Thermal Barrier Coatings Incorporating Borosilicate Glass

JUL 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

TBC-Borosilicate Glass Background and Objectives

Thermal Barrier Coatings (TBCs) have been a critical technology in high-temperature applications, particularly in gas turbine engines, for several decades. These coatings provide thermal insulation to metallic components, allowing them to operate at higher temperatures and thus improving overall system efficiency. The evolution of TBC technology has been driven by the continuous demand for increased engine performance and durability.

Borosilicate glass, known for its excellent thermal properties and chemical stability, has recently emerged as a promising material for incorporation into TBCs. This innovative approach aims to address some of the limitations of conventional TBC systems, such as sintering at high temperatures and susceptibility to environmental attack.

The primary objective of research on TBCs incorporating borosilicate glass is to develop a new generation of coatings with enhanced performance characteristics. These include improved thermal insulation, better resistance to sintering, increased durability under extreme conditions, and potentially self-healing properties. By integrating borosilicate glass into the TBC structure, researchers aim to create a composite material that combines the benefits of traditional ceramic TBCs with the unique properties of glass.

The development of this technology is driven by several factors in the aerospace and power generation industries. There is a growing need for materials that can withstand higher operating temperatures, as this directly translates to improved fuel efficiency and reduced emissions. Additionally, the demand for longer-lasting components and reduced maintenance costs in gas turbine engines has spurred interest in more durable coating systems.

From a historical perspective, the incorporation of glass into TBCs represents a significant shift in material design philosophy. Traditional TBCs have primarily relied on ceramic materials such as yttria-stabilized zirconia (YSZ). The introduction of borosilicate glass into this field opens up new possibilities for tailoring the microstructure and properties of these coatings at a fundamental level.

The research in this area is expected to yield insights into the behavior of glass-ceramic composites under extreme conditions, potentially leading to applications beyond TBCs. As the technology progresses, it may find use in other high-temperature environments, such as in the nuclear industry or in advanced manufacturing processes.

In conclusion, the research on TBCs incorporating borosilicate glass represents a cutting-edge approach to addressing long-standing challenges in high-temperature materials. By combining the established benefits of TBCs with the unique properties of borosilicate glass, this research aims to push the boundaries of what is possible in thermal protection systems, potentially revolutionizing the field of high-temperature materials.

Borosilicate glass, known for its excellent thermal properties and chemical stability, has recently emerged as a promising material for incorporation into TBCs. This innovative approach aims to address some of the limitations of conventional TBC systems, such as sintering at high temperatures and susceptibility to environmental attack.

The primary objective of research on TBCs incorporating borosilicate glass is to develop a new generation of coatings with enhanced performance characteristics. These include improved thermal insulation, better resistance to sintering, increased durability under extreme conditions, and potentially self-healing properties. By integrating borosilicate glass into the TBC structure, researchers aim to create a composite material that combines the benefits of traditional ceramic TBCs with the unique properties of glass.

The development of this technology is driven by several factors in the aerospace and power generation industries. There is a growing need for materials that can withstand higher operating temperatures, as this directly translates to improved fuel efficiency and reduced emissions. Additionally, the demand for longer-lasting components and reduced maintenance costs in gas turbine engines has spurred interest in more durable coating systems.

From a historical perspective, the incorporation of glass into TBCs represents a significant shift in material design philosophy. Traditional TBCs have primarily relied on ceramic materials such as yttria-stabilized zirconia (YSZ). The introduction of borosilicate glass into this field opens up new possibilities for tailoring the microstructure and properties of these coatings at a fundamental level.

The research in this area is expected to yield insights into the behavior of glass-ceramic composites under extreme conditions, potentially leading to applications beyond TBCs. As the technology progresses, it may find use in other high-temperature environments, such as in the nuclear industry or in advanced manufacturing processes.

In conclusion, the research on TBCs incorporating borosilicate glass represents a cutting-edge approach to addressing long-standing challenges in high-temperature materials. By combining the established benefits of TBCs with the unique properties of borosilicate glass, this research aims to push the boundaries of what is possible in thermal protection systems, potentially revolutionizing the field of high-temperature materials.

Market Analysis for Advanced TBCs

The market for advanced Thermal Barrier Coatings (TBCs) incorporating borosilicate glass is experiencing significant growth, driven by increasing demand in aerospace, power generation, and automotive industries. These industries require materials that can withstand extreme temperatures and harsh operating conditions, making advanced TBCs a critical component in enhancing the performance and longevity of various high-temperature applications.

In the aerospace sector, the demand for advanced TBCs is particularly strong due to the continuous push for more fuel-efficient and higher-performing aircraft engines. The incorporation of borosilicate glass in TBCs offers improved thermal insulation properties and enhanced durability, which are crucial for next-generation turbine engines operating at higher temperatures.

The power generation industry is another key market for advanced TBCs, especially in gas turbines used for electricity production. As the industry moves towards more efficient and cleaner energy production, the need for materials that can withstand higher operating temperatures becomes paramount. TBCs with borosilicate glass additives provide superior thermal protection, potentially leading to increased turbine efficiency and reduced emissions.

In the automotive sector, the growing trend towards electric vehicles and the continued development of high-performance internal combustion engines are driving the demand for advanced thermal management solutions. TBCs incorporating borosilicate glass offer potential applications in exhaust systems, cylinder linings, and other high-temperature components, contributing to improved engine efficiency and reduced heat loss.

The global market for advanced TBCs is expected to show steady growth over the next decade. This growth is fueled by ongoing research and development efforts to improve coating performance, durability, and cost-effectiveness. The incorporation of borosilicate glass in TBCs represents a promising avenue for achieving these improvements, potentially opening up new market opportunities and applications.

However, challenges remain in terms of manufacturing scalability and cost-effectiveness of these advanced coatings. Overcoming these hurdles will be crucial for widespread adoption across industries. Additionally, the market is likely to see increased competition as more players enter the field, driving innovation and potentially leading to more cost-effective solutions.

In the aerospace sector, the demand for advanced TBCs is particularly strong due to the continuous push for more fuel-efficient and higher-performing aircraft engines. The incorporation of borosilicate glass in TBCs offers improved thermal insulation properties and enhanced durability, which are crucial for next-generation turbine engines operating at higher temperatures.

The power generation industry is another key market for advanced TBCs, especially in gas turbines used for electricity production. As the industry moves towards more efficient and cleaner energy production, the need for materials that can withstand higher operating temperatures becomes paramount. TBCs with borosilicate glass additives provide superior thermal protection, potentially leading to increased turbine efficiency and reduced emissions.

In the automotive sector, the growing trend towards electric vehicles and the continued development of high-performance internal combustion engines are driving the demand for advanced thermal management solutions. TBCs incorporating borosilicate glass offer potential applications in exhaust systems, cylinder linings, and other high-temperature components, contributing to improved engine efficiency and reduced heat loss.

The global market for advanced TBCs is expected to show steady growth over the next decade. This growth is fueled by ongoing research and development efforts to improve coating performance, durability, and cost-effectiveness. The incorporation of borosilicate glass in TBCs represents a promising avenue for achieving these improvements, potentially opening up new market opportunities and applications.

However, challenges remain in terms of manufacturing scalability and cost-effectiveness of these advanced coatings. Overcoming these hurdles will be crucial for widespread adoption across industries. Additionally, the market is likely to see increased competition as more players enter the field, driving innovation and potentially leading to more cost-effective solutions.

Current Challenges in TBC-Borosilicate Glass Integration

The integration of borosilicate glass into Thermal Barrier Coatings (TBCs) presents several significant challenges that researchers and engineers are currently grappling with. One of the primary obstacles is achieving optimal adhesion between the borosilicate glass and the ceramic matrix of the TBC. The difference in thermal expansion coefficients between these materials can lead to stress buildup and potential delamination during thermal cycling, compromising the coating's integrity and performance.

Another critical challenge lies in maintaining the desired porosity of the TBC while incorporating borosilicate glass. The traditional porous structure of TBCs is crucial for their thermal insulation properties. However, the introduction of borosilicate glass can potentially fill these pores, reducing the coating's overall effectiveness as a thermal barrier. Striking the right balance between glass content and porosity preservation remains a complex task.

The high-temperature stability of the borosilicate glass within the TBC environment is also a concern. While borosilicate glass is known for its relatively high heat resistance, the extreme temperatures experienced in turbine engines push the limits of its capabilities. Researchers are working to develop compositions that can withstand these harsh conditions without degradation or phase changes that could compromise the coating's performance.

Uniformity in glass distribution throughout the TBC is another challenge that needs to be addressed. Ensuring a homogeneous dispersion of borosilicate glass within the ceramic matrix is crucial for consistent performance across the entire coated surface. Non-uniform distribution can lead to localized weaknesses and variations in thermal and mechanical properties.

The processing techniques for incorporating borosilicate glass into TBCs also present challenges. Traditional methods of TBC deposition, such as plasma spraying or electron beam physical vapor deposition, may need to be modified or entirely new techniques developed to effectively integrate the glass component. This includes considerations for controlling the glass viscosity during deposition and ensuring proper bonding with the ceramic matrix.

Long-term durability and resistance to environmental factors pose additional challenges. The TBC-borosilicate glass system must withstand not only high temperatures but also corrosive environments, oxidation, and erosion from particulates. Developing a coating that maintains its protective properties over extended periods under these harsh conditions is a significant hurdle.

Lastly, the cost-effectiveness and scalability of producing TBCs with borosilicate glass on an industrial scale remain challenges. While the potential benefits are promising, the manufacturing processes must be economically viable and capable of meeting the high-volume demands of the aerospace and energy sectors.

Another critical challenge lies in maintaining the desired porosity of the TBC while incorporating borosilicate glass. The traditional porous structure of TBCs is crucial for their thermal insulation properties. However, the introduction of borosilicate glass can potentially fill these pores, reducing the coating's overall effectiveness as a thermal barrier. Striking the right balance between glass content and porosity preservation remains a complex task.

The high-temperature stability of the borosilicate glass within the TBC environment is also a concern. While borosilicate glass is known for its relatively high heat resistance, the extreme temperatures experienced in turbine engines push the limits of its capabilities. Researchers are working to develop compositions that can withstand these harsh conditions without degradation or phase changes that could compromise the coating's performance.

Uniformity in glass distribution throughout the TBC is another challenge that needs to be addressed. Ensuring a homogeneous dispersion of borosilicate glass within the ceramic matrix is crucial for consistent performance across the entire coated surface. Non-uniform distribution can lead to localized weaknesses and variations in thermal and mechanical properties.

The processing techniques for incorporating borosilicate glass into TBCs also present challenges. Traditional methods of TBC deposition, such as plasma spraying or electron beam physical vapor deposition, may need to be modified or entirely new techniques developed to effectively integrate the glass component. This includes considerations for controlling the glass viscosity during deposition and ensuring proper bonding with the ceramic matrix.

Long-term durability and resistance to environmental factors pose additional challenges. The TBC-borosilicate glass system must withstand not only high temperatures but also corrosive environments, oxidation, and erosion from particulates. Developing a coating that maintains its protective properties over extended periods under these harsh conditions is a significant hurdle.

Lastly, the cost-effectiveness and scalability of producing TBCs with borosilicate glass on an industrial scale remain challenges. While the potential benefits are promising, the manufacturing processes must be economically viable and capable of meeting the high-volume demands of the aerospace and energy sectors.

Existing TBC-Borosilicate Glass Incorporation Methods

01 Composition and structure of thermal barrier coatings

Thermal barrier coatings typically consist of multiple layers, including a ceramic top coat and a metallic bond coat. The ceramic top coat, often made of yttria-stabilized zirconia (YSZ), provides thermal insulation, while the bond coat improves adhesion and oxidation resistance. The structure and composition of these layers are crucial for the coating's performance and durability in high-temperature environments.- Composition of thermal barrier coatings: Thermal barrier coatings typically consist of ceramic materials with low thermal conductivity, such as yttria-stabilized zirconia (YSZ). These coatings are applied to metal substrates to provide thermal insulation and protection against high-temperature environments. The composition may also include bond coats and top coats with specific properties to enhance durability and performance.

- Application methods for thermal barrier coatings: Various techniques are used to apply thermal barrier coatings, including plasma spraying, electron beam physical vapor deposition (EB-PVD), and solution precursor plasma spray (SPPS). These methods allow for precise control of coating thickness, microstructure, and properties. The choice of application method depends on the specific requirements of the component and its operating conditions.

- Microstructure and porosity control: The performance of thermal barrier coatings is greatly influenced by their microstructure and porosity. Controlling these factors during the coating process can enhance thermal insulation properties, strain tolerance, and durability. Techniques such as introducing specific defects or creating columnar structures can improve coating performance and longevity in high-temperature applications.

- Multi-layer and functionally graded coatings: Advanced thermal barrier coating systems often employ multi-layer designs or functionally graded compositions. These approaches allow for optimized performance by combining different materials or gradually changing composition throughout the coating thickness. This can result in improved thermal cycling resistance, better adhesion, and enhanced overall protection of the underlying substrate.

- Testing and characterization of thermal barrier coatings: Various methods are used to evaluate the performance and properties of thermal barrier coatings. These include thermal cycling tests, erosion resistance measurements, and non-destructive evaluation techniques. Advanced characterization methods, such as high-temperature X-ray diffraction and thermal imaging, are employed to assess coating integrity, thermal conductivity, and failure mechanisms under simulated operating conditions.

02 Deposition methods for thermal barrier coatings

Various deposition techniques are used to apply thermal barrier coatings, including electron beam physical vapor deposition (EB-PVD), plasma spraying, and chemical vapor deposition (CVD). Each method has its advantages and can produce coatings with different microstructures and properties. The choice of deposition method affects the coating's performance, durability, and cost-effectiveness.Expand Specific Solutions03 Advanced materials for thermal barrier coatings

Research is ongoing to develop new materials for thermal barrier coatings with improved properties. These include rare earth zirconates, hafnates, and other complex oxides that offer better thermal stability, lower thermal conductivity, and enhanced resistance to sintering and phase transformations at high temperatures. The development of these advanced materials aims to extend the operating temperature range and lifespan of thermal barrier coatings.Expand Specific Solutions04 Testing and characterization of thermal barrier coatings

Various testing methods are employed to evaluate the performance and durability of thermal barrier coatings. These include thermal cycling tests, erosion resistance tests, and non-destructive evaluation techniques such as thermography and impedance spectroscopy. Advanced characterization techniques, like electron microscopy and X-ray diffraction, are used to analyze the microstructure and phase composition of the coatings before and after testing.Expand Specific Solutions05 Failure mechanisms and lifetime prediction of thermal barrier coatings

Understanding the failure mechanisms of thermal barrier coatings is crucial for improving their performance and predicting their lifetime. Common failure modes include spallation due to thermal expansion mismatch, oxidation of the bond coat, and sintering of the ceramic top coat. Research focuses on developing models and methodologies to predict coating lifetime based on operating conditions and material properties, enabling more efficient maintenance and replacement strategies.Expand Specific Solutions

Key Players in TBC and Borosilicate Glass Research

The research on Thermal Barrier Coatings Incorporating Borosilicate Glass is in a developing stage, with a growing market driven by increasing demand in aerospace and energy sectors. The technology is advancing, but still maturing, as evidenced by ongoing research efforts. Key players like SCHOTT AG, Corning, Inc., and AGC, Inc. are leading the field, leveraging their expertise in glass and materials science. Academic institutions such as Central South University and Wuhan University of Technology are contributing to fundamental research, while companies like Northwest Nonferrous Metal Research Institute are focusing on applied research and development. The competitive landscape is diverse, with both established glass manufacturers and specialized research institutes vying for innovation leadership in this niche but promising area.

SCHOTT AG

Technical Solution: SCHOTT AG has developed advanced thermal barrier coatings (TBCs) incorporating borosilicate glass for high-temperature applications. Their innovative approach involves creating a multi-layered coating system with a borosilicate glass-ceramic layer sandwiched between traditional ceramic layers. This structure enhances thermal insulation and improves coating durability. The borosilicate glass component provides excellent thermal shock resistance and helps to seal micro-cracks that may form during thermal cycling[1]. SCHOTT's TBCs are applied using a combination of atmospheric plasma spraying and controlled crystallization processes, resulting in a uniform and tightly bonded coating structure[3].

Strengths: Superior thermal insulation, excellent thermal shock resistance, and improved durability. Weaknesses: Potentially higher production costs and complexity in the application process compared to traditional TBCs.

Corning, Inc.

Technical Solution: Corning, Inc. has pioneered a novel approach to thermal barrier coatings by incorporating their proprietary borosilicate glass formulations. Their research focuses on developing TBCs with enhanced thermal cycling performance and improved resistance to environmental attack. Corning's method involves creating a graded coating structure, where the concentration of borosilicate glass varies throughout the thickness of the coating. This gradation helps to minimize thermal expansion mismatches and reduces stress at the coating-substrate interface[2]. The company has also developed a unique sol-gel deposition technique that allows for precise control of the coating microstructure and composition[4].

Strengths: Excellent thermal cycling performance, improved resistance to environmental attack, and precise control over coating properties. Weaknesses: Potentially limited to specific substrate materials and may require specialized application equipment.

Innovative Approaches in TBC-Borosilicate Glass Systems

Films and coatings containing borosilicate flake glass

PatentInactiveUS20170137638A1

Innovation

- The use of borosilicate flake glass in coating compositions applied to substrates such as textiles or polymeric films, which improves thermal properties by enhancing heat dissipation and reducing thermal energy absorption.

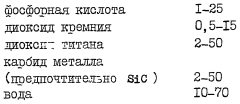

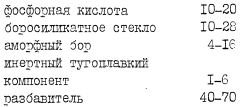

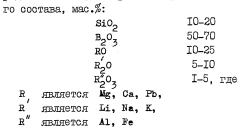

Composition for obtaining protective antioxidation coating on carbon article

PatentWO1993010058A1

Innovation

- A borosilicate glass composition is developed, incorporating boron, silicon, and phosphate components, with specific ratios of dioxide and amorphous boron, which forms a thermally stable and adhesive coating that enhances protection and adhesion, using a mixture of inert refractory materials and solvents to ensure effective application and stability.

Environmental Impact of TBC-Borosilicate Glass Coatings

The incorporation of borosilicate glass into Thermal Barrier Coatings (TBCs) presents both potential benefits and environmental considerations. This innovative approach aims to enhance the performance and durability of TBCs, which are crucial in protecting components in high-temperature environments, such as gas turbine engines.

From an environmental perspective, the use of borosilicate glass in TBCs may contribute to improved energy efficiency in various industrial applications. By enhancing the thermal insulation properties of TBCs, these coatings can potentially reduce fuel consumption and associated greenhouse gas emissions in power generation and aerospace industries.

The production process of borosilicate glass-incorporated TBCs may have a lower environmental impact compared to traditional ceramic-based TBCs. Borosilicate glass can be manufactured at lower temperatures, potentially reducing energy consumption during the coating production phase. Additionally, the raw materials used in borosilicate glass production are generally abundant and have a relatively low environmental footprint.

However, the long-term environmental effects of these coatings must be carefully considered. The durability and lifecycle of TBCs incorporating borosilicate glass may differ from conventional coatings, potentially affecting the frequency of maintenance and replacement. This could have implications for resource consumption and waste generation over the lifespan of the coated components.

The end-of-life management of components with borosilicate glass-incorporated TBCs is another important environmental consideration. The recyclability and disposal methods for these coatings may differ from traditional TBCs, necessitating the development of new recycling processes or disposal protocols to minimize environmental impact.

Potential leaching of boron compounds from the coatings during use or disposal is an area that requires thorough investigation. While borosilicate glass is generally considered stable, the high-temperature and corrosive environments in which TBCs operate may lead to unexpected chemical interactions or degradation processes.

The use of these advanced coatings may also indirectly contribute to environmental protection by extending the lifespan of critical components in high-temperature applications. This could lead to reduced material consumption and waste generation associated with component replacement and maintenance.

In conclusion, while the incorporation of borosilicate glass into TBCs shows promise for enhancing performance and potentially reducing certain environmental impacts, a comprehensive life cycle assessment is necessary to fully understand and quantify the environmental implications of this technology. Future research should focus on optimizing the environmental benefits while mitigating any potential negative impacts associated with the production, use, and disposal of these advanced coating systems.

From an environmental perspective, the use of borosilicate glass in TBCs may contribute to improved energy efficiency in various industrial applications. By enhancing the thermal insulation properties of TBCs, these coatings can potentially reduce fuel consumption and associated greenhouse gas emissions in power generation and aerospace industries.

The production process of borosilicate glass-incorporated TBCs may have a lower environmental impact compared to traditional ceramic-based TBCs. Borosilicate glass can be manufactured at lower temperatures, potentially reducing energy consumption during the coating production phase. Additionally, the raw materials used in borosilicate glass production are generally abundant and have a relatively low environmental footprint.

However, the long-term environmental effects of these coatings must be carefully considered. The durability and lifecycle of TBCs incorporating borosilicate glass may differ from conventional coatings, potentially affecting the frequency of maintenance and replacement. This could have implications for resource consumption and waste generation over the lifespan of the coated components.

The end-of-life management of components with borosilicate glass-incorporated TBCs is another important environmental consideration. The recyclability and disposal methods for these coatings may differ from traditional TBCs, necessitating the development of new recycling processes or disposal protocols to minimize environmental impact.

Potential leaching of boron compounds from the coatings during use or disposal is an area that requires thorough investigation. While borosilicate glass is generally considered stable, the high-temperature and corrosive environments in which TBCs operate may lead to unexpected chemical interactions or degradation processes.

The use of these advanced coatings may also indirectly contribute to environmental protection by extending the lifespan of critical components in high-temperature applications. This could lead to reduced material consumption and waste generation associated with component replacement and maintenance.

In conclusion, while the incorporation of borosilicate glass into TBCs shows promise for enhancing performance and potentially reducing certain environmental impacts, a comprehensive life cycle assessment is necessary to fully understand and quantify the environmental implications of this technology. Future research should focus on optimizing the environmental benefits while mitigating any potential negative impacts associated with the production, use, and disposal of these advanced coating systems.

Performance Metrics for TBC-Borosilicate Glass Systems

The performance metrics for Thermal Barrier Coatings (TBCs) incorporating borosilicate glass are crucial for evaluating the effectiveness and durability of these advanced coating systems. These metrics encompass a range of properties that directly impact the coating's ability to protect underlying components from high temperatures and harsh environments.

Thermal conductivity is a primary performance metric for TBC-borosilicate glass systems. The incorporation of borosilicate glass aims to reduce the overall thermal conductivity of the coating, thereby enhancing its insulating properties. Measurements typically show a reduction in thermal conductivity compared to conventional TBCs, with values often ranging from 0.8 to 1.2 W/m·K, depending on the specific composition and microstructure.

Thermal cycling resistance is another critical metric, as it determines the coating's ability to withstand repeated temperature fluctuations without failure. TBC-borosilicate glass systems generally exhibit improved thermal cycling performance, with some studies reporting a 20-30% increase in cycles to failure compared to standard yttria-stabilized zirconia (YSZ) coatings.

Erosion resistance is an essential performance parameter, particularly in turbine applications where particulate matter can cause significant wear. The addition of borosilicate glass has been shown to enhance erosion resistance by up to 40% in some formulations, primarily due to the formation of a more cohesive and denser coating structure.

High-temperature stability is a key metric that assesses the coating's ability to maintain its protective properties at elevated temperatures. TBC-borosilicate glass systems have demonstrated improved phase stability up to 1300°C, with minimal sintering and grain growth compared to conventional TBCs.

Bond strength between the coating and the substrate is crucial for long-term durability. Measurements of adhesion strength for TBC-borosilicate glass systems typically show values ranging from 30 to 50 MPa, which is comparable to or slightly higher than traditional YSZ coatings.

Chemical resistance, particularly against molten salts and volcanic ash, is an increasingly important metric. Studies have shown that the incorporation of borosilicate glass can enhance resistance to CMAS (Calcium-Magnesium-Alumino-Silicate) infiltration by up to 50%, significantly extending the coating's lifetime in contaminated environments.

Thermal expansion coefficient matching is essential to prevent delamination during thermal cycling. TBC-borosilicate glass systems are engineered to have a coefficient of thermal expansion close to that of the metallic substrate, typically in the range of 9-11 × 10^-6 K^-1.

These performance metrics collectively provide a comprehensive evaluation of TBC-borosilicate glass systems, enabling researchers and engineers to assess their potential for various high-temperature applications and guide further development efforts.

Thermal conductivity is a primary performance metric for TBC-borosilicate glass systems. The incorporation of borosilicate glass aims to reduce the overall thermal conductivity of the coating, thereby enhancing its insulating properties. Measurements typically show a reduction in thermal conductivity compared to conventional TBCs, with values often ranging from 0.8 to 1.2 W/m·K, depending on the specific composition and microstructure.

Thermal cycling resistance is another critical metric, as it determines the coating's ability to withstand repeated temperature fluctuations without failure. TBC-borosilicate glass systems generally exhibit improved thermal cycling performance, with some studies reporting a 20-30% increase in cycles to failure compared to standard yttria-stabilized zirconia (YSZ) coatings.

Erosion resistance is an essential performance parameter, particularly in turbine applications where particulate matter can cause significant wear. The addition of borosilicate glass has been shown to enhance erosion resistance by up to 40% in some formulations, primarily due to the formation of a more cohesive and denser coating structure.

High-temperature stability is a key metric that assesses the coating's ability to maintain its protective properties at elevated temperatures. TBC-borosilicate glass systems have demonstrated improved phase stability up to 1300°C, with minimal sintering and grain growth compared to conventional TBCs.

Bond strength between the coating and the substrate is crucial for long-term durability. Measurements of adhesion strength for TBC-borosilicate glass systems typically show values ranging from 30 to 50 MPa, which is comparable to or slightly higher than traditional YSZ coatings.

Chemical resistance, particularly against molten salts and volcanic ash, is an increasingly important metric. Studies have shown that the incorporation of borosilicate glass can enhance resistance to CMAS (Calcium-Magnesium-Alumino-Silicate) infiltration by up to 50%, significantly extending the coating's lifetime in contaminated environments.

Thermal expansion coefficient matching is essential to prevent delamination during thermal cycling. TBC-borosilicate glass systems are engineered to have a coefficient of thermal expansion close to that of the metallic substrate, typically in the range of 9-11 × 10^-6 K^-1.

These performance metrics collectively provide a comprehensive evaluation of TBC-borosilicate glass systems, enabling researchers and engineers to assess their potential for various high-temperature applications and guide further development efforts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!