Borosilicate Glass in Lab-on-a-chip Devices

JUL 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Borosilicate Glass LOC Evolution and Objectives

Borosilicate glass has emerged as a pivotal material in the development of Lab-on-a-chip (LOC) devices, revolutionizing the field of microfluidics and point-of-care diagnostics. The evolution of borosilicate glass in LOC applications can be traced back to the early 2000s when researchers began exploring alternatives to polymer-based microfluidic devices.

Initially, the primary objective was to overcome the limitations of polymer materials, such as poor chemical resistance and optical properties. Borosilicate glass, with its excellent chemical inertness, thermal stability, and optical transparency, presented a promising solution. The early goals focused on developing fabrication techniques that could effectively pattern and bond borosilicate glass substrates to create intricate microfluidic channels.

As the field progressed, the objectives expanded to include the integration of multiple functionalities within a single glass chip. Researchers aimed to incorporate various analytical processes, such as sample preparation, separation, and detection, onto a single glass platform. This led to the development of more complex LOC designs, including multi-layer structures and the integration of electrodes for electrokinetic manipulations.

The mid-2010s saw a shift towards enhancing the sensitivity and specificity of glass-based LOC devices. Objectives centered around surface modification techniques to improve biomolecule immobilization and reduce non-specific adsorption. Researchers also focused on developing novel detection methods compatible with glass substrates, such as surface-enhanced Raman spectroscopy (SERS) and electrochemical sensing.

In recent years, the focus has shifted towards scalability and cost-effectiveness. The objectives now include developing rapid prototyping methods for glass LOC devices and exploring ways to mass-produce these chips at a lower cost. This has led to innovations in glass micromachining techniques, such as femtosecond laser processing and powder blasting.

Looking ahead, the objectives for borosilicate glass in LOC devices are centered around achieving higher levels of integration and functionality. Researchers are exploring ways to incorporate active components, such as valves and pumps, directly into the glass substrate. There is also a growing interest in developing 3D glass microfluidic structures to enable more complex fluid manipulations and increase the overall functionality of the devices.

Another key objective is to improve the biocompatibility of glass LOC devices for applications in cell culture and organ-on-a-chip systems. This involves developing surface modification techniques that can promote cell adhesion and growth while maintaining the inherent advantages of glass substrates.

Initially, the primary objective was to overcome the limitations of polymer materials, such as poor chemical resistance and optical properties. Borosilicate glass, with its excellent chemical inertness, thermal stability, and optical transparency, presented a promising solution. The early goals focused on developing fabrication techniques that could effectively pattern and bond borosilicate glass substrates to create intricate microfluidic channels.

As the field progressed, the objectives expanded to include the integration of multiple functionalities within a single glass chip. Researchers aimed to incorporate various analytical processes, such as sample preparation, separation, and detection, onto a single glass platform. This led to the development of more complex LOC designs, including multi-layer structures and the integration of electrodes for electrokinetic manipulations.

The mid-2010s saw a shift towards enhancing the sensitivity and specificity of glass-based LOC devices. Objectives centered around surface modification techniques to improve biomolecule immobilization and reduce non-specific adsorption. Researchers also focused on developing novel detection methods compatible with glass substrates, such as surface-enhanced Raman spectroscopy (SERS) and electrochemical sensing.

In recent years, the focus has shifted towards scalability and cost-effectiveness. The objectives now include developing rapid prototyping methods for glass LOC devices and exploring ways to mass-produce these chips at a lower cost. This has led to innovations in glass micromachining techniques, such as femtosecond laser processing and powder blasting.

Looking ahead, the objectives for borosilicate glass in LOC devices are centered around achieving higher levels of integration and functionality. Researchers are exploring ways to incorporate active components, such as valves and pumps, directly into the glass substrate. There is also a growing interest in developing 3D glass microfluidic structures to enable more complex fluid manipulations and increase the overall functionality of the devices.

Another key objective is to improve the biocompatibility of glass LOC devices for applications in cell culture and organ-on-a-chip systems. This involves developing surface modification techniques that can promote cell adhesion and growth while maintaining the inherent advantages of glass substrates.

Market Analysis for Borosilicate Glass LOC Devices

The market for borosilicate glass lab-on-a-chip (LOC) devices is experiencing significant growth, driven by the increasing demand for miniaturized and integrated analytical systems in various fields, including healthcare, pharmaceuticals, and environmental monitoring. Borosilicate glass has emerged as a preferred material for LOC devices due to its excellent optical properties, chemical resistance, and thermal stability.

In the healthcare sector, the adoption of borosilicate glass LOC devices is rapidly expanding, particularly in point-of-care diagnostics and personalized medicine applications. These devices offer rapid, cost-effective, and portable solutions for disease detection and monitoring, addressing the growing need for decentralized healthcare services. The pharmaceutical industry is also leveraging borosilicate glass LOC devices for drug discovery and development processes, enabling high-throughput screening and reducing the time and cost associated with traditional methods.

Environmental monitoring represents another significant market segment for borosilicate glass LOC devices. These devices are increasingly used for water quality analysis, air pollution detection, and soil contamination assessment, providing real-time and on-site monitoring capabilities. The food and beverage industry is also adopting these devices for quality control and safety testing, further expanding the market potential.

The global market for microfluidic devices, which includes borosilicate glass LOC devices, is projected to grow substantially in the coming years. This growth is attributed to the increasing investment in research and development, the rising prevalence of chronic diseases, and the growing demand for point-of-care diagnostics. Additionally, the ongoing technological advancements in microfabrication techniques and the integration of advanced functionalities, such as optical and electrical sensing, are expected to further drive market expansion.

Geographically, North America and Europe currently dominate the market for borosilicate glass LOC devices, owing to the presence of well-established healthcare infrastructure and significant research and development activities. However, the Asia-Pacific region is anticipated to witness the highest growth rate in the coming years, fueled by increasing healthcare expenditure, rising awareness about personalized medicine, and growing investment in life sciences research.

Despite the promising market outlook, challenges such as high initial costs, complex manufacturing processes, and the need for specialized expertise in device design and fabrication may hinder market growth to some extent. However, ongoing efforts to develop cost-effective manufacturing techniques and the increasing collaboration between academic institutions and industry players are expected to address these challenges and further propel market expansion.

In the healthcare sector, the adoption of borosilicate glass LOC devices is rapidly expanding, particularly in point-of-care diagnostics and personalized medicine applications. These devices offer rapid, cost-effective, and portable solutions for disease detection and monitoring, addressing the growing need for decentralized healthcare services. The pharmaceutical industry is also leveraging borosilicate glass LOC devices for drug discovery and development processes, enabling high-throughput screening and reducing the time and cost associated with traditional methods.

Environmental monitoring represents another significant market segment for borosilicate glass LOC devices. These devices are increasingly used for water quality analysis, air pollution detection, and soil contamination assessment, providing real-time and on-site monitoring capabilities. The food and beverage industry is also adopting these devices for quality control and safety testing, further expanding the market potential.

The global market for microfluidic devices, which includes borosilicate glass LOC devices, is projected to grow substantially in the coming years. This growth is attributed to the increasing investment in research and development, the rising prevalence of chronic diseases, and the growing demand for point-of-care diagnostics. Additionally, the ongoing technological advancements in microfabrication techniques and the integration of advanced functionalities, such as optical and electrical sensing, are expected to further drive market expansion.

Geographically, North America and Europe currently dominate the market for borosilicate glass LOC devices, owing to the presence of well-established healthcare infrastructure and significant research and development activities. However, the Asia-Pacific region is anticipated to witness the highest growth rate in the coming years, fueled by increasing healthcare expenditure, rising awareness about personalized medicine, and growing investment in life sciences research.

Despite the promising market outlook, challenges such as high initial costs, complex manufacturing processes, and the need for specialized expertise in device design and fabrication may hinder market growth to some extent. However, ongoing efforts to develop cost-effective manufacturing techniques and the increasing collaboration between academic institutions and industry players are expected to address these challenges and further propel market expansion.

Current Challenges in Borosilicate Glass LOC Fabrication

The fabrication of Lab-on-a-chip (LOC) devices using borosilicate glass presents several significant challenges that researchers and manufacturers must overcome. One of the primary obstacles is the high-temperature processing required for borosilicate glass, which typically involves temperatures exceeding 600°C. This necessitates specialized equipment and facilities, increasing production costs and complexity.

Another major challenge lies in the precise microfabrication of channels and structures within the borosilicate glass. Traditional methods like wet etching often result in isotropic profiles, making it difficult to achieve high-aspect-ratio features crucial for many LOC applications. While techniques such as deep reactive ion etching (DRIE) can produce more anisotropic profiles, they are often less effective on glass compared to silicon substrates.

Bonding is another critical issue in borosilicate glass LOC fabrication. Achieving hermetic seals between glass layers or between glass and other materials (e.g., silicon or polymers) without compromising the integrity of microfluidic channels is technically demanding. Common bonding methods like anodic bonding or fusion bonding require careful control of temperature and pressure, which can lead to channel deformation or collapse.

The integration of functional components, such as electrodes or sensors, into borosilicate glass LOC devices poses additional challenges. The high processing temperatures of glass can damage or alter these components, necessitating innovative approaches to incorporate them without compromising their functionality or the overall device performance.

Surface modification of borosilicate glass for specific LOC applications is also challenging. Achieving consistent and stable surface properties, such as hydrophobicity or biocompatibility, across the entire microfluidic network requires precise control of surface chemistry and often involves complex multi-step processes.

Scaling up production while maintaining quality and reproducibility remains a significant hurdle. The intricate nature of LOC devices demands high precision in every fabrication step, which becomes increasingly difficult to maintain in large-scale manufacturing scenarios. This challenge is particularly pronounced for borosilicate glass due to its rigid nature and high processing requirements.

Lastly, the cost-effectiveness of borosilicate glass LOC devices compared to alternatives like polymer-based systems is a persistent challenge. While glass offers superior optical and chemical properties, the higher material and processing costs can limit its adoption in certain applications, especially where low-cost, disposable devices are preferred.

Another major challenge lies in the precise microfabrication of channels and structures within the borosilicate glass. Traditional methods like wet etching often result in isotropic profiles, making it difficult to achieve high-aspect-ratio features crucial for many LOC applications. While techniques such as deep reactive ion etching (DRIE) can produce more anisotropic profiles, they are often less effective on glass compared to silicon substrates.

Bonding is another critical issue in borosilicate glass LOC fabrication. Achieving hermetic seals between glass layers or between glass and other materials (e.g., silicon or polymers) without compromising the integrity of microfluidic channels is technically demanding. Common bonding methods like anodic bonding or fusion bonding require careful control of temperature and pressure, which can lead to channel deformation or collapse.

The integration of functional components, such as electrodes or sensors, into borosilicate glass LOC devices poses additional challenges. The high processing temperatures of glass can damage or alter these components, necessitating innovative approaches to incorporate them without compromising their functionality or the overall device performance.

Surface modification of borosilicate glass for specific LOC applications is also challenging. Achieving consistent and stable surface properties, such as hydrophobicity or biocompatibility, across the entire microfluidic network requires precise control of surface chemistry and often involves complex multi-step processes.

Scaling up production while maintaining quality and reproducibility remains a significant hurdle. The intricate nature of LOC devices demands high precision in every fabrication step, which becomes increasingly difficult to maintain in large-scale manufacturing scenarios. This challenge is particularly pronounced for borosilicate glass due to its rigid nature and high processing requirements.

Lastly, the cost-effectiveness of borosilicate glass LOC devices compared to alternatives like polymer-based systems is a persistent challenge. While glass offers superior optical and chemical properties, the higher material and processing costs can limit its adoption in certain applications, especially where low-cost, disposable devices are preferred.

Existing Borosilicate Glass LOC Fabrication Techniques

01 Composition and properties of borosilicate glass

Borosilicate glass is a type of glass with silica and boron trioxide as the main glass-forming constituents. It is known for its low thermal expansion coefficient, high chemical resistance, and excellent thermal shock resistance. These properties make it suitable for various applications in laboratory equipment, cookware, and industrial uses.- Composition and properties of borosilicate glass: Borosilicate glass is a type of glass with silica and boron trioxide as the main glass-forming constituents. It is known for its low thermal expansion coefficient, high chemical resistance, and excellent thermal shock resistance. These properties make it suitable for various applications in laboratory equipment, cookware, and industrial uses.

- Manufacturing processes for borosilicate glass: Various manufacturing processes are employed to produce borosilicate glass, including melting, forming, and annealing. Advanced techniques such as float glass production and precision molding are used to create different forms of borosilicate glass products. The manufacturing process can be optimized to enhance specific properties of the glass.

- Applications of borosilicate glass in laboratory and industrial settings: Borosilicate glass is widely used in laboratory glassware, such as beakers, test tubes, and pipettes, due to its chemical resistance and thermal stability. It is also utilized in industrial applications, including chemical processing equipment, sight glasses, and high-temperature windows. The glass's properties make it ideal for environments requiring durability and resistance to thermal shock.

- Borosilicate glass in consumer products: Borosilicate glass is increasingly used in consumer products, particularly in cookware and food storage containers. Its low thermal expansion coefficient makes it resistant to cracking under temperature changes, making it suitable for oven-to-table use. Additionally, it is used in high-quality drinkware and coffee brewing equipment due to its clarity and durability.

- Innovations and modifications in borosilicate glass: Ongoing research and development in borosilicate glass focus on improving its properties and expanding its applications. This includes developing new compositions with enhanced characteristics, such as increased strength or improved optical properties. Innovations also involve surface treatments, coatings, and the incorporation of additional elements to tailor the glass for specific uses in areas like optics, electronics, and renewable energy.

02 Manufacturing processes for borosilicate glass

Various manufacturing processes are employed to produce borosilicate glass, including melting, forming, and annealing. Advanced techniques such as float glass production and precision molding are used to create different forms of borosilicate glass products. The manufacturing process often involves careful control of temperature and composition to achieve desired properties.Expand Specific Solutions03 Applications of borosilicate glass in laboratory and industrial settings

Borosilicate glass is widely used in laboratory glassware, such as beakers, test tubes, and pipettes, due to its chemical resistance and thermal stability. It is also employed in industrial applications, including sight glasses, process vessels, and heat exchangers. The material's durability and transparency make it ideal for these demanding environments.Expand Specific Solutions04 Borosilicate glass in consumer products

Borosilicate glass is increasingly used in consumer products, particularly in kitchenware and household items. Its heat resistance and durability make it suitable for bakeware, storage containers, and coffee makers. The glass is also used in lighting fixtures and solar energy applications due to its optical properties and thermal performance.Expand Specific Solutions05 Innovations and modifications in borosilicate glass

Ongoing research and development in borosilicate glass focus on improving its properties and expanding its applications. This includes developing new compositions with enhanced characteristics, such as increased strength or improved optical properties. Innovations also involve surface treatments, coatings, and the incorporation of additional elements to tailor the glass for specific uses.Expand Specific Solutions

Key Players in Borosilicate Glass LOC Industry

The research on borosilicate glass in lab-on-a-chip devices is in a growth phase, with increasing market size and technological advancements. The global lab-on-a-chip market is expanding rapidly, driven by demand for point-of-care diagnostics and miniaturized analytical systems. Key players like SCHOTT AG, Corning, Inc., and Applied Materials, Inc. are at the forefront of developing advanced borosilicate glass solutions for microfluidic applications. These companies are leveraging their expertise in materials science and manufacturing to improve the performance and reliability of lab-on-a-chip devices. The technology is maturing, with ongoing research focused on enhancing glass properties, surface modifications, and integration with other materials to optimize device functionality and production scalability.

SCHOTT AG

Technical Solution: SCHOTT AG has developed advanced borosilicate glass solutions specifically tailored for lab-on-a-chip devices. Their BOROFLOAT® glass is widely used in microfluidic applications due to its excellent thermal and chemical resistance[1]. The company has implemented precision manufacturing techniques to produce glass wafers with extremely flat and smooth surfaces, crucial for microfluidic channel formation. SCHOTT's borosilicate glass offers high transparency in the visible and near-infrared spectrum, enabling optical detection methods in lab-on-a-chip devices[2]. They have also developed specialized coating technologies to modify surface properties, enhancing fluid control and biocompatibility in microfluidic systems[3].

Strengths: High-quality borosilicate glass with excellent optical and chemical properties, specialized for microfluidics. Weaknesses: Potentially higher cost compared to polymer alternatives, may require specialized processing equipment.

Corning, Inc.

Technical Solution: Corning has pioneered the development of Valor® Glass, a specialized borosilicate glass formulation designed for pharmaceutical packaging but with potential applications in lab-on-a-chip devices. This glass offers superior chemical durability and strength, reducing the risk of breakage and contamination in microfluidic systems[4]. Corning has also developed advanced manufacturing processes for producing ultra-thin glass sheets, which can be used as substrates for lab-on-a-chip devices. Their expertise in fusion draw process allows for the production of glass with exceptional flatness and surface quality, critical for precise microfluidic channel fabrication[5]. Additionally, Corning has invested in surface modification technologies to enhance the compatibility of their glass with various biological samples and reagents used in lab-on-a-chip applications[6].

Strengths: Extensive experience in glass manufacturing, ability to produce ultra-thin and high-quality glass substrates. Weaknesses: Primary focus on larger-scale applications may limit specialized solutions for lab-on-a-chip devices.

Innovations in Borosilicate Glass LOC Materials

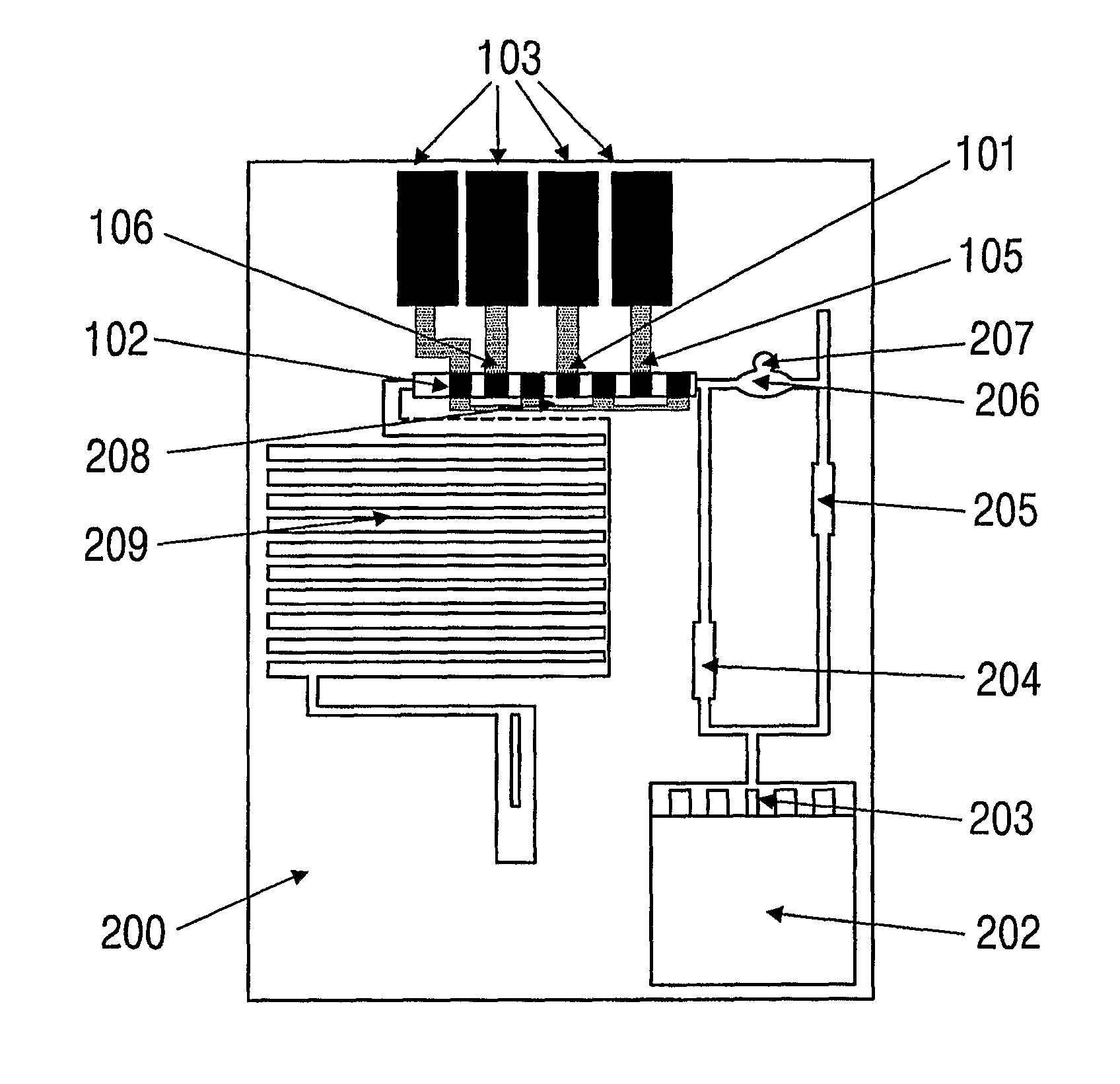

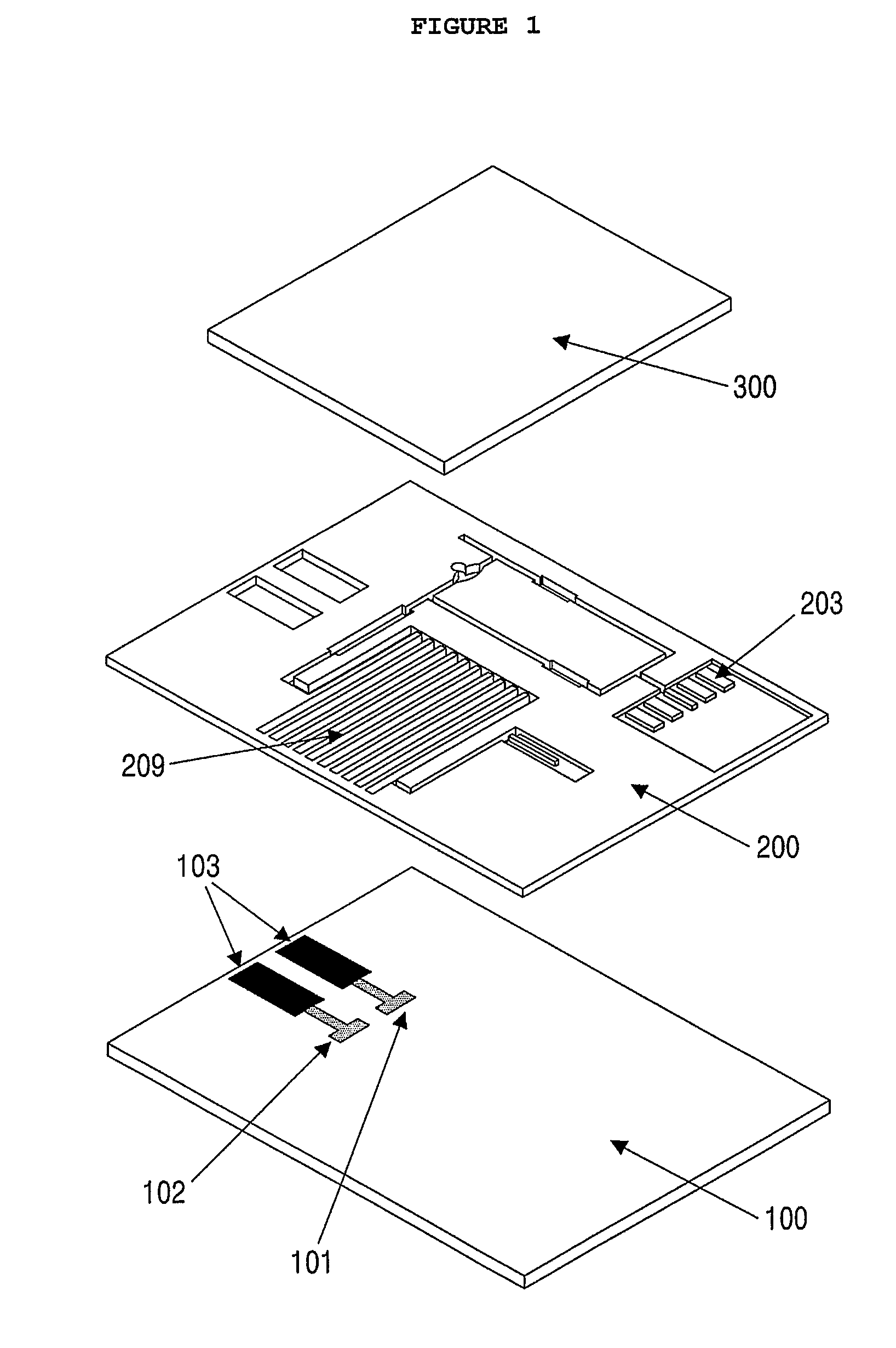

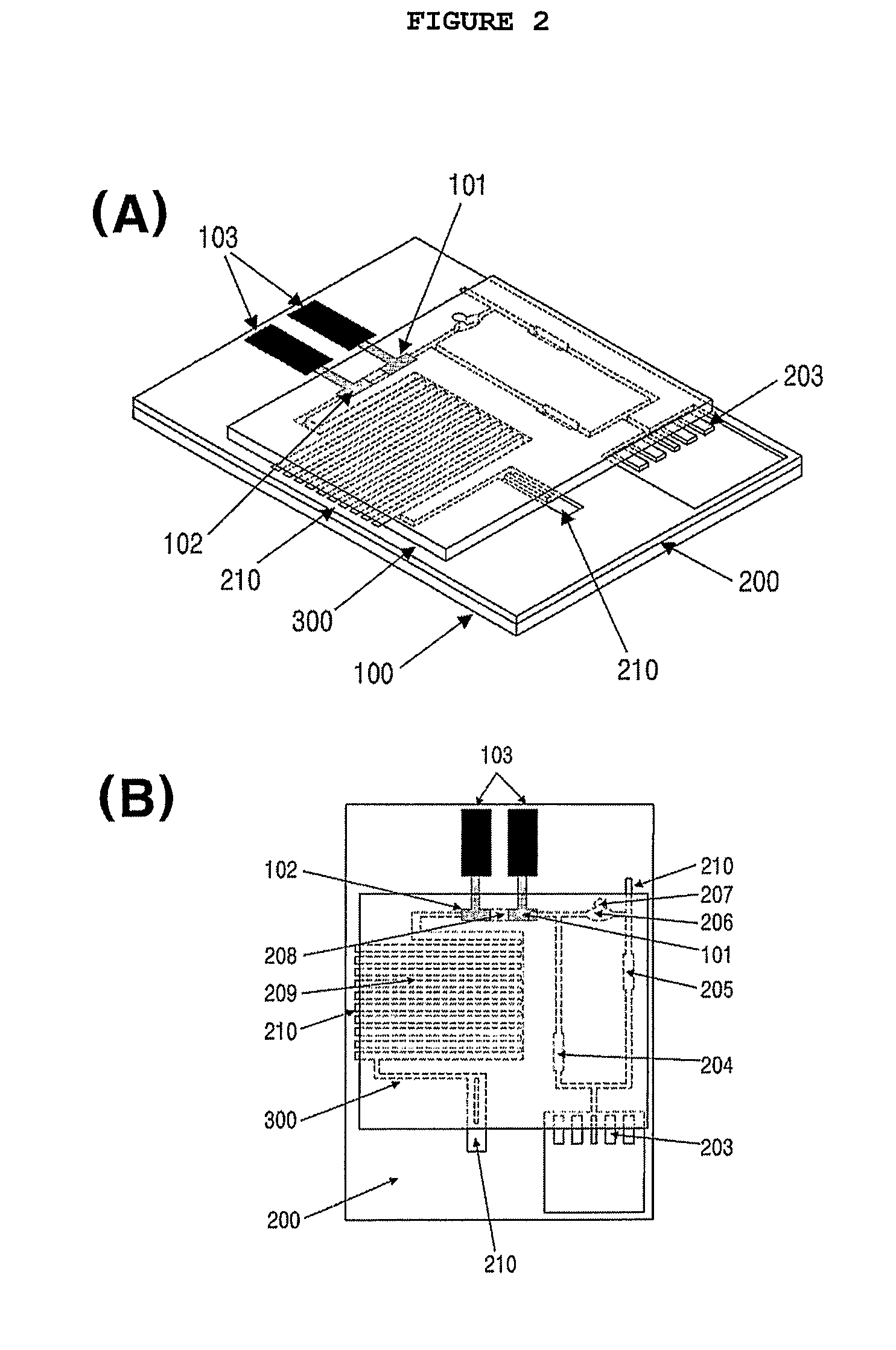

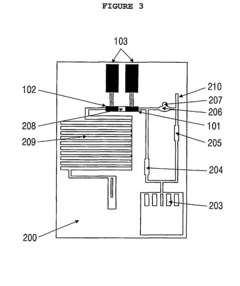

Microfluidic sensor complex structure

PatentActiveUS8337683B2

Innovation

- A microfluidic sensor complex structure is developed, featuring a simple design with capillary-driven sample flow through channels and reservoirs containing antibody-enzyme conjugates and signal-generating substrates, allowing for immune response, washing, and electrochemical analysis in a single step, using a laminate structure with reference and working electrodes and a capillary phenomenon to drive sample movement.

Method for the production of borosilicate glass with a surface suitable for modification glass obtained according to said method and the use thereof

PatentInactiveUS7155934B2

Innovation

- Adding water to melted borosilicate glass in a hydrous atmosphere, preferably using the oxyfuel technique, to increase the water content and form reactive SiOH groups, resulting in a glass with a high density of reactive spots suitable for modification and low fluorescence.

Biocompatibility and Safety Considerations

Biocompatibility and safety considerations are paramount in the development and application of borosilicate glass for lab-on-a-chip devices. The use of borosilicate glass in these microfluidic systems necessitates a thorough evaluation of its interaction with biological samples and its potential impact on the accuracy and reliability of analytical results.

One of the primary advantages of borosilicate glass in lab-on-a-chip devices is its inherent biocompatibility. The material's chemical inertness and resistance to corrosion make it suitable for handling a wide range of biological samples without risking contamination or unwanted reactions. This property is particularly crucial when working with sensitive biological materials such as proteins, DNA, or living cells, as it helps maintain sample integrity throughout the analysis process.

However, the biocompatibility of borosilicate glass can be influenced by surface modifications and treatments applied during the manufacturing process. Researchers must carefully consider the potential effects of these modifications on the material's interaction with biological samples. For instance, surface functionalization techniques used to enhance specific properties of the glass may inadvertently introduce chemical groups that could interfere with certain biological processes or alter the behavior of target analytes.

Safety considerations extend beyond biocompatibility to include the physical properties of borosilicate glass in lab-on-a-chip devices. The material's brittleness and potential for sharp edges if fractured must be addressed in device design and handling protocols. Researchers and end-users must be aware of proper handling techniques to minimize the risk of breakage and potential injuries.

Furthermore, the thermal properties of borosilicate glass play a significant role in safety considerations. While the material's low coefficient of thermal expansion contributes to its stability under varying temperature conditions, extreme temperature changes or localized heating during certain analytical processes may still pose risks. Proper thermal management strategies must be implemented to prevent stress-induced fractures or deformations that could compromise device integrity and user safety.

In the context of lab-on-a-chip applications, the potential for sample retention or carryover between analyses is another critical safety consideration. The surface properties of borosilicate glass must be carefully evaluated to ensure that residual biological materials or chemical compounds do not persist between tests, which could lead to cross-contamination and erroneous results. This aspect is particularly crucial in diagnostic applications where accuracy and reliability are paramount.

Lastly, the long-term stability and degradation characteristics of borosilicate glass in lab-on-a-chip devices must be thoroughly assessed. While the material is known for its chemical durability, prolonged exposure to certain reagents or environmental conditions may gradually affect its surface properties or structural integrity. Understanding these long-term effects is essential for ensuring the continued safety and reliability of devices throughout their intended lifespan.

One of the primary advantages of borosilicate glass in lab-on-a-chip devices is its inherent biocompatibility. The material's chemical inertness and resistance to corrosion make it suitable for handling a wide range of biological samples without risking contamination or unwanted reactions. This property is particularly crucial when working with sensitive biological materials such as proteins, DNA, or living cells, as it helps maintain sample integrity throughout the analysis process.

However, the biocompatibility of borosilicate glass can be influenced by surface modifications and treatments applied during the manufacturing process. Researchers must carefully consider the potential effects of these modifications on the material's interaction with biological samples. For instance, surface functionalization techniques used to enhance specific properties of the glass may inadvertently introduce chemical groups that could interfere with certain biological processes or alter the behavior of target analytes.

Safety considerations extend beyond biocompatibility to include the physical properties of borosilicate glass in lab-on-a-chip devices. The material's brittleness and potential for sharp edges if fractured must be addressed in device design and handling protocols. Researchers and end-users must be aware of proper handling techniques to minimize the risk of breakage and potential injuries.

Furthermore, the thermal properties of borosilicate glass play a significant role in safety considerations. While the material's low coefficient of thermal expansion contributes to its stability under varying temperature conditions, extreme temperature changes or localized heating during certain analytical processes may still pose risks. Proper thermal management strategies must be implemented to prevent stress-induced fractures or deformations that could compromise device integrity and user safety.

In the context of lab-on-a-chip applications, the potential for sample retention or carryover between analyses is another critical safety consideration. The surface properties of borosilicate glass must be carefully evaluated to ensure that residual biological materials or chemical compounds do not persist between tests, which could lead to cross-contamination and erroneous results. This aspect is particularly crucial in diagnostic applications where accuracy and reliability are paramount.

Lastly, the long-term stability and degradation characteristics of borosilicate glass in lab-on-a-chip devices must be thoroughly assessed. While the material is known for its chemical durability, prolonged exposure to certain reagents or environmental conditions may gradually affect its surface properties or structural integrity. Understanding these long-term effects is essential for ensuring the continued safety and reliability of devices throughout their intended lifespan.

Cost-Effectiveness Analysis of Borosilicate Glass LOC

The cost-effectiveness analysis of borosilicate glass in Lab-on-a-chip (LOC) devices is a crucial consideration for both researchers and manufacturers in the field of microfluidics. Borosilicate glass has emerged as a popular material choice for LOC devices due to its unique properties and versatility in various applications.

When evaluating the cost-effectiveness of borosilicate glass LOC devices, it is essential to consider both the initial manufacturing costs and the long-term benefits. The production process of borosilicate glass LOC devices typically involves microfabrication techniques such as photolithography, wet etching, and bonding. While these processes can be more expensive compared to polymer-based alternatives, the durability and reusability of glass devices often offset the initial investment.

One of the primary advantages of borosilicate glass is its excellent optical properties, including high transparency and low autofluorescence. These characteristics are particularly valuable in applications requiring sensitive optical detection, such as fluorescence-based assays. The superior optical performance of glass LOC devices can lead to improved detection limits and overall analytical sensitivity, potentially reducing the need for expensive detection equipment or complex sample preparation steps.

The chemical inertness of borosilicate glass is another factor contributing to its cost-effectiveness. Unlike some polymer materials, glass is resistant to a wide range of chemicals and solvents, making it suitable for diverse applications in chemistry and biology. This chemical stability allows for the use of harsh cleaning protocols and sterilization methods, extending the lifespan of the devices and reducing the need for frequent replacements.

Thermal stability is a significant advantage of borosilicate glass LOC devices, particularly in applications involving temperature-sensitive reactions or thermal cycling. The low coefficient of thermal expansion of borosilicate glass ensures minimal deformation and maintains the integrity of microfluidic channels during temperature changes. This stability can lead to more consistent results and reduced experimental variability, potentially saving time and resources in research and development processes.

While the initial cost of borosilicate glass LOC devices may be higher than some alternatives, the long-term cost-effectiveness becomes apparent when considering factors such as device longevity, reusability, and performance consistency. The ability to reuse glass devices multiple times, coupled with their resistance to degradation, can significantly reduce the overall cost per experiment compared to disposable polymer-based devices.

In conclusion, the cost-effectiveness analysis of borosilicate glass LOC devices reveals a favorable balance between initial investment and long-term benefits. The superior optical, chemical, and thermal properties of borosilicate glass contribute to improved experimental outcomes and device longevity, ultimately leading to cost savings and enhanced research capabilities in microfluidic applications.

When evaluating the cost-effectiveness of borosilicate glass LOC devices, it is essential to consider both the initial manufacturing costs and the long-term benefits. The production process of borosilicate glass LOC devices typically involves microfabrication techniques such as photolithography, wet etching, and bonding. While these processes can be more expensive compared to polymer-based alternatives, the durability and reusability of glass devices often offset the initial investment.

One of the primary advantages of borosilicate glass is its excellent optical properties, including high transparency and low autofluorescence. These characteristics are particularly valuable in applications requiring sensitive optical detection, such as fluorescence-based assays. The superior optical performance of glass LOC devices can lead to improved detection limits and overall analytical sensitivity, potentially reducing the need for expensive detection equipment or complex sample preparation steps.

The chemical inertness of borosilicate glass is another factor contributing to its cost-effectiveness. Unlike some polymer materials, glass is resistant to a wide range of chemicals and solvents, making it suitable for diverse applications in chemistry and biology. This chemical stability allows for the use of harsh cleaning protocols and sterilization methods, extending the lifespan of the devices and reducing the need for frequent replacements.

Thermal stability is a significant advantage of borosilicate glass LOC devices, particularly in applications involving temperature-sensitive reactions or thermal cycling. The low coefficient of thermal expansion of borosilicate glass ensures minimal deformation and maintains the integrity of microfluidic channels during temperature changes. This stability can lead to more consistent results and reduced experimental variability, potentially saving time and resources in research and development processes.

While the initial cost of borosilicate glass LOC devices may be higher than some alternatives, the long-term cost-effectiveness becomes apparent when considering factors such as device longevity, reusability, and performance consistency. The ability to reuse glass devices multiple times, coupled with their resistance to degradation, can significantly reduce the overall cost per experiment compared to disposable polymer-based devices.

In conclusion, the cost-effectiveness analysis of borosilicate glass LOC devices reveals a favorable balance between initial investment and long-term benefits. The superior optical, chemical, and thermal properties of borosilicate glass contribute to improved experimental outcomes and device longevity, ultimately leading to cost savings and enhanced research capabilities in microfluidic applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!