Process Control And Inline Sensing For Direct Lithium Extraction

AUG 27, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DLE Technology Background and Objectives

Direct Lithium Extraction (DLE) has emerged as a revolutionary approach to lithium production, representing a significant departure from traditional extraction methods such as evaporation ponds and hard rock mining. The technology's development can be traced back to the early 2000s, with substantial advancements occurring in the past decade as global demand for lithium has surged due to the electric vehicle revolution and renewable energy storage requirements.

DLE technologies aim to extract lithium directly from brine resources with greater efficiency, reduced environmental impact, and accelerated production timelines compared to conventional methods. The evolution of DLE has been driven by the limitations of traditional extraction processes, which typically require 18-24 months for lithium concentration and recovery, consume vast quantities of water, and have recovery rates of only 30-50%.

Process control and inline sensing represent critical components within the DLE technological framework. These systems enable real-time monitoring and adjustment of extraction parameters, ensuring optimal performance and resource utilization. The development of these control mechanisms has progressed from basic monitoring systems to sophisticated AI-driven predictive control platforms that can adapt to changing brine compositions and environmental conditions.

The primary technical objectives for process control and inline sensing in DLE include achieving lithium recovery rates exceeding 90%, reducing water consumption by over 70% compared to evaporation methods, minimizing chemical reagent usage, and enabling continuous operation with minimal downtime. Additionally, these systems aim to provide precise concentration measurements with error margins below 2% and response times under 60 seconds.

Current technological trends indicate a movement toward integrated sensor arrays that can simultaneously monitor multiple parameters including lithium concentration, impurity levels, pH, temperature, and flow rates. These multi-parameter sensing systems are increasingly being coupled with edge computing capabilities to enable rapid data processing and control decisions without reliance on cloud connectivity in remote extraction locations.

The ultimate goal of advanced process control and inline sensing for DLE is to create a closed-loop system that can autonomously optimize extraction efficiency while adapting to variations in feedstock composition. This would enable consistent production quality regardless of brine source variations, maximize resource recovery, and minimize environmental impact through precise reagent dosing and water management.

As lithium demand projections indicate a potential supply gap of up to 2 million tonnes by 2030, the development of efficient DLE technologies with sophisticated process control represents a strategic imperative for meeting global energy transition goals and establishing sustainable lithium supply chains.

DLE technologies aim to extract lithium directly from brine resources with greater efficiency, reduced environmental impact, and accelerated production timelines compared to conventional methods. The evolution of DLE has been driven by the limitations of traditional extraction processes, which typically require 18-24 months for lithium concentration and recovery, consume vast quantities of water, and have recovery rates of only 30-50%.

Process control and inline sensing represent critical components within the DLE technological framework. These systems enable real-time monitoring and adjustment of extraction parameters, ensuring optimal performance and resource utilization. The development of these control mechanisms has progressed from basic monitoring systems to sophisticated AI-driven predictive control platforms that can adapt to changing brine compositions and environmental conditions.

The primary technical objectives for process control and inline sensing in DLE include achieving lithium recovery rates exceeding 90%, reducing water consumption by over 70% compared to evaporation methods, minimizing chemical reagent usage, and enabling continuous operation with minimal downtime. Additionally, these systems aim to provide precise concentration measurements with error margins below 2% and response times under 60 seconds.

Current technological trends indicate a movement toward integrated sensor arrays that can simultaneously monitor multiple parameters including lithium concentration, impurity levels, pH, temperature, and flow rates. These multi-parameter sensing systems are increasingly being coupled with edge computing capabilities to enable rapid data processing and control decisions without reliance on cloud connectivity in remote extraction locations.

The ultimate goal of advanced process control and inline sensing for DLE is to create a closed-loop system that can autonomously optimize extraction efficiency while adapting to variations in feedstock composition. This would enable consistent production quality regardless of brine source variations, maximize resource recovery, and minimize environmental impact through precise reagent dosing and water management.

As lithium demand projections indicate a potential supply gap of up to 2 million tonnes by 2030, the development of efficient DLE technologies with sophisticated process control represents a strategic imperative for meeting global energy transition goals and establishing sustainable lithium supply chains.

Market Analysis for Direct Lithium Extraction

The global lithium market is experiencing unprecedented growth, primarily driven by the rapid expansion of electric vehicle (EV) production and renewable energy storage systems. Direct Lithium Extraction (DLE) technologies have emerged as a revolutionary approach to lithium production, offering significant advantages over traditional extraction methods. The market for DLE is projected to grow at a CAGR of 30% between 2023-2030, reaching a market value of $5.7 billion by 2030.

Geographically, the DLE market is concentrated in regions with significant lithium brine resources, including the "Lithium Triangle" of South America (Argentina, Bolivia, and Chile), North America (particularly Nevada and California), Australia, and China. These regions collectively account for over 85% of global lithium resources, with the Lithium Triangle alone containing approximately 58% of the world's lithium reserves.

The demand for advanced process control and inline sensing technologies in DLE operations is being driven by several key factors. First, the need for improved efficiency and reduced environmental impact in lithium production processes is paramount as global demand surges. Traditional evaporation pond methods require extensive land use and water consumption, while DLE technologies can reduce water usage by up to 70% when properly monitored and controlled.

Second, quality control requirements are becoming increasingly stringent as battery manufacturers demand higher purity lithium compounds. Inline sensing technologies that can monitor lithium concentration, impurity levels, and process parameters in real-time are essential for meeting these specifications. The market for specialized sensors in DLE applications alone is expected to reach $420 million by 2028.

Third, economic factors are driving adoption of advanced process control systems. DLE operations with sophisticated monitoring and control capabilities can achieve up to 30% lower operational costs compared to those using basic control systems. This translates to approximately $1,200-1,800 per ton of lithium carbonate equivalent in savings.

Market segmentation reveals distinct customer groups: major mining corporations investing in large-scale DLE operations, specialized lithium producers focusing exclusively on DLE technologies, and technology providers developing and supplying process control and sensing solutions. Each segment has different requirements and price sensitivities.

Regulatory trends are also shaping the market landscape. Increasingly stringent environmental regulations regarding water usage, land disturbance, and chemical handling are creating strong incentives for adoption of precisely controlled DLE processes. Countries including Chile and Argentina have implemented specific regulations for lithium extraction that favor technologies with lower environmental footprints and better process control capabilities.

Geographically, the DLE market is concentrated in regions with significant lithium brine resources, including the "Lithium Triangle" of South America (Argentina, Bolivia, and Chile), North America (particularly Nevada and California), Australia, and China. These regions collectively account for over 85% of global lithium resources, with the Lithium Triangle alone containing approximately 58% of the world's lithium reserves.

The demand for advanced process control and inline sensing technologies in DLE operations is being driven by several key factors. First, the need for improved efficiency and reduced environmental impact in lithium production processes is paramount as global demand surges. Traditional evaporation pond methods require extensive land use and water consumption, while DLE technologies can reduce water usage by up to 70% when properly monitored and controlled.

Second, quality control requirements are becoming increasingly stringent as battery manufacturers demand higher purity lithium compounds. Inline sensing technologies that can monitor lithium concentration, impurity levels, and process parameters in real-time are essential for meeting these specifications. The market for specialized sensors in DLE applications alone is expected to reach $420 million by 2028.

Third, economic factors are driving adoption of advanced process control systems. DLE operations with sophisticated monitoring and control capabilities can achieve up to 30% lower operational costs compared to those using basic control systems. This translates to approximately $1,200-1,800 per ton of lithium carbonate equivalent in savings.

Market segmentation reveals distinct customer groups: major mining corporations investing in large-scale DLE operations, specialized lithium producers focusing exclusively on DLE technologies, and technology providers developing and supplying process control and sensing solutions. Each segment has different requirements and price sensitivities.

Regulatory trends are also shaping the market landscape. Increasingly stringent environmental regulations regarding water usage, land disturbance, and chemical handling are creating strong incentives for adoption of precisely controlled DLE processes. Countries including Chile and Argentina have implemented specific regulations for lithium extraction that favor technologies with lower environmental footprints and better process control capabilities.

Process Control Challenges in DLE

Direct Lithium Extraction (DLE) processes face significant control challenges due to the complex nature of lithium extraction from brines and the dynamic conditions encountered during operations. The primary challenge lies in maintaining optimal process parameters across multiple extraction stages while dealing with variable brine compositions and concentrations.

Real-time monitoring of lithium concentration presents a formidable challenge as traditional sampling methods often introduce delays between measurement and control actions. This lag time can result in suboptimal extraction efficiency and increased operational costs. Furthermore, the presence of competing ions such as sodium, potassium, magnesium, and calcium complicates selective extraction and requires sophisticated control strategies to maintain selectivity.

Temperature fluctuations in brine sources significantly impact adsorption kinetics and equilibrium conditions in DLE processes. Control systems must continuously adjust process parameters to compensate for these variations, requiring robust temperature monitoring and compensation algorithms. The challenge is compounded by the need to maintain precise pH levels, as even minor deviations can dramatically affect lithium recovery rates and selectivity coefficients.

Flow rate control represents another critical challenge, as inconsistent flow can lead to channeling effects in adsorption columns, reducing effective contact time between brine and adsorbent materials. Advanced flow distribution systems with multiple sensing points are necessary but introduce additional complexity to the control architecture.

Fouling and scaling of equipment surfaces present persistent challenges that evolve over time, gradually degrading system performance. Current control systems struggle to detect and compensate for these effects before they significantly impact extraction efficiency. This necessitates predictive maintenance algorithms integrated with process control systems.

Regeneration cycles for adsorbent materials require precise timing and condition monitoring to optimize adsorbent lifetime while maintaining extraction efficiency. The control system must balance immediate extraction performance against long-term adsorbent degradation, requiring complex decision-making algorithms.

Energy optimization presents a substantial challenge as DLE processes can be energy-intensive. Control systems must balance extraction efficiency against energy consumption, particularly in remote operations where energy availability may be limited or costly. This requires integrated monitoring of multiple process parameters and sophisticated optimization algorithms.

Water management control is increasingly critical as DLE processes compete with other water users in often arid regions. Process controllers must optimize water usage while maintaining extraction performance, requiring integration with broader resource management systems and environmental monitoring networks.

The integration of these various control parameters into a cohesive, responsive system represents perhaps the greatest challenge in DLE process control, requiring advanced multivariate control strategies and potentially machine learning approaches to handle the complex interactions between process variables.

Real-time monitoring of lithium concentration presents a formidable challenge as traditional sampling methods often introduce delays between measurement and control actions. This lag time can result in suboptimal extraction efficiency and increased operational costs. Furthermore, the presence of competing ions such as sodium, potassium, magnesium, and calcium complicates selective extraction and requires sophisticated control strategies to maintain selectivity.

Temperature fluctuations in brine sources significantly impact adsorption kinetics and equilibrium conditions in DLE processes. Control systems must continuously adjust process parameters to compensate for these variations, requiring robust temperature monitoring and compensation algorithms. The challenge is compounded by the need to maintain precise pH levels, as even minor deviations can dramatically affect lithium recovery rates and selectivity coefficients.

Flow rate control represents another critical challenge, as inconsistent flow can lead to channeling effects in adsorption columns, reducing effective contact time between brine and adsorbent materials. Advanced flow distribution systems with multiple sensing points are necessary but introduce additional complexity to the control architecture.

Fouling and scaling of equipment surfaces present persistent challenges that evolve over time, gradually degrading system performance. Current control systems struggle to detect and compensate for these effects before they significantly impact extraction efficiency. This necessitates predictive maintenance algorithms integrated with process control systems.

Regeneration cycles for adsorbent materials require precise timing and condition monitoring to optimize adsorbent lifetime while maintaining extraction efficiency. The control system must balance immediate extraction performance against long-term adsorbent degradation, requiring complex decision-making algorithms.

Energy optimization presents a substantial challenge as DLE processes can be energy-intensive. Control systems must balance extraction efficiency against energy consumption, particularly in remote operations where energy availability may be limited or costly. This requires integrated monitoring of multiple process parameters and sophisticated optimization algorithms.

Water management control is increasingly critical as DLE processes compete with other water users in often arid regions. Process controllers must optimize water usage while maintaining extraction performance, requiring integration with broader resource management systems and environmental monitoring networks.

The integration of these various control parameters into a cohesive, responsive system represents perhaps the greatest challenge in DLE process control, requiring advanced multivariate control strategies and potentially machine learning approaches to handle the complex interactions between process variables.

Current Process Control Solutions for DLE

01 Real-time monitoring systems for DLE processes

Real-time monitoring systems are essential for Direct Lithium Extraction (DLE) processes to ensure optimal performance and efficiency. These systems utilize various sensors to continuously track critical parameters such as lithium concentration, pH levels, temperature, and flow rates throughout the extraction process. By implementing real-time monitoring, operators can quickly identify deviations from optimal conditions and make necessary adjustments to maintain process efficiency and product quality.- Real-time monitoring systems for DLE processes: Real-time monitoring systems are essential for Direct Lithium Extraction (DLE) processes to ensure optimal performance and efficiency. These systems utilize various sensors to continuously monitor parameters such as lithium concentration, pH levels, temperature, and flow rates. The data collected allows for immediate adjustments to the extraction process, helping to maintain consistent quality and yield. Advanced monitoring systems can also predict potential issues before they occur, reducing downtime and improving overall operational efficiency.

- Inline sensing technologies for lithium concentration measurement: Inline sensing technologies enable continuous measurement of lithium concentration during the extraction process without the need for manual sampling. These technologies include spectroscopic methods, electrochemical sensors, and ion-selective electrodes that can detect lithium ions in solution with high precision. By providing real-time data on lithium concentration, these sensing technologies allow for immediate process adjustments to optimize extraction efficiency and product purity. This approach significantly reduces the time and resources required for quality control compared to traditional laboratory analysis methods.

- Automated control systems for DLE optimization: Automated control systems integrate sensing data with advanced algorithms to optimize Direct Lithium Extraction processes. These systems use artificial intelligence and machine learning to analyze real-time data and automatically adjust process parameters such as flow rates, temperature, and chemical dosing. By continuously optimizing the extraction conditions based on feedback from inline sensors, these automated systems can maximize lithium recovery rates while minimizing energy consumption and chemical usage. The implementation of closed-loop control systems ensures consistent product quality despite variations in brine composition or other operating conditions.

- Quality control and purity monitoring in DLE: Quality control and purity monitoring are critical aspects of Direct Lithium Extraction processes to ensure the final product meets industry standards. Inline sensing technologies can continuously monitor impurity levels, such as sodium, magnesium, and calcium, which can affect the quality of extracted lithium. Advanced spectroscopic methods and ion chromatography techniques enable real-time detection of contaminants at very low concentrations. By implementing comprehensive quality control systems with inline monitoring, producers can ensure consistent purity levels and reduce the need for costly post-processing purification steps.

- Environmental monitoring and sustainable DLE processes: Environmental monitoring systems are increasingly integrated into Direct Lithium Extraction processes to ensure sustainability and regulatory compliance. These systems track water usage, energy consumption, chemical utilization, and waste generation throughout the extraction process. Inline sensors monitor parameters such as brine reinjection quality and potential contaminants to minimize environmental impact. By implementing comprehensive environmental monitoring, DLE operations can optimize resource efficiency, reduce their ecological footprint, and demonstrate compliance with environmental regulations. This approach supports the development of more sustainable lithium production methods that align with global sustainability goals.

02 Inline sensing technologies for lithium concentration measurement

Inline sensing technologies enable continuous measurement of lithium concentration during the extraction process without the need for manual sampling. These technologies include ion-selective electrodes, spectroscopic methods, and electrochemical sensors that can detect lithium ions in solution with high precision. Inline sensing provides immediate feedback on extraction efficiency and helps maintain consistent lithium recovery rates by allowing for real-time adjustments to process parameters.Expand Specific Solutions03 Automated control systems for DLE optimization

Automated control systems integrate sensing data with advanced algorithms to optimize Direct Lithium Extraction processes. These systems use artificial intelligence and machine learning to analyze real-time data and automatically adjust process parameters such as flow rates, temperature, and chemical dosing. By implementing automated control, DLE operations can achieve higher lithium recovery rates, reduced reagent consumption, and improved energy efficiency while maintaining consistent product quality.Expand Specific Solutions04 Quality control and purity monitoring in DLE processes

Quality control and purity monitoring are critical aspects of Direct Lithium Extraction to ensure the final product meets industry specifications. Inline sensing technologies can detect impurities and contaminants throughout the extraction process, allowing for immediate corrective actions. These monitoring systems track not only lithium concentration but also the presence of other elements such as sodium, calcium, and magnesium that can affect product quality. Continuous monitoring helps maintain consistent purity levels and reduces the need for post-processing purification steps.Expand Specific Solutions05 Integration of process control with data management systems

Integration of DLE process control with comprehensive data management systems enables better decision-making and process optimization. These integrated systems collect, store, and analyze data from multiple sensors throughout the extraction process, creating a historical database that can be used for trend analysis and process improvement. By connecting process control with data management, operators can identify patterns, predict maintenance needs, optimize resource allocation, and implement continuous improvement strategies for more efficient lithium extraction operations.Expand Specific Solutions

Key Industry Players in DLE Sector

The direct lithium extraction (DLE) technology market is currently in its early growth phase, characterized by rapid innovation and increasing commercial adoption. The global market size is projected to expand significantly due to rising demand for lithium in battery applications, with estimates suggesting a multi-billion dollar opportunity by 2030. Technologically, the field is advancing from pilot to commercial scale, with varying levels of maturity across different approaches. Leading players include established energy companies like Schlumberger and Saudi Aramco, who are leveraging their process engineering expertise, alongside specialized innovators such as EnergyX, Vulcan Energy, and LiEP Energy focusing on novel extraction methods. Academic institutions including The University of Manchester and Zhejiang University are contributing fundamental research, while companies like Evove and Watercycle Technologies are developing advanced membrane technologies for more efficient extraction processes.

Schlumberger Technologies, Inc.

Technical Solution: Schlumberger has developed advanced process control systems for Direct Lithium Extraction (DLE) that integrate real-time monitoring and adaptive control algorithms. Their technology utilizes specialized ion-selective electrodes and spectroscopic sensors to continuously monitor lithium concentration, pH levels, and impurity content throughout the extraction process. The system employs a closed-loop feedback mechanism that automatically adjusts process parameters such as flow rates, temperature, and chemical dosing based on inline measurements. Schlumberger's approach incorporates predictive modeling capabilities that anticipate process deviations before they occur, allowing for proactive adjustments rather than reactive corrections. Their DLE process control technology also features distributed sensor networks that provide comprehensive spatial monitoring across extraction facilities, enabling identification of localized inefficiencies or anomalies that might be missed by conventional point measurements[1][3]. The system integrates with their broader oilfield digitalization platform, leveraging expertise from their extensive experience in process monitoring in challenging environments.

Strengths: Superior integration with existing oilfield infrastructure; extensive experience with harsh operating environments; comprehensive data analytics capabilities that optimize extraction efficiency. Weaknesses: Higher implementation costs compared to simpler systems; requires specialized technical expertise for maintenance and calibration; may have excessive capabilities for smaller-scale DLE operations.

Koch Technology Solutions LLC

Technical Solution: Koch Technology Solutions has pioneered a comprehensive DLE process control system centered around their proprietary ion exchange technology. Their approach features multi-parameter inline sensing arrays that simultaneously monitor lithium concentration, competing ions (Na+, K+, Mg2+, Ca2+), pH, and conductivity throughout the extraction process. The system employs advanced chemometric algorithms to interpret complex spectral data from their proprietary optical sensors, enabling real-time determination of lithium purity and concentration with precision of ±2%. Koch's process control architecture incorporates adaptive flow management that automatically optimizes the ratio of brine input to sorbent material based on real-time concentration measurements, maximizing lithium recovery while minimizing water and chemical consumption[2]. Their technology includes specialized fouling detection sensors that identify early signs of sorbent degradation or scaling, triggering automated cleaning cycles before efficiency decreases. Koch has also developed machine learning models that continuously refine process parameters based on historical performance data, gradually improving yield and reducing energy consumption over time[4]. The system features modular design allowing for scalability from pilot to commercial-scale operations.

Strengths: Exceptional chemical selectivity for lithium over competing ions; highly automated operation requiring minimal operator intervention; proven scalability from pilot to commercial implementations. Weaknesses: Proprietary consumables create vendor lock-in; higher initial capital expenditure compared to conventional methods; requires specialized technical support for software updates and system optimization.

Critical Sensing Technologies for Lithium Extraction

Nmr analysis for direct lithium extraction

PatentWO2024155572A3

Innovation

- Using nuclear magnetic resonance (NMR) to analyze lithium content in withdrawal materials during the direct lithium extraction process, providing real-time monitoring capabilities.

- Real-time monitoring of lithium loading process through NMR signal analysis, enabling process control during the extraction rather than just post-process analysis.

- Application of NMR technology specifically for monitoring lithium withdrawal material performance during the loading process, representing a specialized analytical approach for DLE.

Method for improving lithium yield in a direct lithium extraction process

PatentPendingUS20250249465A1

Innovation

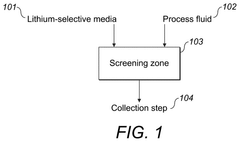

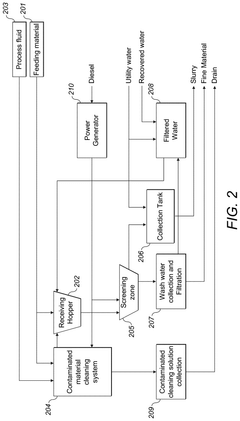

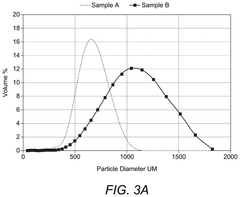

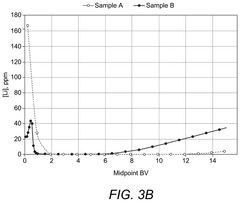

- A method involving a screening process using sieve elements with specific mesh sizes to separate lithium-selective media into desired particle sizes and remove contaminants, followed by dewatering and cleaning, to ensure optimal media performance in packed-bed columns.

Environmental Impact Assessment

Direct Lithium Extraction (DLE) processes present significant environmental considerations that must be thoroughly assessed to ensure sustainable implementation. The environmental footprint of DLE operations varies considerably depending on the specific technology employed, geographical location, and operational parameters. When compared to traditional evaporation pond methods, DLE typically demonstrates reduced land usage requirements, with some technologies requiring up to 90% less surface area for equivalent lithium production.

Water consumption represents a critical environmental factor in DLE operations. While certain DLE technologies have demonstrated water efficiency improvements over conventional extraction methods, others still require substantial water inputs, particularly in closed-loop systems requiring regular regeneration. In water-stressed regions such as the Lithium Triangle (Argentina, Bolivia, Chile), the implementation of advanced inline sensing can optimize water usage by providing real-time monitoring of process efficiency and enabling dynamic adjustments to minimize consumption.

Energy requirements constitute another significant environmental consideration. DLE processes generally demand higher energy inputs than traditional methods, with estimates suggesting 5-15 kWh per kilogram of lithium carbonate equivalent produced. The environmental impact of this energy consumption depends heavily on the regional energy mix. Process control advancements that optimize operational parameters based on real-time data can potentially reduce energy requirements by 10-30%, significantly improving the carbon footprint of extraction operations.

Chemical usage in DLE presents both challenges and opportunities for environmental management. Many DLE processes utilize sorbents, solvents, or membranes that require periodic regeneration with chemicals. Advanced inline sensing technologies capable of monitoring chemical concentrations and effectiveness can substantially reduce chemical waste by optimizing regeneration cycles and preventing unnecessary chemical additions.

Waste stream management represents a crucial environmental consideration for DLE operations. Process control systems integrated with appropriate sensing technologies enable continuous monitoring of brine composition before reinjection, ensuring compliance with environmental regulations and minimizing ecosystem disruption. Studies indicate that properly managed DLE operations can maintain groundwater quality when appropriate monitoring and control systems are implemented.

Greenhouse gas emissions associated with DLE vary significantly based on process design and energy sources. Life cycle assessments suggest that optimized DLE processes with effective process control can reduce the carbon footprint by 30-50% compared to traditional extraction methods when powered by renewable energy sources. The integration of carbon accounting into process control systems represents an emerging trend that enables real-time environmental performance monitoring.

Water consumption represents a critical environmental factor in DLE operations. While certain DLE technologies have demonstrated water efficiency improvements over conventional extraction methods, others still require substantial water inputs, particularly in closed-loop systems requiring regular regeneration. In water-stressed regions such as the Lithium Triangle (Argentina, Bolivia, Chile), the implementation of advanced inline sensing can optimize water usage by providing real-time monitoring of process efficiency and enabling dynamic adjustments to minimize consumption.

Energy requirements constitute another significant environmental consideration. DLE processes generally demand higher energy inputs than traditional methods, with estimates suggesting 5-15 kWh per kilogram of lithium carbonate equivalent produced. The environmental impact of this energy consumption depends heavily on the regional energy mix. Process control advancements that optimize operational parameters based on real-time data can potentially reduce energy requirements by 10-30%, significantly improving the carbon footprint of extraction operations.

Chemical usage in DLE presents both challenges and opportunities for environmental management. Many DLE processes utilize sorbents, solvents, or membranes that require periodic regeneration with chemicals. Advanced inline sensing technologies capable of monitoring chemical concentrations and effectiveness can substantially reduce chemical waste by optimizing regeneration cycles and preventing unnecessary chemical additions.

Waste stream management represents a crucial environmental consideration for DLE operations. Process control systems integrated with appropriate sensing technologies enable continuous monitoring of brine composition before reinjection, ensuring compliance with environmental regulations and minimizing ecosystem disruption. Studies indicate that properly managed DLE operations can maintain groundwater quality when appropriate monitoring and control systems are implemented.

Greenhouse gas emissions associated with DLE vary significantly based on process design and energy sources. Life cycle assessments suggest that optimized DLE processes with effective process control can reduce the carbon footprint by 30-50% compared to traditional extraction methods when powered by renewable energy sources. The integration of carbon accounting into process control systems represents an emerging trend that enables real-time environmental performance monitoring.

Scalability and Economic Viability

The scalability of Direct Lithium Extraction (DLE) technologies represents a critical factor in determining their commercial viability in the global lithium supply chain. Current pilot projects demonstrate promising results, but scaling these operations to industrial levels presents significant challenges. The capital expenditure (CAPEX) requirements for large-scale DLE facilities range from $15,000 to $30,000 per ton of annual lithium carbonate equivalent (LCE) production capacity, positioning them competitively against traditional evaporation pond methods in certain contexts.

Process control and inline sensing technologies play pivotal roles in improving the economic viability of DLE operations. Advanced monitoring systems that provide real-time data on lithium concentration, solution chemistry, and adsorbent performance can significantly reduce operational expenditures (OPEX) by optimizing reagent usage and minimizing energy consumption. These efficiencies become increasingly impactful at larger scales, potentially reducing production costs by 15-25% compared to operations without sophisticated process control.

Water management represents another crucial economic consideration in DLE scalability. While DLE methods generally use less water than evaporative techniques, the processing of large brine volumes still requires substantial water handling infrastructure. Inline sensing technologies that monitor water quality parameters enable more efficient water recycling systems, reducing freshwater requirements by up to 60% in optimized operations and substantially improving the economic profile of large-scale facilities.

Energy consumption remains a significant cost driver for DLE operations, particularly for technologies requiring thermal regeneration of adsorbents or membrane processes. Process control systems that dynamically adjust energy inputs based on real-time performance metrics have demonstrated energy savings of 10-30% in pilot operations. The integration of renewable energy sources, facilitated by sophisticated load management systems, further enhances economic viability, especially in remote locations where grid connectivity is limited.

The economic assessment of scalable DLE operations must also consider the value of higher recovery rates enabled by precise process control. Traditional evaporation methods typically recover 30-50% of available lithium, while optimized DLE systems with advanced sensing can achieve 80-95% recovery rates. This efficiency translates directly to economic value, particularly as lithium prices remain volatile in response to growing demand from the electric vehicle and energy storage sectors.

Market analysis indicates that DLE operations with sophisticated process control and sensing capabilities can achieve break-even production costs between $3,500 and $5,000 per ton of LCE, depending on brine chemistry and local operating conditions. This positions well-optimized DLE technologies competitively within the global lithium production landscape, especially as environmental regulations and water scarcity concerns increasingly impact traditional extraction methods.

Process control and inline sensing technologies play pivotal roles in improving the economic viability of DLE operations. Advanced monitoring systems that provide real-time data on lithium concentration, solution chemistry, and adsorbent performance can significantly reduce operational expenditures (OPEX) by optimizing reagent usage and minimizing energy consumption. These efficiencies become increasingly impactful at larger scales, potentially reducing production costs by 15-25% compared to operations without sophisticated process control.

Water management represents another crucial economic consideration in DLE scalability. While DLE methods generally use less water than evaporative techniques, the processing of large brine volumes still requires substantial water handling infrastructure. Inline sensing technologies that monitor water quality parameters enable more efficient water recycling systems, reducing freshwater requirements by up to 60% in optimized operations and substantially improving the economic profile of large-scale facilities.

Energy consumption remains a significant cost driver for DLE operations, particularly for technologies requiring thermal regeneration of adsorbents or membrane processes. Process control systems that dynamically adjust energy inputs based on real-time performance metrics have demonstrated energy savings of 10-30% in pilot operations. The integration of renewable energy sources, facilitated by sophisticated load management systems, further enhances economic viability, especially in remote locations where grid connectivity is limited.

The economic assessment of scalable DLE operations must also consider the value of higher recovery rates enabled by precise process control. Traditional evaporation methods typically recover 30-50% of available lithium, while optimized DLE systems with advanced sensing can achieve 80-95% recovery rates. This efficiency translates directly to economic value, particularly as lithium prices remain volatile in response to growing demand from the electric vehicle and energy storage sectors.

Market analysis indicates that DLE operations with sophisticated process control and sensing capabilities can achieve break-even production costs between $3,500 and $5,000 per ton of LCE, depending on brine chemistry and local operating conditions. This positions well-optimized DLE technologies competitively within the global lithium production landscape, especially as environmental regulations and water scarcity concerns increasingly impact traditional extraction methods.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!