Butane's Contribution to the Future of Carbon-Neutral Processes

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Butane in Carbon-Neutral Processes: Background and Objectives

Butane, a hydrocarbon with the formula C4H10, has emerged as a significant player in the pursuit of carbon-neutral processes. As global efforts to combat climate change intensify, the role of butane in developing sustainable technologies has gained increasing attention. This compound, traditionally known for its use as a fuel and refrigerant, is now being explored for its potential to contribute to a more environmentally friendly future.

The journey of butane in carbon-neutral processes began with the recognition of its versatile chemical properties. Its relatively simple molecular structure and high energy density make it an attractive candidate for various applications in sustainable chemistry. The evolution of butane's role in this field has been driven by the urgent need to reduce greenhouse gas emissions and transition towards a circular economy.

One of the key objectives in exploring butane's potential is to develop efficient methods for its conversion into value-added products with minimal carbon footprint. This includes the production of hydrogen, a clean energy carrier, through processes such as steam reforming or partial oxidation of butane. These techniques aim to harness butane's energy content while minimizing CO2 emissions, aligning with the broader goals of carbon neutrality.

Another significant area of focus is the utilization of butane in the synthesis of advanced materials. Researchers are investigating ways to transform butane into precursors for carbon nanotubes, graphene, and other nanomaterials. These materials have wide-ranging applications in electronics, energy storage, and environmental remediation, offering pathways to more sustainable technologies.

The development of catalytic processes for butane activation represents a critical technological goal. By designing novel catalysts and reaction systems, scientists aim to enable selective transformations of butane under mild conditions. This approach not only improves energy efficiency but also opens up new possibilities for green chemistry applications.

Butane's role in carbon-neutral processes also extends to its potential as a feedstock for biofuels and biochemicals. Through innovative bioconversion techniques, researchers are exploring ways to transform butane into high-value compounds using engineered microorganisms. This bio-based approach offers a promising route to sustainable chemical production, leveraging the principles of industrial biotechnology.

As we look towards the future, the objectives for butane in carbon-neutral processes are ambitious yet crucial. These include achieving near-zero emissions in butane-based processes, developing closed-loop systems for butane utilization, and integrating butane-derived technologies into broader sustainable energy and materials ecosystems. The realization of these goals will require continued innovation, cross-disciplinary collaboration, and supportive policy frameworks.

The journey of butane in carbon-neutral processes began with the recognition of its versatile chemical properties. Its relatively simple molecular structure and high energy density make it an attractive candidate for various applications in sustainable chemistry. The evolution of butane's role in this field has been driven by the urgent need to reduce greenhouse gas emissions and transition towards a circular economy.

One of the key objectives in exploring butane's potential is to develop efficient methods for its conversion into value-added products with minimal carbon footprint. This includes the production of hydrogen, a clean energy carrier, through processes such as steam reforming or partial oxidation of butane. These techniques aim to harness butane's energy content while minimizing CO2 emissions, aligning with the broader goals of carbon neutrality.

Another significant area of focus is the utilization of butane in the synthesis of advanced materials. Researchers are investigating ways to transform butane into precursors for carbon nanotubes, graphene, and other nanomaterials. These materials have wide-ranging applications in electronics, energy storage, and environmental remediation, offering pathways to more sustainable technologies.

The development of catalytic processes for butane activation represents a critical technological goal. By designing novel catalysts and reaction systems, scientists aim to enable selective transformations of butane under mild conditions. This approach not only improves energy efficiency but also opens up new possibilities for green chemistry applications.

Butane's role in carbon-neutral processes also extends to its potential as a feedstock for biofuels and biochemicals. Through innovative bioconversion techniques, researchers are exploring ways to transform butane into high-value compounds using engineered microorganisms. This bio-based approach offers a promising route to sustainable chemical production, leveraging the principles of industrial biotechnology.

As we look towards the future, the objectives for butane in carbon-neutral processes are ambitious yet crucial. These include achieving near-zero emissions in butane-based processes, developing closed-loop systems for butane utilization, and integrating butane-derived technologies into broader sustainable energy and materials ecosystems. The realization of these goals will require continued innovation, cross-disciplinary collaboration, and supportive policy frameworks.

Market Demand for Carbon-Neutral Chemical Processes

The global market for carbon-neutral chemical processes is experiencing rapid growth, driven by increasing environmental concerns and stringent regulations aimed at reducing greenhouse gas emissions. As industries worldwide strive to achieve net-zero carbon emissions, the demand for sustainable chemical production methods has surged significantly.

The chemical sector, being one of the largest contributors to industrial carbon emissions, is under immense pressure to adopt cleaner production processes. This has created a substantial market opportunity for carbon-neutral technologies, including those involving butane as a potential feedstock. The market size for green chemistry, which encompasses carbon-neutral processes, is projected to expand considerably in the coming years.

Key factors driving this market demand include government policies promoting sustainable industrial practices, consumer preferences for eco-friendly products, and corporate commitments to reduce carbon footprints. Many leading chemical companies have announced ambitious targets to achieve carbon neutrality by 2050 or earlier, further fueling the demand for innovative solutions.

The automotive and construction industries, major consumers of chemical products, are increasingly seeking carbon-neutral materials to meet their own sustainability goals. This trend is creating a ripple effect throughout the chemical supply chain, amplifying the demand for carbon-neutral processes.

Geographically, Europe leads in the adoption of carbon-neutral chemical processes, followed closely by North America. However, the Asia-Pacific region is expected to witness the fastest growth in this market, driven by rapid industrialization and stringent environmental regulations in countries like China and India.

Investors are showing keen interest in companies developing carbon-neutral chemical technologies, as evidenced by the increasing number of venture capital investments and corporate partnerships in this space. This influx of capital is expected to accelerate the development and commercialization of innovative carbon-neutral processes.

The market for carbon capture and utilization (CCU) technologies, which are often integral to carbon-neutral chemical processes, is also experiencing significant growth. These technologies offer the potential to transform captured CO2 into valuable chemical products, creating additional economic incentives for adopting carbon-neutral practices.

Despite the growing demand, challenges remain in scaling up carbon-neutral chemical processes to industrial levels. The market is calling for solutions that not only reduce emissions but also maintain or improve production efficiency and product quality. This presents both a challenge and an opportunity for innovators in the field of carbon-neutral chemical processes, including those exploring the potential of butane as a feedstock.

The chemical sector, being one of the largest contributors to industrial carbon emissions, is under immense pressure to adopt cleaner production processes. This has created a substantial market opportunity for carbon-neutral technologies, including those involving butane as a potential feedstock. The market size for green chemistry, which encompasses carbon-neutral processes, is projected to expand considerably in the coming years.

Key factors driving this market demand include government policies promoting sustainable industrial practices, consumer preferences for eco-friendly products, and corporate commitments to reduce carbon footprints. Many leading chemical companies have announced ambitious targets to achieve carbon neutrality by 2050 or earlier, further fueling the demand for innovative solutions.

The automotive and construction industries, major consumers of chemical products, are increasingly seeking carbon-neutral materials to meet their own sustainability goals. This trend is creating a ripple effect throughout the chemical supply chain, amplifying the demand for carbon-neutral processes.

Geographically, Europe leads in the adoption of carbon-neutral chemical processes, followed closely by North America. However, the Asia-Pacific region is expected to witness the fastest growth in this market, driven by rapid industrialization and stringent environmental regulations in countries like China and India.

Investors are showing keen interest in companies developing carbon-neutral chemical technologies, as evidenced by the increasing number of venture capital investments and corporate partnerships in this space. This influx of capital is expected to accelerate the development and commercialization of innovative carbon-neutral processes.

The market for carbon capture and utilization (CCU) technologies, which are often integral to carbon-neutral chemical processes, is also experiencing significant growth. These technologies offer the potential to transform captured CO2 into valuable chemical products, creating additional economic incentives for adopting carbon-neutral practices.

Despite the growing demand, challenges remain in scaling up carbon-neutral chemical processes to industrial levels. The market is calling for solutions that not only reduce emissions but also maintain or improve production efficiency and product quality. This presents both a challenge and an opportunity for innovators in the field of carbon-neutral chemical processes, including those exploring the potential of butane as a feedstock.

Current State and Challenges in Butane Utilization

The current state of butane utilization in carbon-neutral processes is characterized by both significant progress and persistent challenges. Butane, a versatile hydrocarbon, has gained attention as a potential contributor to sustainable energy solutions due to its relatively high energy density and lower carbon footprint compared to other fossil fuels.

In recent years, there has been a notable shift towards exploring butane's role in renewable energy systems. One of the most promising developments is the use of butane in fuel cells, particularly in direct butane fuel cells (DBFCs). These systems offer higher energy efficiency and lower emissions compared to traditional combustion engines. However, the widespread adoption of DBFCs is hindered by issues such as catalyst degradation and the need for more efficient membrane technologies.

Another area of significant progress is the utilization of butane in biogas production. Anaerobic digestion processes that incorporate butane have shown improved methane yields, contributing to more efficient renewable energy generation. Nevertheless, optimizing these processes for large-scale implementation remains a challenge, particularly in terms of maintaining stable microbial communities and managing potential inhibitory effects.

The petrochemical industry has also made strides in developing more sustainable butane-based processes. Advanced catalytic technologies have enabled the production of valuable chemicals from butane with reduced energy consumption and emissions. However, the industry still grapples with the need for more efficient catalysts and the challenge of integrating these processes into existing infrastructure.

One of the most pressing challenges in butane utilization is the development of effective carbon capture and utilization (CCU) technologies. While butane offers a lower carbon footprint than many alternatives, achieving true carbon neutrality requires innovative approaches to capturing and repurposing emissions. Current CCU technologies often struggle with efficiency and cost-effectiveness when applied to butane-based processes.

The transportation and storage of butane also present ongoing challenges. While liquefied petroleum gas (LPG) systems have improved, there is still a need for more advanced containment and distribution technologies to minimize leakage and enhance safety. This is particularly crucial as the use of butane expands into new applications and markets.

Regulatory frameworks and policy support for butane-based carbon-neutral technologies vary significantly across regions, creating uncertainties for investors and innovators. Harmonizing standards and incentives globally could accelerate the development and adoption of sustainable butane utilization methods.

In conclusion, while butane shows promise in contributing to carbon-neutral processes, significant technological, economic, and regulatory challenges must be overcome to fully realize its potential. Addressing these issues will require continued research, investment, and collaboration across industries and borders.

In recent years, there has been a notable shift towards exploring butane's role in renewable energy systems. One of the most promising developments is the use of butane in fuel cells, particularly in direct butane fuel cells (DBFCs). These systems offer higher energy efficiency and lower emissions compared to traditional combustion engines. However, the widespread adoption of DBFCs is hindered by issues such as catalyst degradation and the need for more efficient membrane technologies.

Another area of significant progress is the utilization of butane in biogas production. Anaerobic digestion processes that incorporate butane have shown improved methane yields, contributing to more efficient renewable energy generation. Nevertheless, optimizing these processes for large-scale implementation remains a challenge, particularly in terms of maintaining stable microbial communities and managing potential inhibitory effects.

The petrochemical industry has also made strides in developing more sustainable butane-based processes. Advanced catalytic technologies have enabled the production of valuable chemicals from butane with reduced energy consumption and emissions. However, the industry still grapples with the need for more efficient catalysts and the challenge of integrating these processes into existing infrastructure.

One of the most pressing challenges in butane utilization is the development of effective carbon capture and utilization (CCU) technologies. While butane offers a lower carbon footprint than many alternatives, achieving true carbon neutrality requires innovative approaches to capturing and repurposing emissions. Current CCU technologies often struggle with efficiency and cost-effectiveness when applied to butane-based processes.

The transportation and storage of butane also present ongoing challenges. While liquefied petroleum gas (LPG) systems have improved, there is still a need for more advanced containment and distribution technologies to minimize leakage and enhance safety. This is particularly crucial as the use of butane expands into new applications and markets.

Regulatory frameworks and policy support for butane-based carbon-neutral technologies vary significantly across regions, creating uncertainties for investors and innovators. Harmonizing standards and incentives globally could accelerate the development and adoption of sustainable butane utilization methods.

In conclusion, while butane shows promise in contributing to carbon-neutral processes, significant technological, economic, and regulatory challenges must be overcome to fully realize its potential. Addressing these issues will require continued research, investment, and collaboration across industries and borders.

Existing Solutions for Butane in Carbon-Neutral Processes

01 Butane gas lighters and refill devices

Various designs for butane gas lighters and refill devices, including improvements in safety features, ignition mechanisms, and refilling systems. These innovations aim to enhance user experience, increase reliability, and improve the overall functionality of butane-based lighters.- Butane gas lighters and refill devices: Various designs and improvements for butane gas lighters and refill devices, including safety mechanisms, ergonomic designs, and efficient refilling systems. These innovations aim to enhance user experience, safety, and convenience in portable gas lighter products.

- Butane purification and separation processes: Methods and systems for purifying and separating butane from other hydrocarbons or mixtures. These processes involve various techniques such as distillation, adsorption, or membrane separation to obtain high-purity butane for industrial or commercial applications.

- Butane fuel storage and dispensing systems: Innovations in butane fuel storage containers and dispensing systems, focusing on improved safety features, leak prevention, and efficient fuel delivery. These developments are applicable to portable stoves, camping equipment, and other butane-powered devices.

- Butane as a refrigerant or heat transfer fluid: Applications of butane as a refrigerant or heat transfer fluid in various cooling systems and heat pumps. These innovations explore the use of butane as an environmentally friendly alternative to traditional refrigerants, focusing on energy efficiency and system performance.

- Butane in chemical synthesis and processing: Utilization of butane in chemical synthesis processes and as a feedstock for producing various chemical compounds. These innovations cover catalytic reactions, oxidation processes, and other chemical transformations involving butane to create value-added products.

02 Butane purification and separation processes

Methods and systems for purifying and separating butane from other hydrocarbons or mixtures. These processes may involve adsorption, distillation, or other separation techniques to obtain high-purity butane for various industrial applications.Expand Specific Solutions03 Butane fuel storage and dispensing systems

Innovations in the storage and dispensing of butane fuel, including improved tank designs, safety valves, and dispensing mechanisms. These advancements aim to enhance the safety, efficiency, and convenience of handling and using butane fuel in various applications.Expand Specific Solutions04 Butane-based heating and cooking appliances

Development of portable heating and cooking appliances that utilize butane as a fuel source. These devices may include camping stoves, portable heaters, and other outdoor equipment designed for efficient and safe use of butane fuel.Expand Specific Solutions05 Butane production and processing methods

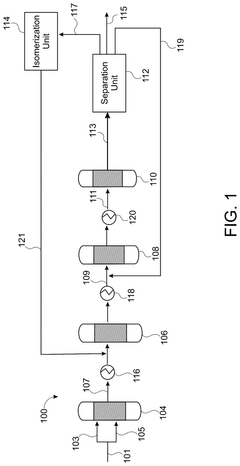

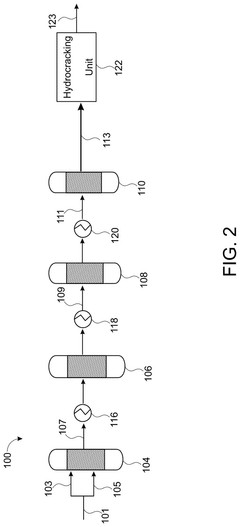

Innovative techniques for the production and processing of butane, including catalytic processes, isomerization, and other chemical reactions. These methods aim to improve the efficiency and yield of butane production for various industrial applications.Expand Specific Solutions

Key Players in Butane and Carbon-Neutral Industries

The competitive landscape for butane's contribution to carbon-neutral processes is evolving rapidly, with the industry in a transitional phase. The market size is expanding as companies seek sustainable alternatives, driven by increasing environmental regulations and consumer demand for greener products. Technologically, the field is progressing from early-stage research to pilot projects and commercial applications. Key players like China Petroleum & Chemical Corp., SABIC, DuPont, and BASF are investing heavily in R&D, focusing on catalytic processes and innovative conversion technologies. Smaller specialized firms and research institutions are also making significant contributions, fostering a dynamic and competitive environment. The involvement of major petrochemical companies indicates the potential for rapid scaling and commercialization of promising technologies in this sector.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) is at the forefront of butane utilization for carbon-neutral processes. Their innovative approach involves the catalytic dehydrogenation of butane to produce butenes, which are then used as feedstock for various petrochemical products[1]. This process significantly reduces carbon emissions compared to traditional methods. Sinopec has also developed a novel butane-to-olefins technology that uses a proprietary catalyst system, achieving high selectivity and conversion rates[2]. Additionally, they are exploring the use of renewable energy sources to power these processes, further enhancing their carbon-neutral potential[3].

Strengths: Extensive R&D capabilities, large-scale implementation potential, and integration with existing petrochemical infrastructure. Weaknesses: High initial investment costs and potential challenges in scaling up new technologies.

SABIC Global Technologies BV

Technical Solution: SABIC Global Technologies BV has developed a groundbreaking approach to utilizing butane in carbon-neutral processes. Their technology focuses on the oxidative dehydrogenation of butane to produce butadiene, a key component in synthetic rubber production[1]. This process uses advanced catalysts that operate at lower temperatures, reducing energy consumption and CO2 emissions[2]. SABIC has also integrated carbon capture and utilization (CCU) technologies into their butane processing facilities, where captured CO2 is used to produce value-added chemicals, creating a circular economy model[3]. Furthermore, they are investigating the use of green hydrogen in butane processing to further reduce the carbon footprint[4].

Strengths: Advanced catalyst technology, integrated CCU systems, and a strong focus on circular economy principles. Weaknesses: Dependence on the availability of green hydrogen and potential scalability issues for CCU technologies.

Core Innovations in Butane-Based Carbon-Neutral Technologies

A process for butane hydrogenolysis having safe thermal operation

PatentPendingUS20250230110A1

Innovation

- A process involving a series of reactors with progressively increasing catalyst loading and reactor temperature rise, optionally with methane dilution, to stabilize the reaction and enhance butane conversion and ethane selectivity.

Environmental Impact Assessment of Butane Utilization

The environmental impact assessment of butane utilization is a critical component in evaluating its potential contribution to carbon-neutral processes. Butane, a hydrocarbon gas, has traditionally been associated with fossil fuel consumption and greenhouse gas emissions. However, recent advancements in technology and process engineering have opened up new possibilities for its sustainable use.

When considering the environmental impact of butane utilization, it is essential to examine the entire lifecycle of the gas, from extraction to end-use. The extraction process, typically associated with natural gas production, can have significant environmental implications, including land disturbance, water pollution, and methane leakage. However, modern extraction techniques and stringent regulations have helped mitigate these impacts to some extent.

In terms of transportation and storage, butane's high energy density allows for efficient distribution, potentially reducing the carbon footprint associated with logistics. Additionally, its ability to be easily liquefied under moderate pressure makes it a versatile fuel for various applications, from portable stoves to industrial processes.

The combustion of butane releases carbon dioxide and water vapor, contributing to greenhouse gas emissions. However, when compared to other fossil fuels, butane produces relatively lower emissions per unit of energy. This characteristic makes it an attractive transitional fuel in the journey towards carbon neutrality.

One of the most promising aspects of butane utilization in carbon-neutral processes is its potential role in the production of hydrogen. Through steam reforming or partial oxidation, butane can be converted into hydrogen, which is widely regarded as a clean energy carrier. This process, coupled with carbon capture and storage technologies, could significantly reduce the overall carbon footprint of hydrogen production.

Furthermore, butane can be derived from renewable sources, such as biomass or waste streams, offering a pathway to carbon-neutral or even carbon-negative processes. Bio-butane, produced through fermentation or thermochemical processes, has the potential to replace fossil-derived butane in various applications without significant modifications to existing infrastructure.

In the context of industrial processes, butane's use as a feedstock for chemical synthesis presents opportunities for carbon neutrality. By incorporating renewable butane or implementing circular economy principles, industries can reduce their reliance on fossil-based raw materials and move towards more sustainable production methods.

However, it is crucial to acknowledge the challenges associated with butane utilization, particularly in terms of fugitive emissions and safety concerns. Proper handling, storage, and leak detection systems are essential to minimize environmental risks and ensure the overall sustainability of butane-based processes.

When considering the environmental impact of butane utilization, it is essential to examine the entire lifecycle of the gas, from extraction to end-use. The extraction process, typically associated with natural gas production, can have significant environmental implications, including land disturbance, water pollution, and methane leakage. However, modern extraction techniques and stringent regulations have helped mitigate these impacts to some extent.

In terms of transportation and storage, butane's high energy density allows for efficient distribution, potentially reducing the carbon footprint associated with logistics. Additionally, its ability to be easily liquefied under moderate pressure makes it a versatile fuel for various applications, from portable stoves to industrial processes.

The combustion of butane releases carbon dioxide and water vapor, contributing to greenhouse gas emissions. However, when compared to other fossil fuels, butane produces relatively lower emissions per unit of energy. This characteristic makes it an attractive transitional fuel in the journey towards carbon neutrality.

One of the most promising aspects of butane utilization in carbon-neutral processes is its potential role in the production of hydrogen. Through steam reforming or partial oxidation, butane can be converted into hydrogen, which is widely regarded as a clean energy carrier. This process, coupled with carbon capture and storage technologies, could significantly reduce the overall carbon footprint of hydrogen production.

Furthermore, butane can be derived from renewable sources, such as biomass or waste streams, offering a pathway to carbon-neutral or even carbon-negative processes. Bio-butane, produced through fermentation or thermochemical processes, has the potential to replace fossil-derived butane in various applications without significant modifications to existing infrastructure.

In the context of industrial processes, butane's use as a feedstock for chemical synthesis presents opportunities for carbon neutrality. By incorporating renewable butane or implementing circular economy principles, industries can reduce their reliance on fossil-based raw materials and move towards more sustainable production methods.

However, it is crucial to acknowledge the challenges associated with butane utilization, particularly in terms of fugitive emissions and safety concerns. Proper handling, storage, and leak detection systems are essential to minimize environmental risks and ensure the overall sustainability of butane-based processes.

Policy and Regulatory Framework for Carbon-Neutral Processes

The policy and regulatory framework for carbon-neutral processes plays a crucial role in shaping the future of sustainable energy solutions, including the potential contribution of butane. Governments worldwide are increasingly implementing stringent regulations and incentives to promote the adoption of carbon-neutral technologies and reduce greenhouse gas emissions.

At the international level, agreements such as the Paris Agreement provide a global framework for climate action, setting targets for reducing carbon emissions and transitioning to cleaner energy sources. These agreements often influence national policies and regulations, creating a cascading effect on industry practices and technological development.

Many countries have established carbon pricing mechanisms, such as carbon taxes or cap-and-trade systems, to incentivize the reduction of carbon emissions. These economic instruments can significantly impact the viability of carbon-neutral processes involving butane, potentially making them more competitive against traditional carbon-intensive alternatives.

Renewable energy mandates and clean fuel standards are becoming increasingly common in various jurisdictions. These policies often require a certain percentage of energy production or fuel consumption to come from renewable or low-carbon sources. Such regulations can create opportunities for butane-based carbon-neutral processes, particularly in sectors where electrification is challenging.

Research and development incentives, including grants, tax credits, and public-private partnerships, are being implemented to accelerate the development of carbon-neutral technologies. These initiatives can provide crucial support for advancing butane-related innovations in carbon-neutral processes, helping to bridge the gap between laboratory research and commercial viability.

Environmental impact assessments and life cycle analysis requirements are becoming more stringent, pushing industries to consider the full environmental footprint of their processes. This trend may favor the adoption of butane-based carbon-neutral solutions that can demonstrate significant reductions in overall emissions compared to conventional methods.

Regulatory frameworks are also evolving to address the specific challenges and opportunities presented by emerging technologies. This includes the development of standards and certifications for carbon-neutral processes, which can help ensure the credibility and effectiveness of butane-based solutions in contributing to climate goals.

As the urgency of climate action increases, policymakers are likely to continue refining and strengthening the regulatory landscape for carbon-neutral processes. This dynamic environment will undoubtedly shape the future role of butane in sustainable energy systems, influencing investment decisions, technological development, and market adoption of innovative solutions.

At the international level, agreements such as the Paris Agreement provide a global framework for climate action, setting targets for reducing carbon emissions and transitioning to cleaner energy sources. These agreements often influence national policies and regulations, creating a cascading effect on industry practices and technological development.

Many countries have established carbon pricing mechanisms, such as carbon taxes or cap-and-trade systems, to incentivize the reduction of carbon emissions. These economic instruments can significantly impact the viability of carbon-neutral processes involving butane, potentially making them more competitive against traditional carbon-intensive alternatives.

Renewable energy mandates and clean fuel standards are becoming increasingly common in various jurisdictions. These policies often require a certain percentage of energy production or fuel consumption to come from renewable or low-carbon sources. Such regulations can create opportunities for butane-based carbon-neutral processes, particularly in sectors where electrification is challenging.

Research and development incentives, including grants, tax credits, and public-private partnerships, are being implemented to accelerate the development of carbon-neutral technologies. These initiatives can provide crucial support for advancing butane-related innovations in carbon-neutral processes, helping to bridge the gap between laboratory research and commercial viability.

Environmental impact assessments and life cycle analysis requirements are becoming more stringent, pushing industries to consider the full environmental footprint of their processes. This trend may favor the adoption of butane-based carbon-neutral solutions that can demonstrate significant reductions in overall emissions compared to conventional methods.

Regulatory frameworks are also evolving to address the specific challenges and opportunities presented by emerging technologies. This includes the development of standards and certifications for carbon-neutral processes, which can help ensure the credibility and effectiveness of butane-based solutions in contributing to climate goals.

As the urgency of climate action increases, policymakers are likely to continue refining and strengthening the regulatory landscape for carbon-neutral processes. This dynamic environment will undoubtedly shape the future role of butane in sustainable energy systems, influencing investment decisions, technological development, and market adoption of innovative solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!