Opportunities In Produced Water And Oilfield Brines For Direct Lithium Extraction

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Extraction from Oilfield Brines: Background and Objectives

Lithium has emerged as a critical element in the global energy transition, with demand projected to increase by over 40 times by 2040 according to the International Energy Agency. This surge is primarily driven by the rapid growth in electric vehicle production and renewable energy storage systems. Traditional lithium extraction methods have predominantly focused on hard rock mining and solar evaporation of salt flats, both of which present significant environmental challenges and geographical limitations.

The concept of extracting lithium from oilfield brines represents a paradigm shift in lithium sourcing strategies. Historically, produced water from oil and gas operations has been treated as a waste product, with management costs exceeding $50 billion annually in the United States alone. However, recent technological advancements have revealed that these brines often contain substantial lithium concentrations, ranging from 10 to 1,000 mg/L, presenting an untapped resource with dual economic and environmental benefits.

The evolution of lithium extraction technologies has accelerated significantly since 2010, with direct lithium extraction (DLE) methods emerging as particularly promising for oilfield brine applications. These techniques leverage selective adsorption, ion exchange, and membrane processes to isolate lithium ions from complex brine solutions without requiring extensive land use or evaporation ponds.

The primary objective of this technological pursuit is to develop economically viable methods for extracting lithium from oilfield brines at commercial scale, thereby creating a domestic supply chain for this strategic material while simultaneously addressing produced water management challenges in hydrocarbon production. This approach aligns with circular economy principles by transforming a waste stream into a valuable resource.

Current global lithium production is concentrated in Australia, Chile, China, and Argentina, creating supply chain vulnerabilities for many industrialized nations. The development of lithium extraction capabilities from oilfield brines could significantly diversify supply sources, particularly in regions with extensive oil and gas operations such as North America, the Middle East, and parts of Europe.

Technical objectives include achieving lithium recovery rates exceeding 80%, developing selective extraction processes that can function in high-salinity environments, minimizing energy consumption, and creating modular systems that can be deployed at various scales across different oilfield operations. The ultimate goal is to establish a cost-competitive alternative to conventional lithium sources while providing environmental benefits through reduced waste disposal requirements.

The concept of extracting lithium from oilfield brines represents a paradigm shift in lithium sourcing strategies. Historically, produced water from oil and gas operations has been treated as a waste product, with management costs exceeding $50 billion annually in the United States alone. However, recent technological advancements have revealed that these brines often contain substantial lithium concentrations, ranging from 10 to 1,000 mg/L, presenting an untapped resource with dual economic and environmental benefits.

The evolution of lithium extraction technologies has accelerated significantly since 2010, with direct lithium extraction (DLE) methods emerging as particularly promising for oilfield brine applications. These techniques leverage selective adsorption, ion exchange, and membrane processes to isolate lithium ions from complex brine solutions without requiring extensive land use or evaporation ponds.

The primary objective of this technological pursuit is to develop economically viable methods for extracting lithium from oilfield brines at commercial scale, thereby creating a domestic supply chain for this strategic material while simultaneously addressing produced water management challenges in hydrocarbon production. This approach aligns with circular economy principles by transforming a waste stream into a valuable resource.

Current global lithium production is concentrated in Australia, Chile, China, and Argentina, creating supply chain vulnerabilities for many industrialized nations. The development of lithium extraction capabilities from oilfield brines could significantly diversify supply sources, particularly in regions with extensive oil and gas operations such as North America, the Middle East, and parts of Europe.

Technical objectives include achieving lithium recovery rates exceeding 80%, developing selective extraction processes that can function in high-salinity environments, minimizing energy consumption, and creating modular systems that can be deployed at various scales across different oilfield operations. The ultimate goal is to establish a cost-competitive alternative to conventional lithium sources while providing environmental benefits through reduced waste disposal requirements.

Market Analysis for Lithium from Produced Water

The global lithium market is experiencing unprecedented growth, driven primarily by the rapid expansion of electric vehicle (EV) production and renewable energy storage systems. Current market valuations place the global lithium market at approximately $7.5 billion in 2022, with projections indicating a compound annual growth rate (CAGR) of 12-15% through 2030, potentially reaching $20-25 billion. This explosive growth has created significant supply constraints in traditional lithium sources.

Conventional lithium extraction methods rely predominantly on hard rock mining (primarily from spodumene) and solar evaporation of salt brines, which together account for over 95% of current global production. Australia leads hard rock production while the "Lithium Triangle" of Chile, Argentina, and Bolivia dominates brine-based extraction. However, these traditional sources face increasing challenges including lengthy development timelines, substantial environmental impacts, and geopolitical complications.

The supply-demand imbalance has created a compelling market opportunity for alternative lithium sources, particularly from produced water and oilfield brines. These unconventional sources represent a potentially massive untapped reservoir of lithium. Industry analyses suggest that produced water from oil and gas operations globally contains lithium concentrations ranging from 10-1,000 mg/L, with some formations exceeding these levels.

North American oilfields, particularly in regions like the Permian Basin, Marcellus Shale, and Alberta Oil Sands, generate billions of gallons of produced water annually. Conservative estimates indicate that capturing just 15-20% of the lithium content from these sources could potentially supply 25-30% of projected North American lithium demand by 2030.

The economic case for lithium extraction from produced water is strengthened by several factors. First, the infrastructure for brine collection already exists as part of oil and gas operations. Second, treating produced water represents a significant cost center for energy companies, creating potential for dual revenue streams through lithium recovery and water treatment cost reduction. Third, regulatory pressures regarding produced water disposal are intensifying, making value-added treatment solutions increasingly attractive.

Market segmentation analysis reveals multiple potential customer groups: battery manufacturers seeking diversified supply chains, oil and gas operators looking to monetize waste streams, and water treatment companies expanding into resource recovery. The most promising initial market appears to be mid-sized battery material processors seeking to secure domestic supply chains in regions with established oil and gas infrastructure.

Pricing dynamics remain favorable despite recent lithium price volatility. Even with lithium carbonate prices retreating from 2022 peaks of $80,000/ton to current levels around $30,000-40,000/ton, the break-even point for most direct lithium extraction (DLE) technologies from produced water is estimated at $12,000-18,000/ton, maintaining substantial profit potential.

Conventional lithium extraction methods rely predominantly on hard rock mining (primarily from spodumene) and solar evaporation of salt brines, which together account for over 95% of current global production. Australia leads hard rock production while the "Lithium Triangle" of Chile, Argentina, and Bolivia dominates brine-based extraction. However, these traditional sources face increasing challenges including lengthy development timelines, substantial environmental impacts, and geopolitical complications.

The supply-demand imbalance has created a compelling market opportunity for alternative lithium sources, particularly from produced water and oilfield brines. These unconventional sources represent a potentially massive untapped reservoir of lithium. Industry analyses suggest that produced water from oil and gas operations globally contains lithium concentrations ranging from 10-1,000 mg/L, with some formations exceeding these levels.

North American oilfields, particularly in regions like the Permian Basin, Marcellus Shale, and Alberta Oil Sands, generate billions of gallons of produced water annually. Conservative estimates indicate that capturing just 15-20% of the lithium content from these sources could potentially supply 25-30% of projected North American lithium demand by 2030.

The economic case for lithium extraction from produced water is strengthened by several factors. First, the infrastructure for brine collection already exists as part of oil and gas operations. Second, treating produced water represents a significant cost center for energy companies, creating potential for dual revenue streams through lithium recovery and water treatment cost reduction. Third, regulatory pressures regarding produced water disposal are intensifying, making value-added treatment solutions increasingly attractive.

Market segmentation analysis reveals multiple potential customer groups: battery manufacturers seeking diversified supply chains, oil and gas operators looking to monetize waste streams, and water treatment companies expanding into resource recovery. The most promising initial market appears to be mid-sized battery material processors seeking to secure domestic supply chains in regions with established oil and gas infrastructure.

Pricing dynamics remain favorable despite recent lithium price volatility. Even with lithium carbonate prices retreating from 2022 peaks of $80,000/ton to current levels around $30,000-40,000/ton, the break-even point for most direct lithium extraction (DLE) technologies from produced water is estimated at $12,000-18,000/ton, maintaining substantial profit potential.

Current DLE Technologies and Technical Barriers

Direct Lithium Extraction (DLE) technologies have emerged as promising alternatives to traditional lithium extraction methods, particularly for unconventional sources like produced water and oilfield brines. Current DLE technologies can be categorized into several main approaches: adsorption-based methods, ion exchange processes, solvent extraction techniques, and membrane-based separation systems.

Adsorption-based technologies utilize specialized materials with high selectivity for lithium ions. These materials, including lithium aluminum layered double hydroxides (LDHs), lithium manganese oxides, and lithium titanium oxides, can selectively capture lithium from complex brine solutions. The process typically involves passing brine through columns containing these adsorbents, followed by a regeneration step using acid or base solutions to recover concentrated lithium.

Ion exchange technologies employ engineered resins or inorganic materials that preferentially exchange lithium ions for other ions. Companies like EnergyX and Lilac Solutions have developed proprietary ion exchange materials that can extract lithium from brines with minimal co-extraction of competing ions like sodium, magnesium, and calcium. These processes often achieve higher recovery rates than traditional evaporation methods.

Membrane-based separation technologies, including nanofiltration and electrodialysis, utilize selective membranes to separate lithium ions from other components in brine solutions. These methods can be energy-intensive but offer advantages in water conservation and processing speed compared to evaporation ponds.

Despite these technological advances, significant barriers remain in implementing DLE for oilfield brines. The primary technical challenge is the complex and variable composition of produced waters, which contain high concentrations of competing ions, particularly sodium, calcium, and magnesium, that can interfere with lithium selectivity. Additionally, the presence of organic compounds, suspended solids, and scaling agents in oilfield brines necessitates extensive pre-treatment steps.

Scalability presents another major hurdle. Many DLE technologies demonstrate promising results in laboratory settings but face challenges in scaling to commercial production levels. The high flow rates and volumes of produced water require robust systems capable of continuous operation under harsh conditions.

Energy requirements constitute a significant barrier, particularly for membrane and electrochemical processes. The energy intensity of these methods can impact economic viability, especially in remote locations where energy infrastructure is limited.

Material durability and longevity also present challenges. Adsorbents and ion exchange materials must withstand repeated cycling and exposure to complex brine chemistries without significant degradation in performance. Current materials often show diminished capacity and selectivity over multiple cycles, necessitating frequent replacement and increasing operational costs.

Adsorption-based technologies utilize specialized materials with high selectivity for lithium ions. These materials, including lithium aluminum layered double hydroxides (LDHs), lithium manganese oxides, and lithium titanium oxides, can selectively capture lithium from complex brine solutions. The process typically involves passing brine through columns containing these adsorbents, followed by a regeneration step using acid or base solutions to recover concentrated lithium.

Ion exchange technologies employ engineered resins or inorganic materials that preferentially exchange lithium ions for other ions. Companies like EnergyX and Lilac Solutions have developed proprietary ion exchange materials that can extract lithium from brines with minimal co-extraction of competing ions like sodium, magnesium, and calcium. These processes often achieve higher recovery rates than traditional evaporation methods.

Membrane-based separation technologies, including nanofiltration and electrodialysis, utilize selective membranes to separate lithium ions from other components in brine solutions. These methods can be energy-intensive but offer advantages in water conservation and processing speed compared to evaporation ponds.

Despite these technological advances, significant barriers remain in implementing DLE for oilfield brines. The primary technical challenge is the complex and variable composition of produced waters, which contain high concentrations of competing ions, particularly sodium, calcium, and magnesium, that can interfere with lithium selectivity. Additionally, the presence of organic compounds, suspended solids, and scaling agents in oilfield brines necessitates extensive pre-treatment steps.

Scalability presents another major hurdle. Many DLE technologies demonstrate promising results in laboratory settings but face challenges in scaling to commercial production levels. The high flow rates and volumes of produced water require robust systems capable of continuous operation under harsh conditions.

Energy requirements constitute a significant barrier, particularly for membrane and electrochemical processes. The energy intensity of these methods can impact economic viability, especially in remote locations where energy infrastructure is limited.

Material durability and longevity also present challenges. Adsorbents and ion exchange materials must withstand repeated cycling and exposure to complex brine chemistries without significant degradation in performance. Current materials often show diminished capacity and selectivity over multiple cycles, necessitating frequent replacement and increasing operational costs.

Technical Solutions for Direct Lithium Extraction

01 Adsorption-based DLE technologies

Adsorption-based Direct Lithium Extraction technologies utilize selective adsorbents to capture lithium ions from brine solutions. These materials can be engineered with specific functional groups that preferentially bind to lithium over competing ions like sodium, potassium, and magnesium. The process typically involves passing brine through columns containing these adsorbents, followed by a desorption step using an eluent to recover concentrated lithium. This approach offers advantages in selectivity and can work effectively with lower-grade brines compared to traditional evaporation methods.- Ion exchange materials for lithium extraction: Various ion exchange materials can be used in Direct Lithium Extraction (DLE) processes to selectively capture lithium ions from brines and other sources. These materials include specialized resins, membranes, and inorganic adsorbents that have high selectivity for lithium over competing ions such as sodium, potassium, and magnesium. The ion exchange process typically involves passing lithium-containing solutions through columns or beds containing these materials, followed by elution steps to recover concentrated lithium solutions.

- Electrochemical methods for lithium recovery: Electrochemical approaches to Direct Lithium Extraction utilize electrical potential differences to selectively separate lithium ions from source solutions. These methods include electrochemical cells with specialized membranes, capacitive deionization systems, and electrodialysis processes. The advantage of electrochemical methods is their ability to operate continuously with potentially lower chemical consumption compared to traditional extraction methods, while providing high selectivity for lithium ions even from low-concentration brines.

- Membrane-based separation technologies: Advanced membrane technologies play a crucial role in Direct Lithium Extraction processes by enabling selective separation of lithium from other components in brine solutions. These technologies include nanofiltration, forward osmosis, and specialized lithium-selective membranes that can effectively concentrate lithium while rejecting competing ions. Membrane-based systems often require less energy than traditional evaporation methods and can be designed for continuous operation with minimal chemical inputs.

- Sorbent materials and adsorption processes: Specialized sorbent materials designed for lithium adsorption represent a significant advancement in Direct Lithium Extraction technology. These materials include lithium-selective metal oxides, lithium manganese oxides, titanium-based adsorbents, and engineered porous materials with lithium-specific binding sites. The adsorption processes typically involve contacting these materials with lithium-containing solutions, followed by desorption steps using acids or other eluents to recover concentrated lithium solutions that can be further processed into battery-grade compounds.

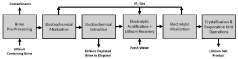

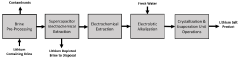

- Process integration and system optimization: Comprehensive DLE systems integrate multiple technologies and process steps to optimize lithium recovery efficiency, minimize environmental impact, and reduce operational costs. These integrated approaches combine pre-treatment steps, primary extraction technologies, and downstream processing to produce battery-grade lithium compounds. System optimization includes energy recovery systems, waste minimization strategies, and process control algorithms that adapt to varying feed compositions. Advanced DLE systems are designed to handle the specific challenges of different lithium sources while maximizing recovery rates and product purity.

02 Membrane and electrochemical DLE processes

Membrane and electrochemical Direct Lithium Extraction processes employ ion-selective membranes and electrical potential to separate lithium from brine solutions. These systems can include electrodialysis, capacitive deionization, or electrochemical cells that enable the selective transport of lithium ions across membranes while blocking other elements. The application of electrical potential creates driving forces that enhance separation efficiency and concentration factors. These technologies can operate continuously and often require less physical footprint compared to traditional evaporation ponds.Expand Specific Solutions03 Solvent extraction and chemical precipitation methods

Solvent extraction and chemical precipitation methods for Direct Lithium Extraction involve the use of specialized chemical reagents to selectively bind with lithium and transfer it between aqueous and organic phases, or to form lithium-containing precipitates that can be separated from solution. These processes often employ pH adjustment, temperature control, and specific complexing agents to enhance selectivity for lithium over competing ions. The methods can be particularly effective for processing concentrated brines and can achieve high recovery rates with proper optimization of reaction conditions.Expand Specific Solutions04 Integrated DLE systems and process optimization

Integrated Direct Lithium Extraction systems combine multiple extraction technologies with pre-treatment and post-processing steps to create comprehensive lithium recovery solutions. These systems often incorporate filtration, impurity removal, concentration, and purification stages to handle diverse brine compositions. Process optimization focuses on reducing energy consumption, minimizing chemical usage, maximizing lithium recovery rates, and enabling water recycling. Advanced control systems and real-time monitoring allow for adaptive operation based on changing feed conditions, enhancing overall efficiency and sustainability of the extraction process.Expand Specific Solutions05 Novel materials and sustainable DLE approaches

Novel materials and sustainable approaches for Direct Lithium Extraction focus on developing environmentally friendly extraction technologies with reduced environmental footprint. These include bio-inspired adsorbents, green solvents, renewable energy integration, and zero liquid discharge systems. Research in this area emphasizes materials with improved selectivity, durability, and regeneration capabilities, such as metal-organic frameworks, inorganic ion exchangers, and composite materials. Sustainable approaches also consider the entire lifecycle of the extraction process, including waste management, water conservation, and energy efficiency to minimize the environmental impact of lithium production.Expand Specific Solutions

Key Industry Players in Oilfield Brine Lithium Recovery

The direct lithium extraction (DLE) from produced water and oilfield brines represents an emerging market in the early growth stage, with global lithium demand projected to increase significantly due to electric vehicle battery requirements. The technology is advancing from pilot to commercial scale, with market size expected to reach several billion dollars by 2030. Technologically, companies are at varying maturity levels: established players like Schlumberger Technologies and China Petroleum & Chemical Corp. leverage their oilfield expertise to integrate DLE into existing operations, while specialized innovators such as Lilac Solutions, EnergyX, and Vulcan Energy are developing proprietary extraction technologies with lower environmental footprints. Academic institutions including The University of Chicago and Chinese Academy of Sciences are contributing fundamental research, creating a competitive landscape where partnerships between resource holders and technology providers are increasingly critical for commercial success.

Energy Exploration Technologies, Inc.

Technical Solution: EnergyX has developed a proprietary lithium extraction technology called LiTAS™ (Lithium Ion Transport and Separation), which utilizes advanced metal-organic framework (MOF) membranes for direct lithium extraction from brines. Their technology employs a mixed matrix membrane approach that selectively filters lithium ions from complex brine solutions. The system works through a combination of size exclusion and electrochemical processes, allowing lithium ions to pass through while blocking larger competing ions. This membrane-based approach enables continuous processing of brine without the need for large evaporation ponds. EnergyX claims their technology can recover up to 90% of available lithium in brines compared to traditional methods that typically recover 30-50%. The process is also significantly faster, reducing extraction time from months to days, and requires substantially less water and land use than conventional evaporation methods.

Strengths: Highly selective membrane technology; reduced water consumption; smaller physical footprint; faster extraction times; adaptable to various brine compositions; environmentally sustainable approach. Weaknesses: Relatively new technology with limited large-scale commercial deployment; potential membrane fouling in complex brine environments; higher initial capital investment; requires specialized expertise for operation and maintenance.

Baker Hughes Oilfield Operations LLC

Technical Solution: Baker Hughes has developed an integrated approach to lithium extraction from oilfield brines that leverages their extensive experience in oil and gas operations. Their technology combines selective adsorption materials with advanced filtration systems specifically designed to handle the high temperatures, pressures, and complex chemistries of oilfield produced waters. The process begins with pre-treatment to remove suspended solids and hydrocarbons, followed by a proprietary adsorption system that selectively captures lithium ions. Baker Hughes' system incorporates their expertise in materials science to develop adsorbents that can withstand the harsh conditions of oilfield brines while maintaining selectivity for lithium. The company has also developed specialized equipment for handling the high volumes of produced water generated at oil and gas operations, enabling lithium extraction to be integrated directly into existing production infrastructure. This approach allows for the valorization of what would otherwise be a waste stream, creating a circular economy opportunity within the energy sector.

Strengths: Extensive experience with oilfield fluids and infrastructure; ability to integrate with existing oil and gas operations; robust equipment designed for harsh conditions; global service network and technical support. Weaknesses: Technology still in development phase for commercial-scale implementation; may require significant customization for different oilfield brine compositions; competing priorities within a large diversified company.

Innovative Patents and Research in Brine Lithium Recovery

Method for the production of lithium carbonate from salt brines

PatentInactiveUS20190276328A1

Innovation

- A process utilizing mechanical evaporators to concentrate lithium-bearing salt brines, producing lithium carbonate along with sodium chloride and calcium chloride, which can be sold as by-products, allowing for continuous operation and improved economic viability.

Process for extraction and production of lithium salt products from brine

PatentInactiveAU2020200573A1

Innovation

- A synergistic integration of physical, chemical, and electrochemical mechanisms in a single unit operation using lithium-intercalating electrodes and an electrochemical control system to selectively extract and recover lithium, allowing for simultaneous extraction and precipitation of lithium salts, reducing the need for intermediate steps and minimizing contamination.

Environmental Impact Assessment of DLE Technologies

The environmental impact of Direct Lithium Extraction (DLE) technologies from produced water and oilfield brines represents a critical consideration in their development and deployment. Traditional lithium extraction methods, particularly evaporation ponds, have significant environmental footprints including high water consumption, land use, and chemical pollution. DLE technologies offer potential improvements but still present their own environmental challenges.

Water usage remains a primary concern for DLE operations. While these technologies generally require less water than evaporation ponds, they still consume substantial amounts during processing and regeneration phases. In water-stressed regions where many oilfield brines exist, this consumption could exacerbate existing water scarcity issues. Some advanced DLE systems have begun implementing closed-loop water recycling to mitigate this impact, though efficiency varies significantly between technologies.

Energy consumption constitutes another major environmental factor. Most DLE processes require considerable energy for pumping, heating, and regeneration of extraction materials. The carbon footprint of these operations depends heavily on the energy source utilized. Renewable energy integration could substantially reduce greenhouse gas emissions associated with DLE, though current implementations predominantly rely on conventional power sources.

Chemical usage in DLE processes presents additional environmental considerations. Sorbents, solvents, and other materials used in extraction may introduce contaminants if improperly managed. The production, transportation, and disposal of these chemicals contribute to the overall environmental impact. Newer generations of DLE technologies are focusing on developing more environmentally benign extraction materials with longer operational lifespans.

Waste management challenges also emerge from DLE operations. The concentrated brine streams produced after lithium extraction contain various minerals and potential contaminants that require proper disposal or further processing. Some innovative approaches are exploring the recovery of additional valuable minerals from these waste streams, potentially transforming an environmental liability into an economic opportunity.

Land disturbance from DLE facilities is generally less extensive than traditional evaporation methods, representing a significant environmental advantage. However, infrastructure requirements for processing facilities, pipelines, and transportation still create ecological disruption that must be managed through proper site selection and restoration practices.

Regulatory frameworks governing the environmental aspects of DLE technologies remain underdeveloped in many regions, creating uncertainty for both operators and communities. Comprehensive life cycle assessments and standardized environmental impact metrics will be essential for meaningful comparison between different DLE approaches and conventional lithium production methods.

Water usage remains a primary concern for DLE operations. While these technologies generally require less water than evaporation ponds, they still consume substantial amounts during processing and regeneration phases. In water-stressed regions where many oilfield brines exist, this consumption could exacerbate existing water scarcity issues. Some advanced DLE systems have begun implementing closed-loop water recycling to mitigate this impact, though efficiency varies significantly between technologies.

Energy consumption constitutes another major environmental factor. Most DLE processes require considerable energy for pumping, heating, and regeneration of extraction materials. The carbon footprint of these operations depends heavily on the energy source utilized. Renewable energy integration could substantially reduce greenhouse gas emissions associated with DLE, though current implementations predominantly rely on conventional power sources.

Chemical usage in DLE processes presents additional environmental considerations. Sorbents, solvents, and other materials used in extraction may introduce contaminants if improperly managed. The production, transportation, and disposal of these chemicals contribute to the overall environmental impact. Newer generations of DLE technologies are focusing on developing more environmentally benign extraction materials with longer operational lifespans.

Waste management challenges also emerge from DLE operations. The concentrated brine streams produced after lithium extraction contain various minerals and potential contaminants that require proper disposal or further processing. Some innovative approaches are exploring the recovery of additional valuable minerals from these waste streams, potentially transforming an environmental liability into an economic opportunity.

Land disturbance from DLE facilities is generally less extensive than traditional evaporation methods, representing a significant environmental advantage. However, infrastructure requirements for processing facilities, pipelines, and transportation still create ecological disruption that must be managed through proper site selection and restoration practices.

Regulatory frameworks governing the environmental aspects of DLE technologies remain underdeveloped in many regions, creating uncertainty for both operators and communities. Comprehensive life cycle assessments and standardized environmental impact metrics will be essential for meaningful comparison between different DLE approaches and conventional lithium production methods.

Economic Feasibility and ROI Analysis

The economic feasibility of Direct Lithium Extraction (DLE) from produced water and oilfield brines represents a critical consideration for industry stakeholders. Current economic analyses indicate that the capital expenditure for DLE facilities ranges between $20,000-$30,000 per ton of annual lithium carbonate equivalent (LCE) production capacity, significantly lower than traditional evaporation pond methods which require $30,000-$50,000 per ton.

Operational expenses for DLE technologies vary between $3,500-$7,500 per ton of LCE, depending on brine composition, lithium concentration, and selected technology. With lithium carbonate market prices fluctuating between $15,000-$75,000 per ton in recent years, the potential for substantial profit margins exists under favorable market conditions.

Return on investment calculations suggest that DLE projects can achieve payback periods of 3-7 years, contingent upon lithium concentration in the brine source. Brines containing over 100 mg/L lithium generally demonstrate more attractive economics, while those with 50-100 mg/L may still be viable depending on extraction efficiency and operational costs.

Sensitivity analysis reveals that project economics are most heavily influenced by three key factors: lithium concentration in source brines, extraction efficiency of the selected technology, and market prices for lithium products. A 10% increase in extraction efficiency can improve ROI by approximately 15-20%, highlighting the importance of technological optimization.

Co-production economics present a particularly compelling case for oil and gas operators. By implementing DLE as an add-on to existing operations, companies can leverage existing infrastructure, reducing capital requirements by 30-40% compared to standalone lithium extraction facilities. This integration creates a dual revenue stream with minimal additional operational complexity.

Scale considerations demonstrate significant economies of scale, with facilities processing over 20,000 barrels of brine per day achieving up to 25% lower per-unit production costs compared to smaller operations. This factor strongly favors partnerships between technology providers and large-scale oil and gas producers with access to substantial brine volumes.

Financing options for DLE projects have expanded as the technology matures, with traditional lenders becoming increasingly comfortable with the risk profile. Government incentives for critical mineral production and clean energy technologies further enhance project economics, potentially reducing effective tax rates by 5-10 percentage points in certain jurisdictions.

Operational expenses for DLE technologies vary between $3,500-$7,500 per ton of LCE, depending on brine composition, lithium concentration, and selected technology. With lithium carbonate market prices fluctuating between $15,000-$75,000 per ton in recent years, the potential for substantial profit margins exists under favorable market conditions.

Return on investment calculations suggest that DLE projects can achieve payback periods of 3-7 years, contingent upon lithium concentration in the brine source. Brines containing over 100 mg/L lithium generally demonstrate more attractive economics, while those with 50-100 mg/L may still be viable depending on extraction efficiency and operational costs.

Sensitivity analysis reveals that project economics are most heavily influenced by three key factors: lithium concentration in source brines, extraction efficiency of the selected technology, and market prices for lithium products. A 10% increase in extraction efficiency can improve ROI by approximately 15-20%, highlighting the importance of technological optimization.

Co-production economics present a particularly compelling case for oil and gas operators. By implementing DLE as an add-on to existing operations, companies can leverage existing infrastructure, reducing capital requirements by 30-40% compared to standalone lithium extraction facilities. This integration creates a dual revenue stream with minimal additional operational complexity.

Scale considerations demonstrate significant economies of scale, with facilities processing over 20,000 barrels of brine per day achieving up to 25% lower per-unit production costs compared to smaller operations. This factor strongly favors partnerships between technology providers and large-scale oil and gas producers with access to substantial brine volumes.

Financing options for DLE projects have expanded as the technology matures, with traditional lenders becoming increasingly comfortable with the risk profile. Government incentives for critical mineral production and clean energy technologies further enhance project economics, potentially reducing effective tax rates by 5-10 percentage points in certain jurisdictions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!