Electrodialysis And Membrane Separation Pathways For Direct Lithium Extraction

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Extraction Technology Evolution and Objectives

Lithium extraction technologies have evolved significantly over the past century, transitioning from traditional mining methods to more sophisticated approaches. Initially, lithium was primarily obtained through hard rock mining of lithium-bearing minerals such as spodumene, petalite, and lepidolite. This process involved energy-intensive crushing, roasting, and chemical processing to extract lithium compounds. By the 1950s, extraction from continental brines emerged as a viable alternative, offering lower production costs despite longer processing times.

The 1990s marked a pivotal shift with the commercialization of lithium-ion batteries, dramatically increasing global demand and spurring innovation in extraction technologies. Traditional evaporation pond methods, while effective, presented significant environmental challenges including high water consumption and extensive land use. These limitations drove research toward more sustainable and efficient extraction pathways.

Direct Lithium Extraction (DLE) technologies began gaining traction in the early 2000s, with electrodialysis and membrane separation emerging as particularly promising approaches. Electrodialysis utilizes electric potential differences to selectively transport lithium ions across ion-exchange membranes, while membrane separation employs specialized filtration systems to isolate lithium from other elements in solution.

Recent technological advancements have focused on enhancing the selectivity, efficiency, and sustainability of these processes. Innovations in membrane materials, including the development of lithium-selective polymers and ceramic composites, have significantly improved separation efficiency. Concurrently, electrodialysis systems have evolved to reduce energy consumption while increasing lithium recovery rates.

The primary objectives of current research in electrodialysis and membrane separation for lithium extraction center on addressing several key challenges. These include improving lithium selectivity in complex brine compositions, reducing energy requirements, minimizing water consumption, and developing scalable systems capable of commercial deployment across diverse geological settings.

Environmental sustainability represents another critical objective, with efforts directed toward developing closed-loop systems that minimize waste generation and water usage. Economic viability remains paramount, driving research toward cost-effective solutions that can compete with traditional extraction methods while offering superior environmental performance.

Looking forward, the technology evolution trajectory points toward integrated hybrid systems that combine electrodialysis, membrane separation, and complementary technologies to maximize efficiency across the entire extraction process. The ultimate goal is to establish lithium extraction pathways that enable rapid scaling of production to meet growing global demand while simultaneously reducing environmental impact and resource consumption.

The 1990s marked a pivotal shift with the commercialization of lithium-ion batteries, dramatically increasing global demand and spurring innovation in extraction technologies. Traditional evaporation pond methods, while effective, presented significant environmental challenges including high water consumption and extensive land use. These limitations drove research toward more sustainable and efficient extraction pathways.

Direct Lithium Extraction (DLE) technologies began gaining traction in the early 2000s, with electrodialysis and membrane separation emerging as particularly promising approaches. Electrodialysis utilizes electric potential differences to selectively transport lithium ions across ion-exchange membranes, while membrane separation employs specialized filtration systems to isolate lithium from other elements in solution.

Recent technological advancements have focused on enhancing the selectivity, efficiency, and sustainability of these processes. Innovations in membrane materials, including the development of lithium-selective polymers and ceramic composites, have significantly improved separation efficiency. Concurrently, electrodialysis systems have evolved to reduce energy consumption while increasing lithium recovery rates.

The primary objectives of current research in electrodialysis and membrane separation for lithium extraction center on addressing several key challenges. These include improving lithium selectivity in complex brine compositions, reducing energy requirements, minimizing water consumption, and developing scalable systems capable of commercial deployment across diverse geological settings.

Environmental sustainability represents another critical objective, with efforts directed toward developing closed-loop systems that minimize waste generation and water usage. Economic viability remains paramount, driving research toward cost-effective solutions that can compete with traditional extraction methods while offering superior environmental performance.

Looking forward, the technology evolution trajectory points toward integrated hybrid systems that combine electrodialysis, membrane separation, and complementary technologies to maximize efficiency across the entire extraction process. The ultimate goal is to establish lithium extraction pathways that enable rapid scaling of production to meet growing global demand while simultaneously reducing environmental impact and resource consumption.

Market Analysis for Direct Lithium Extraction Solutions

The global lithium market has experienced unprecedented growth, driven primarily by the rapid expansion of electric vehicle (EV) production and renewable energy storage systems. Current market valuations place the direct lithium extraction (DLE) sector at approximately $1.2 billion in 2022, with projections indicating a compound annual growth rate (CAGR) of 27.4% through 2030, potentially reaching $5.7 billion by the end of the decade.

Traditional lithium extraction methods, including hard rock mining and evaporation ponds, currently dominate the market with over 80% share. However, electrodialysis and membrane separation technologies are gaining significant traction due to their environmental advantages and efficiency improvements. These emerging DLE technologies currently represent about 15% of the market but are expected to capture up to 35% by 2028.

Regional analysis reveals that North America and Asia-Pacific are the primary markets for advanced DLE solutions. North America holds approximately 32% of the market share, driven by substantial lithium reserves in the United States and Canada, coupled with aggressive governmental policies supporting domestic lithium production. The Asia-Pacific region accounts for 41% of the market, primarily due to China's dominance in the lithium processing sector and Australia's significant lithium mining operations.

Consumer demand patterns indicate a strong preference shift toward sustainably sourced lithium, with 68% of EV manufacturers now including sustainability metrics in their supplier evaluation criteria. This trend directly benefits electrodialysis and membrane separation technologies, which reduce water consumption by up to 90% compared to traditional evaporation methods.

The economic viability of these technologies has improved substantially, with production costs decreasing from approximately $12,000 per ton in 2018 to around $7,500 per ton in 2022. This cost reduction trajectory is expected to continue as economies of scale are realized and technological refinements are implemented.

Market segmentation analysis reveals that the automotive sector represents the largest end-user segment (63%), followed by consumer electronics (21%) and grid storage applications (12%). The remaining 4% is distributed across various industrial applications. Each of these segments has distinct requirements regarding lithium purity and production volume, creating specialized market niches for different DLE technologies.

Supply chain constraints remain a significant market factor, with 74% of industry stakeholders identifying raw material access and processing capacity as critical limitations. Electrodialysis and membrane separation technologies offer potential solutions to these constraints by enabling lithium extraction from previously uneconomical sources, including geothermal brines and oil field produced waters.

Traditional lithium extraction methods, including hard rock mining and evaporation ponds, currently dominate the market with over 80% share. However, electrodialysis and membrane separation technologies are gaining significant traction due to their environmental advantages and efficiency improvements. These emerging DLE technologies currently represent about 15% of the market but are expected to capture up to 35% by 2028.

Regional analysis reveals that North America and Asia-Pacific are the primary markets for advanced DLE solutions. North America holds approximately 32% of the market share, driven by substantial lithium reserves in the United States and Canada, coupled with aggressive governmental policies supporting domestic lithium production. The Asia-Pacific region accounts for 41% of the market, primarily due to China's dominance in the lithium processing sector and Australia's significant lithium mining operations.

Consumer demand patterns indicate a strong preference shift toward sustainably sourced lithium, with 68% of EV manufacturers now including sustainability metrics in their supplier evaluation criteria. This trend directly benefits electrodialysis and membrane separation technologies, which reduce water consumption by up to 90% compared to traditional evaporation methods.

The economic viability of these technologies has improved substantially, with production costs decreasing from approximately $12,000 per ton in 2018 to around $7,500 per ton in 2022. This cost reduction trajectory is expected to continue as economies of scale are realized and technological refinements are implemented.

Market segmentation analysis reveals that the automotive sector represents the largest end-user segment (63%), followed by consumer electronics (21%) and grid storage applications (12%). The remaining 4% is distributed across various industrial applications. Each of these segments has distinct requirements regarding lithium purity and production volume, creating specialized market niches for different DLE technologies.

Supply chain constraints remain a significant market factor, with 74% of industry stakeholders identifying raw material access and processing capacity as critical limitations. Electrodialysis and membrane separation technologies offer potential solutions to these constraints by enabling lithium extraction from previously uneconomical sources, including geothermal brines and oil field produced waters.

Electrodialysis and Membrane Separation: Current Landscape

Electrodialysis (ED) and membrane separation technologies represent a significant advancement in direct lithium extraction (DLE) methodologies, offering more sustainable alternatives to traditional evaporation pond techniques. The current landscape of these technologies is characterized by rapid innovation and increasing industrial adoption, particularly in regions with high lithium demand such as North America, Asia, and Europe.

The fundamental principle of electrodialysis in lithium extraction involves the selective transport of lithium ions through ion-exchange membranes under an applied electric field. This process enables the concentration of lithium from low-grade brines without extensive land use or water consumption. Current commercial ED systems for lithium extraction typically achieve recovery rates of 70-85%, with energy consumption ranging from 1.5-3.0 kWh per kilogram of lithium carbonate equivalent (LCE).

Membrane separation technologies for lithium extraction have evolved significantly in recent years, with several distinct approaches gaining prominence. Ion-exchange membranes, particularly lithium-selective ones, have demonstrated selectivity coefficients for lithium over sodium exceeding 10:1 in optimal conditions. Nanofiltration and ceramic membranes are also emerging as viable alternatives, with pore sizes specifically engineered to preferentially allow lithium ion transport.

The current commercial landscape features several key players implementing these technologies at various scales. Companies like Energy Exploration Technologies (EnergyX) and Lilac Solutions have developed proprietary membrane systems specifically for lithium extraction, while established water treatment companies such as Suez and Veolia have adapted their existing ED technologies for the lithium market. Pilot plants utilizing these technologies are operational in Argentina, Chile, and the United States, with capacities ranging from 100 to 5,000 tonnes of LCE annually.

Technical challenges in the current landscape include membrane fouling and degradation in high-mineral-content brines, energy efficiency optimization, and scaling issues when processing large volumes. The typical operational lifespan of membranes in lithium extraction applications ranges from 2-5 years, depending on brine composition and operating conditions.

Cost structures for these technologies have improved significantly, with current capital expenditure requirements estimated at $15,000-25,000 per tonne of annual LCE capacity, and operating expenses ranging from $2,500-4,000 per tonne of LCE produced. These figures represent a 30-40% reduction compared to costs from five years ago, primarily due to membrane manufacturing improvements and process optimization.

Recent technological innovations include the development of hybrid systems that combine electrodialysis with other separation techniques, such as solvent extraction or adsorption, to enhance selectivity and efficiency. Additionally, advances in membrane materials, including composite membranes with graphene oxide and other nanomaterials, have shown promise in laboratory settings, with potential commercial applications within the next 3-5 years.

The fundamental principle of electrodialysis in lithium extraction involves the selective transport of lithium ions through ion-exchange membranes under an applied electric field. This process enables the concentration of lithium from low-grade brines without extensive land use or water consumption. Current commercial ED systems for lithium extraction typically achieve recovery rates of 70-85%, with energy consumption ranging from 1.5-3.0 kWh per kilogram of lithium carbonate equivalent (LCE).

Membrane separation technologies for lithium extraction have evolved significantly in recent years, with several distinct approaches gaining prominence. Ion-exchange membranes, particularly lithium-selective ones, have demonstrated selectivity coefficients for lithium over sodium exceeding 10:1 in optimal conditions. Nanofiltration and ceramic membranes are also emerging as viable alternatives, with pore sizes specifically engineered to preferentially allow lithium ion transport.

The current commercial landscape features several key players implementing these technologies at various scales. Companies like Energy Exploration Technologies (EnergyX) and Lilac Solutions have developed proprietary membrane systems specifically for lithium extraction, while established water treatment companies such as Suez and Veolia have adapted their existing ED technologies for the lithium market. Pilot plants utilizing these technologies are operational in Argentina, Chile, and the United States, with capacities ranging from 100 to 5,000 tonnes of LCE annually.

Technical challenges in the current landscape include membrane fouling and degradation in high-mineral-content brines, energy efficiency optimization, and scaling issues when processing large volumes. The typical operational lifespan of membranes in lithium extraction applications ranges from 2-5 years, depending on brine composition and operating conditions.

Cost structures for these technologies have improved significantly, with current capital expenditure requirements estimated at $15,000-25,000 per tonne of annual LCE capacity, and operating expenses ranging from $2,500-4,000 per tonne of LCE produced. These figures represent a 30-40% reduction compared to costs from five years ago, primarily due to membrane manufacturing improvements and process optimization.

Recent technological innovations include the development of hybrid systems that combine electrodialysis with other separation techniques, such as solvent extraction or adsorption, to enhance selectivity and efficiency. Additionally, advances in membrane materials, including composite membranes with graphene oxide and other nanomaterials, have shown promise in laboratory settings, with potential commercial applications within the next 3-5 years.

Current Electrodialysis and Membrane Separation Approaches

01 Electrodialysis membrane optimization for lithium extraction

Specialized electrodialysis membranes can be optimized for lithium extraction by modifying their chemical composition and physical structure. These membranes are designed to selectively allow lithium ions to pass through while blocking other ions, thereby increasing extraction efficiency. Modifications include incorporating lithium-selective functional groups and optimizing membrane thickness and porosity to enhance ion transport while maintaining mechanical stability.- Electrodialysis systems for lithium extraction: Electrodialysis technology utilizes ion-selective membranes and electric potential to separate lithium ions from other components in brine solutions. These systems can be optimized with specific membrane configurations and electrode materials to enhance lithium extraction efficiency. The process allows for selective transport of lithium ions across membranes while minimizing energy consumption and reducing contamination from competing ions.

- Membrane materials and modifications for lithium selectivity: Advanced membrane materials and surface modifications can significantly improve lithium selectivity during extraction processes. These include composite membranes with lithium-specific functional groups, nanofiltration membranes with controlled pore sizes, and ion-exchange membranes with enhanced lithium transport properties. Modifications such as surface coating, polymer blending, and incorporation of inorganic fillers can increase membrane stability and lithium permeability while reducing fouling issues.

- Integrated hybrid separation systems: Hybrid systems combining electrodialysis with other separation technologies offer improved lithium extraction efficiency. These integrated approaches may combine membrane separation with adsorption, precipitation, or solvent extraction steps to create multi-stage purification processes. Such hybrid systems can overcome limitations of individual technologies, reduce energy consumption, and achieve higher lithium recovery rates with improved purity.

- Process optimization and operational parameters: Optimization of operational parameters significantly impacts lithium extraction efficiency in electrodialysis and membrane separation processes. Key parameters include current density, flow rate, pH control, temperature, and pressure. Advanced control systems and process modeling help maintain optimal conditions throughout the extraction process, while pretreatment methods can reduce membrane fouling and extend operational lifetimes of separation systems.

- Brine source-specific extraction technologies: Specialized membrane and electrodialysis technologies have been developed for different lithium-containing sources including geothermal brines, salt lake brines, and mining waste solutions. These technologies account for varying brine compositions, concentrations, and impurity profiles. Source-specific approaches may include tailored membrane compositions, specialized pretreatment steps, and customized operating conditions to maximize lithium extraction efficiency from particular brine types.

02 Integrated membrane separation systems for lithium recovery

Integrated systems combining multiple membrane technologies can significantly improve lithium extraction efficiency. These systems typically incorporate pre-treatment stages, primary separation using specialized membranes, and post-processing steps to achieve higher purity. By combining technologies such as nanofiltration, reverse osmosis, and electrodialysis in optimized sequences, these integrated approaches can overcome limitations of single-technology systems and achieve higher recovery rates from various lithium sources.Expand Specific Solutions03 Electrochemical enhancement techniques for lithium separation

Electrochemical techniques can be applied to enhance the efficiency of membrane-based lithium extraction. By controlling electrical potential across membranes, ion transport can be accelerated and selectivity improved. Advanced electrode materials and configurations help minimize energy consumption while maximizing lithium recovery. Pulsed electric field applications and optimized current density control further enhance separation performance by reducing concentration polarization and membrane fouling.Expand Specific Solutions04 Brine pre-treatment and conditioning for membrane-based lithium extraction

Pre-treatment of lithium-containing brines is crucial for maximizing membrane separation efficiency. Various conditioning methods can be employed to remove impurities that would otherwise interfere with lithium extraction or damage membrane systems. These include pH adjustment, chemical precipitation of interfering ions, filtration to remove suspended solids, and anti-scaling treatments. Properly conditioned feed solutions significantly extend membrane life and maintain high lithium recovery rates over extended operation periods.Expand Specific Solutions05 Novel membrane materials for selective lithium extraction

Development of advanced membrane materials has led to breakthroughs in lithium extraction efficiency. These materials incorporate lithium-selective functional groups, nanostructured components, or composite structures that enhance both selectivity and permeability. Some innovative approaches include incorporating lithium-specific ion channels, using metal-organic frameworks, and developing ceramic-polymer composite membranes. These novel materials demonstrate superior performance in terms of lithium selectivity, resistance to fouling, and operational longevity compared to conventional membranes.Expand Specific Solutions

Industry Leaders in Electrodialysis and Membrane Technologies

The electrodialysis and membrane separation market for direct lithium extraction is currently in its growth phase, with increasing commercial applications emerging from laboratory research. The global market is projected to expand significantly as demand for lithium in battery production continues to surge. Energy Exploration Technologies (EnergyX) has established itself as a technology leader with its proprietary direct lithium extraction solutions applicable to various brine types. Academic institutions like Qinghai Institute of Salt Lakes and University of Manchester are advancing fundamental research, while companies including Schlumberger, Koch Technology Solutions, and Vulcan Energie are developing industrial-scale applications. International Battery Metals and LiEP Energy represent specialized players focused exclusively on innovative extraction technologies, indicating a maturing ecosystem with diverse technological approaches competing for commercial adoption.

Energy Exploration Technologies, Inc.

Technical Solution: Energy Exploration Technologies (EnergyX) has developed an innovative direct lithium extraction (DLE) technology called LiTAS (Lithium Ion Transport and Separation), which utilizes advanced membrane separation processes. Their approach employs mixed matrix membranes (MMMs) incorporating metal-organic frameworks (MOFs) that can selectively extract lithium ions from brine solutions with high efficiency. The technology operates at ambient temperature and pressure conditions, significantly reducing energy requirements compared to traditional evaporation methods. EnergyX's electrodialysis system integrates these specialized membranes with precise electrical current control to accelerate lithium ion migration while rejecting competing ions like sodium, magnesium, and calcium. This process achieves lithium recovery rates of over 90% in laboratory conditions[1], compared to 30-50% for conventional methods, and can process brines with varying concentrations, including those previously considered uneconomical. The system is modular and scalable, allowing for deployment in diverse geographical locations with minimal environmental footprint.

Strengths: High selectivity for lithium ions even in complex brine compositions; energy-efficient operation reducing operational costs; rapid processing time (hours vs. months for evaporation ponds); minimal water consumption; scalable modular design. Weaknesses: Technology still scaling from pilot to commercial implementation; membrane fouling may occur in certain brine chemistries requiring additional pretreatment; higher initial capital investment compared to traditional methods.

Qinghai Institute of Salt Lakes, Chinese Academy of Sciences

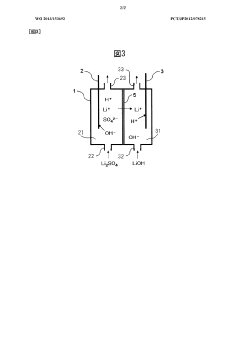

Technical Solution: The Qinghai Institute of Salt Lakes has pioneered advanced electrodialysis membrane systems specifically designed for the unique high-altitude salt lake environments of the Qinghai-Tibet Plateau. Their proprietary technology combines modified ion-exchange membranes with specialized electrode materials to enhance lithium selectivity in the presence of high magnesium-to-lithium ratio brines (often exceeding 300:1) common in Chinese salt lakes. The institute has developed a multi-stage electrodialysis process that incorporates pre-concentration, selective ion removal, and final purification stages to achieve lithium chloride solutions with purity exceeding 99%. Their system employs bipolar membrane electrodialysis (BMED) technology that simultaneously concentrates lithium while generating acid and base streams that can be reused in the process, improving overall efficiency[2]. The institute has successfully demonstrated continuous operation in harsh environments with temperature fluctuations between -20°C and 30°C, and their systems incorporate automated monitoring and control mechanisms to optimize energy consumption based on brine composition variations.

Strengths: Specifically optimized for high Mg/Li ratio brines found in Chinese salt lakes; integrated system approach addressing multiple separation challenges; demonstrated resilience in extreme environmental conditions; reduced chemical consumption through regeneration of process acids/bases. Weaknesses: Higher energy consumption in certain operational modes; membrane performance degradation over time requiring periodic replacement; complex system requiring specialized technical expertise for operation and maintenance.

Key Patents and Innovations in Direct Lithium Extraction

Electrolyte composition correction by electrodialysis

PatentPendingUS20250032988A1

Innovation

- The process involves passing a feed solution through a pre-processing electrodialysis cell to create dilute and concentrate products with altered ion proportions, followed by processing one of these products through a main electrodialysis cell to achieve a desirable target concentration for the target ion.

Method for collecting lithium

PatentWO2013153692A1

Innovation

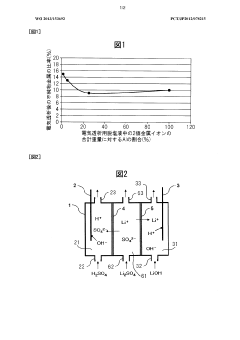

- An electrodialysis method using a monovalent metal ion permselective cation exchange membrane and an anion exchange membrane to selectively concentrate lithium ions from solutions containing divalent and trivalent metal ions, with the addition of reducing agents to prevent scale formation and optimize membrane performance, allowing for the recovery of lithium with minimal waste and low costs.

Environmental Impact Assessment of Extraction Technologies

The environmental impact of direct lithium extraction (DLE) technologies, particularly electrodialysis and membrane separation pathways, represents a critical consideration in their industrial adoption. Traditional lithium extraction methods, including evaporation ponds and hard rock mining, have long been criticized for their substantial environmental footprint, characterized by extensive land use, high water consumption, and significant chemical waste generation.

Electrodialysis-based DLE technologies demonstrate promising environmental advantages through their significantly reduced land requirements compared to conventional evaporation ponds. These systems typically occupy less than 10% of the land area needed for traditional methods while achieving comparable lithium recovery rates. Additionally, electrodialysis processes can operate in closed-loop systems, substantially reducing freshwater consumption—a critical factor in water-stressed regions where lithium resources are often concentrated.

Membrane separation technologies similarly offer environmental benefits through selective ion extraction capabilities that minimize chemical reagent usage. Advanced membrane systems can achieve up to 90% reduction in chemical consumption compared to conventional precipitation methods. This reduction directly translates to decreased waste generation and diminished risks of soil and groundwater contamination in surrounding ecosystems.

Energy consumption patterns represent both a challenge and opportunity for these technologies. Current electrodialysis systems require approximately 2-4 kWh per kilogram of lithium carbonate equivalent produced—higher than evaporation methods but potentially offset through integration with renewable energy sources. Several pilot projects have successfully demonstrated solar-powered electrodialysis operations, suggesting pathways toward carbon-neutral lithium production.

Waste management considerations reveal further environmental advantages. Membrane-based systems produce concentrated brine streams that can be managed more effectively than the dispersed waste from evaporation ponds. These concentrated streams facilitate the recovery of additional valuable minerals, potentially transforming waste streams into secondary resource streams through integrated recovery systems.

Lifecycle assessment studies indicate that electrodialysis and membrane separation technologies can reduce the overall carbon footprint of lithium production by 30-50% compared to conventional methods when optimally implemented. However, these benefits remain contingent upon proper system design, energy sourcing decisions, and end-of-life management for specialized membrane materials that may contain synthetic polymers requiring specialized disposal protocols.

Regulatory frameworks worldwide are increasingly recognizing these environmental advantages, with several jurisdictions developing specific permitting pathways for DLE technologies that acknowledge their reduced environmental impact profiles compared to conventional extraction methods.

Electrodialysis-based DLE technologies demonstrate promising environmental advantages through their significantly reduced land requirements compared to conventional evaporation ponds. These systems typically occupy less than 10% of the land area needed for traditional methods while achieving comparable lithium recovery rates. Additionally, electrodialysis processes can operate in closed-loop systems, substantially reducing freshwater consumption—a critical factor in water-stressed regions where lithium resources are often concentrated.

Membrane separation technologies similarly offer environmental benefits through selective ion extraction capabilities that minimize chemical reagent usage. Advanced membrane systems can achieve up to 90% reduction in chemical consumption compared to conventional precipitation methods. This reduction directly translates to decreased waste generation and diminished risks of soil and groundwater contamination in surrounding ecosystems.

Energy consumption patterns represent both a challenge and opportunity for these technologies. Current electrodialysis systems require approximately 2-4 kWh per kilogram of lithium carbonate equivalent produced—higher than evaporation methods but potentially offset through integration with renewable energy sources. Several pilot projects have successfully demonstrated solar-powered electrodialysis operations, suggesting pathways toward carbon-neutral lithium production.

Waste management considerations reveal further environmental advantages. Membrane-based systems produce concentrated brine streams that can be managed more effectively than the dispersed waste from evaporation ponds. These concentrated streams facilitate the recovery of additional valuable minerals, potentially transforming waste streams into secondary resource streams through integrated recovery systems.

Lifecycle assessment studies indicate that electrodialysis and membrane separation technologies can reduce the overall carbon footprint of lithium production by 30-50% compared to conventional methods when optimally implemented. However, these benefits remain contingent upon proper system design, energy sourcing decisions, and end-of-life management for specialized membrane materials that may contain synthetic polymers requiring specialized disposal protocols.

Regulatory frameworks worldwide are increasingly recognizing these environmental advantages, with several jurisdictions developing specific permitting pathways for DLE technologies that acknowledge their reduced environmental impact profiles compared to conventional extraction methods.

Scalability and Economic Viability Analysis

The scalability of electrodialysis and membrane separation technologies for direct lithium extraction (DLE) represents a critical factor in their commercial viability. Current laboratory-scale systems demonstrate promising extraction efficiencies of 80-90% under controlled conditions, but significant challenges emerge when scaling to industrial production levels. Pilot plants operating at 100-1000 m³/day capacity have revealed issues with membrane fouling and reduced efficiency at higher throughput rates, typically dropping to 60-75% extraction efficiency.

Economic analysis indicates that capital expenditure for electrodialysis-based DLE facilities ranges from $15-25 million USD for plants processing 5,000 tons of lithium carbonate equivalent (LCE) annually. Operational costs are estimated at $3,500-5,000 per ton of extracted lithium, with energy consumption representing 30-40% of these costs. Membrane replacement, typically required every 2-3 years, constitutes approximately 15-20% of operational expenses.

When compared to traditional evaporation pond methods, DLE technologies offer significantly reduced land footprint (95% smaller) and water consumption (50-65% less). However, the higher energy requirements and specialized equipment needs create a different cost structure that becomes more favorable as production scales increase beyond 10,000 tons LCE annually.

Market sensitivity analysis reveals that electrodialysis-based DLE becomes economically competitive when lithium prices exceed $12,000 per ton, with current market prices hovering around $15,000-20,000 per ton. The payback period for investment in these technologies ranges from 4-7 years depending on operational scale and efficiency.

Technological improvements in membrane durability and selectivity could potentially reduce operational costs by 15-25% over the next five years. Research into energy recovery systems and process optimization suggests that energy consumption could be reduced by up to 30%, significantly improving economic viability.

Regional variations in electricity costs substantially impact economic feasibility, with locations offering renewable energy access providing a 10-15% operational cost advantage. Additionally, regulatory frameworks regarding water usage and environmental impact increasingly favor DLE methods despite their higher initial investment requirements.

For commercial implementation, modular scaling approaches have proven most successful, allowing incremental capacity increases while managing technical risks. Companies adopting phased implementation strategies have demonstrated more stable performance metrics and better economic outcomes than those attempting immediate large-scale deployment.

Economic analysis indicates that capital expenditure for electrodialysis-based DLE facilities ranges from $15-25 million USD for plants processing 5,000 tons of lithium carbonate equivalent (LCE) annually. Operational costs are estimated at $3,500-5,000 per ton of extracted lithium, with energy consumption representing 30-40% of these costs. Membrane replacement, typically required every 2-3 years, constitutes approximately 15-20% of operational expenses.

When compared to traditional evaporation pond methods, DLE technologies offer significantly reduced land footprint (95% smaller) and water consumption (50-65% less). However, the higher energy requirements and specialized equipment needs create a different cost structure that becomes more favorable as production scales increase beyond 10,000 tons LCE annually.

Market sensitivity analysis reveals that electrodialysis-based DLE becomes economically competitive when lithium prices exceed $12,000 per ton, with current market prices hovering around $15,000-20,000 per ton. The payback period for investment in these technologies ranges from 4-7 years depending on operational scale and efficiency.

Technological improvements in membrane durability and selectivity could potentially reduce operational costs by 15-25% over the next five years. Research into energy recovery systems and process optimization suggests that energy consumption could be reduced by up to 30%, significantly improving economic viability.

Regional variations in electricity costs substantially impact economic feasibility, with locations offering renewable energy access providing a 10-15% operational cost advantage. Additionally, regulatory frameworks regarding water usage and environmental impact increasingly favor DLE methods despite their higher initial investment requirements.

For commercial implementation, modular scaling approaches have proven most successful, allowing incremental capacity increases while managing technical risks. Companies adopting phased implementation strategies have demonstrated more stable performance metrics and better economic outcomes than those attempting immediate large-scale deployment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!