Microfluidic Device Fabrication Utilizing Borosilicate Glass

JUL 3, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microfluidic Borosilicate Glass Background

Microfluidic devices have revolutionized the field of analytical chemistry and biomedical research by enabling precise control and manipulation of fluids at the microscale. The use of borosilicate glass in the fabrication of these devices has gained significant attention due to its unique properties and advantages over other materials.

Borosilicate glass, first developed in the late 19th century, is a type of glass composed primarily of silica and boron oxide. Its low thermal expansion coefficient, high chemical resistance, and excellent optical properties make it an ideal material for microfluidic applications. The history of borosilicate glass in microfluidics can be traced back to the early 2000s when researchers began exploring its potential for lab-on-a-chip devices.

The evolution of microfluidic device fabrication using borosilicate glass has been driven by the need for more robust, chemically inert, and optically transparent platforms. Initially, simple etching techniques were employed to create channels in glass substrates. However, as the field progressed, more sophisticated methods such as laser ablation, powder blasting, and deep reactive ion etching (DRIE) were developed to achieve higher precision and complexity in device designs.

One of the key advantages of borosilicate glass in microfluidics is its compatibility with a wide range of chemicals and solvents. This property is particularly valuable in applications involving aggressive reagents or organic solvents, where polymer-based devices may degrade or leach unwanted compounds. Additionally, the thermal stability of borosilicate glass allows for its use in high-temperature applications, expanding the range of possible reactions and processes that can be performed on-chip.

The optical transparency of borosilicate glass has also played a crucial role in its adoption for microfluidic devices. This characteristic enables real-time visualization and monitoring of fluid flow, chemical reactions, and biological processes within the device. Furthermore, the ability to integrate optical detection methods directly into the device has led to the development of highly sensitive and miniaturized analytical systems.

As research in this field has progressed, the integration of additional functionalities into borosilicate glass microfluidic devices has become a focus area. This includes the incorporation of electrodes for electrochemical sensing, the creation of three-dimensional structures for enhanced fluid manipulation, and the development of hybrid devices combining glass with other materials to leverage their respective strengths.

The current landscape of microfluidic device fabrication utilizing borosilicate glass is characterized by a growing emphasis on scalability and reproducibility. Researchers and manufacturers are exploring ways to transition from laboratory-scale production to industrial-scale manufacturing while maintaining the high precision and quality required for these devices. This shift is crucial for the widespread adoption of borosilicate glass microfluidic devices in commercial applications, ranging from point-of-care diagnostics to high-throughput screening in drug discovery.

Borosilicate glass, first developed in the late 19th century, is a type of glass composed primarily of silica and boron oxide. Its low thermal expansion coefficient, high chemical resistance, and excellent optical properties make it an ideal material for microfluidic applications. The history of borosilicate glass in microfluidics can be traced back to the early 2000s when researchers began exploring its potential for lab-on-a-chip devices.

The evolution of microfluidic device fabrication using borosilicate glass has been driven by the need for more robust, chemically inert, and optically transparent platforms. Initially, simple etching techniques were employed to create channels in glass substrates. However, as the field progressed, more sophisticated methods such as laser ablation, powder blasting, and deep reactive ion etching (DRIE) were developed to achieve higher precision and complexity in device designs.

One of the key advantages of borosilicate glass in microfluidics is its compatibility with a wide range of chemicals and solvents. This property is particularly valuable in applications involving aggressive reagents or organic solvents, where polymer-based devices may degrade or leach unwanted compounds. Additionally, the thermal stability of borosilicate glass allows for its use in high-temperature applications, expanding the range of possible reactions and processes that can be performed on-chip.

The optical transparency of borosilicate glass has also played a crucial role in its adoption for microfluidic devices. This characteristic enables real-time visualization and monitoring of fluid flow, chemical reactions, and biological processes within the device. Furthermore, the ability to integrate optical detection methods directly into the device has led to the development of highly sensitive and miniaturized analytical systems.

As research in this field has progressed, the integration of additional functionalities into borosilicate glass microfluidic devices has become a focus area. This includes the incorporation of electrodes for electrochemical sensing, the creation of three-dimensional structures for enhanced fluid manipulation, and the development of hybrid devices combining glass with other materials to leverage their respective strengths.

The current landscape of microfluidic device fabrication utilizing borosilicate glass is characterized by a growing emphasis on scalability and reproducibility. Researchers and manufacturers are exploring ways to transition from laboratory-scale production to industrial-scale manufacturing while maintaining the high precision and quality required for these devices. This shift is crucial for the widespread adoption of borosilicate glass microfluidic devices in commercial applications, ranging from point-of-care diagnostics to high-throughput screening in drug discovery.

Market Analysis for Microfluidic Devices

The microfluidic devices market has experienced significant growth in recent years, driven by advancements in technology and increasing applications across various industries. The global market for microfluidic devices is projected to reach substantial value by 2026, with a compound annual growth rate (CAGR) exceeding 20% during the forecast period. This rapid expansion is attributed to the rising demand for point-of-care diagnostics, drug discovery and development, and personalized medicine.

The healthcare sector remains the primary driver of market growth, with applications in diagnostics, drug delivery, and analytical testing. The ability of microfluidic devices to handle small sample volumes, reduce reagent consumption, and provide rapid results has made them particularly attractive in clinical settings. Additionally, the pharmaceutical industry has embraced microfluidic technology for drug screening and development, contributing to market expansion.

Geographically, North America dominates the microfluidic devices market, followed by Europe and Asia-Pacific. The United States, in particular, leads in terms of research and development, with numerous academic institutions and biotechnology companies actively pursuing microfluidic innovations. However, emerging economies in Asia-Pacific, such as China and India, are expected to witness the fastest growth rates due to increasing healthcare expenditure and growing adoption of advanced medical technologies.

The market landscape is characterized by a mix of established players and innovative start-ups. Key market participants include Danaher Corporation, Thermo Fisher Scientific, and Bio-Rad Laboratories, among others. These companies are investing heavily in research and development to maintain their competitive edge and expand their product portfolios.

One of the most promising segments within the microfluidic devices market is the lab-on-a-chip technology, which integrates multiple laboratory functions on a single chip. This segment is anticipated to witness substantial growth due to its potential in rapid diagnostics and personalized medicine applications.

The COVID-19 pandemic has further accelerated market growth, highlighting the importance of rapid, portable diagnostic tools. Microfluidic-based testing platforms have emerged as crucial components in the global response to the pandemic, offering quick and accurate results for virus detection.

Despite the positive outlook, challenges remain in the widespread adoption of microfluidic devices. These include the high initial costs associated with device development and manufacturing, as well as the need for standardization across different platforms. However, ongoing research in materials science, including the use of borosilicate glass for device fabrication, is expected to address some of these challenges and further drive market growth in the coming years.

The healthcare sector remains the primary driver of market growth, with applications in diagnostics, drug delivery, and analytical testing. The ability of microfluidic devices to handle small sample volumes, reduce reagent consumption, and provide rapid results has made them particularly attractive in clinical settings. Additionally, the pharmaceutical industry has embraced microfluidic technology for drug screening and development, contributing to market expansion.

Geographically, North America dominates the microfluidic devices market, followed by Europe and Asia-Pacific. The United States, in particular, leads in terms of research and development, with numerous academic institutions and biotechnology companies actively pursuing microfluidic innovations. However, emerging economies in Asia-Pacific, such as China and India, are expected to witness the fastest growth rates due to increasing healthcare expenditure and growing adoption of advanced medical technologies.

The market landscape is characterized by a mix of established players and innovative start-ups. Key market participants include Danaher Corporation, Thermo Fisher Scientific, and Bio-Rad Laboratories, among others. These companies are investing heavily in research and development to maintain their competitive edge and expand their product portfolios.

One of the most promising segments within the microfluidic devices market is the lab-on-a-chip technology, which integrates multiple laboratory functions on a single chip. This segment is anticipated to witness substantial growth due to its potential in rapid diagnostics and personalized medicine applications.

The COVID-19 pandemic has further accelerated market growth, highlighting the importance of rapid, portable diagnostic tools. Microfluidic-based testing platforms have emerged as crucial components in the global response to the pandemic, offering quick and accurate results for virus detection.

Despite the positive outlook, challenges remain in the widespread adoption of microfluidic devices. These include the high initial costs associated with device development and manufacturing, as well as the need for standardization across different platforms. However, ongoing research in materials science, including the use of borosilicate glass for device fabrication, is expected to address some of these challenges and further drive market growth in the coming years.

Borosilicate Glass Fabrication Challenges

The fabrication of microfluidic devices using borosilicate glass presents several significant challenges that researchers and manufacturers must overcome. One of the primary difficulties lies in the precise micromachining of borosilicate glass, which is essential for creating intricate channel structures and features. The material's hardness and brittleness make it resistant to conventional machining techniques, often resulting in chipping, cracking, or uneven surfaces.

Etching processes, particularly wet etching with hydrofluoric acid (HF), pose another set of challenges. While HF etching can create smooth channel surfaces, it is notoriously difficult to control, leading to potential issues with channel geometry and depth uniformity. The isotropic nature of wet etching in glass can also result in undercutting, which may compromise the structural integrity of microfluidic features.

Thermal bonding, a critical step in microfluidic device assembly, presents its own set of obstacles when working with borosilicate glass. The high temperatures required for effective bonding can lead to thermal stress, warping, or even collapse of microchannels. Achieving a hermetic seal without altering the carefully crafted microstructures demands precise control over temperature, pressure, and surface preparation.

Surface modification of borosilicate glass channels is another area of concern. Creating stable and uniform surface chemistries for specific applications, such as protein adsorption prevention or cell culture, can be challenging due to the inherent chemical inertness of borosilicate glass. This often necessitates complex and time-consuming surface treatment protocols.

The integration of additional functionalities, such as electrodes or sensors, into borosilicate glass microfluidic devices presents further fabrication hurdles. The need for precise alignment and bonding of multiple layers, each potentially containing different materials, adds complexity to the manufacturing process and can impact yield rates.

Scaling up production from laboratory prototypes to commercial manufacturing introduces additional challenges. Ensuring consistency and reproducibility across large batches of devices, while maintaining the high precision required for microfluidic applications, demands sophisticated process control and quality assurance measures.

Lastly, the cost and time associated with borosilicate glass microfluidic device fabrication remain significant barriers to widespread adoption. The specialized equipment, clean room facilities, and skilled labor required for glass microfabrication contribute to higher production costs compared to polymer-based alternatives, potentially limiting the commercial viability of certain applications.

Etching processes, particularly wet etching with hydrofluoric acid (HF), pose another set of challenges. While HF etching can create smooth channel surfaces, it is notoriously difficult to control, leading to potential issues with channel geometry and depth uniformity. The isotropic nature of wet etching in glass can also result in undercutting, which may compromise the structural integrity of microfluidic features.

Thermal bonding, a critical step in microfluidic device assembly, presents its own set of obstacles when working with borosilicate glass. The high temperatures required for effective bonding can lead to thermal stress, warping, or even collapse of microchannels. Achieving a hermetic seal without altering the carefully crafted microstructures demands precise control over temperature, pressure, and surface preparation.

Surface modification of borosilicate glass channels is another area of concern. Creating stable and uniform surface chemistries for specific applications, such as protein adsorption prevention or cell culture, can be challenging due to the inherent chemical inertness of borosilicate glass. This often necessitates complex and time-consuming surface treatment protocols.

The integration of additional functionalities, such as electrodes or sensors, into borosilicate glass microfluidic devices presents further fabrication hurdles. The need for precise alignment and bonding of multiple layers, each potentially containing different materials, adds complexity to the manufacturing process and can impact yield rates.

Scaling up production from laboratory prototypes to commercial manufacturing introduces additional challenges. Ensuring consistency and reproducibility across large batches of devices, while maintaining the high precision required for microfluidic applications, demands sophisticated process control and quality assurance measures.

Lastly, the cost and time associated with borosilicate glass microfluidic device fabrication remain significant barriers to widespread adoption. The specialized equipment, clean room facilities, and skilled labor required for glass microfabrication contribute to higher production costs compared to polymer-based alternatives, potentially limiting the commercial viability of certain applications.

Current Borosilicate Glass Fabrication Methods

01 Fabrication techniques for microfluidic devices

Various fabrication methods are employed to create microfluidic devices, including photolithography, soft lithography, and 3D printing. These techniques allow for precise control over channel dimensions and geometries, enabling the creation of complex microfluidic structures for diverse applications in chemistry, biology, and medicine.- Fabrication techniques for microfluidic devices: Various methods are employed to manufacture microfluidic devices, including micromachining, soft lithography, and 3D printing. These techniques allow for precise control over channel dimensions and geometries, enabling the creation of complex microfluidic structures for diverse applications in chemistry, biology, and medicine.

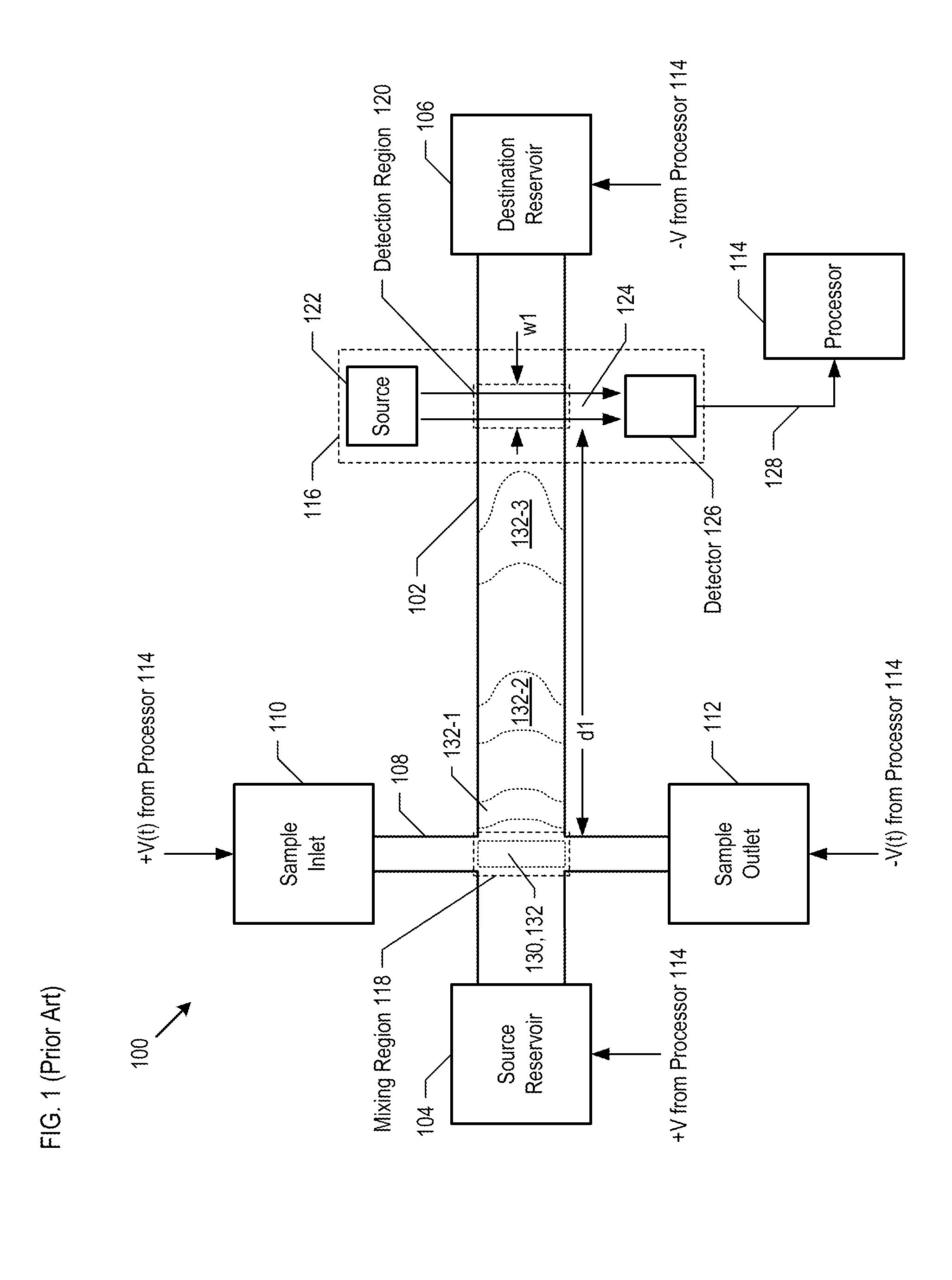

- Integration of sensors and actuators: Microfluidic devices often incorporate sensors and actuators for fluid manipulation and analysis. These components enable real-time monitoring of flow rates, pressure, and chemical composition, as well as precise control over fluid movement within the device. Integration of these elements enhances the functionality and versatility of microfluidic systems.

- Droplet-based microfluidics: Droplet-based microfluidic systems utilize discrete liquid droplets as microreactors or carriers for biological samples. This approach allows for high-throughput analysis, precise control over reaction conditions, and reduced reagent consumption. Droplet generation, manipulation, and analysis are key aspects of this technology.

- Microfluidic devices for biomedical applications: Microfluidic devices are widely used in biomedical research and diagnostics. Applications include point-of-care testing, drug discovery, organ-on-a-chip models, and cell sorting. These devices offer advantages such as reduced sample volumes, faster analysis times, and the ability to perform multiple assays simultaneously.

- Flow control and mixing in microfluidic devices: Efficient flow control and mixing are crucial aspects of microfluidic device design. Various techniques are employed to achieve precise fluid manipulation, including passive and active mixing strategies, valve systems, and flow focusing. These methods enable controlled reactions, sample preparation, and analysis within the microfluidic channels.

02 Integration of sensors and detection systems

Microfluidic devices often incorporate integrated sensors and detection systems for real-time monitoring and analysis. These may include optical, electrochemical, or mechanical sensors that enable the measurement of various parameters such as flow rate, pressure, or chemical composition within the microfluidic channels.Expand Specific Solutions03 Fluid control and manipulation techniques

Advanced fluid control mechanisms are implemented in microfluidic devices to manipulate small volumes of liquids. These may include electrokinetic, pneumatic, or capillary-driven flow control methods, as well as the use of valves and pumps to precisely regulate fluid movement within the device.Expand Specific Solutions04 Applications in biomedical research and diagnostics

Microfluidic devices find extensive use in biomedical research and diagnostics, enabling applications such as single-cell analysis, drug screening, and point-of-care testing. These devices offer advantages in terms of reduced sample volume requirements, faster analysis times, and improved sensitivity compared to traditional methods.Expand Specific Solutions05 Integration with other technologies

Microfluidic devices are increasingly being integrated with other technologies to enhance their capabilities. This includes combining microfluidics with electronics, optics, or nanomaterials to create multifunctional devices for applications in areas such as organ-on-a-chip systems, wearable sensors, or advanced analytical instruments.Expand Specific Solutions

Key Microfluidic Industry Players

The microfluidic device fabrication utilizing borosilicate glass market is in a growth phase, driven by increasing demand in biomedical and pharmaceutical applications. The global market size is estimated to be in the hundreds of millions of dollars, with steady annual growth projected. Technologically, the field is advancing rapidly, with key players like Corning, SCHOTT AG, and CSG Holding Co. leading innovation. These companies are developing improved fabrication techniques, enhancing material properties, and expanding application areas. Emerging players such as Hunan Kibing Pharmaceutical Material Technology and LioniX International are also contributing to technological advancements, particularly in specialized applications. The competitive landscape is characterized by a mix of established glass manufacturers and specialized microfluidics companies, indicating a maturing but still evolving market.

Corning, Inc.

Technical Solution: Corning has developed advanced microfluidic device fabrication techniques using borosilicate glass. Their approach involves precision glass forming and etching processes to create intricate microfluidic channels and structures. They utilize their proprietary Valor® Glass technology, which offers superior chemical durability and mechanical strength[1]. Corning's method includes high-temperature fusion bonding of multiple glass layers to form sealed microfluidic devices. They have also implemented surface modification techniques to control the wettability and functionality of the microfluidic channels[2]. Corning's fabrication process allows for the creation of complex 3D microfluidic structures with high aspect ratios and smooth channel surfaces, crucial for efficient fluid flow and precise control in microfluidic applications[3].

Strengths: Superior glass quality, precision fabrication capabilities, and extensive experience in glass technologies. Weaknesses: Potentially higher production costs compared to polymer-based microfluidics.

SCHOTT AG

Technical Solution: SCHOTT AG has pioneered innovative techniques for microfluidic device fabrication using borosilicate glass. Their approach combines precision glass machining with advanced bonding technologies. SCHOTT utilizes their high-quality BOROFLOAT® borosilicate glass, known for its excellent thermal and chemical resistance[4]. Their fabrication process involves photolithography and wet etching to create precise microfluidic channels, followed by thermal bonding to seal the devices. SCHOTT has developed a unique anodic bonding technique for joining borosilicate glass to silicon, enabling the creation of hybrid microfluidic devices[5]. They have also implemented laser-assisted etching methods to achieve high-aspect-ratio structures in borosilicate glass, allowing for more complex microfluidic designs[6].

Strengths: High-quality borosilicate glass production, advanced bonding techniques, and ability to create hybrid devices. Weaknesses: Limited flexibility in rapid prototyping compared to some polymer-based methods.

Innovative Microfluidic Glass Etching Techniques

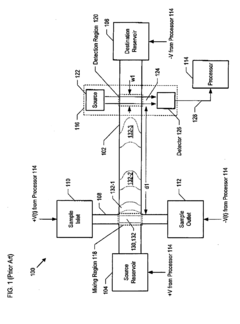

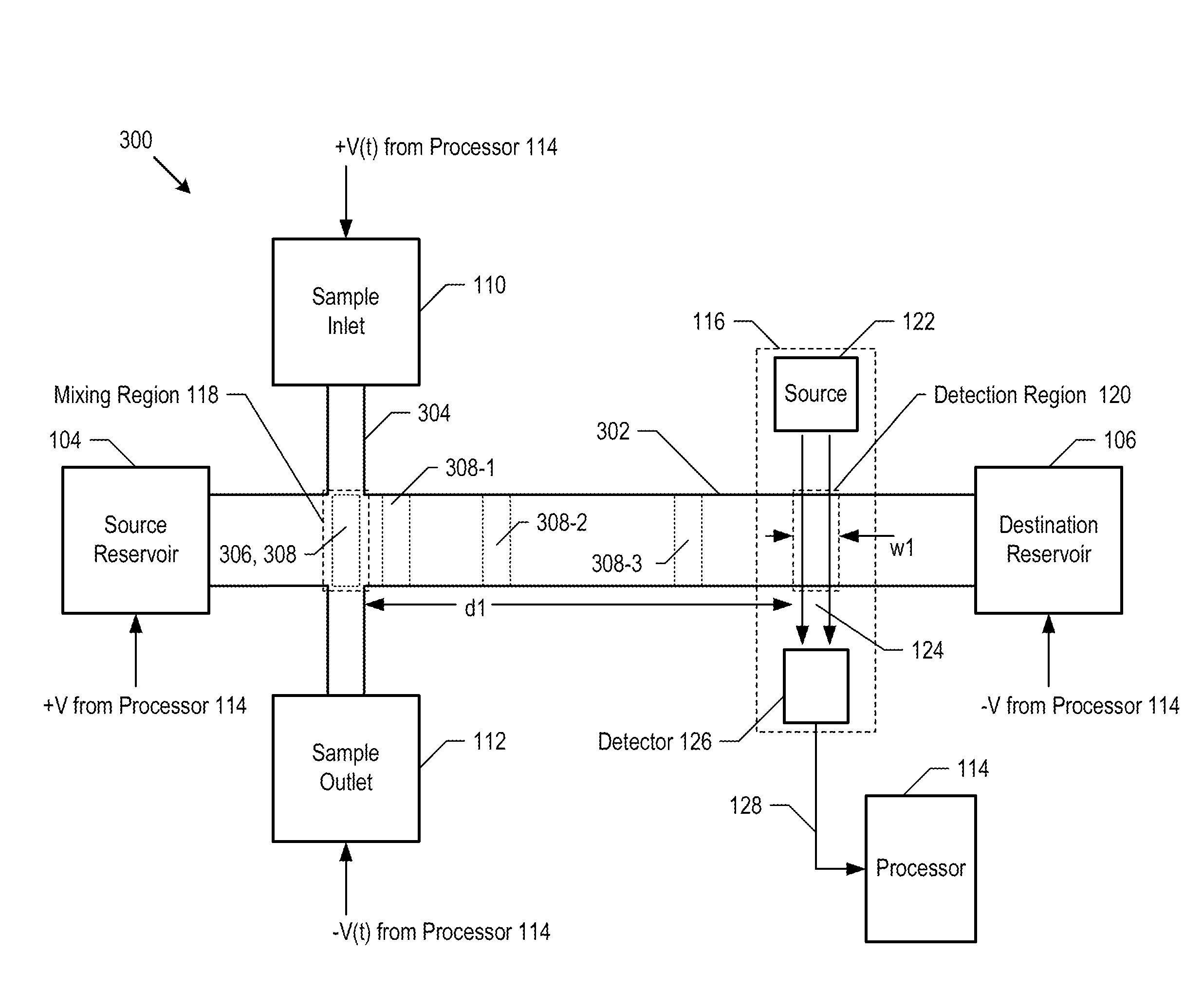

Microfluidic system with surface coating

PatentInactiveEP2146201A1

Innovation

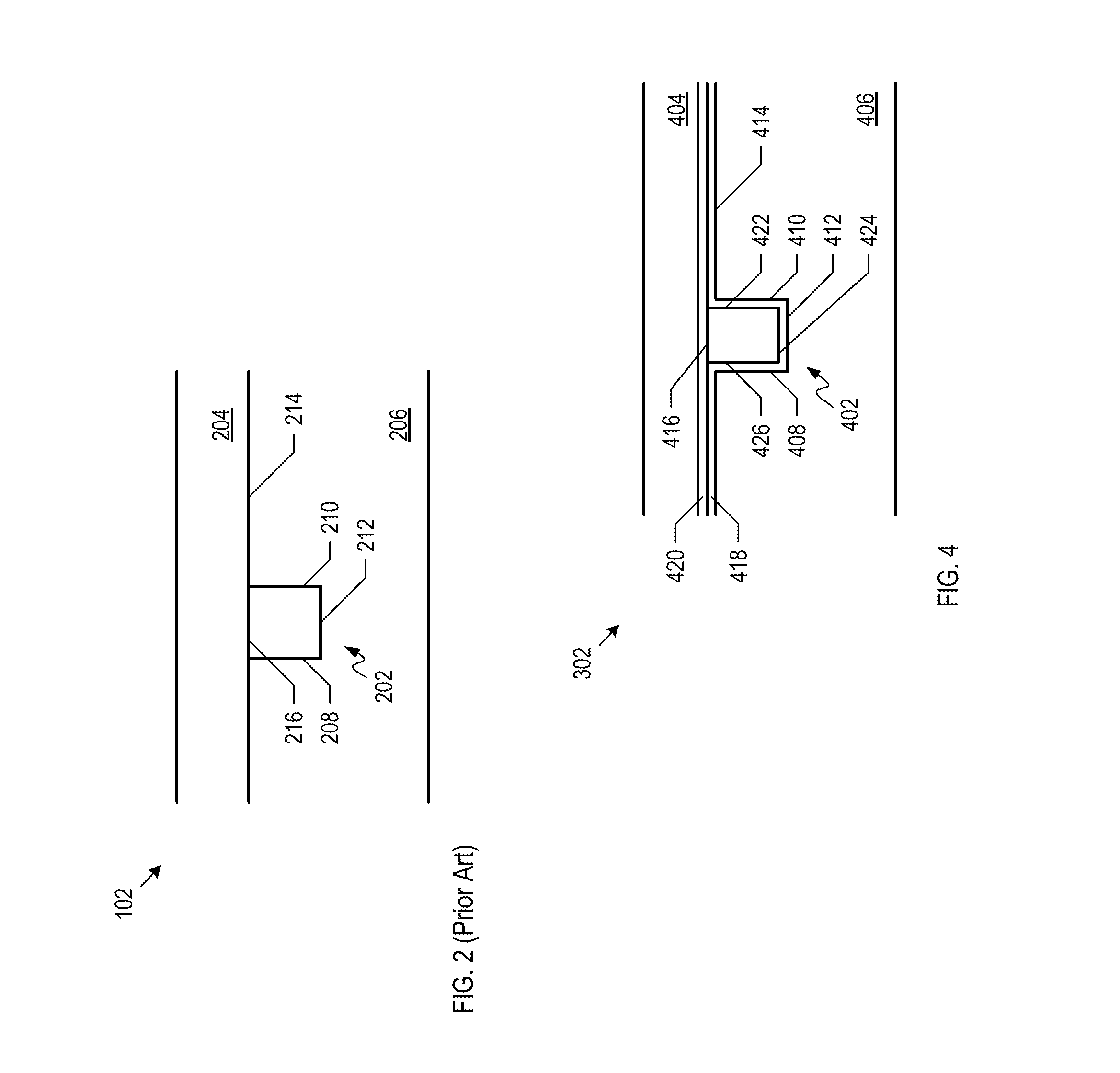

- The use of borophosphosilicate glass layers on the microfluidic channel surfaces to reduce surface roughness and enhance electrokinetic potential, allowing for well-formed analyte plugs and flexible channel designs with various cross-sectional shapes, including non-circular configurations.

Microfluidic system

PatentInactiveUS20130256138A1

Innovation

- The use of borophosphosilicate glass layers on the channel surfaces to reduce surface roughness and enhance electrokinetic potential, allowing for well-formed analyte plugs and flexible channel designs, including non-circular cross-sectional shapes, and enabling thermo-anodic bonding for channel enclosure.

Material Properties and Characterization

Borosilicate glass is a crucial material in the fabrication of microfluidic devices due to its unique properties and versatile characteristics. This glass type is composed primarily of silica and boron trioxide, with small amounts of alkali and alumina. Its low coefficient of thermal expansion, high chemical resistance, and excellent optical clarity make it an ideal choice for microfluidic applications.

The material properties of borosilicate glass play a significant role in its suitability for microfluidic device fabrication. Its thermal expansion coefficient is approximately one-third that of ordinary glass, allowing for better thermal stability during fabrication processes and device operation. This property is particularly important when dealing with temperature-sensitive reactions or when thermal cycling is required in microfluidic applications.

Chemical resistance is another key attribute of borosilicate glass. It exhibits exceptional resistance to acids, alkalis, and organic solvents, making it suitable for a wide range of chemical and biological applications. This resistance ensures the longevity and reliability of microfluidic devices, even when exposed to harsh chemical environments.

Optical clarity is a critical factor in many microfluidic applications, especially those involving microscopy or spectroscopic analysis. Borosilicate glass offers excellent transparency across a wide range of wavelengths, from ultraviolet to near-infrared. This property allows for high-quality imaging and detection of analytes within microfluidic channels.

Characterization of borosilicate glass for microfluidic device fabrication involves several techniques. Surface roughness analysis using atomic force microscopy (AFM) or profilometry is essential to ensure smooth channel surfaces, which is crucial for consistent fluid flow and preventing unwanted particle adhesion. Contact angle measurements provide information about the glass surface's wettability, which affects fluid behavior within the microchannels.

X-ray photoelectron spectroscopy (XPS) and energy-dispersive X-ray spectroscopy (EDX) are employed to analyze the chemical composition of the glass surface. These techniques are particularly useful for assessing the effectiveness of surface modification processes, which are often necessary to tailor the glass properties for specific microfluidic applications.

Mechanical strength testing, including flexural and tensile strength measurements, is crucial to ensure the durability of the fabricated devices. This is particularly important for applications involving high-pressure fluid flows or when the device needs to withstand external mechanical stresses.

Thermal analysis techniques, such as differential scanning calorimetry (DSC) and thermogravimetric analysis (TGA), provide insights into the glass transition temperature and thermal stability of the borosilicate glass. This information is vital for optimizing fabrication processes that involve high temperatures, such as thermal bonding or annealing steps.

In conclusion, the comprehensive characterization of borosilicate glass properties is essential for successful microfluidic device fabrication. Understanding and optimizing these properties enable researchers and manufacturers to create high-performance, reliable, and versatile microfluidic devices for a wide range of applications in chemistry, biology, and medical diagnostics.

The material properties of borosilicate glass play a significant role in its suitability for microfluidic device fabrication. Its thermal expansion coefficient is approximately one-third that of ordinary glass, allowing for better thermal stability during fabrication processes and device operation. This property is particularly important when dealing with temperature-sensitive reactions or when thermal cycling is required in microfluidic applications.

Chemical resistance is another key attribute of borosilicate glass. It exhibits exceptional resistance to acids, alkalis, and organic solvents, making it suitable for a wide range of chemical and biological applications. This resistance ensures the longevity and reliability of microfluidic devices, even when exposed to harsh chemical environments.

Optical clarity is a critical factor in many microfluidic applications, especially those involving microscopy or spectroscopic analysis. Borosilicate glass offers excellent transparency across a wide range of wavelengths, from ultraviolet to near-infrared. This property allows for high-quality imaging and detection of analytes within microfluidic channels.

Characterization of borosilicate glass for microfluidic device fabrication involves several techniques. Surface roughness analysis using atomic force microscopy (AFM) or profilometry is essential to ensure smooth channel surfaces, which is crucial for consistent fluid flow and preventing unwanted particle adhesion. Contact angle measurements provide information about the glass surface's wettability, which affects fluid behavior within the microchannels.

X-ray photoelectron spectroscopy (XPS) and energy-dispersive X-ray spectroscopy (EDX) are employed to analyze the chemical composition of the glass surface. These techniques are particularly useful for assessing the effectiveness of surface modification processes, which are often necessary to tailor the glass properties for specific microfluidic applications.

Mechanical strength testing, including flexural and tensile strength measurements, is crucial to ensure the durability of the fabricated devices. This is particularly important for applications involving high-pressure fluid flows or when the device needs to withstand external mechanical stresses.

Thermal analysis techniques, such as differential scanning calorimetry (DSC) and thermogravimetric analysis (TGA), provide insights into the glass transition temperature and thermal stability of the borosilicate glass. This information is vital for optimizing fabrication processes that involve high temperatures, such as thermal bonding or annealing steps.

In conclusion, the comprehensive characterization of borosilicate glass properties is essential for successful microfluidic device fabrication. Understanding and optimizing these properties enable researchers and manufacturers to create high-performance, reliable, and versatile microfluidic devices for a wide range of applications in chemistry, biology, and medical diagnostics.

Microfluidic Device Applications

Microfluidic devices have revolutionized various fields, offering unprecedented control over fluid manipulation at microscale levels. These devices find applications across a wide spectrum of industries and research areas, showcasing their versatility and importance in modern science and technology.

In the biomedical field, microfluidic devices have become indispensable tools for diagnostics, drug discovery, and personalized medicine. They enable rapid and precise analysis of biological samples, such as blood or tissue, with minimal sample volumes. Point-of-care diagnostics benefit greatly from microfluidic technology, allowing for quick and accurate disease detection in resource-limited settings. Furthermore, organ-on-a-chip systems, which replicate the functions of human organs on a miniature scale, rely heavily on microfluidic principles for drug screening and toxicity testing.

The chemical industry has also embraced microfluidic technology for process intensification and optimization. Microreactors, a subset of microfluidic devices, offer enhanced control over reaction conditions, leading to improved yield and selectivity in chemical synthesis. These devices are particularly valuable in the production of fine chemicals and pharmaceuticals, where precise control over reaction parameters is crucial.

In environmental monitoring, microfluidic devices play a vital role in water and air quality analysis. Their ability to detect and quantify pollutants at low concentrations makes them ideal for continuous environmental monitoring systems. Additionally, microfluidic devices are being developed for the detection of pathogens and contaminants in food and beverages, enhancing food safety measures.

The energy sector is exploring microfluidic applications for enhanced oil recovery and fuel cell development. Microfluidic devices allow for the study of multiphase flows in porous media, providing insights into oil extraction processes. In fuel cell research, these devices facilitate the investigation of electrochemical reactions and mass transport phenomena at the microscale.

Emerging applications of microfluidic devices include their use in 3D printing and advanced materials synthesis. Droplet-based microfluidics enables the production of monodisperse particles and emulsions, which find applications in cosmetics, food science, and materials engineering. Moreover, microfluidic devices are being integrated with other technologies, such as optics and electronics, to create lab-on-a-chip systems for diverse applications in sensing and analysis.

As the field of microfluidics continues to evolve, new applications are constantly emerging. The integration of artificial intelligence and machine learning with microfluidic systems promises to further expand their capabilities and applications across various domains. The ongoing miniaturization and automation trends in microfluidic device fabrication are expected to drive their adoption in both research and industrial settings, solidifying their position as a key enabling technology for the 21st century.

In the biomedical field, microfluidic devices have become indispensable tools for diagnostics, drug discovery, and personalized medicine. They enable rapid and precise analysis of biological samples, such as blood or tissue, with minimal sample volumes. Point-of-care diagnostics benefit greatly from microfluidic technology, allowing for quick and accurate disease detection in resource-limited settings. Furthermore, organ-on-a-chip systems, which replicate the functions of human organs on a miniature scale, rely heavily on microfluidic principles for drug screening and toxicity testing.

The chemical industry has also embraced microfluidic technology for process intensification and optimization. Microreactors, a subset of microfluidic devices, offer enhanced control over reaction conditions, leading to improved yield and selectivity in chemical synthesis. These devices are particularly valuable in the production of fine chemicals and pharmaceuticals, where precise control over reaction parameters is crucial.

In environmental monitoring, microfluidic devices play a vital role in water and air quality analysis. Their ability to detect and quantify pollutants at low concentrations makes them ideal for continuous environmental monitoring systems. Additionally, microfluidic devices are being developed for the detection of pathogens and contaminants in food and beverages, enhancing food safety measures.

The energy sector is exploring microfluidic applications for enhanced oil recovery and fuel cell development. Microfluidic devices allow for the study of multiphase flows in porous media, providing insights into oil extraction processes. In fuel cell research, these devices facilitate the investigation of electrochemical reactions and mass transport phenomena at the microscale.

Emerging applications of microfluidic devices include their use in 3D printing and advanced materials synthesis. Droplet-based microfluidics enables the production of monodisperse particles and emulsions, which find applications in cosmetics, food science, and materials engineering. Moreover, microfluidic devices are being integrated with other technologies, such as optics and electronics, to create lab-on-a-chip systems for diverse applications in sensing and analysis.

As the field of microfluidics continues to evolve, new applications are constantly emerging. The integration of artificial intelligence and machine learning with microfluidic systems promises to further expand their capabilities and applications across various domains. The ongoing miniaturization and automation trends in microfluidic device fabrication are expected to drive their adoption in both research and industrial settings, solidifying their position as a key enabling technology for the 21st century.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!