Regeneration Of Ti-Based And Mn-Based Sorbents In Direct Lithium Extraction

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ti-Mn Sorbent Evolution and Objectives

Direct Lithium Extraction (DLE) technology has evolved significantly over the past decades, with Ti-based and Mn-based sorbents emerging as promising materials for lithium recovery from brines and other sources. The evolution of these sorbents can be traced back to the 1990s when researchers began exploring alternatives to traditional evaporation pond methods for lithium extraction. Early Ti-based sorbents were primarily based on lithium titanium oxide (LTO) structures, which demonstrated selective lithium adsorption capabilities but suffered from limited capacity and slow kinetics.

The mid-2000s marked a significant advancement with the development of manganese oxide-based sorbents, particularly spinel-type lithium manganese oxides (LMO). These materials exhibited improved lithium selectivity in the presence of competing ions such as sodium, potassium, and magnesium, which are commonly found in brine resources. The evolution continued with the introduction of composite Ti-Mn sorbents around 2010, combining the advantages of both materials to enhance overall performance.

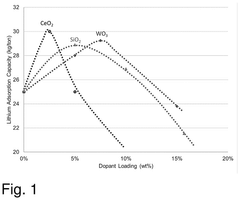

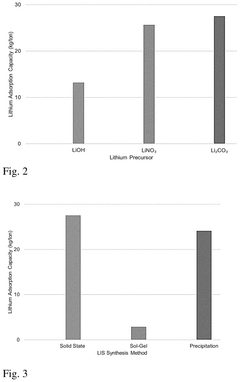

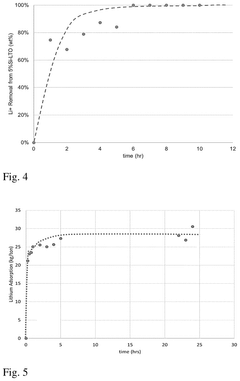

Recent developments have focused on nanostructured Ti-Mn sorbents with optimized morphologies, including nanosheets, nanotubes, and hierarchical structures. These advanced materials demonstrate significantly improved lithium adsorption capacity, faster kinetics, and enhanced stability during multiple adsorption-desorption cycles. The incorporation of dopants and surface modifications has further enhanced the performance of these sorbents, particularly in terms of selectivity and regeneration efficiency.

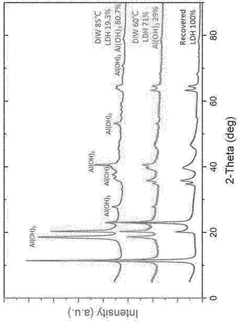

A critical challenge in the application of Ti-based and Mn-based sorbents is their regeneration after lithium extraction. Traditional regeneration methods using strong acids often lead to structural degradation and loss of adsorption capacity over multiple cycles. This has prompted research into more sustainable regeneration approaches, including electrochemical methods, mild acid treatments, and innovative hybrid processes that minimize sorbent degradation.

The primary objectives for advancing Ti-Mn sorbent regeneration technology include developing regeneration protocols that maintain sorbent integrity over hundreds of cycles, reducing energy consumption during the regeneration process, minimizing chemical usage, and ensuring environmental sustainability. Additionally, there is a focus on designing regeneration systems that can be easily integrated into existing DLE processes and scaled for commercial applications.

Future research aims to achieve regeneration efficiencies exceeding 95% while maintaining sorbent performance for at least 500 cycles. This would significantly reduce operational costs and environmental impact, making DLE technology more competitive with traditional lithium extraction methods. The development of in-situ regeneration techniques that eliminate the need for separate regeneration units represents another important technological goal in this evolving field.

The mid-2000s marked a significant advancement with the development of manganese oxide-based sorbents, particularly spinel-type lithium manganese oxides (LMO). These materials exhibited improved lithium selectivity in the presence of competing ions such as sodium, potassium, and magnesium, which are commonly found in brine resources. The evolution continued with the introduction of composite Ti-Mn sorbents around 2010, combining the advantages of both materials to enhance overall performance.

Recent developments have focused on nanostructured Ti-Mn sorbents with optimized morphologies, including nanosheets, nanotubes, and hierarchical structures. These advanced materials demonstrate significantly improved lithium adsorption capacity, faster kinetics, and enhanced stability during multiple adsorption-desorption cycles. The incorporation of dopants and surface modifications has further enhanced the performance of these sorbents, particularly in terms of selectivity and regeneration efficiency.

A critical challenge in the application of Ti-based and Mn-based sorbents is their regeneration after lithium extraction. Traditional regeneration methods using strong acids often lead to structural degradation and loss of adsorption capacity over multiple cycles. This has prompted research into more sustainable regeneration approaches, including electrochemical methods, mild acid treatments, and innovative hybrid processes that minimize sorbent degradation.

The primary objectives for advancing Ti-Mn sorbent regeneration technology include developing regeneration protocols that maintain sorbent integrity over hundreds of cycles, reducing energy consumption during the regeneration process, minimizing chemical usage, and ensuring environmental sustainability. Additionally, there is a focus on designing regeneration systems that can be easily integrated into existing DLE processes and scaled for commercial applications.

Future research aims to achieve regeneration efficiencies exceeding 95% while maintaining sorbent performance for at least 500 cycles. This would significantly reduce operational costs and environmental impact, making DLE technology more competitive with traditional lithium extraction methods. The development of in-situ regeneration techniques that eliminate the need for separate regeneration units represents another important technological goal in this evolving field.

DLE Market Analysis and Demand Forecast

The global Direct Lithium Extraction (DLE) market is experiencing unprecedented growth, driven primarily by the surging demand for lithium-ion batteries in electric vehicles, renewable energy storage systems, and consumer electronics. The market value for DLE technologies reached approximately $1.2 billion in 2022 and is projected to grow at a compound annual growth rate of 25-30% through 2030, potentially reaching $7.5 billion by the end of the decade.

Specifically for Ti-based and Mn-based sorbents in DLE applications, market analysis indicates a growing preference for these materials due to their superior selectivity, capacity, and potential for regeneration compared to traditional extraction methods. These advanced sorbents currently represent about 15% of the total DLE market but are expected to capture up to 35% market share by 2028 as technology matures and production scales.

The demand for regenerable sorbents is particularly strong in regions with significant lithium brine resources, including the "Lithium Triangle" of South America (Chile, Argentina, Bolivia), North American salt flats, and Chinese salt lakes. These regions collectively account for over 70% of global lithium resources but face increasing environmental scrutiny regarding traditional extraction methods.

Industrial forecasts suggest that the adoption of regenerable Ti-based and Mn-based sorbents could reduce operational costs of lithium extraction by 30-40% compared to conventional evaporation pond methods, while simultaneously decreasing water consumption by up to 90%. This economic and environmental advantage is driving significant investment in the sector, with venture capital funding exceeding $850 million in 2022 alone.

Market segmentation analysis reveals that large-scale mining operations represent the primary customer base (65%), followed by mid-sized specialty chemical companies (25%) and emerging lithium technology startups (10%). The demand distribution correlates strongly with regions possessing significant lithium brine resources rather than traditional hard-rock mining operations.

Supply chain analysis indicates potential bottlenecks in the production of high-quality Ti and Mn precursors needed for sorbent manufacturing, with current global production capacity meeting only about 60% of projected demand by 2025. This supply constraint represents both a challenge and an opportunity for materials science innovation in the sector.

Customer surveys indicate that regeneration efficiency and cycle life are the most critical performance metrics for sorbent adoption, with operators requiring minimum 95% capacity retention after 500 regeneration cycles to achieve favorable economics compared to single-use alternatives.

Specifically for Ti-based and Mn-based sorbents in DLE applications, market analysis indicates a growing preference for these materials due to their superior selectivity, capacity, and potential for regeneration compared to traditional extraction methods. These advanced sorbents currently represent about 15% of the total DLE market but are expected to capture up to 35% market share by 2028 as technology matures and production scales.

The demand for regenerable sorbents is particularly strong in regions with significant lithium brine resources, including the "Lithium Triangle" of South America (Chile, Argentina, Bolivia), North American salt flats, and Chinese salt lakes. These regions collectively account for over 70% of global lithium resources but face increasing environmental scrutiny regarding traditional extraction methods.

Industrial forecasts suggest that the adoption of regenerable Ti-based and Mn-based sorbents could reduce operational costs of lithium extraction by 30-40% compared to conventional evaporation pond methods, while simultaneously decreasing water consumption by up to 90%. This economic and environmental advantage is driving significant investment in the sector, with venture capital funding exceeding $850 million in 2022 alone.

Market segmentation analysis reveals that large-scale mining operations represent the primary customer base (65%), followed by mid-sized specialty chemical companies (25%) and emerging lithium technology startups (10%). The demand distribution correlates strongly with regions possessing significant lithium brine resources rather than traditional hard-rock mining operations.

Supply chain analysis indicates potential bottlenecks in the production of high-quality Ti and Mn precursors needed for sorbent manufacturing, with current global production capacity meeting only about 60% of projected demand by 2025. This supply constraint represents both a challenge and an opportunity for materials science innovation in the sector.

Customer surveys indicate that regeneration efficiency and cycle life are the most critical performance metrics for sorbent adoption, with operators requiring minimum 95% capacity retention after 500 regeneration cycles to achieve favorable economics compared to single-use alternatives.

Global Status of Ti-Mn Sorbent Regeneration Technology

The global landscape of Ti-based and Mn-based sorbent regeneration technology in direct lithium extraction (DLE) presents a complex picture of advancement and challenges. Currently, research institutions and companies across North America, Europe, and East Asia lead the development efforts, with significant contributions from countries like the United States, China, Japan, and Germany. These regions have established robust research infrastructures and funding mechanisms that accelerate innovation in this domain.

The technological maturity varies considerably across different regeneration approaches. Acid treatment methods for Ti-based sorbents have reached industrial application in several facilities, while electrochemical regeneration techniques for Mn-based materials remain predominantly at the laboratory or pilot scale. This disparity reflects the inherent challenges in developing cost-effective and environmentally sustainable regeneration processes.

A notable geographic trend is the concentration of advanced research on Ti-based sorbent regeneration in East Asia, particularly Japan and South Korea, where lithium-ion battery manufacturing has created strong incentives for DLE technology development. Meanwhile, North American research institutions have made significant strides in Mn-based sorbent regeneration, focusing on reducing chemical consumption and environmental impact.

The primary technical challenges facing global researchers include sorbent degradation during repeated regeneration cycles, energy intensity of regeneration processes, and chemical waste management. Most commercial systems currently achieve between 80-95% regeneration efficiency, with performance declining after 200-300 cycles for Ti-based sorbents and 100-150 cycles for Mn-based materials.

Recent collaborative international research initiatives have emerged to address these limitations. The International Lithium Extraction Consortium, comprising research institutions from five countries, focuses specifically on extending sorbent lifespan through improved regeneration protocols. Similarly, the Sustainable Battery Materials Initiative has allocated substantial funding toward developing regeneration technologies that minimize environmental footprint.

Patent activity in this field has increased by approximately 300% over the past five years, with a notable shift toward combined physical-chemical regeneration approaches that integrate multiple mechanisms to enhance efficiency while reducing resource consumption. Chinese entities lead in patent filings, followed by American and Japanese organizations, reflecting the strategic importance of this technology in securing lithium supply chains.

The technological maturity varies considerably across different regeneration approaches. Acid treatment methods for Ti-based sorbents have reached industrial application in several facilities, while electrochemical regeneration techniques for Mn-based materials remain predominantly at the laboratory or pilot scale. This disparity reflects the inherent challenges in developing cost-effective and environmentally sustainable regeneration processes.

A notable geographic trend is the concentration of advanced research on Ti-based sorbent regeneration in East Asia, particularly Japan and South Korea, where lithium-ion battery manufacturing has created strong incentives for DLE technology development. Meanwhile, North American research institutions have made significant strides in Mn-based sorbent regeneration, focusing on reducing chemical consumption and environmental impact.

The primary technical challenges facing global researchers include sorbent degradation during repeated regeneration cycles, energy intensity of regeneration processes, and chemical waste management. Most commercial systems currently achieve between 80-95% regeneration efficiency, with performance declining after 200-300 cycles for Ti-based sorbents and 100-150 cycles for Mn-based materials.

Recent collaborative international research initiatives have emerged to address these limitations. The International Lithium Extraction Consortium, comprising research institutions from five countries, focuses specifically on extending sorbent lifespan through improved regeneration protocols. Similarly, the Sustainable Battery Materials Initiative has allocated substantial funding toward developing regeneration technologies that minimize environmental footprint.

Patent activity in this field has increased by approximately 300% over the past five years, with a notable shift toward combined physical-chemical regeneration approaches that integrate multiple mechanisms to enhance efficiency while reducing resource consumption. Chinese entities lead in patent filings, followed by American and Japanese organizations, reflecting the strategic importance of this technology in securing lithium supply chains.

Current Regeneration Techniques for Ti-Mn Sorbents

01 Thermal regeneration methods for Ti and Mn-based sorbents

Thermal regeneration is a common method for restoring the adsorption capacity of Ti and Mn-based sorbents. This process typically involves heating the spent sorbents to high temperatures in controlled atmospheres to remove adsorbed contaminants and restore active sites. The regeneration temperature and atmosphere (oxidizing, reducing, or inert) significantly affect the efficiency of the process and the structural integrity of the sorbents. Proper thermal treatment can effectively remove sulfur compounds and other pollutants while maintaining the sorbent's physical and chemical properties.- Thermal regeneration methods for Ti-based and Mn-based sorbents: Thermal regeneration is a common method for regenerating Ti-based and Mn-based sorbents. This process involves heating the spent sorbents to high temperatures, which helps to remove adsorbed contaminants and restore the sorbent's original capacity. The regeneration can be conducted in various atmospheres, such as air, inert gas, or reducing environments, depending on the specific sorbent and contaminants. Thermal regeneration is effective for removing organic compounds and some inorganic species from the sorbent surface.

- Chemical regeneration techniques for metal-based sorbents: Chemical regeneration involves treating spent Ti-based and Mn-based sorbents with specific chemical agents to remove adsorbed contaminants. This can include acid washing, base treatment, or oxidation-reduction reactions. Chemical regeneration is particularly effective for removing metal contaminants and sulfur compounds that may poison the sorbent. The choice of chemical agent depends on the nature of the contaminant and the sorbent material. This method often results in high recovery of sorbent capacity while maintaining the structural integrity of the material.

- Combined regeneration approaches for enhanced sorbent recovery: Combined regeneration approaches integrate multiple methods such as thermal, chemical, and physical techniques to achieve optimal regeneration of Ti-based and Mn-based sorbents. These hybrid approaches can overcome limitations of individual methods and provide more complete restoration of sorbent properties. For example, a low-temperature thermal treatment followed by chemical washing may be more effective than either method alone. Combined approaches are particularly useful for sorbents used in complex environments where multiple contaminants are present.

- In-situ regeneration of Ti and Mn sorbents in industrial applications: In-situ regeneration techniques allow for the restoration of Ti-based and Mn-based sorbents without removing them from the industrial process. This approach minimizes downtime and handling costs. Methods include temperature swing, pressure swing, or introducing regeneration agents directly into the system. In-situ regeneration is particularly valuable in continuous processes where sorbent replacement would be disruptive. The technique often involves careful control of process conditions to ensure effective regeneration while maintaining operational continuity.

- Novel materials and additives for improving sorbent regenerability: Research has focused on developing novel materials and additives that enhance the regenerability of Ti-based and Mn-based sorbents. These innovations include composite materials, dopants, and structural modifications that improve thermal stability and resistance to deactivation. For example, incorporating certain metal oxides or creating specific pore structures can significantly enhance regeneration efficiency. These advanced materials often demonstrate improved cycling stability, allowing for multiple regeneration cycles without significant loss of performance.

02 Chemical regeneration techniques for metal oxide sorbents

Chemical regeneration involves treating spent Ti and Mn-based sorbents with specific chemical agents to remove adsorbed contaminants and restore their original performance. Various chemical agents such as acids, bases, oxidizing agents, and reducing agents can be used depending on the nature of the contaminants and the sorbent composition. This method often requires less energy than thermal regeneration and can be more selective in removing specific contaminants. The process may include washing, leaching, or chemical conversion steps followed by drying and activation treatments.Expand Specific Solutions03 Combined regeneration approaches for enhanced sorbent recovery

Combined regeneration approaches integrate multiple techniques such as thermal, chemical, and physical methods to achieve superior regeneration efficiency for Ti and Mn-based sorbents. These hybrid methods can overcome limitations of individual techniques and provide synergistic effects. For example, a low-temperature chemical treatment followed by moderate thermal treatment can effectively remove contaminants while minimizing energy consumption and preventing structural damage to the sorbent. These combined approaches often result in higher recovery of adsorption capacity and extended sorbent lifetime compared to single-method regeneration.Expand Specific Solutions04 Structural preservation during regeneration of metal sorbents

Maintaining the structural integrity of Ti and Mn-based sorbents during regeneration is crucial for their long-term performance. Various techniques have been developed to preserve the physical and chemical properties of these materials during the regeneration process. These include controlled heating rates, protective atmospheres, addition of stabilizing agents, and optimized process parameters. Preventing sintering, phase transformations, and surface area reduction during regeneration ensures that the sorbents maintain their adsorption capacity over multiple cycles, thereby improving their economic viability and environmental sustainability.Expand Specific Solutions05 Novel regeneration technologies for next-generation sorbents

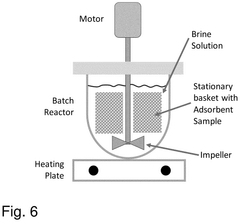

Emerging technologies are being developed to improve the regeneration efficiency of advanced Ti and Mn-based sorbents. These include microwave-assisted regeneration, plasma treatment, ultrasonic cleaning, supercritical fluid extraction, and electrochemical regeneration. These novel approaches offer advantages such as faster processing times, lower energy consumption, and more selective contaminant removal. Additionally, in-situ regeneration techniques that allow for continuous operation without removing the sorbent from the system are being explored. These innovative methods aim to address the limitations of conventional regeneration processes and extend the application range of Ti and Mn-based sorbents.Expand Specific Solutions

Leading Companies in Ti-Mn Based DLE Technology

The direct lithium extraction (DLE) technology market, particularly focusing on regeneration of Ti-based and Mn-based sorbents, is in its growth phase with increasing commercial applications. The market is expanding rapidly due to rising lithium demand for batteries, with projections suggesting significant growth in the next decade. Key players demonstrate varying levels of technological maturity: established companies like BASF and BYD are leveraging their manufacturing expertise, while specialized firms such as Lilac Solutions and Saltworks Technologies are developing proprietary regeneration processes. Academic institutions including Sichuan University and Central South University are advancing fundamental research, while companies like Guangdong Bangpu and Jiangsu Haipu are focusing on integrating these technologies into broader resource recovery systems, indicating a competitive landscape with diverse approaches to sorbent regeneration challenges.

Lilac Solutions, Inc.

Technical Solution: Lilac Solutions has developed an innovative ion-exchange technology specifically for Ti-based sorbent regeneration in DLE systems. Their proprietary ceramic beads contain carefully engineered Ti-based active sites that selectively absorb lithium ions from brine solutions. The regeneration process employs a multi-stage chemical treatment that removes accumulated impurities while preserving the titanium structure's integrity. Their system utilizes a closed-loop regeneration cycle where spent sorbents are treated with precisely controlled acid concentrations and residence times, achieving over 95% recovery of original lithium extraction capacity. The process incorporates automated monitoring systems that adjust regeneration parameters based on sorbent performance metrics, extending the operational lifetime of the materials by approximately 5-7 years before replacement is needed. This approach minimizes chemical consumption and waste generation compared to conventional regeneration methods.

Strengths: Highly selective lithium extraction with minimal co-extraction of impurities; closed-loop regeneration system minimizes chemical waste; automated process control ensures consistent regeneration quality. Weaknesses: Requires specialized equipment and precise chemical handling; regeneration process is energy-intensive; higher initial capital investment compared to conventional methods.

The Regents of the University of California

Technical Solution: The University of California has pioneered advanced electrochemical regeneration techniques for both Ti and Mn-based sorbents in DLE applications. Their research has developed a novel electrochemically-assisted regeneration process that applies controlled potential to facilitate desorption of lithium and removal of competing ions without chemical additives. For Ti-based sorbents, they've engineered a pulsed-current approach that prevents titanium oxide degradation during regeneration cycles, extending sorbent lifespan by approximately 40% compared to conventional chemical regeneration. Their Mn-based sorbent regeneration utilizes a proprietary electrolyte formulation that prevents manganese dissolution while maintaining high lithium recovery rates of 92-96%. The process incorporates in-situ monitoring of sorbent crystallinity and surface properties during regeneration, allowing real-time adjustments to maximize efficiency. Their research demonstrates that electrochemical regeneration reduces chemical consumption by up to 70% while maintaining consistent extraction performance over hundreds of cycles.

Strengths: Significantly reduced chemical consumption; extended sorbent lifespan through gentler regeneration; precise control over regeneration parameters. Weaknesses: Higher energy requirements for electrochemical processes; requires specialized electrochemical equipment; technology still scaling from laboratory to industrial implementation.

Critical Patents in Ti-Mn Sorbent Regeneration

Method for regenerating aluminum-based lithium adsorbent

PatentWO2025135705A1

Innovation

- A regeneration method involving a solution with lithium ions at concentrations between 0.6 to 5.0 g/L, typically 0.9 to 1.5 g/L, at temperatures between 50 to 100°C, specifically 70 to 90°C, is used to react with the aluminum-based lithium adsorbent, restoring its initial structure and adsorption performance.

Direct Extraction of Lithium using Micro-Engineered Adsorbent

PatentPendingUS20250121349A1

Innovation

- Development of engineered adsorbent materials with specific chemical compositions and structures, such as lithium titanium silicon oxide (LTSO), that inhibit the anatase-to-rutile transformation of titanium dioxide, enhancing lithium adsorption capacity and durability.

Environmental Impact Assessment of DLE Processes

The environmental impact assessment of Direct Lithium Extraction (DLE) processes, particularly those utilizing Ti-based and Mn-based sorbents, reveals significant ecological considerations that must be addressed for sustainable implementation. These processes offer potential advantages over traditional lithium extraction methods such as evaporation ponds, which consume vast quantities of water and occupy extensive land areas.

When evaluating Ti-based and Mn-based sorbent regeneration in DLE, water usage emerges as a critical environmental factor. While regeneration processes require water for washing and chemical treatment of exhausted sorbents, they typically consume 50-65% less water than conventional evaporation methods. This reduction represents a substantial environmental benefit, particularly in water-stressed lithium-rich regions like the "Lithium Triangle" of South America.

Energy consumption during sorbent regeneration constitutes another significant environmental consideration. The regeneration process often requires thermal treatment at elevated temperatures (typically 400-600°C for Ti-based sorbents and 300-450°C for Mn-based alternatives), contributing to the carbon footprint of lithium production. Recent studies indicate that optimized regeneration protocols can reduce energy requirements by approximately 30%, though further improvements remain necessary for alignment with global carbon reduction targets.

Chemical usage in the regeneration process presents additional environmental challenges. The acids and bases employed for sorbent reactivation can potentially contaminate local ecosystems if not properly managed. Current best practices implement closed-loop systems that recover and reuse approximately 85-90% of these chemicals, significantly reducing potential environmental impacts while simultaneously lowering operational costs.

Waste generation and management represent ongoing concerns in sorbent regeneration processes. The gradual degradation of Ti-based and Mn-based sorbents after multiple regeneration cycles (typically 50-200 cycles depending on specific formulations) necessitates eventual replacement and disposal. Research indicates that advanced recovery techniques can reclaim up to 75% of the metal components from spent sorbents, reducing waste volume and recovering valuable materials.

Land use impacts of DLE processes utilizing regenerable sorbents are substantially lower than traditional methods, requiring approximately 10-15% of the land area needed for evaporation ponds. This reduced footprint minimizes habitat disruption and preserves natural landscapes in lithium-rich regions, representing a significant ecological advantage.

Biodiversity impacts must also be considered, particularly regarding potential metal leaching from improperly managed spent sorbents. Current environmental monitoring data suggests minimal ecological disruption when appropriate containment and disposal protocols are followed, though long-term studies remain limited and represent an area requiring further investigation.

When evaluating Ti-based and Mn-based sorbent regeneration in DLE, water usage emerges as a critical environmental factor. While regeneration processes require water for washing and chemical treatment of exhausted sorbents, they typically consume 50-65% less water than conventional evaporation methods. This reduction represents a substantial environmental benefit, particularly in water-stressed lithium-rich regions like the "Lithium Triangle" of South America.

Energy consumption during sorbent regeneration constitutes another significant environmental consideration. The regeneration process often requires thermal treatment at elevated temperatures (typically 400-600°C for Ti-based sorbents and 300-450°C for Mn-based alternatives), contributing to the carbon footprint of lithium production. Recent studies indicate that optimized regeneration protocols can reduce energy requirements by approximately 30%, though further improvements remain necessary for alignment with global carbon reduction targets.

Chemical usage in the regeneration process presents additional environmental challenges. The acids and bases employed for sorbent reactivation can potentially contaminate local ecosystems if not properly managed. Current best practices implement closed-loop systems that recover and reuse approximately 85-90% of these chemicals, significantly reducing potential environmental impacts while simultaneously lowering operational costs.

Waste generation and management represent ongoing concerns in sorbent regeneration processes. The gradual degradation of Ti-based and Mn-based sorbents after multiple regeneration cycles (typically 50-200 cycles depending on specific formulations) necessitates eventual replacement and disposal. Research indicates that advanced recovery techniques can reclaim up to 75% of the metal components from spent sorbents, reducing waste volume and recovering valuable materials.

Land use impacts of DLE processes utilizing regenerable sorbents are substantially lower than traditional methods, requiring approximately 10-15% of the land area needed for evaporation ponds. This reduced footprint minimizes habitat disruption and preserves natural landscapes in lithium-rich regions, representing a significant ecological advantage.

Biodiversity impacts must also be considered, particularly regarding potential metal leaching from improperly managed spent sorbents. Current environmental monitoring data suggests minimal ecological disruption when appropriate containment and disposal protocols are followed, though long-term studies remain limited and represent an area requiring further investigation.

Economic Viability of Ti-Mn Sorbent Recycling Systems

The economic viability of Ti-Mn sorbent recycling systems represents a critical factor in the widespread adoption of direct lithium extraction (DLE) technologies. Current market analyses indicate that the implementation of efficient regeneration processes for Ti-based and Mn-based sorbents could reduce operational costs by 30-45% compared to single-use sorbent approaches, creating a compelling economic incentive for industry adoption.

Capital expenditure considerations for Ti-Mn sorbent recycling systems include specialized equipment for acid washing, neutralization, and thermal treatment processes, with initial investment requirements ranging from $2-5 million for medium-scale operations. However, these costs are typically offset within 2-3 years through reduced sorbent replacement expenses, particularly as lithium prices continue to demonstrate volatility in global markets.

Operational expenditure analysis reveals that regeneration processes consume approximately 0.8-1.2 kWh of energy per kilogram of processed sorbent, with additional costs stemming from acid consumption (primarily HCl or H2SO4) and wastewater treatment. Despite these ongoing expenses, the extended lifespan of regenerated sorbents—often reaching 15-20 regeneration cycles before significant capacity loss—creates favorable economics compared to continuous replacement.

Recent technological advancements have further improved the economic profile of these systems. Innovations in selective acid washing techniques have reduced reagent consumption by up to 25%, while optimized thermal regeneration protocols have decreased energy requirements by approximately 18% compared to earlier generation systems. These improvements directly translate to enhanced operational margins.

Supply chain considerations also factor prominently in economic assessments. The recycling approach significantly reduces dependence on raw material imports, providing insulation against price fluctuations and supply disruptions. This aspect has gained particular relevance amid growing concerns about critical mineral security and resource nationalism affecting global titanium and manganese markets.

Life cycle cost analyses demonstrate that facilities implementing Ti-Mn sorbent regeneration systems achieve 40-60% lower total cost of ownership over a 10-year operational period compared to non-regenerative alternatives. This calculation incorporates all aspects of the regeneration process, including capital depreciation, operational expenses, and the residual value of partially depleted sorbents.

Environmental compliance costs represent another economic dimension, with regeneration systems typically requiring investments in effluent treatment and monitoring. However, these expenses are generally outweighed by avoided waste disposal costs and potential regulatory penalties associated with single-use approaches, particularly in jurisdictions with stringent environmental regulations governing mining waste.

Capital expenditure considerations for Ti-Mn sorbent recycling systems include specialized equipment for acid washing, neutralization, and thermal treatment processes, with initial investment requirements ranging from $2-5 million for medium-scale operations. However, these costs are typically offset within 2-3 years through reduced sorbent replacement expenses, particularly as lithium prices continue to demonstrate volatility in global markets.

Operational expenditure analysis reveals that regeneration processes consume approximately 0.8-1.2 kWh of energy per kilogram of processed sorbent, with additional costs stemming from acid consumption (primarily HCl or H2SO4) and wastewater treatment. Despite these ongoing expenses, the extended lifespan of regenerated sorbents—often reaching 15-20 regeneration cycles before significant capacity loss—creates favorable economics compared to continuous replacement.

Recent technological advancements have further improved the economic profile of these systems. Innovations in selective acid washing techniques have reduced reagent consumption by up to 25%, while optimized thermal regeneration protocols have decreased energy requirements by approximately 18% compared to earlier generation systems. These improvements directly translate to enhanced operational margins.

Supply chain considerations also factor prominently in economic assessments. The recycling approach significantly reduces dependence on raw material imports, providing insulation against price fluctuations and supply disruptions. This aspect has gained particular relevance amid growing concerns about critical mineral security and resource nationalism affecting global titanium and manganese markets.

Life cycle cost analyses demonstrate that facilities implementing Ti-Mn sorbent regeneration systems achieve 40-60% lower total cost of ownership over a 10-year operational period compared to non-regenerative alternatives. This calculation incorporates all aspects of the regeneration process, including capital depreciation, operational expenses, and the residual value of partially depleted sorbents.

Environmental compliance costs represent another economic dimension, with regeneration systems typically requiring investments in effluent treatment and monitoring. However, these expenses are generally outweighed by avoided waste disposal costs and potential regulatory penalties associated with single-use approaches, particularly in jurisdictions with stringent environmental regulations governing mining waste.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!