Permitting Logistics And Community Engagement For Direct Lithium Extraction

AUG 27, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DLE Technology Background and Objectives

Direct Lithium Extraction (DLE) technology represents a paradigm shift in lithium production, evolving from traditional methods that have dominated the industry for decades. The conventional approaches—solar evaporation from salt flats (salars) and hard-rock mining—have significant environmental footprints and operational limitations. DLE emerged in the early 2000s as researchers sought more sustainable and efficient extraction methods to meet the rapidly growing demand for lithium, primarily driven by the electric vehicle revolution and renewable energy storage systems.

The technological evolution of DLE has accelerated dramatically in the past decade, with significant advancements in selective adsorption materials, membrane technologies, and electrochemical processes. These innovations aim to extract lithium directly from brine resources with minimal environmental impact, reduced water consumption, and significantly shorter production timelines compared to traditional evaporation methods that can take 18-24 months.

The primary objective of DLE technology development is to establish economically viable processes that can extract lithium from various sources—including geothermal brines, oilfield brines, and even seawater—with high recovery rates and minimal environmental disruption. This represents a critical advancement as the global lithium demand is projected to increase by 40-fold by 2040, according to the International Energy Agency.

Current DLE technologies fall into several categories: adsorption using inorganic materials, solvent extraction, ion exchange, and membrane processes. Each approach offers distinct advantages and challenges in terms of selectivity, recovery rates, and operational requirements. The technical objectives focus on improving lithium selectivity in complex brine chemistries, reducing energy consumption, minimizing chemical usage, and developing processes that can be scaled commercially.

Permitting logistics and community engagement have emerged as crucial factors in DLE implementation. Unlike traditional mining operations that often face significant opposition due to land disturbance and water usage, DLE projects potentially offer a smaller physical footprint and reduced environmental impact. However, they still require careful navigation of regulatory frameworks that vary significantly across jurisdictions and may not yet be adapted to these newer technologies.

The technological goal is to develop DLE systems that not only maximize lithium recovery but also address community concerns regarding water usage, potential contamination, and land rights. This includes designing closed-loop systems that minimize freshwater consumption, implementing robust monitoring protocols, and developing transparent engagement processes with local communities, particularly indigenous populations who may have historical claims to the land or water resources being utilized.

The technological evolution of DLE has accelerated dramatically in the past decade, with significant advancements in selective adsorption materials, membrane technologies, and electrochemical processes. These innovations aim to extract lithium directly from brine resources with minimal environmental impact, reduced water consumption, and significantly shorter production timelines compared to traditional evaporation methods that can take 18-24 months.

The primary objective of DLE technology development is to establish economically viable processes that can extract lithium from various sources—including geothermal brines, oilfield brines, and even seawater—with high recovery rates and minimal environmental disruption. This represents a critical advancement as the global lithium demand is projected to increase by 40-fold by 2040, according to the International Energy Agency.

Current DLE technologies fall into several categories: adsorption using inorganic materials, solvent extraction, ion exchange, and membrane processes. Each approach offers distinct advantages and challenges in terms of selectivity, recovery rates, and operational requirements. The technical objectives focus on improving lithium selectivity in complex brine chemistries, reducing energy consumption, minimizing chemical usage, and developing processes that can be scaled commercially.

Permitting logistics and community engagement have emerged as crucial factors in DLE implementation. Unlike traditional mining operations that often face significant opposition due to land disturbance and water usage, DLE projects potentially offer a smaller physical footprint and reduced environmental impact. However, they still require careful navigation of regulatory frameworks that vary significantly across jurisdictions and may not yet be adapted to these newer technologies.

The technological goal is to develop DLE systems that not only maximize lithium recovery but also address community concerns regarding water usage, potential contamination, and land rights. This includes designing closed-loop systems that minimize freshwater consumption, implementing robust monitoring protocols, and developing transparent engagement processes with local communities, particularly indigenous populations who may have historical claims to the land or water resources being utilized.

Market Analysis for Direct Lithium Extraction

The global lithium market is experiencing unprecedented growth, primarily driven by the rapid expansion of electric vehicle (EV) production and renewable energy storage systems. Current market valuations place the lithium industry at approximately $7.5 billion in 2023, with projections indicating a compound annual growth rate (CAGR) of 21.3% through 2030, potentially reaching $34.3 billion. Direct Lithium Extraction (DLE) technologies are positioned to capture a significant portion of this expanding market.

Traditional lithium extraction methods, including hard rock mining and evaporation ponds, currently dominate the supply chain, accounting for over 90% of global production. However, DLE technologies are gaining traction due to their potential environmental and efficiency advantages. Market analysis indicates that DLE could potentially reduce extraction costs by 30-50% compared to conventional methods while simultaneously decreasing water usage by up to 70%.

The geographical distribution of lithium demand reveals that Asia Pacific, particularly China, remains the largest consumer, representing approximately 65% of global lithium consumption. North America and Europe are experiencing the fastest growth rates in demand, with increases of 35% and 29% respectively in the past year, driven by ambitious EV adoption targets and manufacturing expansions.

Supply chain dynamics are evolving rapidly as automotive manufacturers and battery producers seek to secure stable lithium supplies. This has resulted in a 213% increase in strategic partnerships and vertical integration initiatives between mining companies and end-users over the past three years. DLE technologies are increasingly featured in these arrangements due to their scalability and reduced time-to-market potential.

Consumer and regulatory pressures for environmentally responsible sourcing are creating premium market segments for sustainably extracted lithium. Products utilizing DLE-sourced lithium can command price premiums of 5-15% in environmentally conscious markets, particularly in Europe and North America. This trend is expected to strengthen as ESG (Environmental, Social, and Governance) considerations become more prominent in investment decisions.

Community engagement aspects of lithium extraction represent both a challenge and opportunity in the market landscape. Projects with strong community support experience 40% fewer delays in permitting processes and demonstrate 25% better operational continuity. This highlights the economic value of effective community engagement strategies, particularly for DLE operations which typically have smaller physical footprints but may raise concerns about groundwater impacts.

The competitive landscape is diversifying rapidly, with over 30 companies now actively developing proprietary DLE technologies. Market concentration remains relatively low, with the top five DLE technology providers controlling approximately 38% of the intellectual property in this space, indicating significant opportunities for innovation and market entry.

Traditional lithium extraction methods, including hard rock mining and evaporation ponds, currently dominate the supply chain, accounting for over 90% of global production. However, DLE technologies are gaining traction due to their potential environmental and efficiency advantages. Market analysis indicates that DLE could potentially reduce extraction costs by 30-50% compared to conventional methods while simultaneously decreasing water usage by up to 70%.

The geographical distribution of lithium demand reveals that Asia Pacific, particularly China, remains the largest consumer, representing approximately 65% of global lithium consumption. North America and Europe are experiencing the fastest growth rates in demand, with increases of 35% and 29% respectively in the past year, driven by ambitious EV adoption targets and manufacturing expansions.

Supply chain dynamics are evolving rapidly as automotive manufacturers and battery producers seek to secure stable lithium supplies. This has resulted in a 213% increase in strategic partnerships and vertical integration initiatives between mining companies and end-users over the past three years. DLE technologies are increasingly featured in these arrangements due to their scalability and reduced time-to-market potential.

Consumer and regulatory pressures for environmentally responsible sourcing are creating premium market segments for sustainably extracted lithium. Products utilizing DLE-sourced lithium can command price premiums of 5-15% in environmentally conscious markets, particularly in Europe and North America. This trend is expected to strengthen as ESG (Environmental, Social, and Governance) considerations become more prominent in investment decisions.

Community engagement aspects of lithium extraction represent both a challenge and opportunity in the market landscape. Projects with strong community support experience 40% fewer delays in permitting processes and demonstrate 25% better operational continuity. This highlights the economic value of effective community engagement strategies, particularly for DLE operations which typically have smaller physical footprints but may raise concerns about groundwater impacts.

The competitive landscape is diversifying rapidly, with over 30 companies now actively developing proprietary DLE technologies. Market concentration remains relatively low, with the top five DLE technology providers controlling approximately 38% of the intellectual property in this space, indicating significant opportunities for innovation and market entry.

Technical Challenges in DLE Implementation

Direct Lithium Extraction (DLE) technologies face significant technical challenges that must be addressed for successful implementation. The complexity of lithium-bearing brines varies considerably across different geothermal and salt flat resources, requiring customized technical approaches. Each brine source presents unique chemical compositions with varying concentrations of lithium, sodium, potassium, magnesium, calcium, and other elements that can interfere with extraction processes.

Selectivity remains a primary technical hurdle, as most DLE technologies struggle to efficiently separate lithium from other similar ions, particularly sodium and magnesium. This challenge is compounded by the relatively low concentration of lithium in most brines (typically 50-200 ppm) compared to other elements present in concentrations orders of magnitude higher. The development of highly selective sorbents, membranes, or extraction media that can operate effectively in these complex chemical environments continues to be a critical research focus.

Water consumption presents another significant challenge, particularly in arid regions where many lithium resources are located. While DLE is often promoted as more water-efficient than traditional evaporation ponds, many current technologies still require substantial water inputs for processing and regeneration cycles. Developing closed-loop water systems and minimizing freshwater requirements remains technically challenging but environmentally necessary.

Energy requirements for DLE systems are considerably higher than traditional methods, creating both technical and economic barriers. Most technologies require significant electricity for pumping, heating, cooling, and regeneration processes. In remote locations where many lithium resources exist, establishing reliable and affordable energy infrastructure presents additional complications. Renewable energy integration offers potential solutions but adds layers of technical complexity to project implementation.

Scaling from laboratory to commercial operations introduces numerous engineering challenges. Many promising DLE technologies demonstrate excellent performance in controlled laboratory settings but encounter difficulties when scaled to process the thousands of cubic meters of brine needed for commercial viability. Issues include sorbent degradation over multiple cycles, membrane fouling, equipment corrosion from high-salinity brines, and maintaining consistent performance under variable field conditions.

Waste management represents a significant technical challenge that intersects with permitting requirements. DLE processes generate various waste streams including depleted brines, spent sorbents, and chemical reagents that require proper handling and disposal. Developing effective methods to treat, reuse, or safely dispose of these materials is technically complex but essential for environmental compliance and community acceptance.

The integration of DLE systems with existing geothermal operations or development of standalone facilities requires sophisticated engineering solutions to handle high temperatures, pressures, and flow rates while maintaining extraction efficiency. These technical challenges directly impact the permitting process, as regulatory authorities require detailed technical plans demonstrating environmental safeguards and operational reliability.

Selectivity remains a primary technical hurdle, as most DLE technologies struggle to efficiently separate lithium from other similar ions, particularly sodium and magnesium. This challenge is compounded by the relatively low concentration of lithium in most brines (typically 50-200 ppm) compared to other elements present in concentrations orders of magnitude higher. The development of highly selective sorbents, membranes, or extraction media that can operate effectively in these complex chemical environments continues to be a critical research focus.

Water consumption presents another significant challenge, particularly in arid regions where many lithium resources are located. While DLE is often promoted as more water-efficient than traditional evaporation ponds, many current technologies still require substantial water inputs for processing and regeneration cycles. Developing closed-loop water systems and minimizing freshwater requirements remains technically challenging but environmentally necessary.

Energy requirements for DLE systems are considerably higher than traditional methods, creating both technical and economic barriers. Most technologies require significant electricity for pumping, heating, cooling, and regeneration processes. In remote locations where many lithium resources exist, establishing reliable and affordable energy infrastructure presents additional complications. Renewable energy integration offers potential solutions but adds layers of technical complexity to project implementation.

Scaling from laboratory to commercial operations introduces numerous engineering challenges. Many promising DLE technologies demonstrate excellent performance in controlled laboratory settings but encounter difficulties when scaled to process the thousands of cubic meters of brine needed for commercial viability. Issues include sorbent degradation over multiple cycles, membrane fouling, equipment corrosion from high-salinity brines, and maintaining consistent performance under variable field conditions.

Waste management represents a significant technical challenge that intersects with permitting requirements. DLE processes generate various waste streams including depleted brines, spent sorbents, and chemical reagents that require proper handling and disposal. Developing effective methods to treat, reuse, or safely dispose of these materials is technically complex but essential for environmental compliance and community acceptance.

The integration of DLE systems with existing geothermal operations or development of standalone facilities requires sophisticated engineering solutions to handle high temperatures, pressures, and flow rates while maintaining extraction efficiency. These technical challenges directly impact the permitting process, as regulatory authorities require detailed technical plans demonstrating environmental safeguards and operational reliability.

Current DLE Permitting Solutions

01 Adsorption-based lithium extraction methods

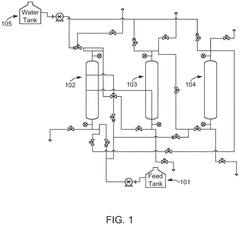

Adsorption-based methods utilize specialized materials that selectively bind to lithium ions from brine solutions. These adsorbents can be inorganic ion exchangers, organic resins, or composite materials with high selectivity for lithium over competing ions like sodium, magnesium, and calcium. The process typically involves passing lithium-containing brine through columns packed with these adsorbents, followed by desorption using acid or other regeneration solutions to recover concentrated lithium.- Adsorption-based lithium extraction methods: Direct lithium extraction techniques using adsorption materials that selectively capture lithium ions from brine solutions. These methods typically employ specialized sorbents or ion exchange materials that have high selectivity for lithium over competing ions such as sodium, potassium, and magnesium. The process involves passing lithium-containing brines through columns or beds of these materials, followed by desorption steps to recover concentrated lithium solutions.

- Membrane-based separation technologies: Technologies utilizing various membrane systems for direct lithium extraction from brines and other sources. These approaches may include nanofiltration, reverse osmosis, or electrodialysis membranes that allow selective passage of lithium ions while rejecting other elements. Membrane-based methods offer advantages in terms of continuous operation and potentially lower energy requirements compared to traditional evaporation techniques.

- Electrochemical lithium extraction processes: Electrochemical methods for direct lithium extraction that utilize electrical potential differences to selectively recover lithium from brines and other sources. These techniques may involve electrochemical cells with specialized electrodes that can capture lithium ions when current is applied. The captured lithium can then be released by reversing the electrical potential, resulting in concentrated lithium solutions suitable for further processing.

- Solvent extraction and chemical precipitation methods: Chemical approaches to direct lithium extraction involving liquid-liquid extraction with specialized solvents or precipitation reactions. These methods use carefully selected chemicals that react preferentially with lithium to form compounds that can be separated from the brine solution. The lithium compounds are then processed further to obtain lithium products of commercial purity. These techniques can be effective for brines with complex compositions.

- Integrated lithium extraction and processing systems: Comprehensive systems that combine multiple technologies for direct lithium extraction with downstream processing to produce battery-grade lithium compounds. These integrated approaches may incorporate adsorption, membrane, or electrochemical extraction methods followed by purification, concentration, and conversion steps. Such systems are designed to minimize waste, reduce environmental impact, and optimize lithium recovery from various sources including brines, geothermal waters, and recycled materials.

02 Membrane and electrochemical extraction technologies

Electrochemical methods employ ion-selective membranes and electrical potential to separate lithium ions from brine solutions. These technologies include electrodialysis, capacitive deionization, and electrochemical cells specifically designed for lithium extraction. The application of electrical current drives lithium ions through selective membranes while excluding other ions, resulting in concentrated lithium solutions. These methods can achieve high recovery rates with lower energy consumption compared to traditional evaporation techniques.Expand Specific Solutions03 Solvent extraction and chemical precipitation techniques

Solvent extraction utilizes specific organic extractants that selectively complex with lithium ions, transferring them from an aqueous phase to an organic phase. The lithium can then be stripped from the organic phase using acid solutions. Chemical precipitation methods involve adding reagents that form insoluble lithium compounds, which can be separated and processed further. These techniques can be applied to various lithium sources including brines, geothermal waters, and process solutions from mineral processing.Expand Specific Solutions04 Integrated lithium extraction systems and process optimization

Integrated systems combine multiple extraction technologies to maximize lithium recovery efficiency. These systems often incorporate pre-treatment steps to remove impurities, primary extraction using adsorption or membrane technologies, and post-processing to produce battery-grade lithium compounds. Process optimization focuses on reducing water consumption, minimizing chemical usage, and improving energy efficiency. Advanced control systems and real-time monitoring enable adaptive operation based on feed composition variations.Expand Specific Solutions05 Direct extraction from unconventional sources and environmental considerations

Novel technologies enable lithium extraction from unconventional sources such as geothermal brines, oil field produced waters, and mining waste streams. These methods are designed to minimize environmental impact through reduced land footprint, water consumption, and waste generation compared to traditional evaporation ponds. Closed-loop systems recycle process water and reagents, while selective extraction reduces the need for extensive purification steps. Sustainable approaches focus on reducing carbon emissions and preserving local ecosystems while meeting growing lithium demand.Expand Specific Solutions

Key Industry Players in DLE Market

The direct lithium extraction (DLE) technology market is in its early growth phase, characterized by rapid innovation and increasing commercial deployment. The global market for lithium extraction is expanding significantly, driven by electric vehicle battery demand, with projections exceeding $10 billion by 2030. Technologically, companies like Lilac Solutions and Summit Nanotech are pioneering advanced ion-exchange methods, while established players such as Schlumberger and Baker Hughes bring industrial-scale implementation expertise. Academic institutions including Penn State and North Carolina State University are contributing fundamental research, while companies like American Battery Technology and Vulcan Energy are focusing on environmentally sustainable extraction processes. The regulatory landscape for permitting and community engagement remains complex, requiring specialized expertise as the industry matures.

Lilac Solutions, Inc.

Technical Solution: Lilac Solutions has developed an ion-exchange technology specifically designed for direct lithium extraction (DLE) from brine resources. Their approach uses proprietary ion-exchange beads that selectively absorb lithium from brine while leaving other elements behind. The process operates in a closed-loop system where the lithium-loaded beads are washed with an acid solution to release concentrated lithium chloride, which is then processed into battery-grade lithium products. Lilac's technology enables lithium extraction from previously uneconomical resources with minimal environmental footprint compared to traditional evaporation ponds. The company has implemented community engagement strategies that include transparent communication with local stakeholders, educational programs about their technology's reduced water consumption (approximately 90% less than evaporation ponds), and partnerships with local authorities to ensure regulatory compliance while addressing community concerns about water usage and land disturbance.

Strengths: Highly selective lithium extraction with minimal water consumption; rapid processing time (hours vs. months for evaporation ponds); adaptable to various brine chemistries; significantly reduced land footprint. Weaknesses: Requires specialized equipment and expertise; higher upfront capital costs compared to traditional methods; potential challenges in scaling to industrial production levels; dependency on chemical reagents that need proper handling and disposal.

Baker Hughes Oilfield Operations LLC

Technical Solution: Baker Hughes has leveraged its extensive experience in oilfield operations to develop direct lithium extraction technologies compatible with existing well infrastructure. Their approach integrates with geothermal power generation systems to create a dual-purpose extraction process that harvests both renewable energy and lithium from geothermal brines. The company utilizes advanced membrane and adsorption technologies that can be deployed at wellheads to selectively extract lithium while the brine remains in a pressurized state. This reduces the need for additional pumping infrastructure and minimizes surface disturbance. Baker Hughes has implemented a comprehensive community engagement framework that includes early stakeholder identification, regular consultation meetings, and transparent impact assessments. Their permitting strategy leverages existing relationships with regulatory bodies from their oil and gas operations, applying established environmental compliance protocols to lithium extraction projects. The company has also developed specialized training programs for local workforces to create employment opportunities in communities where their DLE projects operate.

Strengths: Integration with existing well infrastructure reduces capital expenditure; dual-purpose extraction creates additional revenue streams; extensive experience navigating complex regulatory environments; established relationships with local communities in resource-rich areas. Weaknesses: Technology primarily optimized for geothermal brines rather than salt flats or salars; dependency on specific geological conditions; potential public perception challenges due to association with fossil fuel industry; requires significant technical expertise for operation.

Critical Patents and Innovations in DLE

Process for selective purification of lithium from an aqueous lithium salt-containing solution

PatentPendingEP4442343A1

Innovation

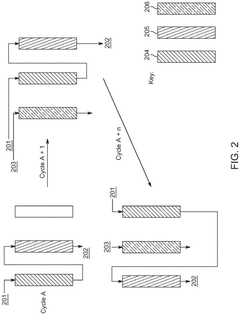

- Configuring columns in a carousel or lead-lag configuration with three or more packed-bed columns, where at least two are at adsorption stages and one at a desorption stage, allowing direct transitions without intermediate washing stages, to maximize uptime and reduce cycle time.

Community Engagement Frameworks for DLE Projects

Effective community engagement frameworks are essential for the successful implementation of Direct Lithium Extraction (DLE) projects. These frameworks provide structured approaches for companies to interact with local communities, indigenous groups, and other stakeholders throughout the project lifecycle. The International Association for Public Participation (IAP2) Spectrum offers a valuable foundation, categorizing engagement levels from informing to empowering, which DLE developers can adapt to different project phases.

Stakeholder mapping represents a critical initial step in any engagement framework, identifying key community groups, their interests, concerns, and potential influence on project outcomes. For DLE projects specifically, this mapping should include indigenous communities with historical connections to lithium-rich regions, local businesses that may benefit from or be disrupted by operations, environmental advocacy groups, and regional governmental bodies.

Transparency mechanisms form another vital component of engagement frameworks, establishing clear protocols for information sharing about project timelines, environmental impacts, water usage concerns, and economic benefits. Leading DLE companies have implemented digital platforms that provide real-time monitoring data accessible to community members, building trust through verifiable information rather than promises alone.

Benefit-sharing agreements have emerged as standard practice within comprehensive engagement frameworks, formalizing how project advantages will be distributed among local communities. These agreements typically address employment opportunities, skills development programs, infrastructure improvements, and revenue-sharing arrangements. The Salton Sea DLE initiatives in California demonstrate how structured benefit-sharing can create community advocates rather than opponents.

Cultural heritage protection protocols must be integrated into engagement frameworks, particularly in regions with significant indigenous populations. These protocols establish processes for identifying culturally significant sites, conducting appropriate consultations before ground disturbance, and implementing mitigation measures when impacts cannot be avoided. The experience of lithium developers in the Andean regions has shown that neglecting these considerations can lead to project delays and community opposition.

Grievance resolution mechanisms provide structured pathways for addressing community concerns throughout project development and operation. Effective frameworks include multiple reporting channels, transparent investigation procedures, and escalation options when initial resolutions prove unsatisfactory. Third-party mediation options have proven particularly valuable in resolving complex disputes between DLE operators and community stakeholders.

Stakeholder mapping represents a critical initial step in any engagement framework, identifying key community groups, their interests, concerns, and potential influence on project outcomes. For DLE projects specifically, this mapping should include indigenous communities with historical connections to lithium-rich regions, local businesses that may benefit from or be disrupted by operations, environmental advocacy groups, and regional governmental bodies.

Transparency mechanisms form another vital component of engagement frameworks, establishing clear protocols for information sharing about project timelines, environmental impacts, water usage concerns, and economic benefits. Leading DLE companies have implemented digital platforms that provide real-time monitoring data accessible to community members, building trust through verifiable information rather than promises alone.

Benefit-sharing agreements have emerged as standard practice within comprehensive engagement frameworks, formalizing how project advantages will be distributed among local communities. These agreements typically address employment opportunities, skills development programs, infrastructure improvements, and revenue-sharing arrangements. The Salton Sea DLE initiatives in California demonstrate how structured benefit-sharing can create community advocates rather than opponents.

Cultural heritage protection protocols must be integrated into engagement frameworks, particularly in regions with significant indigenous populations. These protocols establish processes for identifying culturally significant sites, conducting appropriate consultations before ground disturbance, and implementing mitigation measures when impacts cannot be avoided. The experience of lithium developers in the Andean regions has shown that neglecting these considerations can lead to project delays and community opposition.

Grievance resolution mechanisms provide structured pathways for addressing community concerns throughout project development and operation. Effective frameworks include multiple reporting channels, transparent investigation procedures, and escalation options when initial resolutions prove unsatisfactory. Third-party mediation options have proven particularly valuable in resolving complex disputes between DLE operators and community stakeholders.

Environmental Impact Assessment of DLE Operations

Direct Lithium Extraction (DLE) operations, while offering significant advantages over traditional extraction methods, still pose various environmental impacts that require thorough assessment. The environmental footprint of DLE technologies extends across multiple ecological dimensions that must be systematically evaluated to ensure sustainable implementation.

Water usage represents a primary environmental concern for DLE operations. Although DLE typically requires less water than evaporation ponds, the technology still demands substantial water resources, particularly in water-stressed regions where lithium deposits are often located. Comprehensive water balance assessments must quantify consumption rates, identify potential sources of water stress, and evaluate opportunities for water recycling and conservation within the extraction process.

Chemical usage in DLE processes presents another significant environmental consideration. The selective sorbents, ion exchange resins, and processing chemicals employed in various DLE methods may introduce contaminants to surrounding ecosystems if not properly managed. Environmental impact assessments must characterize the toxicity profiles of these substances and evaluate potential pathways for environmental release through air emissions, wastewater discharge, or solid waste disposal.

Land disturbance from DLE operations, while generally less extensive than traditional evaporation methods, still requires careful evaluation. Infrastructure development, including processing facilities, pipelines, and access roads, can fragment habitats and disrupt local ecosystems. Assessments should quantify the spatial footprint of operations and identify sensitive ecological areas requiring special protection measures.

Energy consumption represents a critical environmental parameter for DLE technologies. The processes often require significant electrical inputs for pumping, heating, and regeneration of extraction media. Environmental assessments must calculate the carbon footprint associated with these energy requirements and explore opportunities for renewable energy integration to minimize greenhouse gas emissions.

Waste management considerations are essential components of environmental impact assessments for DLE operations. The handling and disposal of spent extraction media, process residues, and brine after lithium removal all present potential environmental risks. Proper characterization of waste streams, development of appropriate disposal protocols, and exploration of beneficial reuse options should be central to environmental planning.

Groundwater and surface water quality protection demands rigorous monitoring programs to detect potential contamination from DLE operations. Baseline studies establishing pre-operational water quality conditions, coupled with ongoing monitoring throughout the project lifecycle, provide essential data for environmental protection and regulatory compliance.

Water usage represents a primary environmental concern for DLE operations. Although DLE typically requires less water than evaporation ponds, the technology still demands substantial water resources, particularly in water-stressed regions where lithium deposits are often located. Comprehensive water balance assessments must quantify consumption rates, identify potential sources of water stress, and evaluate opportunities for water recycling and conservation within the extraction process.

Chemical usage in DLE processes presents another significant environmental consideration. The selective sorbents, ion exchange resins, and processing chemicals employed in various DLE methods may introduce contaminants to surrounding ecosystems if not properly managed. Environmental impact assessments must characterize the toxicity profiles of these substances and evaluate potential pathways for environmental release through air emissions, wastewater discharge, or solid waste disposal.

Land disturbance from DLE operations, while generally less extensive than traditional evaporation methods, still requires careful evaluation. Infrastructure development, including processing facilities, pipelines, and access roads, can fragment habitats and disrupt local ecosystems. Assessments should quantify the spatial footprint of operations and identify sensitive ecological areas requiring special protection measures.

Energy consumption represents a critical environmental parameter for DLE technologies. The processes often require significant electrical inputs for pumping, heating, and regeneration of extraction media. Environmental assessments must calculate the carbon footprint associated with these energy requirements and explore opportunities for renewable energy integration to minimize greenhouse gas emissions.

Waste management considerations are essential components of environmental impact assessments for DLE operations. The handling and disposal of spent extraction media, process residues, and brine after lithium removal all present potential environmental risks. Proper characterization of waste streams, development of appropriate disposal protocols, and exploration of beneficial reuse options should be central to environmental planning.

Groundwater and surface water quality protection demands rigorous monitoring programs to detect potential contamination from DLE operations. Baseline studies establishing pre-operational water quality conditions, coupled with ongoing monitoring throughout the project lifecycle, provide essential data for environmental protection and regulatory compliance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!