Techno-Economic Analysis And CAPEX/OPEX Drivers For Direct Lithium Extraction

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DLE Technology Background and Objectives

Direct Lithium Extraction (DLE) represents a paradigm shift in lithium production, emerging as a response to the growing global demand for lithium-ion batteries in electric vehicles, renewable energy storage systems, and consumer electronics. Traditional lithium extraction methods, primarily evaporative brine processing and hard-rock mining, have dominated the industry for decades but face significant limitations in efficiency, environmental impact, and production timelines.

The evolution of DLE technology can be traced back to the early 2000s, with significant acceleration in research and development occurring over the past decade. This acceleration coincides with the exponential growth in lithium demand, which is projected to increase by 400-500% by 2030 compared to 2020 levels, driven primarily by the electric vehicle revolution and grid-scale energy storage requirements.

DLE technologies encompass a diverse range of approaches including adsorption, ion exchange, solvent extraction, and membrane processes, all aimed at selectively extracting lithium from brine resources with greater efficiency and reduced environmental footprint compared to conventional methods. The fundamental principle involves the selective capture of lithium ions from brine solutions, followed by a recovery process that produces a concentrated lithium solution suitable for further processing.

The primary technical objectives of DLE development include achieving higher lithium recovery rates (targeting >90% compared to 40-50% in traditional evaporation methods), reducing water consumption, minimizing land footprint, accelerating production timelines from years to days or weeks, and enabling the processing of previously uneconomical lithium resources with lower concentrations or challenging chemical compositions.

From an economic perspective, DLE aims to reduce both capital expenditure (CAPEX) and operational expenditure (OPEX) per ton of lithium carbonate equivalent (LCE) produced, while simultaneously increasing production flexibility and reducing market entry barriers. Current techno-economic analyses suggest that mature DLE technologies could potentially achieve production costs competitive with or lower than conventional methods, particularly when factoring in environmental compliance costs and time-to-market advantages.

The technological trajectory of DLE is characterized by continuous improvements in sorbent materials, process efficiency, energy consumption, and integration with existing brine operations. Recent breakthroughs in selective lithium sorbents with high capacity, fast kinetics, and excellent cycling stability represent significant milestones in overcoming historical limitations of DLE approaches.

As the technology continues to mature, the focus is increasingly shifting toward commercial-scale demonstration projects that validate laboratory and pilot-scale results under real-world conditions, establishing the technical and economic viability of DLE as a transformative approach to meeting global lithium demand sustainably.

The evolution of DLE technology can be traced back to the early 2000s, with significant acceleration in research and development occurring over the past decade. This acceleration coincides with the exponential growth in lithium demand, which is projected to increase by 400-500% by 2030 compared to 2020 levels, driven primarily by the electric vehicle revolution and grid-scale energy storage requirements.

DLE technologies encompass a diverse range of approaches including adsorption, ion exchange, solvent extraction, and membrane processes, all aimed at selectively extracting lithium from brine resources with greater efficiency and reduced environmental footprint compared to conventional methods. The fundamental principle involves the selective capture of lithium ions from brine solutions, followed by a recovery process that produces a concentrated lithium solution suitable for further processing.

The primary technical objectives of DLE development include achieving higher lithium recovery rates (targeting >90% compared to 40-50% in traditional evaporation methods), reducing water consumption, minimizing land footprint, accelerating production timelines from years to days or weeks, and enabling the processing of previously uneconomical lithium resources with lower concentrations or challenging chemical compositions.

From an economic perspective, DLE aims to reduce both capital expenditure (CAPEX) and operational expenditure (OPEX) per ton of lithium carbonate equivalent (LCE) produced, while simultaneously increasing production flexibility and reducing market entry barriers. Current techno-economic analyses suggest that mature DLE technologies could potentially achieve production costs competitive with or lower than conventional methods, particularly when factoring in environmental compliance costs and time-to-market advantages.

The technological trajectory of DLE is characterized by continuous improvements in sorbent materials, process efficiency, energy consumption, and integration with existing brine operations. Recent breakthroughs in selective lithium sorbents with high capacity, fast kinetics, and excellent cycling stability represent significant milestones in overcoming historical limitations of DLE approaches.

As the technology continues to mature, the focus is increasingly shifting toward commercial-scale demonstration projects that validate laboratory and pilot-scale results under real-world conditions, establishing the technical and economic viability of DLE as a transformative approach to meeting global lithium demand sustainably.

Market Demand Analysis for Lithium Resources

The global lithium market is experiencing unprecedented growth, primarily driven by the rapid expansion of electric vehicle (EV) production and energy storage systems. Current projections indicate that lithium demand will increase from approximately 500,000 metric tons of lithium carbonate equivalent (LCE) in 2021 to over 3 million metric tons by 2030, representing a compound annual growth rate (CAGR) of over 25%.

This surge in demand has created significant pressure on traditional lithium extraction methods, which predominantly rely on evaporative brine processing and hard rock mining. These conventional approaches face limitations in terms of production capacity, environmental impact, and geographical constraints, creating a substantial market opportunity for Direct Lithium Extraction (DLE) technologies.

The automotive industry represents the largest demand segment, accounting for roughly 80% of lithium consumption, with consumer electronics and grid-scale energy storage comprising the remaining market share. Major automotive manufacturers have announced ambitious electrification targets, with several planning to phase out internal combustion engines entirely within the next 10-15 years.

Supply chain security has emerged as a critical concern for both manufacturers and governments. Currently, lithium production is geographically concentrated, with Australia, Chile, China, and Argentina controlling over 90% of global supply. This concentration has prompted many countries to classify lithium as a strategic resource and implement policies to develop domestic supply chains.

Price volatility has been a defining characteristic of the lithium market in recent years. Spot prices for battery-grade lithium carbonate reached historic highs of $78,000 per ton in 2022, representing a 550% increase from 2020 levels. While prices have subsequently moderated, long-term forecasts suggest sustained elevated pricing due to structural supply constraints.

The quality requirements for lithium in battery applications continue to become more stringent, with manufacturers demanding higher purity levels to improve battery performance and longevity. DLE technologies offer significant advantages in this regard, as they can potentially deliver battery-grade lithium with fewer processing steps than conventional methods.

Environmental and social governance (ESG) considerations are increasingly influencing market dynamics. Investors and end-users are placing greater emphasis on sustainable production methods with reduced water consumption, carbon emissions, and land disturbance. This trend favors DLE technologies, which typically have smaller environmental footprints compared to traditional extraction methods.

Regional lithium markets show varying growth trajectories, with Asia-Pacific remaining the dominant consumption center due to its battery manufacturing capacity. However, North America and Europe are rapidly developing their own battery supply chains, creating new demand centers and opportunities for localized lithium production through DLE.

This surge in demand has created significant pressure on traditional lithium extraction methods, which predominantly rely on evaporative brine processing and hard rock mining. These conventional approaches face limitations in terms of production capacity, environmental impact, and geographical constraints, creating a substantial market opportunity for Direct Lithium Extraction (DLE) technologies.

The automotive industry represents the largest demand segment, accounting for roughly 80% of lithium consumption, with consumer electronics and grid-scale energy storage comprising the remaining market share. Major automotive manufacturers have announced ambitious electrification targets, with several planning to phase out internal combustion engines entirely within the next 10-15 years.

Supply chain security has emerged as a critical concern for both manufacturers and governments. Currently, lithium production is geographically concentrated, with Australia, Chile, China, and Argentina controlling over 90% of global supply. This concentration has prompted many countries to classify lithium as a strategic resource and implement policies to develop domestic supply chains.

Price volatility has been a defining characteristic of the lithium market in recent years. Spot prices for battery-grade lithium carbonate reached historic highs of $78,000 per ton in 2022, representing a 550% increase from 2020 levels. While prices have subsequently moderated, long-term forecasts suggest sustained elevated pricing due to structural supply constraints.

The quality requirements for lithium in battery applications continue to become more stringent, with manufacturers demanding higher purity levels to improve battery performance and longevity. DLE technologies offer significant advantages in this regard, as they can potentially deliver battery-grade lithium with fewer processing steps than conventional methods.

Environmental and social governance (ESG) considerations are increasingly influencing market dynamics. Investors and end-users are placing greater emphasis on sustainable production methods with reduced water consumption, carbon emissions, and land disturbance. This trend favors DLE technologies, which typically have smaller environmental footprints compared to traditional extraction methods.

Regional lithium markets show varying growth trajectories, with Asia-Pacific remaining the dominant consumption center due to its battery manufacturing capacity. However, North America and Europe are rapidly developing their own battery supply chains, creating new demand centers and opportunities for localized lithium production through DLE.

Current DLE Technical Challenges and Limitations

Despite the promising potential of Direct Lithium Extraction (DLE) technologies, several significant technical challenges and limitations currently impede widespread commercial adoption. The heterogeneity of lithium-containing brines presents a fundamental obstacle, as each resource possesses unique chemical compositions requiring tailored extraction approaches. This variability complicates the development of universally applicable DLE solutions and necessitates resource-specific process optimization.

Selectivity remains a critical challenge for most DLE technologies. The presence of competing ions—particularly magnesium, calcium, sodium, and potassium—in concentrations often significantly higher than lithium creates substantial separation difficulties. Current ion exchange materials and membranes struggle to achieve high lithium selectivity without extensive pre-treatment steps, increasing operational complexity and costs.

Water consumption represents another major limitation, particularly in arid regions where many lithium resources are located. While DLE is often promoted as water-efficient compared to evaporation ponds, many processes still require significant freshwater for washing and regeneration cycles. This creates tension between lithium production and local water resource management.

The durability and lifespan of DLE materials pose ongoing challenges. Adsorbents, membranes, and electrodes frequently experience performance degradation due to fouling, scaling, and chemical deterioration when exposed to complex brine environments. This necessitates frequent replacement, significantly impacting operational expenses and process reliability.

Energy intensity remains problematic across most DLE technologies. Processes involving multiple pumping stages, heating requirements, or electrochemical systems demand substantial energy inputs. This energy consumption directly affects operational costs and carbon footprints, potentially undermining sustainability claims.

Scale-up challenges persist as laboratory successes often fail to translate to commercial-scale operations. Flow dynamics, materials handling, and process control become exponentially more complex at industrial scales. Few DLE technologies have demonstrated consistent performance beyond pilot scale, creating uncertainty around capital expenditure projections.

Waste management presents additional complications. The handling and disposal of spent regeneration solutions, process chemicals, and depleted brines require careful consideration. Environmental regulations increasingly demand comprehensive waste management strategies, adding complexity and cost to DLE operations.

Finally, process integration challenges exist when incorporating DLE into broader lithium production chains. The interface between extraction and subsequent concentration, purification, and conversion steps often requires additional processing, potentially offsetting the efficiency gains promised by DLE technologies.

Selectivity remains a critical challenge for most DLE technologies. The presence of competing ions—particularly magnesium, calcium, sodium, and potassium—in concentrations often significantly higher than lithium creates substantial separation difficulties. Current ion exchange materials and membranes struggle to achieve high lithium selectivity without extensive pre-treatment steps, increasing operational complexity and costs.

Water consumption represents another major limitation, particularly in arid regions where many lithium resources are located. While DLE is often promoted as water-efficient compared to evaporation ponds, many processes still require significant freshwater for washing and regeneration cycles. This creates tension between lithium production and local water resource management.

The durability and lifespan of DLE materials pose ongoing challenges. Adsorbents, membranes, and electrodes frequently experience performance degradation due to fouling, scaling, and chemical deterioration when exposed to complex brine environments. This necessitates frequent replacement, significantly impacting operational expenses and process reliability.

Energy intensity remains problematic across most DLE technologies. Processes involving multiple pumping stages, heating requirements, or electrochemical systems demand substantial energy inputs. This energy consumption directly affects operational costs and carbon footprints, potentially undermining sustainability claims.

Scale-up challenges persist as laboratory successes often fail to translate to commercial-scale operations. Flow dynamics, materials handling, and process control become exponentially more complex at industrial scales. Few DLE technologies have demonstrated consistent performance beyond pilot scale, creating uncertainty around capital expenditure projections.

Waste management presents additional complications. The handling and disposal of spent regeneration solutions, process chemicals, and depleted brines require careful consideration. Environmental regulations increasingly demand comprehensive waste management strategies, adding complexity and cost to DLE operations.

Finally, process integration challenges exist when incorporating DLE into broader lithium production chains. The interface between extraction and subsequent concentration, purification, and conversion steps often requires additional processing, potentially offsetting the efficiency gains promised by DLE technologies.

Current DLE Process Solutions and Economics

01 Extraction technology selection and optimization

The choice of extraction technology significantly impacts both capital and operational expenditures in DLE projects. Different technologies such as ion exchange, adsorption, and membrane processes have varying equipment requirements, energy consumption profiles, and extraction efficiencies. Optimization of these technologies based on brine chemistry and project requirements can substantially reduce CAPEX through more efficient equipment sizing and OPEX through lower energy and reagent consumption.- Extraction technology selection and optimization: The choice of extraction technology significantly impacts both capital and operational expenditures in Direct Lithium Extraction (DLE) processes. Different technologies such as ion exchange, adsorption, and membrane-based systems have varying equipment requirements, energy consumption profiles, and operational complexities. Optimization of these technologies based on specific brine chemistry and project requirements can lead to substantial cost reductions. Factors such as selectivity for lithium over other ions, regeneration efficiency, and material durability directly influence the economic viability of DLE operations.

- Brine pre-treatment and post-processing requirements: The quality of input brine and necessary post-extraction processing significantly drive DLE economics. Pre-treatment steps to remove impurities such as magnesium, calcium, and boron may require additional equipment and chemicals, increasing both CAPEX and OPEX. Similarly, post-extraction concentration and purification steps to achieve battery-grade lithium compounds add substantial costs. The complexity of these processes varies based on brine composition, with higher impurity levels generally resulting in higher processing costs. Innovations in pre-treatment and post-processing can substantially improve project economics.

- Energy and water consumption management: Energy and water requirements represent major operational cost drivers for DLE projects. Energy is needed for pumping brine, regeneration of extraction media, and downstream processing. Water is consumed in regeneration cycles and processing steps. The availability and cost of these resources vary significantly by location, with remote sites often facing higher costs. Implementation of energy-efficient technologies, renewable energy sources, and water recycling systems can significantly reduce operational expenses. Projects in water-scarce regions may require additional investment in water treatment and conservation technologies.

- Sorbent/extraction media performance and lifecycle: The performance characteristics and lifecycle of extraction media or sorbents are critical cost factors in DLE operations. Key parameters include lithium loading capacity, selectivity, regeneration efficiency, and operational lifespan. Higher-performing media may have higher upfront costs but can reduce operational expenses through improved efficiency and reduced replacement frequency. Media degradation over time due to chemical, thermal, or mechanical stress necessitates regular replacement, representing a significant recurring cost. Research into more durable and efficient extraction media aims to improve the economic profile of DLE projects.

- Scale and process integration considerations: The scale of DLE operations and their integration with existing processes significantly impact economic viability. Economies of scale can reduce per-unit production costs, but require higher initial capital investment. Integration with existing operations, such as geothermal power plants or traditional salt production, can provide synergies that reduce both capital and operational expenses. Modular designs offer flexibility in scaling and potentially lower initial capital requirements, though they may have higher per-unit production costs at smaller scales. Strategic decisions regarding project scale and integration must balance market demand, capital availability, and operational efficiency.

02 Brine pre-treatment and post-processing systems

Pre-treatment systems to remove impurities and post-processing requirements for lithium concentration and purification represent significant cost drivers. The complexity of these systems depends on source brine composition, with higher impurity levels requiring more extensive treatment. Innovations in pre-treatment technologies can reduce equipment costs and operational expenses related to chemical consumption, while advanced post-processing can improve lithium recovery rates and product quality, affecting overall project economics.Expand Specific Solutions03 Energy consumption and source optimization

Energy requirements for pumping, heating, cooling, and electrochemical processes constitute a major operational expense in DLE operations. The selection of energy sources (renewable vs. conventional) impacts both environmental footprint and long-term operational costs. Integration of renewable energy systems may increase initial capital expenditure but can significantly reduce operational expenses over the project lifetime. Energy recovery systems and process heat integration can further optimize energy consumption and reduce costs.Expand Specific Solutions04 Water management and recycling systems

Water usage, treatment, and recycling represent critical cost factors in DLE operations, particularly in water-scarce regions. The implementation of closed-loop water systems requires additional capital investment but can substantially reduce operational costs and environmental impact. Advanced water treatment technologies, including membrane filtration and evaporation systems, affect both initial equipment costs and ongoing operational expenses. Water management strategies must balance technical requirements with local regulatory compliance and sustainability goals.Expand Specific Solutions05 Scale and location-specific factors

Project scale and location significantly influence both capital and operational expenditures. Economies of scale can reduce per-unit production costs but require larger initial investments. Location-specific factors such as infrastructure availability, climate conditions, labor costs, and regulatory requirements impact project economics. Remote locations may necessitate additional infrastructure development, increasing capital costs, while extreme climates can affect operational efficiency and maintenance requirements. Modular design approaches can optimize capital deployment and allow for phased capacity expansion.Expand Specific Solutions

Key Industry Players in Direct Lithium Extraction

Direct Lithium Extraction (DLE) technology is currently in an early growth phase, with the global market expected to expand significantly due to increasing demand for lithium in battery applications. The market size is projected to reach several billion dollars by 2030, driven by the electric vehicle revolution and energy storage needs. Technologically, DLE is still evolving with varying degrees of maturity across different approaches. Leading players include Lilac Solutions, which has developed innovative ion-exchange technology, and Schlumberger, leveraging its extensive experience in resource extraction. Academic institutions like Penn State Research Foundation and The University of Manchester are advancing fundamental research, while companies such as Koch Technology Solutions and Watercycle Technologies are developing commercial applications. The competitive landscape features both established energy companies and specialized startups, with increasing collaboration between technology developers and traditional lithium producers to optimize CAPEX/OPEX parameters.

Schlumberger Technologies, Inc.

Technical Solution: Schlumberger has developed an advanced Direct Lithium Extraction (DLE) technology leveraging their extensive experience in oilfield services and fluid management. Their approach combines selective adsorption materials with sophisticated process control systems to efficiently extract lithium from various brine sources. The technology utilizes proprietary adsorbents that demonstrate high selectivity for lithium ions while minimizing uptake of competing elements. Schlumberger's system operates in a continuous flow configuration with multiple adsorption columns working in parallel, allowing for uninterrupted production while individual columns undergo regeneration. Their techno-economic analysis indicates capital expenditure reductions of approximately 40-50% compared to traditional evaporation pond methods, primarily through elimination of large land requirements and reduced construction timelines. The technology achieves lithium recovery rates of 80-90%, significantly higher than conventional methods. Operational expenditures are optimized through automated process control systems that adjust parameters based on incoming brine composition, minimizing reagent consumption and energy usage. The modular design allows for scalable implementation with initial capacity as low as 1,000-5,000 tonnes LCE/year, with the ability to expand incrementally as demand increases.

Strengths: Extensive global operational experience in fluid handling systems, robust engineering designed for continuous operation in harsh environments, and sophisticated process control systems that optimize performance. Weaknesses: Higher energy requirements compared to evaporation methods, potential for adsorbent degradation requiring periodic replacement, and complex regeneration chemistry that may require specialized handling.

Koch Technology Solutions LLC

Technical Solution: Koch Technology Solutions has developed an advanced membrane-based Direct Lithium Extraction (DLE) technology that utilizes selective separation processes to extract lithium from various brine sources. Their system employs proprietary membrane technology combined with specialized pre-treatment processes to handle diverse brine compositions. The technology operates through a multi-stage filtration and separation process that selectively allows lithium ions to pass while rejecting competing ions. Koch's economic analysis indicates their approach reduces water consumption by approximately 90% compared to evaporation ponds, while achieving lithium recovery rates of 85-95%. Their CAPEX model demonstrates significant advantages through modularization and standardization of equipment, allowing for scalable deployment with initial investments approximately 40-50% lower than conventional methods. The operational expenditure is optimized through energy-efficient designs that reduce power consumption by an estimated 30% compared to competing DLE technologies, with membrane replacement schedules designed to minimize downtime and maintenance costs.

Strengths: Highly selective lithium extraction with minimal pre-treatment requirements, modular design allowing for flexible capacity scaling, and significantly reduced water footprint. Weaknesses: Higher initial technology costs compared to some competing methods, potential membrane fouling in certain brine compositions requiring additional maintenance, and relatively higher energy requirements for the separation process.

Critical Patents and Innovations in DLE Technology

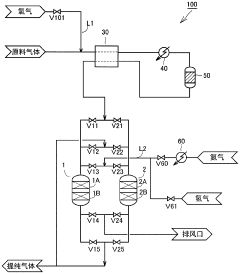

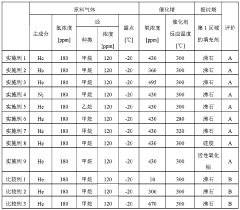

Purified gas manufacturing device, and purified gas manufacturing method

PatentInactiveCN111491711A

Innovation

- A device including a catalytic tower and a purification tower is designed. In the catalytic tower, catalytic reactions are carried out in the presence of oxygen to convert combustible components. In the purification tower, water and oxygen are adsorbed by materials such as zeolite, activated alumina and silica gel, and the copper content is used. High getters further remove oxygen, enabling continuous operation and reducing equipment count.

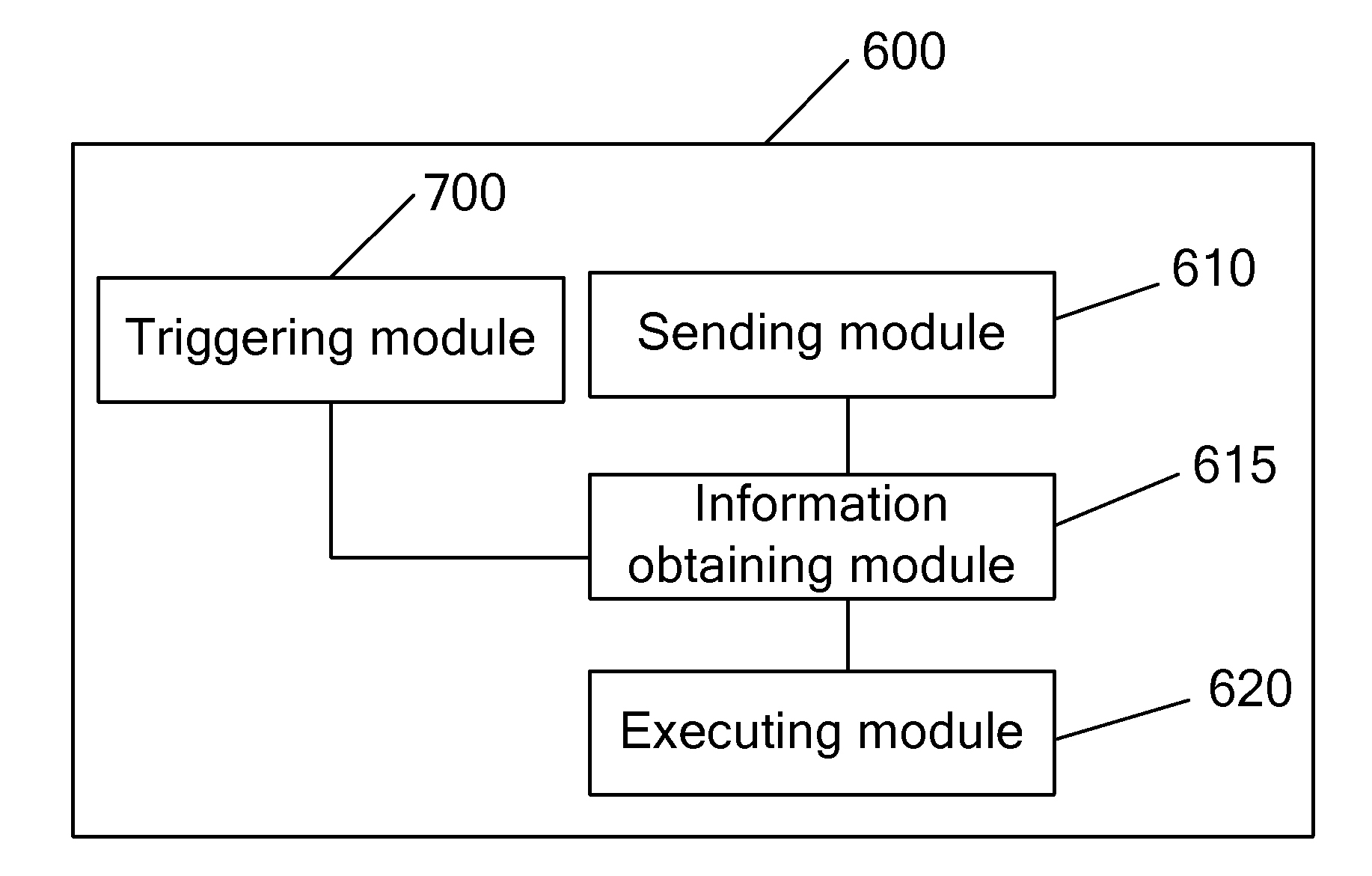

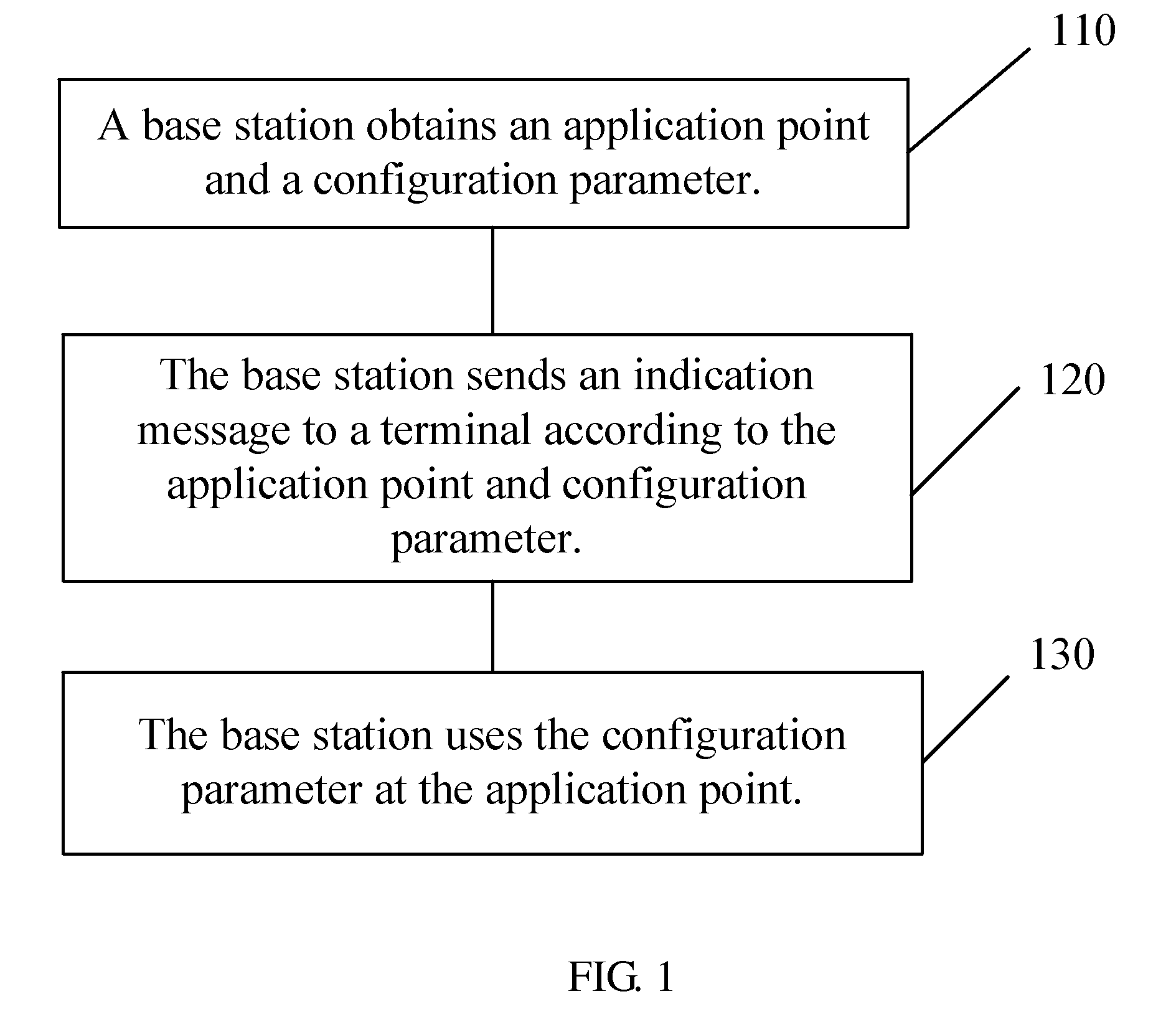

Method, device, and system for regulating power consumption

PatentActiveUS20120034948A1

Innovation

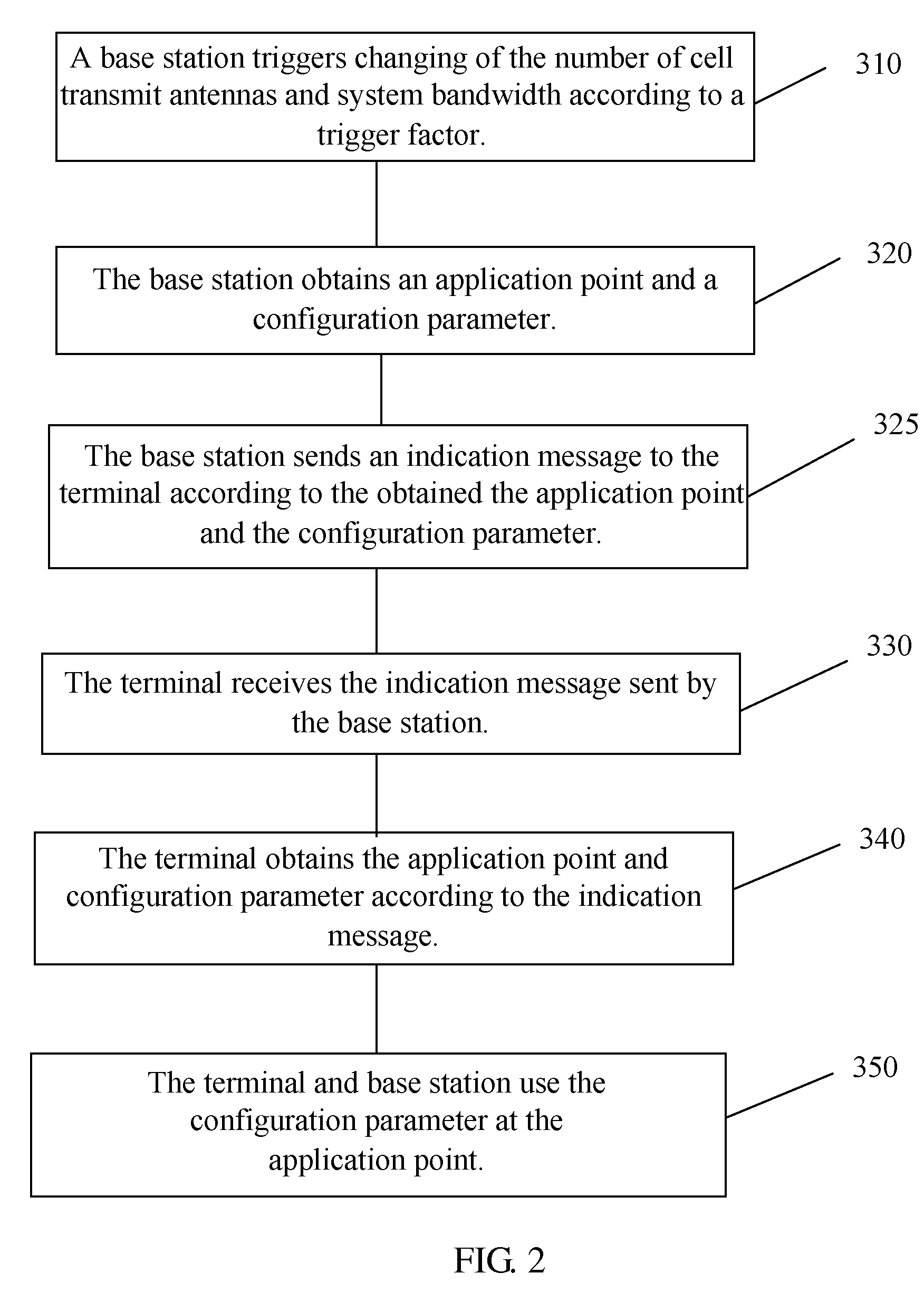

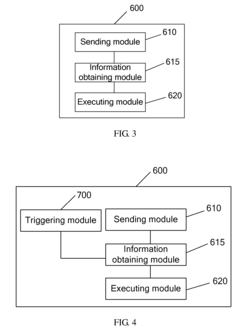

- A method and system where a base station dynamically adjusts the number of cell antennas or system bandwidth based on application points and configuration parameters, sending indication messages to terminals to implement these changes, thereby reducing power consumption while maintaining normal user communication.

CAPEX/OPEX Breakdown and Cost Drivers

The capital expenditure (CAPEX) for Direct Lithium Extraction (DLE) projects primarily encompasses infrastructure development, equipment procurement, and facility construction. Initial investment typically ranges from $15,000 to $30,000 per ton of annual lithium carbonate equivalent (LCE) production capacity, significantly higher than conventional evaporation pond methods. This variance depends on project scale, with larger operations benefiting from economies of scale that can reduce per-ton costs by 20-30%.

Major CAPEX components include specialized ion exchange or adsorption materials, which can represent 25-35% of total capital costs. These materials, often proprietary and technologically advanced, require substantial upfront investment but are critical to extraction efficiency. Processing equipment, including pumps, filtration systems, and crystallization units, constitutes another 20-30% of capital expenditure.

Site preparation and construction typically account for 15-25% of CAPEX, varying significantly based on location accessibility, existing infrastructure, and geological conditions. Projects in remote locations may require additional investment in roads, power generation, and water management systems, potentially increasing this component by 40-50%.

Operating expenditure (OPEX) for DLE operations ranges from $3,500 to $7,000 per ton of LCE, with energy consumption representing the most significant cost driver at 30-40% of total operating expenses. DLE processes require substantial electricity for pumping, heating, and electrochemical operations, with energy requirements of 2.5-4.0 MWh per ton of LCE produced.

Chemical reagents and consumables constitute 20-30% of OPEX, including acids, bases, and precipitation agents necessary for lithium processing and purification. The replacement and regeneration of ion exchange materials add another 15-25% to operating costs, with material lifespan typically ranging from 2-5 years depending on brine chemistry and operational parameters.

Labor costs represent 10-15% of OPEX, with skilled technical personnel commanding premium salaries in the specialized lithium extraction sector. Maintenance expenses account for 8-12% of operating costs, with harsh operating conditions (high temperatures, corrosive brines) accelerating equipment deterioration and necessitating regular replacement of components.

Water management represents a growing cost concern, particularly in water-stressed regions, accounting for 5-10% of OPEX. Advanced DLE technologies are increasingly focusing on water recycling and minimization strategies to address both environmental concerns and operational costs, with potential to reduce water-related expenses by 30-40% through closed-loop systems.

Major CAPEX components include specialized ion exchange or adsorption materials, which can represent 25-35% of total capital costs. These materials, often proprietary and technologically advanced, require substantial upfront investment but are critical to extraction efficiency. Processing equipment, including pumps, filtration systems, and crystallization units, constitutes another 20-30% of capital expenditure.

Site preparation and construction typically account for 15-25% of CAPEX, varying significantly based on location accessibility, existing infrastructure, and geological conditions. Projects in remote locations may require additional investment in roads, power generation, and water management systems, potentially increasing this component by 40-50%.

Operating expenditure (OPEX) for DLE operations ranges from $3,500 to $7,000 per ton of LCE, with energy consumption representing the most significant cost driver at 30-40% of total operating expenses. DLE processes require substantial electricity for pumping, heating, and electrochemical operations, with energy requirements of 2.5-4.0 MWh per ton of LCE produced.

Chemical reagents and consumables constitute 20-30% of OPEX, including acids, bases, and precipitation agents necessary for lithium processing and purification. The replacement and regeneration of ion exchange materials add another 15-25% to operating costs, with material lifespan typically ranging from 2-5 years depending on brine chemistry and operational parameters.

Labor costs represent 10-15% of OPEX, with skilled technical personnel commanding premium salaries in the specialized lithium extraction sector. Maintenance expenses account for 8-12% of operating costs, with harsh operating conditions (high temperatures, corrosive brines) accelerating equipment deterioration and necessitating regular replacement of components.

Water management represents a growing cost concern, particularly in water-stressed regions, accounting for 5-10% of OPEX. Advanced DLE technologies are increasingly focusing on water recycling and minimization strategies to address both environmental concerns and operational costs, with potential to reduce water-related expenses by 30-40% through closed-loop systems.

Environmental Impact and Sustainability Considerations

Direct Lithium Extraction (DLE) technologies present significant environmental advantages over traditional lithium extraction methods, particularly concerning water usage and land disturbance. Conventional evaporation pond methods consume approximately 500,000 gallons of water per metric ton of lithium carbonate produced, whereas advanced DLE technologies can reduce this consumption by up to 90%. This substantial water conservation is critical in water-stressed regions where lithium resources are abundant, such as the Lithium Triangle spanning Chile, Argentina, and Bolivia.

The reduced land footprint of DLE operations represents another key environmental benefit. Traditional evaporation ponds require extensive surface areas—approximately 2,000 hectares per 20,000 tons of annual lithium carbonate production. DLE facilities can operate with minimal surface disturbance, preserving natural habitats and reducing ecosystem fragmentation in sensitive areas.

Carbon emissions associated with DLE vary significantly based on energy sources utilized. When powered by renewable energy, DLE can achieve a carbon footprint reduction of 30-60% compared to conventional methods. However, energy-intensive processes like membrane filtration and adsorption technologies may increase operational emissions if reliant on fossil fuel power sources, potentially offsetting some environmental advantages.

Waste management presents both challenges and opportunities for DLE sustainability. While eliminating the need for evaporation ponds reduces certain waste streams, DLE generates specific byproducts including spent sorbents, used membranes, and chemical reagents requiring proper disposal or recycling. Emerging circular economy approaches are focusing on recovering valuable co-products from brine streams, including magnesium, boron, and potassium compounds, potentially transforming waste streams into revenue sources.

Water quality protection remains paramount in DLE implementation. Advanced monitoring systems and closed-loop processing can minimize contamination risks to surrounding aquifers and surface waters. Regulatory frameworks are evolving to address these concerns, with increasing emphasis on comprehensive environmental impact assessments prior to project approval.

The life cycle sustainability of DLE must consider the entire value chain, from extraction through processing to end-of-life management of components. Recent life cycle assessments indicate that DLE technologies, when optimally implemented, can reduce overall environmental impact by 30-40% compared to conventional extraction methods, supporting the sustainability credentials of lithium supply for clean energy applications.

The reduced land footprint of DLE operations represents another key environmental benefit. Traditional evaporation ponds require extensive surface areas—approximately 2,000 hectares per 20,000 tons of annual lithium carbonate production. DLE facilities can operate with minimal surface disturbance, preserving natural habitats and reducing ecosystem fragmentation in sensitive areas.

Carbon emissions associated with DLE vary significantly based on energy sources utilized. When powered by renewable energy, DLE can achieve a carbon footprint reduction of 30-60% compared to conventional methods. However, energy-intensive processes like membrane filtration and adsorption technologies may increase operational emissions if reliant on fossil fuel power sources, potentially offsetting some environmental advantages.

Waste management presents both challenges and opportunities for DLE sustainability. While eliminating the need for evaporation ponds reduces certain waste streams, DLE generates specific byproducts including spent sorbents, used membranes, and chemical reagents requiring proper disposal or recycling. Emerging circular economy approaches are focusing on recovering valuable co-products from brine streams, including magnesium, boron, and potassium compounds, potentially transforming waste streams into revenue sources.

Water quality protection remains paramount in DLE implementation. Advanced monitoring systems and closed-loop processing can minimize contamination risks to surrounding aquifers and surface waters. Regulatory frameworks are evolving to address these concerns, with increasing emphasis on comprehensive environmental impact assessments prior to project approval.

The life cycle sustainability of DLE must consider the entire value chain, from extraction through processing to end-of-life management of components. Recent life cycle assessments indicate that DLE technologies, when optimally implemented, can reduce overall environmental impact by 30-40% compared to conventional extraction methods, supporting the sustainability credentials of lithium supply for clean energy applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!