Borosilicate Glass in Photonic Integrated Circuits

JUL 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Borosilicate Glass PIC Background and Objectives

Photonic integrated circuits (PICs) have emerged as a revolutionary technology in the field of optoelectronics, offering the potential for miniaturization, enhanced performance, and cost-effective production of optical systems. Within this domain, borosilicate glass has gained significant attention as a promising material for PIC fabrication. The evolution of borosilicate glass in PICs can be traced back to its initial use in optical fibers and bulk optics, where its excellent optical properties and thermal stability were first recognized.

The development of borosilicate glass for PIC applications has been driven by the increasing demand for high-performance, low-cost optical components in telecommunications, sensing, and data processing industries. As traditional silicon-based PICs faced limitations in terms of optical transmission and integration with active components, researchers began exploring alternative materials that could overcome these challenges while maintaining compatibility with existing fabrication processes.

Borosilicate glass emerged as a compelling candidate due to its unique combination of properties, including low optical loss, high transparency over a wide wavelength range, and thermal expansion coefficient closely matching that of silicon. These characteristics make it particularly suitable for creating passive optical components such as waveguides, splitters, and couplers, as well as for packaging and interfacing with other materials in hybrid PIC designs.

The objectives of research on borosilicate glass in PICs are multifaceted. Primarily, there is a focus on developing advanced fabrication techniques that enable the creation of complex optical structures with high precision and repeatability. This includes exploring methods such as femtosecond laser writing, ion exchange, and thin-film deposition to achieve the desired optical properties and geometries.

Another key goal is to enhance the integration capabilities of borosilicate glass with other materials and active components. This involves investigating techniques for bonding borosilicate glass to silicon, III-V semiconductors, and other substrates, as well as developing methods for incorporating light sources, detectors, and modulators into borosilicate glass-based PICs.

Furthermore, researchers aim to exploit the unique properties of borosilicate glass to create novel functionalities and improve the performance of existing PIC designs. This includes leveraging its high nonlinearity for all-optical signal processing, utilizing its low thermal sensitivity for temperature-insensitive devices, and exploring its potential for three-dimensional optical circuits.

As the field progresses, there is also a growing emphasis on scalability and manufacturability. Efforts are being made to adapt borosilicate glass fabrication processes to large-scale production, ensuring compatibility with standard semiconductor manufacturing techniques and developing cost-effective solutions for mass production of borosilicate glass-based PICs.

The development of borosilicate glass for PIC applications has been driven by the increasing demand for high-performance, low-cost optical components in telecommunications, sensing, and data processing industries. As traditional silicon-based PICs faced limitations in terms of optical transmission and integration with active components, researchers began exploring alternative materials that could overcome these challenges while maintaining compatibility with existing fabrication processes.

Borosilicate glass emerged as a compelling candidate due to its unique combination of properties, including low optical loss, high transparency over a wide wavelength range, and thermal expansion coefficient closely matching that of silicon. These characteristics make it particularly suitable for creating passive optical components such as waveguides, splitters, and couplers, as well as for packaging and interfacing with other materials in hybrid PIC designs.

The objectives of research on borosilicate glass in PICs are multifaceted. Primarily, there is a focus on developing advanced fabrication techniques that enable the creation of complex optical structures with high precision and repeatability. This includes exploring methods such as femtosecond laser writing, ion exchange, and thin-film deposition to achieve the desired optical properties and geometries.

Another key goal is to enhance the integration capabilities of borosilicate glass with other materials and active components. This involves investigating techniques for bonding borosilicate glass to silicon, III-V semiconductors, and other substrates, as well as developing methods for incorporating light sources, detectors, and modulators into borosilicate glass-based PICs.

Furthermore, researchers aim to exploit the unique properties of borosilicate glass to create novel functionalities and improve the performance of existing PIC designs. This includes leveraging its high nonlinearity for all-optical signal processing, utilizing its low thermal sensitivity for temperature-insensitive devices, and exploring its potential for three-dimensional optical circuits.

As the field progresses, there is also a growing emphasis on scalability and manufacturability. Efforts are being made to adapt borosilicate glass fabrication processes to large-scale production, ensuring compatibility with standard semiconductor manufacturing techniques and developing cost-effective solutions for mass production of borosilicate glass-based PICs.

Market Analysis for Borosilicate Glass in PICs

The market for borosilicate glass in photonic integrated circuits (PICs) is experiencing significant growth, driven by the increasing demand for high-performance optical components in various applications. Borosilicate glass, known for its excellent optical properties and thermal stability, has emerged as a promising material for PIC fabrication, particularly in areas where silicon-based solutions face limitations.

The global PIC market is projected to expand rapidly in the coming years, with a compound annual growth rate (CAGR) exceeding 20% through 2026. Within this broader market, the demand for borosilicate glass-based PICs is expected to grow at an even faster rate due to their unique advantages in specific applications. Key market segments driving this growth include telecommunications, data centers, biosensing, and quantum computing.

In the telecommunications sector, borosilicate glass PICs are gaining traction for their ability to support higher data transmission rates and lower signal losses compared to traditional materials. The ongoing rollout of 5G networks and the anticipated 6G technology are expected to further boost demand for these advanced optical components.

Data centers represent another significant market opportunity for borosilicate glass PICs. As data traffic continues to surge, there is an increasing need for more efficient and compact optical interconnects. Borosilicate glass-based solutions offer improved thermal management and higher integration density, making them attractive for next-generation data center architectures.

The biosensing market is also showing strong potential for borosilicate glass PICs. Their biocompatibility and chemical resistance make them ideal for lab-on-a-chip applications and point-of-care diagnostics. The growing emphasis on personalized medicine and rapid disease detection is expected to drive demand in this sector.

Quantum computing, while still in its early stages, presents a promising long-term market for borosilicate glass PICs. The material's low-loss properties and ability to maintain quantum coherence make it suitable for developing quantum photonic circuits, a critical component in quantum information processing systems.

Despite the positive market outlook, challenges remain. The relatively higher cost of borosilicate glass compared to silicon and the need for specialized manufacturing processes may limit adoption in some price-sensitive applications. Additionally, competition from other emerging materials, such as lithium niobate and indium phosphide, could impact market share in certain segments.

Overall, the market analysis indicates a strong growth trajectory for borosilicate glass in PICs, driven by its superior performance in specific applications and the expanding demand for advanced optical technologies across multiple industries. As manufacturing processes improve and economies of scale are achieved, the market penetration of borosilicate glass PICs is expected to accelerate, potentially reshaping the landscape of integrated photonics.

The global PIC market is projected to expand rapidly in the coming years, with a compound annual growth rate (CAGR) exceeding 20% through 2026. Within this broader market, the demand for borosilicate glass-based PICs is expected to grow at an even faster rate due to their unique advantages in specific applications. Key market segments driving this growth include telecommunications, data centers, biosensing, and quantum computing.

In the telecommunications sector, borosilicate glass PICs are gaining traction for their ability to support higher data transmission rates and lower signal losses compared to traditional materials. The ongoing rollout of 5G networks and the anticipated 6G technology are expected to further boost demand for these advanced optical components.

Data centers represent another significant market opportunity for borosilicate glass PICs. As data traffic continues to surge, there is an increasing need for more efficient and compact optical interconnects. Borosilicate glass-based solutions offer improved thermal management and higher integration density, making them attractive for next-generation data center architectures.

The biosensing market is also showing strong potential for borosilicate glass PICs. Their biocompatibility and chemical resistance make them ideal for lab-on-a-chip applications and point-of-care diagnostics. The growing emphasis on personalized medicine and rapid disease detection is expected to drive demand in this sector.

Quantum computing, while still in its early stages, presents a promising long-term market for borosilicate glass PICs. The material's low-loss properties and ability to maintain quantum coherence make it suitable for developing quantum photonic circuits, a critical component in quantum information processing systems.

Despite the positive market outlook, challenges remain. The relatively higher cost of borosilicate glass compared to silicon and the need for specialized manufacturing processes may limit adoption in some price-sensitive applications. Additionally, competition from other emerging materials, such as lithium niobate and indium phosphide, could impact market share in certain segments.

Overall, the market analysis indicates a strong growth trajectory for borosilicate glass in PICs, driven by its superior performance in specific applications and the expanding demand for advanced optical technologies across multiple industries. As manufacturing processes improve and economies of scale are achieved, the market penetration of borosilicate glass PICs is expected to accelerate, potentially reshaping the landscape of integrated photonics.

Current Challenges in Borosilicate Glass PIC Integration

The integration of borosilicate glass in photonic integrated circuits (PICs) presents several significant challenges that researchers and engineers are currently grappling with. One of the primary obstacles is the precise control of the refractive index during the glass fabrication process. Borosilicate glass, while offering excellent optical properties, can exhibit variations in its refractive index due to compositional fluctuations and thermal history. This inconsistency can lead to unpredictable light propagation within the PIC, affecting the overall performance and reliability of the device.

Another major challenge lies in the development of efficient coupling mechanisms between borosilicate glass waveguides and other PIC components. The refractive index mismatch between borosilicate glass and commonly used materials like silicon or III-V semiconductors can result in significant coupling losses. Researchers are exploring various techniques such as tapered waveguides, grating couplers, and mode converters to mitigate these losses, but achieving high coupling efficiency remains a complex task.

The thermal expansion coefficient mismatch between borosilicate glass and other materials used in PICs poses a substantial challenge for long-term stability and reliability. As PICs often operate under varying temperature conditions, the differential thermal expansion can induce stress and potentially lead to delamination or cracking of the glass layers. Developing robust bonding techniques and stress-relief mechanisms is crucial to ensure the longevity of borosilicate glass-based PICs.

Fabrication processes for integrating borosilicate glass into PICs also present significant hurdles. Traditional semiconductor fabrication techniques are not always directly applicable to glass materials, necessitating the development of novel processing methods. Challenges include achieving high-precision etching of glass structures, creating smooth surfaces to minimize scattering losses, and ensuring compatibility with existing cleanroom processes.

Furthermore, the integration of active components, such as lasers or modulators, with borosilicate glass waveguides remains a complex issue. The relatively low thermal conductivity of glass can lead to heat dissipation problems in active devices, potentially affecting their performance and lifetime. Researchers are exploring hybrid integration approaches and advanced thermal management strategies to address this challenge.

Lastly, the scalability of borosilicate glass PIC manufacturing processes poses a significant challenge for widespread adoption. Current fabrication techniques often involve complex and time-consuming steps, making large-scale production economically challenging. Developing more efficient and cost-effective manufacturing processes that maintain the high optical quality of borosilicate glass components is essential for the commercial viability of this technology in PIC applications.

Another major challenge lies in the development of efficient coupling mechanisms between borosilicate glass waveguides and other PIC components. The refractive index mismatch between borosilicate glass and commonly used materials like silicon or III-V semiconductors can result in significant coupling losses. Researchers are exploring various techniques such as tapered waveguides, grating couplers, and mode converters to mitigate these losses, but achieving high coupling efficiency remains a complex task.

The thermal expansion coefficient mismatch between borosilicate glass and other materials used in PICs poses a substantial challenge for long-term stability and reliability. As PICs often operate under varying temperature conditions, the differential thermal expansion can induce stress and potentially lead to delamination or cracking of the glass layers. Developing robust bonding techniques and stress-relief mechanisms is crucial to ensure the longevity of borosilicate glass-based PICs.

Fabrication processes for integrating borosilicate glass into PICs also present significant hurdles. Traditional semiconductor fabrication techniques are not always directly applicable to glass materials, necessitating the development of novel processing methods. Challenges include achieving high-precision etching of glass structures, creating smooth surfaces to minimize scattering losses, and ensuring compatibility with existing cleanroom processes.

Furthermore, the integration of active components, such as lasers or modulators, with borosilicate glass waveguides remains a complex issue. The relatively low thermal conductivity of glass can lead to heat dissipation problems in active devices, potentially affecting their performance and lifetime. Researchers are exploring hybrid integration approaches and advanced thermal management strategies to address this challenge.

Lastly, the scalability of borosilicate glass PIC manufacturing processes poses a significant challenge for widespread adoption. Current fabrication techniques often involve complex and time-consuming steps, making large-scale production economically challenging. Developing more efficient and cost-effective manufacturing processes that maintain the high optical quality of borosilicate glass components is essential for the commercial viability of this technology in PIC applications.

Existing Borosilicate Glass PIC Fabrication Techniques

01 Composition and properties of borosilicate glass

Borosilicate glass is a type of glass with silica and boron trioxide as the main glass-forming constituents. It is known for its low thermal expansion coefficient, high chemical resistance, and excellent thermal shock resistance. These properties make it suitable for various applications in laboratory equipment, cookware, and industrial uses.- Composition and properties of borosilicate glass: Borosilicate glass is a type of glass with silica and boron trioxide as the main glass-forming constituents. It is known for its low thermal expansion coefficient, high chemical resistance, and excellent thermal shock resistance. These properties make it suitable for various applications in laboratory equipment, cookware, and industrial uses.

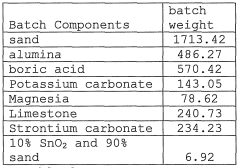

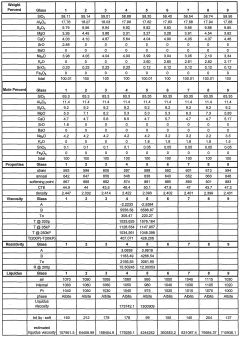

- Manufacturing processes for borosilicate glass: Various manufacturing processes are employed to produce borosilicate glass, including melting, forming, and annealing. Advanced techniques such as float glass production and precision molding are used to create different forms of borosilicate glass products. The manufacturing process often involves careful control of temperature and composition to achieve desired properties.

- Applications of borosilicate glass in laboratory and industrial settings: Borosilicate glass is widely used in laboratory glassware, such as beakers, test tubes, and pipettes, due to its chemical resistance and thermal stability. It is also employed in industrial applications, including sight glasses, process vessels, and heat exchangers. The material's durability and transparency make it ideal for these demanding environments.

- Borosilicate glass in consumer products: Borosilicate glass is increasingly used in consumer products, particularly in kitchenware and household items. Its heat resistance and durability make it suitable for bakeware, storage containers, and coffee makers. The material's clarity and eco-friendly nature also make it popular for reusable water bottles and food storage solutions.

- Innovations and modifications in borosilicate glass: Ongoing research and development in borosilicate glass focus on improving its properties and expanding its applications. This includes developing new compositions with enhanced characteristics, such as increased strength or improved optical properties. Innovations also involve surface treatments, coatings, and the incorporation of additional elements to tailor the glass for specific uses.

02 Manufacturing processes for borosilicate glass

Various manufacturing processes are employed to produce borosilicate glass, including melting, forming, and annealing. Advanced techniques such as float glass production and precision molding are used to create different forms of borosilicate glass products. The manufacturing process often involves careful control of temperature and composition to achieve desired properties.Expand Specific Solutions03 Applications of borosilicate glass in laboratory and industrial settings

Borosilicate glass finds extensive use in laboratory glassware, such as beakers, test tubes, and pipettes, due to its chemical resistance and thermal stability. It is also used in industrial applications, including sight glasses, process vessels, and heat exchangers. The material's durability and transparency make it ideal for these demanding environments.Expand Specific Solutions04 Borosilicate glass in consumer products

Borosilicate glass is widely used in consumer products, particularly in kitchenware and household items. Its heat resistance and durability make it suitable for bakeware, storage containers, and coffee makers. The glass is also used in lighting fixtures and certain electronic displays due to its thermal and electrical properties.Expand Specific Solutions05 Innovations and modifications in borosilicate glass

Ongoing research and development in borosilicate glass focus on improving its properties and expanding its applications. This includes developing new compositions, surface treatments, and manufacturing techniques to enhance strength, optical properties, and specialized functionalities. Recent innovations aim to create borosilicate glass with improved performance in areas such as energy efficiency and biomedical applications.Expand Specific Solutions

Key Players in Borosilicate Glass PIC Development

The research on borosilicate glass in photonic integrated circuits is in an emerging stage, with growing market potential as the technology matures. The global photonic integrated circuit market is projected to reach $3.5 billion by 2025, with a CAGR of 25.8%. Key players like SCHOTT AG, Corning, and AGC Inc. are leading the development of borosilicate glass for this application, leveraging their expertise in specialty glass manufacturing. Companies such as Applied Materials and Infineon Technologies are also contributing to the advancement of photonic integrated circuits, focusing on semiconductor integration and manufacturing processes. As the technology progresses, collaboration between academic institutions and industry leaders is expected to drive innovation and commercialization in this field.

SCHOTT AG

Technical Solution: SCHOTT AG has developed advanced borosilicate glass solutions for photonic integrated circuits (PICs). Their BOROFLOAT® specialty glass offers excellent optical properties and thermal stability, making it ideal for PIC applications. The glass features high transmission in the visible and near-infrared spectrum, low autofluorescence, and resistance to high-energy radiation[1]. SCHOTT has also introduced ultra-thin glass wafers with thicknesses down to 25 micrometers, enabling the production of more compact and efficient PICs[2]. Their glass-to-glass bonding technology allows for the creation of complex 3D photonic structures, enhancing the functionality and integration density of PICs[3].

Strengths: High optical quality, thermal stability, and versatility for various PIC applications. Weaknesses: May require specialized processing techniques and equipment for integration with semiconductor materials.

Corning, Inc.

Technical Solution: Corning has made significant strides in borosilicate glass research for photonic integrated circuits. Their Corning® HPFS® Fused Silica and ULE® (Ultra-Low Expansion) glass materials offer exceptional optical and thermal properties suitable for PIC applications. Corning has developed precision glass forming techniques that allow for the creation of complex optical structures with nanometer-scale accuracy[4]. They have also introduced ion-exchange strengthening processes for borosilicate glass, improving its mechanical durability for use in PICs[5]. Corning's recent advancements include the development of glass-based optical interposers that enable high-density photonic integration and improved signal integrity in PICs[6].

Strengths: Excellent optical properties, precision manufacturing capabilities, and innovative glass strengthening techniques. Weaknesses: Higher cost compared to some alternative materials, potentially limiting widespread adoption in cost-sensitive applications.

Core Innovations in Borosilicate Glass for PICs

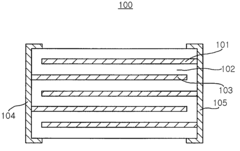

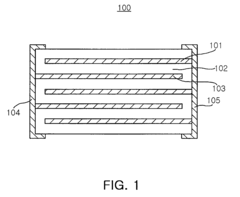

Borosilicate glass compositions for sintering agent, dielectric compositions and multilayer ceramic capacitor using the same

PatentActiveUS20100165542A1

Innovation

- Borosilicate glass compositions are used as a sintering agent, formulated with specific ratios of alkali oxides, alkaline earth oxides, and rare earth oxides, which allow for low-temperature sintering of ceramic dielectrics and enhance hot insulation resistance by forming a stable glass network that reduces the sintering temperature to 1100°C or less.

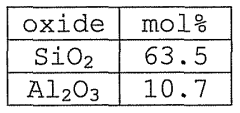

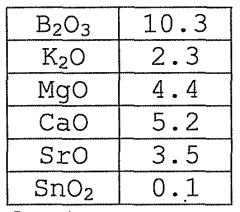

Intermediate thermal expansion coefficient glass

PatentWO2010042460A2

Innovation

- Developing a glass composition with 60-65% SiO2, 8-12% Al2O3, 7-15% B2O3, and 9-15% RO, where M is an alkali metal and R is an alkaline earth metal, which reduces melting temperatures and thermal expansion coefficient, allowing for lower energy consumption and cost-effective production.

Material Properties and Characterization Methods

Borosilicate glass has emerged as a promising material for photonic integrated circuits (PICs) due to its unique combination of optical and physical properties. The material exhibits low optical loss in the visible and near-infrared regions, making it suitable for a wide range of photonic applications. Its refractive index, typically around 1.47, provides sufficient contrast for waveguiding while maintaining compatibility with other optical materials.

One of the key advantages of borosilicate glass is its excellent thermal stability. With a low coefficient of thermal expansion, it minimizes stress-induced birefringence and maintains optical performance over a wide temperature range. This property is crucial for ensuring the reliability and consistency of PICs in various operating conditions.

The mechanical strength of borosilicate glass is another important characteristic. It offers good resistance to scratching and impact, which is beneficial for the fabrication and handling of photonic devices. Additionally, its chemical durability makes it resistant to many common solvents and chemicals used in semiconductor processing.

Characterization of borosilicate glass for PIC applications involves several methods. Optical characterization techniques, such as ellipsometry and prism coupling, are used to measure the refractive index and thickness of thin films. These measurements are essential for designing waveguides and other optical components with precise dimensions and optical properties.

Surface roughness analysis is crucial for minimizing scattering losses in waveguides. Atomic force microscopy (AFM) and scanning electron microscopy (SEM) are commonly employed to evaluate surface quality and identify potential defects. These techniques provide nanometer-scale resolution, allowing for detailed analysis of surface morphology.

Spectroscopic methods, including Fourier-transform infrared spectroscopy (FTIR) and Raman spectroscopy, are used to study the molecular structure and composition of borosilicate glass. These techniques can reveal information about the glass network structure and the presence of impurities that may affect optical performance.

Thermal analysis techniques, such as differential scanning calorimetry (DSC) and thermogravimetric analysis (TGA), are employed to investigate the thermal properties of borosilicate glass. These methods provide insights into the glass transition temperature, thermal stability, and potential phase changes that could impact device performance.

Mechanical testing, including nanoindentation and flexural strength measurements, is conducted to assess the material's resistance to deformation and fracture. These properties are important for ensuring the structural integrity of PICs during fabrication and operation.

One of the key advantages of borosilicate glass is its excellent thermal stability. With a low coefficient of thermal expansion, it minimizes stress-induced birefringence and maintains optical performance over a wide temperature range. This property is crucial for ensuring the reliability and consistency of PICs in various operating conditions.

The mechanical strength of borosilicate glass is another important characteristic. It offers good resistance to scratching and impact, which is beneficial for the fabrication and handling of photonic devices. Additionally, its chemical durability makes it resistant to many common solvents and chemicals used in semiconductor processing.

Characterization of borosilicate glass for PIC applications involves several methods. Optical characterization techniques, such as ellipsometry and prism coupling, are used to measure the refractive index and thickness of thin films. These measurements are essential for designing waveguides and other optical components with precise dimensions and optical properties.

Surface roughness analysis is crucial for minimizing scattering losses in waveguides. Atomic force microscopy (AFM) and scanning electron microscopy (SEM) are commonly employed to evaluate surface quality and identify potential defects. These techniques provide nanometer-scale resolution, allowing for detailed analysis of surface morphology.

Spectroscopic methods, including Fourier-transform infrared spectroscopy (FTIR) and Raman spectroscopy, are used to study the molecular structure and composition of borosilicate glass. These techniques can reveal information about the glass network structure and the presence of impurities that may affect optical performance.

Thermal analysis techniques, such as differential scanning calorimetry (DSC) and thermogravimetric analysis (TGA), are employed to investigate the thermal properties of borosilicate glass. These methods provide insights into the glass transition temperature, thermal stability, and potential phase changes that could impact device performance.

Mechanical testing, including nanoindentation and flexural strength measurements, is conducted to assess the material's resistance to deformation and fracture. These properties are important for ensuring the structural integrity of PICs during fabrication and operation.

Environmental Impact and Sustainability Considerations

The integration of borosilicate glass in photonic integrated circuits (PICs) presents both environmental challenges and opportunities for sustainability. Borosilicate glass, known for its low thermal expansion coefficient and excellent optical properties, offers potential advantages in terms of energy efficiency and device longevity. However, its production and disposal processes require careful consideration to minimize environmental impact.

The manufacturing of borosilicate glass for PICs involves high-temperature processes, which can be energy-intensive. This energy consumption contributes to greenhouse gas emissions if not sourced from renewable energy. However, the durability and thermal stability of borosilicate glass can lead to longer-lasting devices, potentially reducing the frequency of replacements and associated electronic waste.

In terms of raw materials, borosilicate glass primarily consists of silica and boron oxide. While silica is abundant, boron mining can have environmental implications, including habitat disruption and water pollution. Sustainable sourcing practices and efficient use of boron in glass production are crucial for minimizing these impacts.

The integration of borosilicate glass in PICs can contribute to improved energy efficiency in optical communication systems. The low optical loss and high refractive index of borosilicate glass enable the development of more compact and efficient photonic devices, potentially reducing overall power consumption in data centers and telecommunication networks.

End-of-life considerations for borosilicate glass in PICs are also important. While glass is generally recyclable, the complex nature of integrated circuits can make separation and recycling challenging. Research into design for disassembly and specialized recycling processes for PICs incorporating borosilicate glass is necessary to ensure proper material recovery and minimize landfill waste.

The use of borosilicate glass in PICs may also have indirect environmental benefits. For instance, the development of more efficient and compact photonic devices could lead to reduced material usage in electronic systems overall. Additionally, advancements in PIC technology enabled by borosilicate glass could contribute to more efficient sensing and monitoring systems for environmental applications.

As the field progresses, life cycle assessments (LCAs) of borosilicate glass-based PICs will be crucial for quantifying their environmental impact compared to alternative materials and technologies. These assessments should consider factors such as energy consumption, resource depletion, emissions, and waste generation throughout the product lifecycle.

The manufacturing of borosilicate glass for PICs involves high-temperature processes, which can be energy-intensive. This energy consumption contributes to greenhouse gas emissions if not sourced from renewable energy. However, the durability and thermal stability of borosilicate glass can lead to longer-lasting devices, potentially reducing the frequency of replacements and associated electronic waste.

In terms of raw materials, borosilicate glass primarily consists of silica and boron oxide. While silica is abundant, boron mining can have environmental implications, including habitat disruption and water pollution. Sustainable sourcing practices and efficient use of boron in glass production are crucial for minimizing these impacts.

The integration of borosilicate glass in PICs can contribute to improved energy efficiency in optical communication systems. The low optical loss and high refractive index of borosilicate glass enable the development of more compact and efficient photonic devices, potentially reducing overall power consumption in data centers and telecommunication networks.

End-of-life considerations for borosilicate glass in PICs are also important. While glass is generally recyclable, the complex nature of integrated circuits can make separation and recycling challenging. Research into design for disassembly and specialized recycling processes for PICs incorporating borosilicate glass is necessary to ensure proper material recovery and minimize landfill waste.

The use of borosilicate glass in PICs may also have indirect environmental benefits. For instance, the development of more efficient and compact photonic devices could lead to reduced material usage in electronic systems overall. Additionally, advancements in PIC technology enabled by borosilicate glass could contribute to more efficient sensing and monitoring systems for environmental applications.

As the field progresses, life cycle assessments (LCAs) of borosilicate glass-based PICs will be crucial for quantifying their environmental impact compared to alternative materials and technologies. These assessments should consider factors such as energy consumption, resource depletion, emissions, and waste generation throughout the product lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!