Carbon Intensity And Energy Consumption Models For Direct Lithium Extraction

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DLE Technology Background and Objectives

Direct Lithium Extraction (DLE) has emerged as a transformative technology in the lithium production landscape over the past decade. Traditional lithium extraction methods, primarily evaporative ponds and hard rock mining, have dominated the industry since the 1950s. However, these conventional approaches face significant environmental challenges, including extensive water consumption, large land footprints, and lengthy production timelines spanning 18-24 months.

DLE technologies represent a paradigm shift in lithium production, offering potential solutions to these longstanding challenges. The fundamental principle behind DLE involves selectively extracting lithium from brine resources using advanced materials and processes that can significantly reduce environmental impact while increasing recovery efficiency. The evolution of DLE has accelerated notably since 2015, with substantial technological advancements in selective adsorption materials, membrane systems, and electrochemical processes.

The primary objective of DLE technology development is to establish environmentally sustainable lithium production methods that minimize carbon intensity and energy consumption while maximizing resource efficiency. This aligns with the growing global demand for lithium, projected to increase by 40-fold by 2040 according to the International Energy Agency, driven primarily by the electric vehicle revolution and renewable energy storage requirements.

Current DLE technologies can be categorized into three main approaches: adsorption-based systems using selective materials, membrane-based separation processes, and electrochemical methods. Each approach presents distinct energy consumption profiles and carbon footprints that require comprehensive modeling and analysis to optimize environmental performance.

The carbon intensity of DLE operations varies significantly based on process design, energy source, and operational efficiency. Initial studies suggest that advanced DLE systems may reduce carbon emissions by 30-60% compared to conventional methods, though these figures require further validation across different geological and operational contexts.

Energy consumption modeling for DLE systems must account for multiple factors including pumping requirements, processing energy, material regeneration cycles, and water management. Preliminary data indicates energy requirements ranging from 5-15 kWh per kilogram of lithium carbonate equivalent (LCE) produced, though this varies substantially between different technological approaches.

The technological trajectory aims to develop next-generation DLE systems that can achieve carbon neutrality while maintaining economic viability. This requires integrated modeling approaches that combine process engineering, life cycle assessment, and techno-economic analysis to optimize both environmental and economic performance parameters simultaneously.

DLE technologies represent a paradigm shift in lithium production, offering potential solutions to these longstanding challenges. The fundamental principle behind DLE involves selectively extracting lithium from brine resources using advanced materials and processes that can significantly reduce environmental impact while increasing recovery efficiency. The evolution of DLE has accelerated notably since 2015, with substantial technological advancements in selective adsorption materials, membrane systems, and electrochemical processes.

The primary objective of DLE technology development is to establish environmentally sustainable lithium production methods that minimize carbon intensity and energy consumption while maximizing resource efficiency. This aligns with the growing global demand for lithium, projected to increase by 40-fold by 2040 according to the International Energy Agency, driven primarily by the electric vehicle revolution and renewable energy storage requirements.

Current DLE technologies can be categorized into three main approaches: adsorption-based systems using selective materials, membrane-based separation processes, and electrochemical methods. Each approach presents distinct energy consumption profiles and carbon footprints that require comprehensive modeling and analysis to optimize environmental performance.

The carbon intensity of DLE operations varies significantly based on process design, energy source, and operational efficiency. Initial studies suggest that advanced DLE systems may reduce carbon emissions by 30-60% compared to conventional methods, though these figures require further validation across different geological and operational contexts.

Energy consumption modeling for DLE systems must account for multiple factors including pumping requirements, processing energy, material regeneration cycles, and water management. Preliminary data indicates energy requirements ranging from 5-15 kWh per kilogram of lithium carbonate equivalent (LCE) produced, though this varies substantially between different technological approaches.

The technological trajectory aims to develop next-generation DLE systems that can achieve carbon neutrality while maintaining economic viability. This requires integrated modeling approaches that combine process engineering, life cycle assessment, and techno-economic analysis to optimize both environmental and economic performance parameters simultaneously.

Market Analysis for Low-Carbon Lithium Production

The global lithium market is experiencing unprecedented growth driven by the rapid expansion of electric vehicle (EV) production and renewable energy storage systems. Current projections indicate the lithium market will reach $8.2 billion by 2028, with a compound annual growth rate (CAGR) of approximately 14.8% from 2023. This growth trajectory is directly linked to the increasing demand for low-carbon technologies, particularly in transportation and energy sectors.

The demand for lithium is expected to triple by 2025 and increase by more than six-fold by 2030 compared to 2020 levels. This surge is primarily fueled by battery manufacturers and automakers who are accelerating their transition to electric mobility. Major automotive companies have committed to electrifying significant portions of their fleets within the next decade, creating sustained demand for lithium resources.

Environmental considerations are increasingly influencing market dynamics, with consumers, investors, and regulators showing strong preference for materials with lower carbon footprints. This trend is creating a premium market segment for low-carbon lithium, with price differentials of 10-15% observed for materials produced through environmentally responsible methods. The European Union's Battery Regulation and similar frameworks in North America are establishing formal carbon intensity thresholds for battery materials, effectively creating regulatory drivers for low-carbon lithium production.

Direct Lithium Extraction (DLE) technologies are positioned to capture significant market share due to their potential environmental advantages over traditional extraction methods. Market analysis indicates that DLE could account for approximately 25% of global lithium production by 2030, representing a substantial shift in production methodologies. This transition is supported by the technology's reduced land and water requirements, faster production timelines, and potentially lower carbon emissions.

Regional market dynamics show varying levels of readiness for low-carbon lithium adoption. Europe leads in regulatory frameworks promoting sustainable battery supply chains, while North America is rapidly developing domestic production capabilities to reduce dependency on imports. The Asia-Pacific region, particularly China, dominates current lithium processing but faces increasing pressure to adopt greener technologies.

Investment patterns reflect growing confidence in low-carbon lithium production, with venture capital and corporate investments in DLE technologies exceeding $1.2 billion in 2022 alone. Major mining companies are diversifying their portfolios by acquiring or partnering with DLE technology developers, indicating industry-wide recognition of the strategic importance of low-carbon extraction methods.

The market for carbon accounting and certification systems for lithium production is also emerging as a critical component of the supply chain, with several third-party verification schemes gaining traction among producers and consumers seeking transparency in environmental performance claims.

The demand for lithium is expected to triple by 2025 and increase by more than six-fold by 2030 compared to 2020 levels. This surge is primarily fueled by battery manufacturers and automakers who are accelerating their transition to electric mobility. Major automotive companies have committed to electrifying significant portions of their fleets within the next decade, creating sustained demand for lithium resources.

Environmental considerations are increasingly influencing market dynamics, with consumers, investors, and regulators showing strong preference for materials with lower carbon footprints. This trend is creating a premium market segment for low-carbon lithium, with price differentials of 10-15% observed for materials produced through environmentally responsible methods. The European Union's Battery Regulation and similar frameworks in North America are establishing formal carbon intensity thresholds for battery materials, effectively creating regulatory drivers for low-carbon lithium production.

Direct Lithium Extraction (DLE) technologies are positioned to capture significant market share due to their potential environmental advantages over traditional extraction methods. Market analysis indicates that DLE could account for approximately 25% of global lithium production by 2030, representing a substantial shift in production methodologies. This transition is supported by the technology's reduced land and water requirements, faster production timelines, and potentially lower carbon emissions.

Regional market dynamics show varying levels of readiness for low-carbon lithium adoption. Europe leads in regulatory frameworks promoting sustainable battery supply chains, while North America is rapidly developing domestic production capabilities to reduce dependency on imports. The Asia-Pacific region, particularly China, dominates current lithium processing but faces increasing pressure to adopt greener technologies.

Investment patterns reflect growing confidence in low-carbon lithium production, with venture capital and corporate investments in DLE technologies exceeding $1.2 billion in 2022 alone. Major mining companies are diversifying their portfolios by acquiring or partnering with DLE technology developers, indicating industry-wide recognition of the strategic importance of low-carbon extraction methods.

The market for carbon accounting and certification systems for lithium production is also emerging as a critical component of the supply chain, with several third-party verification schemes gaining traction among producers and consumers seeking transparency in environmental performance claims.

Current DLE Technologies and Energy Challenges

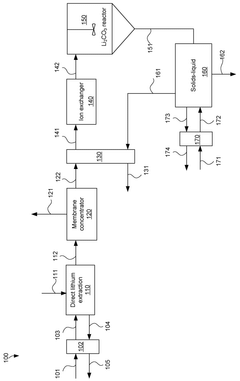

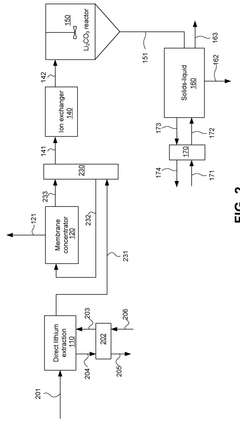

Direct Lithium Extraction (DLE) technologies have emerged as promising alternatives to traditional lithium extraction methods, offering potential reductions in environmental impact and processing time. Current DLE technologies can be broadly categorized into three main approaches: adsorption-based methods, ion exchange processes, and membrane-based separation techniques.

Adsorption-based DLE technologies utilize specialized materials that selectively capture lithium ions from brine solutions. These materials, including lithium manganese oxides, titanium oxides, and aluminum-based adsorbents, require significant energy for regeneration cycles. The energy consumption primarily stems from heating processes (80-100°C) needed to release captured lithium and prepare adsorbents for reuse.

Ion exchange technologies employ engineered materials that exchange lithium ions with other ions in solution. Commercial systems like Lilac Solutions' technology use proprietary ion exchange beads that require multiple regeneration cycles. These processes demand substantial electrical energy for pumping and thermal energy for material regeneration, with energy intensities ranging from 5-15 kWh per kilogram of lithium carbonate equivalent (LCE).

Membrane-based separation technologies, including nanofiltration and electrodialysis, utilize selective membranes to separate lithium from other constituents. These systems require significant electrical energy to maintain pressure differentials or electrical potential across membranes, with energy requirements typically between 10-20 kWh per kilogram of LCE.

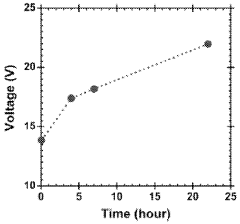

A critical challenge facing all DLE technologies is their high energy intensity compared to traditional evaporation pond methods. While conventional methods primarily use solar energy for evaporation, DLE requires continuous electrical and thermal energy inputs. This translates to carbon footprints of 5-15 kg CO₂e per kilogram of lithium produced, depending on the energy source and specific technology employed.

Water consumption presents another significant challenge, with most DLE technologies requiring substantial freshwater inputs for processing and regeneration cycles. This creates a paradoxical situation where technologies designed to support green energy transition may strain water resources in already water-stressed regions where lithium is abundant.

Scale-up challenges further complicate energy considerations. Laboratory-scale energy efficiencies often deteriorate when technologies are deployed at commercial scale due to heat losses, pumping inefficiencies, and real-world operational constraints. Several pilot projects have reported energy consumption 30-50% higher than theoretical models predicted.

The geographical context of DLE deployment significantly impacts carbon intensity. Implementation in regions with renewable-dominant electricity grids (like Chile with its solar resources) can reduce carbon footprints by 40-60% compared to deployment in coal-dependent regions. This geographical variability creates complex trade-offs between proximity to lithium resources and access to low-carbon energy sources.

Adsorption-based DLE technologies utilize specialized materials that selectively capture lithium ions from brine solutions. These materials, including lithium manganese oxides, titanium oxides, and aluminum-based adsorbents, require significant energy for regeneration cycles. The energy consumption primarily stems from heating processes (80-100°C) needed to release captured lithium and prepare adsorbents for reuse.

Ion exchange technologies employ engineered materials that exchange lithium ions with other ions in solution. Commercial systems like Lilac Solutions' technology use proprietary ion exchange beads that require multiple regeneration cycles. These processes demand substantial electrical energy for pumping and thermal energy for material regeneration, with energy intensities ranging from 5-15 kWh per kilogram of lithium carbonate equivalent (LCE).

Membrane-based separation technologies, including nanofiltration and electrodialysis, utilize selective membranes to separate lithium from other constituents. These systems require significant electrical energy to maintain pressure differentials or electrical potential across membranes, with energy requirements typically between 10-20 kWh per kilogram of LCE.

A critical challenge facing all DLE technologies is their high energy intensity compared to traditional evaporation pond methods. While conventional methods primarily use solar energy for evaporation, DLE requires continuous electrical and thermal energy inputs. This translates to carbon footprints of 5-15 kg CO₂e per kilogram of lithium produced, depending on the energy source and specific technology employed.

Water consumption presents another significant challenge, with most DLE technologies requiring substantial freshwater inputs for processing and regeneration cycles. This creates a paradoxical situation where technologies designed to support green energy transition may strain water resources in already water-stressed regions where lithium is abundant.

Scale-up challenges further complicate energy considerations. Laboratory-scale energy efficiencies often deteriorate when technologies are deployed at commercial scale due to heat losses, pumping inefficiencies, and real-world operational constraints. Several pilot projects have reported energy consumption 30-50% higher than theoretical models predicted.

The geographical context of DLE deployment significantly impacts carbon intensity. Implementation in regions with renewable-dominant electricity grids (like Chile with its solar resources) can reduce carbon footprints by 40-60% compared to deployment in coal-dependent regions. This geographical variability creates complex trade-offs between proximity to lithium resources and access to low-carbon energy sources.

Current Energy Consumption Models for DLE

01 Energy-efficient DLE processes

Direct Lithium Extraction (DLE) technologies have been developed to reduce energy consumption compared to traditional evaporation methods. These processes utilize selective adsorption materials, ion exchange resins, or membranes that can extract lithium ions from brines with minimal energy input. The energy efficiency is achieved through optimized process designs that minimize heating requirements and utilize renewable energy sources where possible, significantly reducing the carbon footprint of lithium production.- Energy-efficient DLE processes: Direct Lithium Extraction (DLE) technologies have been developed to reduce energy consumption compared to traditional evaporation methods. These processes utilize selective adsorption materials, ion exchange resins, or membranes that can extract lithium ions from brines with minimal energy input. The energy efficiency is achieved through optimized process designs that minimize heating requirements and utilize renewable energy sources where possible, significantly reducing the carbon footprint of lithium production.

- Carbon intensity reduction strategies: Various approaches have been implemented to reduce the carbon intensity of DLE operations. These include integration of renewable energy sources such as solar and geothermal power, carbon capture technologies, and process optimizations that minimize greenhouse gas emissions. Some systems incorporate closed-loop designs that recycle process water and reagents, further reducing the environmental impact and carbon footprint of lithium extraction operations.

- Advanced membrane and filtration technologies: Innovative membrane and filtration technologies have been developed specifically for DLE applications to reduce energy consumption. These systems utilize specialized membranes that selectively allow lithium ions to pass while rejecting other elements, requiring less energy than conventional separation methods. Some designs incorporate pressure-driven or electrically-assisted membrane processes that operate at ambient temperatures, significantly reducing the thermal energy requirements compared to evaporation-based extraction methods.

- Integrated energy recovery systems: DLE processes have been enhanced with integrated energy recovery systems that capture and reuse thermal and mechanical energy within the extraction process. These systems include heat exchangers, pressure recovery devices, and waste heat utilization technologies that significantly reduce the net energy consumption of the extraction process. By recovering energy that would otherwise be lost, these integrated systems improve overall energy efficiency and reduce the carbon intensity of lithium production.

- Optimization of chemical consumption and regeneration: Innovations in DLE technology have focused on optimizing chemical consumption and regeneration processes to reduce both energy requirements and carbon intensity. These advancements include the development of highly selective sorbents that can be regenerated with minimal chemical inputs, closed-loop chemical recycling systems, and process optimizations that reduce the frequency of regeneration cycles. By minimizing chemical usage and associated processing steps, these technologies reduce both the direct energy consumption and the embedded carbon footprint of the extraction process.

02 Carbon intensity reduction strategies

Various approaches have been implemented to reduce the carbon intensity of DLE operations. These include integration of renewable energy sources such as solar and geothermal power, carbon capture technologies, and process optimizations that minimize greenhouse gas emissions. Some systems incorporate closed-loop designs that recycle process water and reagents, further reducing the environmental impact and carbon footprint of lithium extraction operations.Expand Specific Solutions03 Advanced membrane and electrochemical technologies

Innovative membrane and electrochemical technologies have been developed to improve the energy efficiency of DLE processes. These technologies utilize selective ion transport mechanisms and electrochemical driving forces to separate lithium from other ions in brine solutions. By operating at ambient temperatures and pressures, these systems significantly reduce energy requirements compared to conventional thermal processes, while maintaining high lithium recovery rates and product purity.Expand Specific Solutions04 Heat recovery and thermal management systems

Efficient thermal management and heat recovery systems have been integrated into DLE processes to minimize energy consumption. These systems capture and reuse waste heat from various process stages, reducing the overall energy demand. Advanced heat exchangers, thermal storage solutions, and process integration techniques optimize energy utilization throughout the extraction process, contributing to lower carbon intensity and operational costs.Expand Specific Solutions05 Monitoring and optimization of energy consumption

Sophisticated monitoring and control systems have been developed to optimize energy consumption in DLE operations. These systems utilize sensors, data analytics, and artificial intelligence to continuously monitor process parameters and adjust operating conditions for maximum energy efficiency. Real-time monitoring enables identification of energy-intensive steps and implementation of corrective measures, leading to reduced carbon intensity and improved sustainability of lithium extraction processes.Expand Specific Solutions

Key Industry Players in DLE Technology

The direct lithium extraction (DLE) market is in its early growth phase, characterized by increasing demand driven by the global push for electrification and clean energy. The market is projected to expand significantly as lithium demand for batteries continues to rise, with current technologies still evolving toward commercial viability. Key players in this competitive landscape include established energy companies like Schlumberger, which brings extensive extraction expertise, alongside specialized innovators such as International Battery Metals, Vulcan Energy, and Saltworks Technologies focusing on reducing carbon intensity and water consumption. Academic institutions including MIT, Tsinghua University, and The University of Manchester are contributing breakthrough research in energy efficiency models. The industry is witnessing strategic partnerships between technology developers and lithium producers to optimize extraction processes while minimizing environmental impact.

Lyten, Inc.

Technical Solution: Lyten has developed an innovative approach to lithium extraction that focuses on both carbon reduction and energy efficiency through their proprietary 3D Graphene material platform. Their direct lithium extraction technology utilizes specially engineered 3D Graphene-based sorbents that can selectively bind to lithium ions in brine solutions with exceptional efficiency. The company's process operates at near-ambient temperatures and pressures, requiring significantly less energy than conventional methods. Lyten's system employs a closed-loop design that recycles processing fluids and minimizes water consumption, with recovery rates exceeding 85% of available lithium. Their energy consumption model indicates a reduction of approximately 60% compared to traditional evaporation pond methods, with corresponding carbon intensity reductions of up to 70%. The modular extraction units can be powered by renewable energy sources, further reducing carbon footprint. Lyten's technology also addresses the challenge of processing low-concentration brines that would be uneconomical with conventional methods, expanding the potential lithium resource base.

Strengths: Advanced 3D Graphene sorbent technology with high selectivity for lithium; significantly reduced energy requirements and carbon emissions; modular design allowing for deployment at various scales; ability to process low-concentration brines economically. Weaknesses: Relatively new technology with limited large-scale deployment history; requires specialized graphene materials production; potential challenges in sorbent regeneration and lifetime; higher upfront costs compared to traditional extraction methods.

Vulcan Energie Ressourcen GmbH

Technical Solution: Vulcan Energy has pioneered a "Zero Carbon Lithium" extraction process specifically designed for geothermal brines in the Upper Rhine Valley of Germany. Their integrated approach combines geothermal energy production with direct lithium extraction, creating a self-powering system that eliminates the need for external energy sources. The process utilizes the natural heat from geothermal brines (reaching temperatures of 165°C) to power the lithium extraction process, which employs proprietary sorbents to selectively capture lithium ions. Their life cycle assessment shows a negative carbon footprint of -2.9 kg CO2 equivalent per kg of lithium hydroxide produced, compared to 15+ kg CO2 for conventional methods. Vulcan's ZERO CARBON LITHIUM™ process includes a closed-loop system that reinjection of brine after lithium extraction, maintaining reservoir pressure and minimizing environmental impact. The company's pilot plant has demonstrated successful extraction at scale, with plans for commercial production of 40,000 tonnes of lithium hydroxide annually by 2025.

Strengths: Carbon-negative lithium production through integration with geothermal energy; closed-loop system with minimal water consumption; utilizes existing geothermal infrastructure; produces battery-grade lithium hydroxide directly. Weaknesses: Limited to regions with suitable geothermal resources; higher initial capital expenditure; technology still scaling to full commercial production; process efficiency dependent on specific geothermal brine characteristics.

Carbon Footprint Assessment Frameworks for DLE

Carbon dioxide negative direct lithium extraction (DLE) process: bipolar electrodialysis (BPED) to lithium hydroxide monohydrate and lithium carbonate

PatentWO2023249955A1

Innovation

- The implementation of a selective cation exchange membrane (sCEM) with coatings that facilitate the selective permeation of monovalent ions over divalent ions, enabling direct production of high-purity lithium hydroxide (LiOH) and lithium carbonate (Li2CO3) while avoiding the formation of insoluble hydroxides, and utilizing a carbon-negative approach by repurposing captured CO2 to reduce environmental impact.

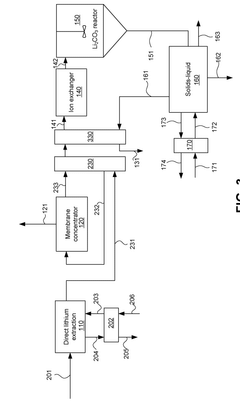

Process and system for preparing lithium carbonate with energy recovery

PatentWO2025156059A1

Innovation

- A process involving direct lithium extraction, membrane concentration, chelating ion exchange, and energy recovery through heat exchangers to produce lithium carbonate while optimizing energy efficiency.

Environmental Regulations Impact on DLE Development

Environmental regulations are increasingly shaping the development trajectory of Direct Lithium Extraction (DLE) technologies, with carbon intensity and energy consumption models serving as critical evaluation frameworks. The global push toward decarbonization has resulted in stringent emissions regulations across major lithium-producing regions, directly influencing DLE implementation strategies. In the European Union, the Carbon Border Adjustment Mechanism (CBAM) imposes carbon pricing on imported goods, including lithium products, creating economic incentives for lower-carbon extraction methods.

The United States has introduced tax credits through the Inflation Reduction Act specifically targeting critical minerals extraction with lower carbon footprints, providing financial advantages to DLE operations that can demonstrate reduced emissions compared to traditional evaporation pond methods. Similarly, Chile and Argentina have established water usage restrictions in the lithium-rich but water-scarce Atacama region, indirectly favoring DLE technologies that consume significantly less water than conventional methods.

Regulatory frameworks are increasingly requiring comprehensive Life Cycle Assessments (LCAs) for new extraction projects, with carbon intensity metrics becoming standard evaluation criteria for project approval. These assessments must quantify not only operational emissions but also embedded carbon in equipment and infrastructure. Companies developing DLE technologies now routinely incorporate regulatory compliance forecasting into their technology roadmaps, anticipating stricter emissions standards over project lifetimes.

Energy source regulations have emerged as particularly influential, with several jurisdictions mandating renewable energy integration for new mining operations. This has accelerated the development of DLE variants specifically optimized for renewable energy compatibility, addressing intermittency challenges through process modifications. The International Energy Agency's Critical Minerals Policy Tracker indicates a 47% increase in climate-related regulations affecting lithium extraction since 2020.

Reporting requirements have also expanded, with mandatory disclosure of energy consumption metrics becoming standard in major markets. The Task Force on Climate-related Financial Disclosures (TCFD) framework has been adopted by numerous lithium producers, creating standardized approaches to energy and carbon reporting that influence technology selection criteria for new projects.

These regulatory pressures have catalyzed innovation in DLE energy efficiency, with recent technological developments specifically targeting compliance with anticipated regulatory thresholds. Companies demonstrating lower carbon intensity in their extraction processes are gaining competitive advantages in permitting processes and access to capital markets, creating market-driven incentives that complement regulatory requirements.

The United States has introduced tax credits through the Inflation Reduction Act specifically targeting critical minerals extraction with lower carbon footprints, providing financial advantages to DLE operations that can demonstrate reduced emissions compared to traditional evaporation pond methods. Similarly, Chile and Argentina have established water usage restrictions in the lithium-rich but water-scarce Atacama region, indirectly favoring DLE technologies that consume significantly less water than conventional methods.

Regulatory frameworks are increasingly requiring comprehensive Life Cycle Assessments (LCAs) for new extraction projects, with carbon intensity metrics becoming standard evaluation criteria for project approval. These assessments must quantify not only operational emissions but also embedded carbon in equipment and infrastructure. Companies developing DLE technologies now routinely incorporate regulatory compliance forecasting into their technology roadmaps, anticipating stricter emissions standards over project lifetimes.

Energy source regulations have emerged as particularly influential, with several jurisdictions mandating renewable energy integration for new mining operations. This has accelerated the development of DLE variants specifically optimized for renewable energy compatibility, addressing intermittency challenges through process modifications. The International Energy Agency's Critical Minerals Policy Tracker indicates a 47% increase in climate-related regulations affecting lithium extraction since 2020.

Reporting requirements have also expanded, with mandatory disclosure of energy consumption metrics becoming standard in major markets. The Task Force on Climate-related Financial Disclosures (TCFD) framework has been adopted by numerous lithium producers, creating standardized approaches to energy and carbon reporting that influence technology selection criteria for new projects.

These regulatory pressures have catalyzed innovation in DLE energy efficiency, with recent technological developments specifically targeting compliance with anticipated regulatory thresholds. Companies demonstrating lower carbon intensity in their extraction processes are gaining competitive advantages in permitting processes and access to capital markets, creating market-driven incentives that complement regulatory requirements.

Life Cycle Assessment of DLE Technologies

Life Cycle Assessment (LCA) of Direct Lithium Extraction (DLE) technologies provides critical insights into the environmental sustainability of these emerging methods compared to traditional lithium production. Current LCA studies indicate that DLE technologies generally demonstrate lower carbon footprints than conventional evaporation pond methods, with potential reductions of 30-60% in greenhouse gas emissions depending on the specific technology employed.

The energy consumption profile of DLE varies significantly across different technological approaches. Adsorption-based methods typically require 5-15 kWh per kilogram of lithium carbonate equivalent (LCE), while ion exchange systems consume approximately 8-20 kWh/kg LCE. Membrane-based extraction technologies demonstrate energy requirements in the range of 10-25 kWh/kg LCE, with variations based on membrane efficiency and operational parameters.

Water usage represents another critical environmental factor in LCA evaluations. Traditional evaporation methods consume 500-2,000 liters of water per kilogram of lithium produced through evaporation losses, while DLE technologies significantly reduce this to approximately 50-300 liters per kilogram, representing an 80-90% reduction in water consumption intensity.

Chemical consumption in DLE processes contributes substantially to their environmental footprint. The life cycle impacts of reagents used in regeneration cycles, including acids, bases, and specialized solvents, must be factored into comprehensive assessments. These chemicals typically account for 15-30% of the total carbon footprint of DLE operations.

Land use impacts also differ dramatically between conventional and DLE methods. Traditional evaporation ponds require 2-3 square kilometers per 20,000 tonnes of annual LCE production, while DLE facilities can achieve the same output with less than 0.1 square kilometers, representing a 95% reduction in land disturbance.

Regional variations in energy grid composition significantly influence the carbon intensity of DLE operations. When powered by renewable energy sources, the carbon footprint of DLE can be reduced by up to 70% compared to operations relying on fossil fuel-based electricity. This highlights the importance of considering local energy infrastructure when assessing the environmental performance of DLE implementations.

End-of-life considerations for DLE technologies remain less thoroughly studied in current LCA research. The recyclability of specialized adsorbents, membranes, and ion exchange materials presents both challenges and opportunities for improving the overall sustainability profile of these technologies. Emerging circular economy approaches suggest potential for 60-80% recovery and reuse of key materials used in DLE systems.

The energy consumption profile of DLE varies significantly across different technological approaches. Adsorption-based methods typically require 5-15 kWh per kilogram of lithium carbonate equivalent (LCE), while ion exchange systems consume approximately 8-20 kWh/kg LCE. Membrane-based extraction technologies demonstrate energy requirements in the range of 10-25 kWh/kg LCE, with variations based on membrane efficiency and operational parameters.

Water usage represents another critical environmental factor in LCA evaluations. Traditional evaporation methods consume 500-2,000 liters of water per kilogram of lithium produced through evaporation losses, while DLE technologies significantly reduce this to approximately 50-300 liters per kilogram, representing an 80-90% reduction in water consumption intensity.

Chemical consumption in DLE processes contributes substantially to their environmental footprint. The life cycle impacts of reagents used in regeneration cycles, including acids, bases, and specialized solvents, must be factored into comprehensive assessments. These chemicals typically account for 15-30% of the total carbon footprint of DLE operations.

Land use impacts also differ dramatically between conventional and DLE methods. Traditional evaporation ponds require 2-3 square kilometers per 20,000 tonnes of annual LCE production, while DLE facilities can achieve the same output with less than 0.1 square kilometers, representing a 95% reduction in land disturbance.

Regional variations in energy grid composition significantly influence the carbon intensity of DLE operations. When powered by renewable energy sources, the carbon footprint of DLE can be reduced by up to 70% compared to operations relying on fossil fuel-based electricity. This highlights the importance of considering local energy infrastructure when assessing the environmental performance of DLE implementations.

End-of-life considerations for DLE technologies remain less thoroughly studied in current LCA research. The recyclability of specialized adsorbents, membranes, and ion exchange materials presents both challenges and opportunities for improving the overall sustainability profile of these technologies. Emerging circular economy approaches suggest potential for 60-80% recovery and reuse of key materials used in DLE systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!