Integration Of Geothermal Brines With Power Plants For Direct Lithium Extraction

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Geothermal Lithium Extraction Background and Objectives

The integration of geothermal brines with power plants for direct lithium extraction represents a convergence of renewable energy production and critical mineral recovery. This technological approach has evolved significantly over the past decade, driven by increasing global demand for lithium in battery technologies and the push for more sustainable extraction methods. Historically, lithium has been primarily obtained through hard rock mining or solar evaporation of salt flats, both of which present considerable environmental challenges and resource inefficiencies.

Geothermal brines, naturally occurring hot, mineral-rich fluids found in geothermal reservoirs, have been utilized for electricity generation since the early 20th century. However, the recognition of these brines as potential lithium sources is relatively recent, with pioneering research emerging in the 1970s but gaining significant momentum only in the past decade.

The technological evolution has progressed from basic proof-of-concept studies to pilot plants demonstrating the feasibility of extracting lithium from geothermal fluids while simultaneously generating renewable electricity. This dual-purpose approach represents a paradigm shift in resource utilization efficiency, potentially transforming what was once considered a waste product into a valuable resource stream.

Current technological objectives focus on developing scalable, economically viable processes that can selectively extract lithium from complex brine compositions without disrupting power generation operations. Key goals include increasing lithium recovery rates, reducing chemical consumption, minimizing water usage, and ensuring the overall process remains carbon-neutral or negative.

The integration aims to address several critical challenges facing both the energy and mining sectors. For the energy sector, it offers potential revenue diversification for geothermal power plants, potentially improving their economic viability. For the mining sector, it presents a pathway to more sustainable lithium production with significantly reduced environmental footprint compared to conventional methods.

Looking forward, the technology trajectory points toward more advanced selective extraction technologies, including novel sorbents, membranes, and electrochemical approaches specifically designed for the unique challenges of geothermal environments. The ultimate objective is to establish closed-loop systems where geothermal energy powers both electricity generation and mineral extraction processes, with minimal environmental impact and maximum resource recovery.

This technological approach aligns with broader global trends toward circular economy principles and the critical minerals security strategies being developed by many nations, particularly those with significant geothermal resources but limited conventional lithium reserves.

Geothermal brines, naturally occurring hot, mineral-rich fluids found in geothermal reservoirs, have been utilized for electricity generation since the early 20th century. However, the recognition of these brines as potential lithium sources is relatively recent, with pioneering research emerging in the 1970s but gaining significant momentum only in the past decade.

The technological evolution has progressed from basic proof-of-concept studies to pilot plants demonstrating the feasibility of extracting lithium from geothermal fluids while simultaneously generating renewable electricity. This dual-purpose approach represents a paradigm shift in resource utilization efficiency, potentially transforming what was once considered a waste product into a valuable resource stream.

Current technological objectives focus on developing scalable, economically viable processes that can selectively extract lithium from complex brine compositions without disrupting power generation operations. Key goals include increasing lithium recovery rates, reducing chemical consumption, minimizing water usage, and ensuring the overall process remains carbon-neutral or negative.

The integration aims to address several critical challenges facing both the energy and mining sectors. For the energy sector, it offers potential revenue diversification for geothermal power plants, potentially improving their economic viability. For the mining sector, it presents a pathway to more sustainable lithium production with significantly reduced environmental footprint compared to conventional methods.

Looking forward, the technology trajectory points toward more advanced selective extraction technologies, including novel sorbents, membranes, and electrochemical approaches specifically designed for the unique challenges of geothermal environments. The ultimate objective is to establish closed-loop systems where geothermal energy powers both electricity generation and mineral extraction processes, with minimal environmental impact and maximum resource recovery.

This technological approach aligns with broader global trends toward circular economy principles and the critical minerals security strategies being developed by many nations, particularly those with significant geothermal resources but limited conventional lithium reserves.

Market Analysis for Geothermal Lithium Production

The global lithium market is experiencing unprecedented growth, driven primarily by the rapid expansion of electric vehicle (EV) production and renewable energy storage systems. Current market valuations place the lithium industry at approximately $7.5 billion, with projections indicating a compound annual growth rate (CAGR) of 12-15% through 2030. This exponential growth trajectory creates a significant opportunity for innovative lithium extraction technologies, particularly those integrated with existing energy infrastructure.

Geothermal brine-based lithium extraction represents a particularly promising market segment. Unlike traditional lithium mining operations that rely on evaporation ponds or hard rock mining, geothermal lithium production offers dual revenue streams through both electricity generation and mineral extraction. This integrated approach substantially improves the economic viability of geothermal power plants, potentially transforming marginally profitable energy operations into highly lucrative combined facilities.

Market analysis indicates that the demand-supply gap for lithium is widening dramatically. Current global production capacity stands at approximately 600,000 metric tons of lithium carbonate equivalent (LCE) annually, while demand projections for 2030 exceed 1.5 million metric tons. This supply shortfall creates favorable pricing conditions for new market entrants, particularly those with environmentally sustainable extraction methods.

The geothermal lithium sector benefits from several market advantages compared to conventional lithium production. First, its significantly reduced environmental footprint aligns with increasingly stringent ESG (Environmental, Social, and Governance) requirements from both regulators and investors. Second, the concentrated nature of lithium in certain geothermal brines (particularly in locations like California's Salton Sea) offers extraction efficiencies that can potentially reduce production costs below the industry average of $5,000-7,000 per ton.

Regional market analysis reveals particularly strong potential in specific geographic areas with convergent geothermal resources and lithium-rich brines. The Salton Sea Known Geothermal Resource Area (KGRA) in California contains estimated lithium reserves exceeding 15 million metric tons, while similar promising deposits exist in Nevada, Utah, Germany's Rhine Valley, and Chile's Atacama region.

Market segmentation analysis indicates that battery-grade lithium compounds command premium pricing, with lithium hydroxide currently valued 15-20% higher than lithium carbonate due to its application in high-performance EV batteries. This price differential creates additional incentive for developing advanced direct lithium extraction (DLE) technologies capable of producing battery-grade materials directly from geothermal brines.

The competitive landscape remains relatively open, with few established players having successfully commercialized integrated geothermal lithium extraction at scale. This presents a significant first-mover advantage opportunity for companies that can rapidly develop and deploy effective integration technologies connecting existing geothermal power infrastructure with efficient lithium recovery systems.

Geothermal brine-based lithium extraction represents a particularly promising market segment. Unlike traditional lithium mining operations that rely on evaporation ponds or hard rock mining, geothermal lithium production offers dual revenue streams through both electricity generation and mineral extraction. This integrated approach substantially improves the economic viability of geothermal power plants, potentially transforming marginally profitable energy operations into highly lucrative combined facilities.

Market analysis indicates that the demand-supply gap for lithium is widening dramatically. Current global production capacity stands at approximately 600,000 metric tons of lithium carbonate equivalent (LCE) annually, while demand projections for 2030 exceed 1.5 million metric tons. This supply shortfall creates favorable pricing conditions for new market entrants, particularly those with environmentally sustainable extraction methods.

The geothermal lithium sector benefits from several market advantages compared to conventional lithium production. First, its significantly reduced environmental footprint aligns with increasingly stringent ESG (Environmental, Social, and Governance) requirements from both regulators and investors. Second, the concentrated nature of lithium in certain geothermal brines (particularly in locations like California's Salton Sea) offers extraction efficiencies that can potentially reduce production costs below the industry average of $5,000-7,000 per ton.

Regional market analysis reveals particularly strong potential in specific geographic areas with convergent geothermal resources and lithium-rich brines. The Salton Sea Known Geothermal Resource Area (KGRA) in California contains estimated lithium reserves exceeding 15 million metric tons, while similar promising deposits exist in Nevada, Utah, Germany's Rhine Valley, and Chile's Atacama region.

Market segmentation analysis indicates that battery-grade lithium compounds command premium pricing, with lithium hydroxide currently valued 15-20% higher than lithium carbonate due to its application in high-performance EV batteries. This price differential creates additional incentive for developing advanced direct lithium extraction (DLE) technologies capable of producing battery-grade materials directly from geothermal brines.

The competitive landscape remains relatively open, with few established players having successfully commercialized integrated geothermal lithium extraction at scale. This presents a significant first-mover advantage opportunity for companies that can rapidly develop and deploy effective integration technologies connecting existing geothermal power infrastructure with efficient lithium recovery systems.

Technical Challenges in Geothermal Brine Processing

Geothermal brine processing presents several significant technical challenges that must be addressed for successful integration with power plants for direct lithium extraction. The high temperature and pressure conditions of geothermal brines, typically ranging from 100°C to over 300°C and pressures up to 100 bar, create a hostile environment for extraction equipment and processes. These extreme conditions accelerate corrosion and scaling, reducing equipment lifespan and operational efficiency.

The complex chemical composition of geothermal brines further complicates processing efforts. These brines contain not only lithium (typically at concentrations of 10-200 mg/L) but also high levels of dissolved solids, including sodium, potassium, calcium, magnesium, and various heavy metals. This multi-element mixture creates significant separation challenges and requires sophisticated selective extraction technologies to isolate lithium effectively.

Scaling and precipitation represent another major technical hurdle. As pressure and temperature decrease during brine handling, dissolved minerals tend to precipitate, forming scale deposits that clog pipes, heat exchangers, and extraction media. Common scale-forming compounds include silica, calcium carbonate, and metal sulfides, which can rapidly reduce system efficiency and increase maintenance requirements.

Energy optimization presents a critical challenge in the integration process. Extracting lithium from geothermal brines requires additional energy inputs beyond power generation, potentially reducing the net energy output of the combined system. Balancing lithium extraction with power production efficiency requires careful thermal management and process integration to minimize energy penalties.

The variability of brine composition between different geothermal resources and even within the same reservoir over time creates difficulties in designing standardized extraction systems. This variability necessitates adaptive processing technologies and real-time monitoring systems capable of adjusting to changing brine characteristics.

Membrane and sorbent technologies used for lithium extraction face durability issues in geothermal environments. Current selective lithium extraction media often degrade rapidly under high temperatures and in the presence of competing ions, requiring frequent replacement and reducing economic viability. Development of heat-resistant, fouling-resistant materials represents a significant research challenge.

Water management also presents substantial difficulties, as geothermal lithium extraction typically requires additional water for processing and washing steps. In many geothermal regions where water resources are already constrained, this creates sustainability concerns and potential regulatory hurdles that must be addressed through water recycling and conservation strategies.

The complex chemical composition of geothermal brines further complicates processing efforts. These brines contain not only lithium (typically at concentrations of 10-200 mg/L) but also high levels of dissolved solids, including sodium, potassium, calcium, magnesium, and various heavy metals. This multi-element mixture creates significant separation challenges and requires sophisticated selective extraction technologies to isolate lithium effectively.

Scaling and precipitation represent another major technical hurdle. As pressure and temperature decrease during brine handling, dissolved minerals tend to precipitate, forming scale deposits that clog pipes, heat exchangers, and extraction media. Common scale-forming compounds include silica, calcium carbonate, and metal sulfides, which can rapidly reduce system efficiency and increase maintenance requirements.

Energy optimization presents a critical challenge in the integration process. Extracting lithium from geothermal brines requires additional energy inputs beyond power generation, potentially reducing the net energy output of the combined system. Balancing lithium extraction with power production efficiency requires careful thermal management and process integration to minimize energy penalties.

The variability of brine composition between different geothermal resources and even within the same reservoir over time creates difficulties in designing standardized extraction systems. This variability necessitates adaptive processing technologies and real-time monitoring systems capable of adjusting to changing brine characteristics.

Membrane and sorbent technologies used for lithium extraction face durability issues in geothermal environments. Current selective lithium extraction media often degrade rapidly under high temperatures and in the presence of competing ions, requiring frequent replacement and reducing economic viability. Development of heat-resistant, fouling-resistant materials represents a significant research challenge.

Water management also presents substantial difficulties, as geothermal lithium extraction typically requires additional water for processing and washing steps. In many geothermal regions where water resources are already constrained, this creates sustainability concerns and potential regulatory hurdles that must be addressed through water recycling and conservation strategies.

Current Integration Methods for Power Plants and DLE

01 Direct lithium extraction from geothermal brines

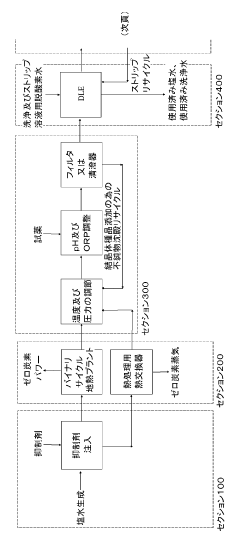

Methods for extracting lithium directly from geothermal brines involve specialized sorbents and ion exchange materials that selectively capture lithium ions from the brine solution. These processes can be integrated with existing geothermal power plants to utilize the hot brines that are already being extracted for energy production. The direct extraction methods offer advantages over traditional evaporation ponds, including faster processing times and reduced environmental footprint.- Direct lithium extraction from geothermal brines: Methods for extracting lithium directly from geothermal brines involve specialized techniques to separate lithium ions from other components in the brine. These processes typically use selective adsorption materials, ion exchange resins, or membrane technologies that can capture lithium while leaving other elements behind. The direct extraction approach offers advantages over traditional evaporation methods, including faster processing times, smaller environmental footprint, and higher recovery rates of lithium from the brine source.

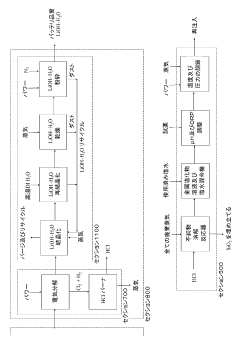

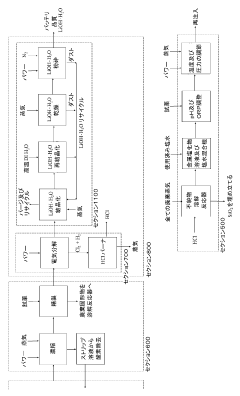

- Integration of lithium extraction with geothermal power generation: Systems that combine lithium extraction with geothermal power generation create synergistic benefits by utilizing the same geothermal fluid for both energy production and mineral recovery. In these integrated systems, the geothermal brine first passes through power generation facilities where thermal energy is converted to electricity, and then the cooled brine is processed for lithium extraction before reinjection. This approach maximizes resource utilization, improves overall economics, and reduces environmental impact compared to standalone operations.

- Advanced sorbent materials for selective lithium capture: Specialized sorbent materials designed for selective lithium capture from geothermal brines represent a key technological advancement in direct lithium extraction. These materials include engineered inorganic adsorbents, functionalized polymers, and composite materials with high selectivity for lithium ions even in the presence of competing ions like sodium, potassium, and magnesium. The development of these materials focuses on improving lithium loading capacity, selectivity, regeneration efficiency, and operational stability under the harsh conditions typical of geothermal brines.

- Brine pre-treatment and post-processing systems: Effective brine pre-treatment and post-processing systems are essential for successful lithium extraction from geothermal sources. Pre-treatment processes remove impurities, adjust pH, and condition the brine to optimize lithium extraction efficiency. Post-processing systems concentrate and purify the extracted lithium to produce commercial-grade lithium compounds such as lithium carbonate or lithium hydroxide. These systems may include filtration, precipitation, crystallization, and purification steps designed to handle the specific challenges of geothermal brines.

- Closed-loop and sustainable lithium extraction processes: Closed-loop and sustainable lithium extraction processes aim to minimize environmental impact while maximizing resource recovery from geothermal brines. These systems feature brine reinjection to maintain reservoir pressure, water recycling to reduce consumption, waste heat recovery for improved energy efficiency, and zero liquid discharge approaches. Advanced process control and monitoring systems ensure optimal operation while minimizing chemical usage and waste generation. These environmentally conscious designs represent the next generation of lithium extraction technology for geothermal resources.

02 Integration of lithium extraction with geothermal power generation

Systems that combine lithium extraction with geothermal power generation create synergistic benefits by utilizing the same geothermal fluid for both energy production and mineral recovery. These integrated systems can improve overall efficiency by using waste heat from power generation to support the lithium extraction process. The integration also provides economic advantages by diversifying revenue streams from a single resource and reducing operational costs through shared infrastructure.Expand Specific Solutions03 Advanced separation technologies for lithium recovery

Advanced technologies for separating lithium from geothermal brines include membrane processes, electrochemical methods, and novel adsorption materials. These technologies can achieve higher lithium recovery rates and purity levels compared to conventional methods. Some approaches use selective membranes that allow lithium ions to pass while blocking other elements, while others employ electrochemical cells that can concentrate lithium through controlled electrical potential.Expand Specific Solutions04 Brine pre-treatment and post-processing methods

Effective lithium extraction requires proper pre-treatment of geothermal brines to remove impurities and post-processing of the extracted lithium to achieve commercial-grade products. Pre-treatment methods include filtration, pH adjustment, and removal of interfering elements such as calcium and magnesium. Post-processing typically involves concentration, purification, and conversion of lithium into marketable forms such as lithium carbonate or lithium hydroxide through precipitation and crystallization processes.Expand Specific Solutions05 Sustainable and closed-loop extraction systems

Sustainable approaches to lithium extraction from geothermal brines focus on minimizing environmental impact through closed-loop systems that reuse process water and reduce waste. These systems often incorporate renewable energy sources to power the extraction process and employ technologies that minimize chemical usage. By reinjecting treated brine back into the geothermal reservoir, these methods help maintain reservoir pressure and extend the operational life of both the lithium extraction and power generation facilities.Expand Specific Solutions

Industry Leaders in Geothermal Lithium Integration

The integration of geothermal brines with power plants for direct lithium extraction represents an emerging market in the early growth phase, with global lithium demand projected to increase significantly due to electric vehicle adoption. The technology is transitioning from experimental to commercial scale, with market size expected to reach several billion dollars by 2030. Companies like Vulcan Energy Resources and International Battery Metals are pioneering zero-carbon lithium extraction methods, while established players such as Baker Hughes bring expertise from traditional energy sectors. Academic institutions including MIT and Rice University are advancing fundamental research, collaborating with industry partners to overcome technical challenges in membrane technology, brine processing, and system integration. Chinese companies like Jiangsu Jiuwu Hi-Tech and BGT Group are rapidly developing competitive extraction technologies, positioning themselves in this strategic resource sector.

Vulcan Energie Ressourcen GmbH

Technical Solution: Vulcan has developed a Zero Carbon Lithium™ process that integrates geothermal energy production with direct lithium extraction (DLE) from geothermal brines. Their technology utilizes sorption-based DLE methods to selectively extract lithium from hot geothermal brines while simultaneously generating renewable geothermal energy. The process begins with extraction of lithium-rich geothermal brine from deep wells in the Upper Rhine Valley, where temperatures reach 165°C. The thermal energy is first harvested for power generation through heat exchangers and turbines, then the cooled brine passes through their proprietary DLE system which uses specialized sorbents to selectively capture lithium ions. After lithium extraction, the depleted brine is reinjected back into the reservoir, creating a closed-loop system that minimizes environmental impact. Their integrated approach produces both renewable energy and battery-grade lithium hydroxide without carbon emissions or excessive water consumption.

Strengths: Zero carbon footprint through integration with renewable geothermal energy; closed-loop system minimizes environmental impact; produces battery-grade lithium with minimal waste. Weaknesses: Limited to regions with suitable geothermal resources; high initial capital costs; technology still scaling to commercial production levels; process efficiency dependent on brine composition and temperature.

Baker Hughes Oilfield Operations LLC

Technical Solution: Baker Hughes has developed an integrated system for lithium extraction from geothermal brines that leverages their extensive experience in oilfield operations and fluid handling. Their approach combines specialized downhole equipment with surface processing technologies designed to work seamlessly with geothermal power generation. The system begins with optimized production well designs and specialized pumping equipment that can handle high-temperature, mineral-rich brines while maintaining operational efficiency. Once at the surface, the hot brine first passes through the power generation system where thermal energy is converted to electricity. The partially cooled brine then enters Baker Hughes' proprietary extraction system that employs selective adsorption technology using engineered sorbents specifically designed for geothermal brine chemistry. Their process includes multi-stage filtration to remove impurities, followed by concentration and purification steps to produce battery-grade lithium compounds. The system incorporates advanced automation and monitoring capabilities derived from their oilfield expertise, allowing for real-time optimization of both power generation and lithium recovery parameters.

Strengths: Extensive experience with subsurface operations and fluid handling systems; robust equipment designed for harsh brine environments; integrated monitoring and control systems; global service infrastructure. Weaknesses: Primary expertise in oil and gas rather than lithium chemistry; relatively new entrant to lithium market; technology may require significant customization for different geothermal resources; potential scaling challenges with highly mineralized brines.

Key Patents in Geothermal Brine Lithium Recovery

SYSTEM AND PROCESS FOR THE DIRECT EXTRACTION OF LITHIUM

PatentUndeterminedCL202202687A1

Innovation

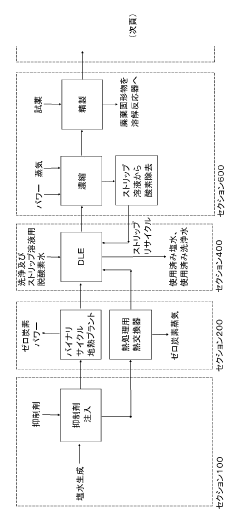

- Integration of a binary cycle geothermal plant with direct lithium extraction, concentration, and battery chemical processing circuits in a sequential combination for sustainable lithium production.

- Powering the entire lithium extraction and processing system using only electricity and heat from the geothermal plant without carbon-based fuels, creating a carbon-neutral production process.

- Capturing and containing non-condensable gases from geothermal brine rather than emitting them to the atmosphere, reducing environmental impact.

Systems and Processes for Direct Lithium Extraction and Production of Low Carbon Intensity Lithium Chemicals from Geothermal Brine

PatentInactiveJP2023525640A

Innovation

- Integration of direct lithium extraction (DLE) with binary cycle geothermal plants to create a carbon-free lithium production system.

- Sequential combination of DLE circuit, lithium chloride concentration purification circuit, and lithium battery chemistry treatment circuit powered by renewable geothermal energy.

- Capture and containment of non-condensable gases from geothermal brine to prevent atmospheric release, reducing the carbon footprint of lithium production.

Environmental Impact Assessment

The integration of geothermal brines with power plants for direct lithium extraction presents several environmental considerations that must be thoroughly assessed. The process offers significant environmental advantages compared to traditional lithium extraction methods, particularly by reducing land disturbance and water consumption associated with evaporation ponds. Geothermal brine utilization represents a circular economy approach, extracting valuable minerals from fluids already being processed for energy generation.

Water management remains a critical environmental factor in these integrated systems. While direct lithium extraction (DLE) from geothermal brines requires substantially less freshwater than conventional mining operations, the handling and disposal of processed brines demand careful management to prevent potential groundwater contamination. Most advanced DLE technologies now incorporate closed-loop systems that reinject treated brines back into geothermal reservoirs, minimizing water consumption and maintaining reservoir pressure.

Air quality impacts from these integrated facilities are generally minimal compared to traditional extraction methods. The elimination of large evaporation ponds reduces dust emissions and volatile compound releases. However, the energy requirements for DLE processes must be considered in the overall environmental footprint assessment, though this concern is mitigated when powered by the co-located geothermal energy.

Regarding land use, integrated geothermal-lithium facilities demonstrate a significantly smaller physical footprint than conventional lithium operations. This reduced spatial requirement minimizes habitat disruption and preserves natural landscapes, particularly valuable in ecologically sensitive regions where lithium resources are often found.

Chemical usage in DLE processes presents another environmental consideration. Various sorbents, solvents, and ion exchange materials employed in lithium extraction must be evaluated for their environmental persistence, toxicity, and disposal requirements. Recent technological advances have focused on developing more environmentally benign extraction chemicals and improving their recovery and reuse rates.

Carbon emissions represent a notable advantage of integrated geothermal-lithium systems. These facilities can achieve near-zero carbon lithium production when powered by their geothermal component, aligning with global decarbonization goals and potentially qualifying products for premium pricing in markets demanding low-carbon materials.

Ecosystem impacts must also be monitored, particularly regarding potential thermal changes in groundwater systems and surface water bodies if brine management is improperly executed. Comprehensive baseline studies and ongoing monitoring programs are essential components of environmental management plans for these facilities.

Water management remains a critical environmental factor in these integrated systems. While direct lithium extraction (DLE) from geothermal brines requires substantially less freshwater than conventional mining operations, the handling and disposal of processed brines demand careful management to prevent potential groundwater contamination. Most advanced DLE technologies now incorporate closed-loop systems that reinject treated brines back into geothermal reservoirs, minimizing water consumption and maintaining reservoir pressure.

Air quality impacts from these integrated facilities are generally minimal compared to traditional extraction methods. The elimination of large evaporation ponds reduces dust emissions and volatile compound releases. However, the energy requirements for DLE processes must be considered in the overall environmental footprint assessment, though this concern is mitigated when powered by the co-located geothermal energy.

Regarding land use, integrated geothermal-lithium facilities demonstrate a significantly smaller physical footprint than conventional lithium operations. This reduced spatial requirement minimizes habitat disruption and preserves natural landscapes, particularly valuable in ecologically sensitive regions where lithium resources are often found.

Chemical usage in DLE processes presents another environmental consideration. Various sorbents, solvents, and ion exchange materials employed in lithium extraction must be evaluated for their environmental persistence, toxicity, and disposal requirements. Recent technological advances have focused on developing more environmentally benign extraction chemicals and improving their recovery and reuse rates.

Carbon emissions represent a notable advantage of integrated geothermal-lithium systems. These facilities can achieve near-zero carbon lithium production when powered by their geothermal component, aligning with global decarbonization goals and potentially qualifying products for premium pricing in markets demanding low-carbon materials.

Ecosystem impacts must also be monitored, particularly regarding potential thermal changes in groundwater systems and surface water bodies if brine management is improperly executed. Comprehensive baseline studies and ongoing monitoring programs are essential components of environmental management plans for these facilities.

Economic Feasibility and ROI Analysis

The economic feasibility of integrating geothermal brines with power plants for direct lithium extraction (DLE) presents a compelling investment opportunity with significant potential returns. Initial capital expenditure requirements range from $30-50 million for pilot-scale operations to $400-600 million for commercial-scale facilities, depending on brine chemistry, extraction technology selection, and infrastructure requirements.

Operating expenses primarily consist of energy consumption, chemical reagents, maintenance, and labor costs. Energy represents 30-40% of operational expenses, though this can be substantially offset when integrated with existing geothermal power plants, creating a symbiotic relationship that enhances overall project economics. Chemical reagents account for approximately 20-25% of operational costs, varying based on the specific DLE technology employed.

Revenue projections are highly favorable given current lithium market dynamics. With lithium carbonate prices ranging between $15,000-$75,000 per metric ton (experiencing significant volatility in recent years), and production capacities of 5,000-20,000 tons annually for commercial operations, gross annual revenues can reach $75-300 million under conservative pricing scenarios.

Return on investment analysis indicates payback periods of 3-7 years for most integrated geothermal-DLE projects, with internal rates of return (IRR) between 15-30% depending on lithium prices, extraction efficiency, and operational scale. Projects utilizing existing geothermal infrastructure demonstrate significantly improved economics, with payback periods potentially reduced by 1-2 years.

Sensitivity analysis reveals that lithium market prices represent the most significant variable affecting project economics, followed by extraction efficiency and energy costs. A 20% fluctuation in lithium prices can alter IRR by 5-8 percentage points, highlighting the importance of securing offtake agreements and hedging strategies.

Government incentives, including tax credits for critical mineral production, grants for clean energy projects, and expedited permitting processes, can substantially improve project economics. The Inflation Reduction Act in the United States, for instance, provides production tax credits that can enhance project IRR by 3-5 percentage points.

Risk mitigation strategies should include phased implementation approaches, beginning with pilot operations before scaling to commercial production, diversification of revenue streams through potential extraction of other valuable minerals present in brines (zinc, manganese, etc.), and strategic partnerships with battery manufacturers or automotive companies to secure stable demand channels.

Operating expenses primarily consist of energy consumption, chemical reagents, maintenance, and labor costs. Energy represents 30-40% of operational expenses, though this can be substantially offset when integrated with existing geothermal power plants, creating a symbiotic relationship that enhances overall project economics. Chemical reagents account for approximately 20-25% of operational costs, varying based on the specific DLE technology employed.

Revenue projections are highly favorable given current lithium market dynamics. With lithium carbonate prices ranging between $15,000-$75,000 per metric ton (experiencing significant volatility in recent years), and production capacities of 5,000-20,000 tons annually for commercial operations, gross annual revenues can reach $75-300 million under conservative pricing scenarios.

Return on investment analysis indicates payback periods of 3-7 years for most integrated geothermal-DLE projects, with internal rates of return (IRR) between 15-30% depending on lithium prices, extraction efficiency, and operational scale. Projects utilizing existing geothermal infrastructure demonstrate significantly improved economics, with payback periods potentially reduced by 1-2 years.

Sensitivity analysis reveals that lithium market prices represent the most significant variable affecting project economics, followed by extraction efficiency and energy costs. A 20% fluctuation in lithium prices can alter IRR by 5-8 percentage points, highlighting the importance of securing offtake agreements and hedging strategies.

Government incentives, including tax credits for critical mineral production, grants for clean energy projects, and expedited permitting processes, can substantially improve project economics. The Inflation Reduction Act in the United States, for instance, provides production tax credits that can enhance project IRR by 3-5 percentage points.

Risk mitigation strategies should include phased implementation approaches, beginning with pilot operations before scaling to commercial production, diversification of revenue streams through potential extraction of other valuable minerals present in brines (zinc, manganese, etc.), and strategic partnerships with battery manufacturers or automotive companies to secure stable demand channels.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!