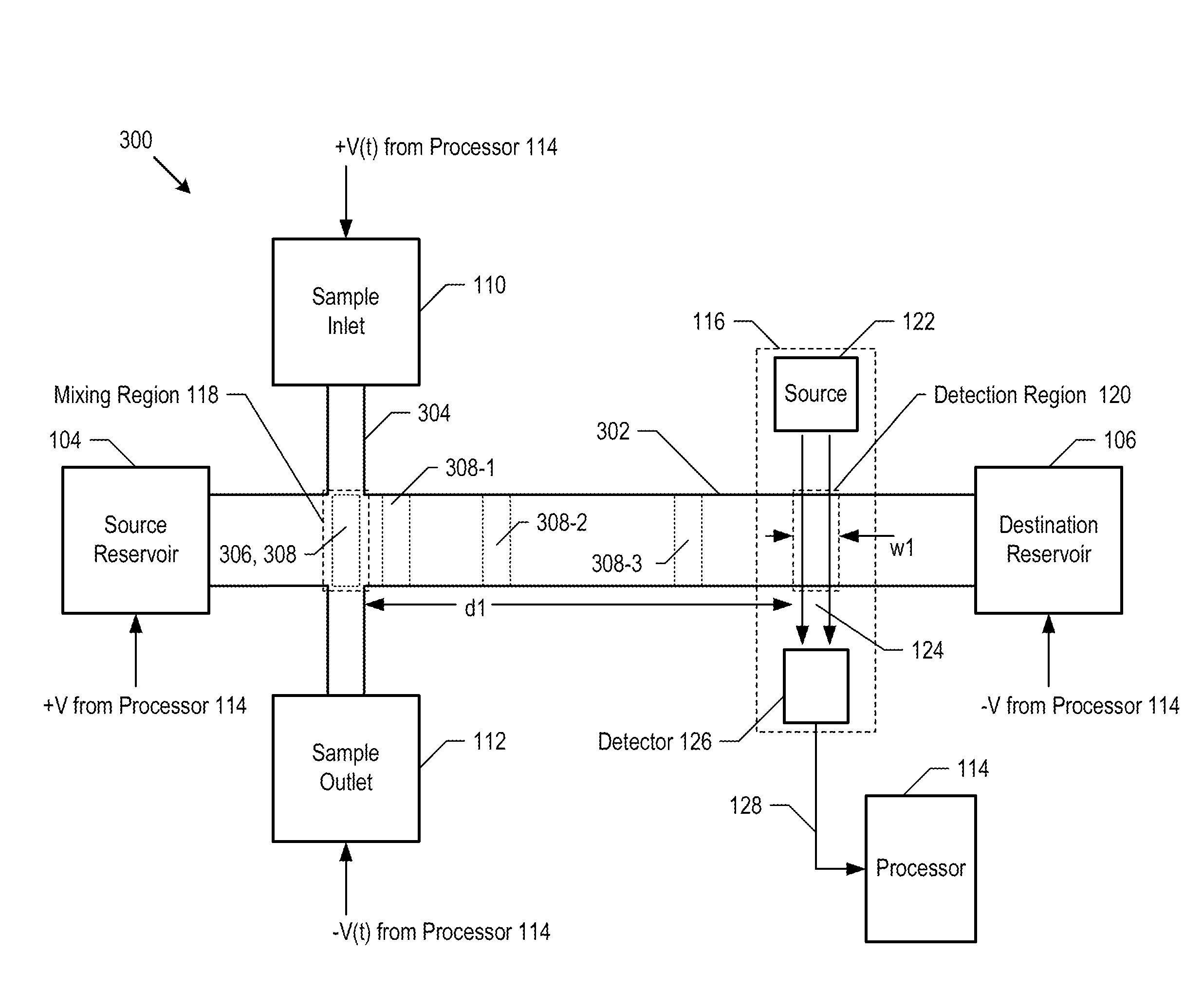

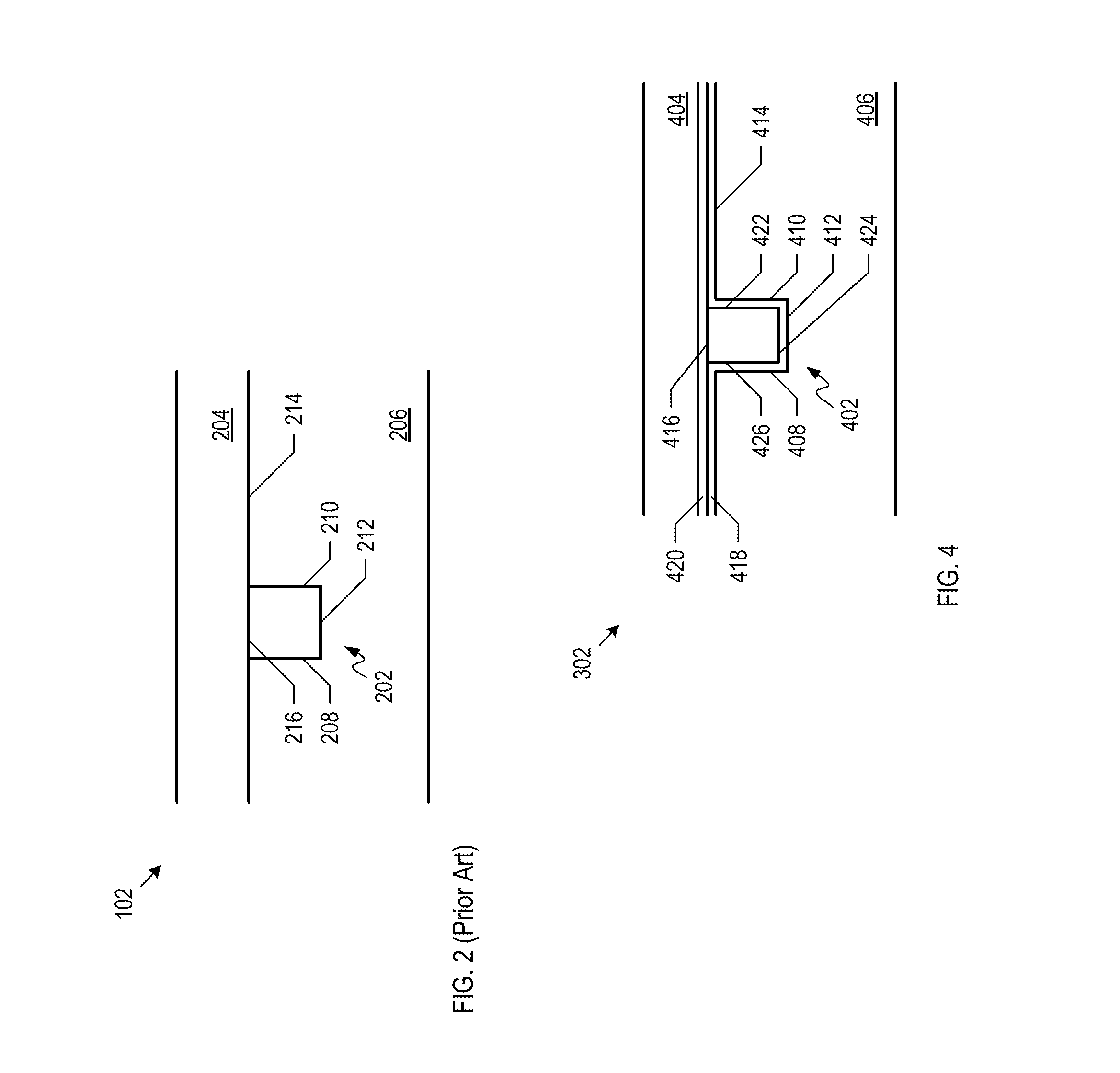

- The use of borophosphosilicate glass layers on the microfluidic channel surfaces to reduce surface roughness and enhance electrokinetic potential, allowing for well-formed analyte plugs and flexible channel designs with various cross-sectional shapes, including non-circular configurations.

Microfluidic system

PatentInactiveUS20130256138A1

Innovation

- The use of borophosphosilicate glass layers on the channel surfaces to reduce surface roughness and enhance electrokinetic potential, allowing for well-formed analyte plugs and flexible channel designs, including non-circular cross-sectional shapes, and enabling thermo-anodic bonding for channel enclosure.

Material Properties and Performance Evaluation

Fused borosilicate glass is a material of significant interest in the development of microchannels due to its unique properties and performance characteristics. This glass composition offers a combination of thermal, chemical, and mechanical properties that make it particularly suitable for microchannel applications.

The thermal properties of fused borosilicate glass are crucial for its performance in microchannel systems. It exhibits a low coefficient of thermal expansion, typically around 3.3 × 10^-6 K^-1, which is significantly lower than that of soda-lime glass. This property ensures dimensional stability across a wide range of temperatures, reducing the risk of thermal stress and cracking during operation. Additionally, its high softening point (approximately 820°C) and annealing point (565°C) allow for a broader range of operating temperatures compared to other glass types.

Chemical resistance is another key attribute of fused borosilicate glass. It demonstrates excellent resistance to a wide range of chemicals, including acids, alkalis, and organic solvents. This resistance is particularly important in microchannel applications where various reagents and samples may come into contact with the channel walls. The inert nature of the glass surface also minimizes the risk of contamination or unwanted reactions, ensuring the integrity of the samples and processes within the microchannels.

Mechanically, fused borosilicate glass offers a good balance of strength and workability. Its Young's modulus of approximately 64 GPa provides sufficient rigidity for microchannel structures while still allowing for precise fabrication techniques. The material's hardness, typically around 6 on the Mohs scale, contributes to the durability of the microchannels, resisting scratches and wear during use.

Optical properties are also significant in many microchannel applications. Fused borosilicate glass exhibits high transparency across a wide spectrum, including visible and near-UV wavelengths. This transparency, coupled with its low autofluorescence, makes it an excellent choice for applications involving optical detection or microscopy.

In terms of performance evaluation, fused borosilicate glass microchannels have demonstrated excellent results in various applications. Flow characteristics within these channels are typically laminar and predictable, allowing for precise control of fluid dynamics. The smooth surface of the glass, achievable through proper fabrication techniques, minimizes flow resistance and reduces the risk of particle adhesion or biofilm formation.

Thermal management in fused borosilicate glass microchannels is generally superior to that of polymer-based systems. The material's thermal conductivity, while lower than metals, is sufficient for many applications and allows for efficient heat transfer in thermal management systems or temperature-controlled reactions.

Long-term stability is another area where fused borosilicate glass excels. Unlike some polymer materials, it does not degrade or leach contaminants over time, ensuring consistent performance and reliability in long-duration experiments or industrial processes. This stability, combined with its biocompatibility, makes it particularly suitable for biomedical and analytical applications.

The thermal properties of fused borosilicate glass are crucial for its performance in microchannel systems. It exhibits a low coefficient of thermal expansion, typically around 3.3 × 10^-6 K^-1, which is significantly lower than that of soda-lime glass. This property ensures dimensional stability across a wide range of temperatures, reducing the risk of thermal stress and cracking during operation. Additionally, its high softening point (approximately 820°C) and annealing point (565°C) allow for a broader range of operating temperatures compared to other glass types.

Chemical resistance is another key attribute of fused borosilicate glass. It demonstrates excellent resistance to a wide range of chemicals, including acids, alkalis, and organic solvents. This resistance is particularly important in microchannel applications where various reagents and samples may come into contact with the channel walls. The inert nature of the glass surface also minimizes the risk of contamination or unwanted reactions, ensuring the integrity of the samples and processes within the microchannels.

Mechanically, fused borosilicate glass offers a good balance of strength and workability. Its Young's modulus of approximately 64 GPa provides sufficient rigidity for microchannel structures while still allowing for precise fabrication techniques. The material's hardness, typically around 6 on the Mohs scale, contributes to the durability of the microchannels, resisting scratches and wear during use.

Optical properties are also significant in many microchannel applications. Fused borosilicate glass exhibits high transparency across a wide spectrum, including visible and near-UV wavelengths. This transparency, coupled with its low autofluorescence, makes it an excellent choice for applications involving optical detection or microscopy.

In terms of performance evaluation, fused borosilicate glass microchannels have demonstrated excellent results in various applications. Flow characteristics within these channels are typically laminar and predictable, allowing for precise control of fluid dynamics. The smooth surface of the glass, achievable through proper fabrication techniques, minimizes flow resistance and reduces the risk of particle adhesion or biofilm formation.

Thermal management in fused borosilicate glass microchannels is generally superior to that of polymer-based systems. The material's thermal conductivity, while lower than metals, is sufficient for many applications and allows for efficient heat transfer in thermal management systems or temperature-controlled reactions.

Long-term stability is another area where fused borosilicate glass excels. Unlike some polymer materials, it does not degrade or leach contaminants over time, ensuring consistent performance and reliability in long-duration experiments or industrial processes. This stability, combined with its biocompatibility, makes it particularly suitable for biomedical and analytical applications.

Applications and Integration in Lab-on-a-Chip Systems

Fused borosilicate glass microchannels have found extensive applications in lab-on-a-chip systems, revolutionizing the field of microfluidics and enabling miniaturized analytical processes. These microchannels offer several advantages, including excellent chemical resistance, optical transparency, and thermal stability, making them ideal for various biomedical and chemical analysis applications.

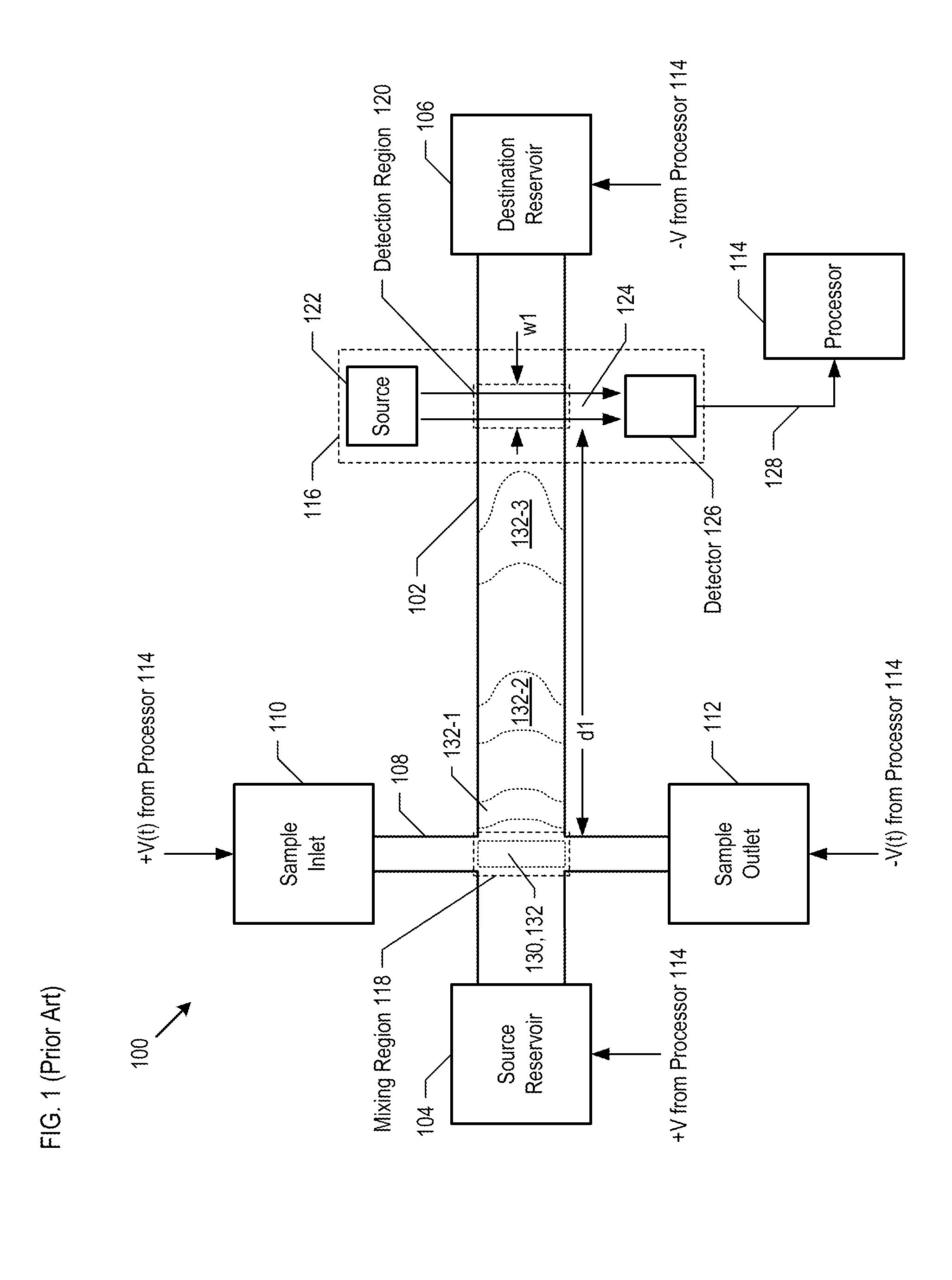

In lab-on-a-chip systems, fused borosilicate glass microchannels serve as the foundation for integrating multiple laboratory functions onto a single, compact device. These systems typically incorporate sample preparation, reagent mixing, separation, and detection processes within a miniaturized platform. The integration of microchannels allows for precise control over fluid flow, enabling efficient manipulation of small sample volumes and reagents.

One of the primary applications of fused borosilicate glass microchannels in lab-on-a-chip systems is in DNA analysis and sequencing. The microchannels provide a controlled environment for DNA amplification, separation, and detection, allowing for rapid and accurate genetic analysis. Additionally, these systems have been employed in protein analysis, cell sorting, and drug screening applications, offering high-throughput capabilities and reduced sample consumption.

The integration of fused borosilicate glass microchannels in lab-on-a-chip systems has also facilitated the development of point-of-care diagnostic devices. These portable systems enable rapid and on-site detection of various biomarkers, pathogens, and diseases, making them valuable tools in healthcare settings, particularly in resource-limited environments.

Furthermore, the optical properties of fused borosilicate glass microchannels have enabled the integration of advanced detection techniques, such as fluorescence microscopy and surface plasmon resonance, into lab-on-a-chip systems. This integration enhances the sensitivity and specificity of analytical processes, allowing for the detection of low-concentration analytes and the study of molecular interactions at the microscale.

The scalability and reproducibility of fused borosilicate glass microchannels have contributed to the development of standardized lab-on-a-chip platforms. These platforms can be easily customized for specific applications while maintaining consistent performance across different devices, facilitating their adoption in research and industrial settings.

As the field of microfluidics continues to advance, the integration of fused borosilicate glass microchannels in lab-on-a-chip systems is expected to expand further. Emerging applications include organ-on-a-chip models for drug development, environmental monitoring systems, and advanced biosensors for personalized medicine. The ongoing research in this area focuses on improving fabrication techniques, enhancing surface functionalization, and developing novel detection methods to unlock the full potential of these integrated systems.

In lab-on-a-chip systems, fused borosilicate glass microchannels serve as the foundation for integrating multiple laboratory functions onto a single, compact device. These systems typically incorporate sample preparation, reagent mixing, separation, and detection processes within a miniaturized platform. The integration of microchannels allows for precise control over fluid flow, enabling efficient manipulation of small sample volumes and reagents.

One of the primary applications of fused borosilicate glass microchannels in lab-on-a-chip systems is in DNA analysis and sequencing. The microchannels provide a controlled environment for DNA amplification, separation, and detection, allowing for rapid and accurate genetic analysis. Additionally, these systems have been employed in protein analysis, cell sorting, and drug screening applications, offering high-throughput capabilities and reduced sample consumption.

The integration of fused borosilicate glass microchannels in lab-on-a-chip systems has also facilitated the development of point-of-care diagnostic devices. These portable systems enable rapid and on-site detection of various biomarkers, pathogens, and diseases, making them valuable tools in healthcare settings, particularly in resource-limited environments.

Furthermore, the optical properties of fused borosilicate glass microchannels have enabled the integration of advanced detection techniques, such as fluorescence microscopy and surface plasmon resonance, into lab-on-a-chip systems. This integration enhances the sensitivity and specificity of analytical processes, allowing for the detection of low-concentration analytes and the study of molecular interactions at the microscale.

The scalability and reproducibility of fused borosilicate glass microchannels have contributed to the development of standardized lab-on-a-chip platforms. These platforms can be easily customized for specific applications while maintaining consistent performance across different devices, facilitating their adoption in research and industrial settings.

As the field of microfluidics continues to advance, the integration of fused borosilicate glass microchannels in lab-on-a-chip systems is expected to expand further. Emerging applications include organ-on-a-chip models for drug development, environmental monitoring systems, and advanced biosensors for personalized medicine. The ongoing research in this area focuses on improving fabrication techniques, enhancing surface functionalization, and developing novel detection methods to unlock the full potential of these integrated systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!