Product Quality And Battery-Grade Specifications For Direct Lithium Extraction

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DLE Technology Background and Objectives

Direct Lithium Extraction (DLE) technology has emerged as a revolutionary approach to lithium production, representing a significant departure from traditional extraction methods such as evaporation ponds and hard rock mining. The development of DLE can be traced back to the early 2000s, with significant advancements occurring in the past decade as global demand for lithium has surged due to the rapid growth of electric vehicle and energy storage markets.

The evolution of DLE technology has been driven by several factors, including the need for more environmentally sustainable extraction methods, reduced water consumption, smaller land footprint, and faster production cycles compared to conventional approaches. Traditional evaporation pond methods typically require 18-24 months to produce lithium carbonate, whereas DLE technologies aim to reduce this timeframe to days or weeks.

Current DLE technologies primarily utilize selective adsorption, ion exchange membranes, or solvent extraction processes to selectively capture lithium ions from brine solutions. These methods have demonstrated potential to achieve higher recovery rates (80-90%) compared to evaporation ponds (approximately 50%), while also producing higher purity lithium products.

The primary technical objective of DLE development is to consistently produce battery-grade lithium compounds that meet the stringent specifications required by lithium-ion battery manufacturers. Battery-grade lithium typically requires 99.5% or higher purity, with strict limits on impurities such as sodium, magnesium, calcium, and heavy metals that can negatively impact battery performance and safety.

Secondary objectives include optimizing the economic viability of DLE processes by reducing capital and operational expenditures, minimizing energy consumption, and developing technologies that can be effectively scaled to commercial production levels. Environmental sustainability objectives focus on minimizing water usage, reducing chemical consumption, and developing closed-loop systems that minimize waste generation.

Recent technological trends indicate a growing focus on developing DLE processes that can be tailored to specific brine chemistries, as lithium-rich brines vary significantly in composition across different geographical regions. Additionally, there is increasing emphasis on integrating DLE technologies with renewable energy sources to further reduce the carbon footprint of lithium production.

The ultimate goal of DLE technology advancement is to establish economically viable and environmentally sustainable production pathways that can meet the rapidly growing global demand for high-purity lithium compounds, particularly for electric vehicle batteries and grid-scale energy storage applications, while addressing the limitations of conventional extraction methods.

The evolution of DLE technology has been driven by several factors, including the need for more environmentally sustainable extraction methods, reduced water consumption, smaller land footprint, and faster production cycles compared to conventional approaches. Traditional evaporation pond methods typically require 18-24 months to produce lithium carbonate, whereas DLE technologies aim to reduce this timeframe to days or weeks.

Current DLE technologies primarily utilize selective adsorption, ion exchange membranes, or solvent extraction processes to selectively capture lithium ions from brine solutions. These methods have demonstrated potential to achieve higher recovery rates (80-90%) compared to evaporation ponds (approximately 50%), while also producing higher purity lithium products.

The primary technical objective of DLE development is to consistently produce battery-grade lithium compounds that meet the stringent specifications required by lithium-ion battery manufacturers. Battery-grade lithium typically requires 99.5% or higher purity, with strict limits on impurities such as sodium, magnesium, calcium, and heavy metals that can negatively impact battery performance and safety.

Secondary objectives include optimizing the economic viability of DLE processes by reducing capital and operational expenditures, minimizing energy consumption, and developing technologies that can be effectively scaled to commercial production levels. Environmental sustainability objectives focus on minimizing water usage, reducing chemical consumption, and developing closed-loop systems that minimize waste generation.

Recent technological trends indicate a growing focus on developing DLE processes that can be tailored to specific brine chemistries, as lithium-rich brines vary significantly in composition across different geographical regions. Additionally, there is increasing emphasis on integrating DLE technologies with renewable energy sources to further reduce the carbon footprint of lithium production.

The ultimate goal of DLE technology advancement is to establish economically viable and environmentally sustainable production pathways that can meet the rapidly growing global demand for high-purity lithium compounds, particularly for electric vehicle batteries and grid-scale energy storage applications, while addressing the limitations of conventional extraction methods.

Market Demand Analysis for Battery-Grade Lithium

The global lithium market is experiencing unprecedented growth, primarily driven by the rapid expansion of the electric vehicle (EV) industry and renewable energy storage systems. Current projections indicate the global lithium demand will reach 1.5 million metric tons of lithium carbonate equivalent (LCE) by 2030, representing a compound annual growth rate (CAGR) of approximately 20% from 2023 levels. Battery-grade lithium, which requires 99.5% or higher purity, constitutes over 80% of this demand.

The EV sector remains the dominant consumer of battery-grade lithium, with major automotive manufacturers accelerating their electrification strategies. Tesla, Volkswagen, GM, and BYD have collectively committed over $300 billion to EV development through 2030, necessitating secure lithium supply chains. Industry analysts forecast global EV sales to exceed 30 million units annually by 2030, representing a seven-fold increase from 2022 levels.

Energy storage systems (ESS) represent the second-largest growth segment for battery-grade lithium demand. Grid-scale storage installations are projected to increase by 25% annually through 2030, driven by renewable energy integration requirements and grid stabilization needs. Countries with ambitious renewable energy targets, particularly China, the United States, and the European Union, are leading this expansion.

Consumer electronics continues to provide stable demand for high-purity lithium, though its market share is decreasing relative to EVs and ESS applications. Nevertheless, the sector still accounts for approximately 15% of battery-grade lithium consumption.

Regional demand patterns show Asia-Pacific, particularly China, dominating consumption with over 65% of global battery-grade lithium utilization. However, significant growth is emerging in North America and Europe as these regions establish domestic battery manufacturing capabilities to reduce dependency on Asian supply chains.

Price sensitivity analysis reveals battery manufacturers are willing to pay premium prices for consistent, high-quality lithium products that meet stringent specifications. The price differential between technical-grade and battery-grade lithium has widened to 30-40%, highlighting the value placed on purity and consistency.

Direct Lithium Extraction (DLE) technologies are gaining attention specifically because they can potentially deliver higher purity lithium products with fewer processing steps than traditional extraction methods. Market research indicates that lithium producers who can consistently deliver battery-grade specifications through DLE methods could command price premiums of 15-20% over conventional producers.

The market increasingly demands sustainable production practices, with major battery manufacturers and automakers establishing environmental, social, and governance (ESG) requirements for their lithium suppliers. DLE methods that minimize water usage and environmental footprint are therefore positioned advantageously in this evolving market landscape.

The EV sector remains the dominant consumer of battery-grade lithium, with major automotive manufacturers accelerating their electrification strategies. Tesla, Volkswagen, GM, and BYD have collectively committed over $300 billion to EV development through 2030, necessitating secure lithium supply chains. Industry analysts forecast global EV sales to exceed 30 million units annually by 2030, representing a seven-fold increase from 2022 levels.

Energy storage systems (ESS) represent the second-largest growth segment for battery-grade lithium demand. Grid-scale storage installations are projected to increase by 25% annually through 2030, driven by renewable energy integration requirements and grid stabilization needs. Countries with ambitious renewable energy targets, particularly China, the United States, and the European Union, are leading this expansion.

Consumer electronics continues to provide stable demand for high-purity lithium, though its market share is decreasing relative to EVs and ESS applications. Nevertheless, the sector still accounts for approximately 15% of battery-grade lithium consumption.

Regional demand patterns show Asia-Pacific, particularly China, dominating consumption with over 65% of global battery-grade lithium utilization. However, significant growth is emerging in North America and Europe as these regions establish domestic battery manufacturing capabilities to reduce dependency on Asian supply chains.

Price sensitivity analysis reveals battery manufacturers are willing to pay premium prices for consistent, high-quality lithium products that meet stringent specifications. The price differential between technical-grade and battery-grade lithium has widened to 30-40%, highlighting the value placed on purity and consistency.

Direct Lithium Extraction (DLE) technologies are gaining attention specifically because they can potentially deliver higher purity lithium products with fewer processing steps than traditional extraction methods. Market research indicates that lithium producers who can consistently deliver battery-grade specifications through DLE methods could command price premiums of 15-20% over conventional producers.

The market increasingly demands sustainable production practices, with major battery manufacturers and automakers establishing environmental, social, and governance (ESG) requirements for their lithium suppliers. DLE methods that minimize water usage and environmental footprint are therefore positioned advantageously in this evolving market landscape.

Current DLE Technical Challenges and Limitations

Despite significant advancements in Direct Lithium Extraction (DLE) technologies, several critical challenges persist that limit widespread commercial adoption and consistent production of battery-grade lithium compounds. The primary technical hurdle remains the selective extraction of lithium from complex brines containing numerous competing ions such as sodium, potassium, magnesium, and calcium. These competing ions often interfere with extraction processes, reducing efficiency and contaminating the final product.

Water consumption represents another significant limitation, as many DLE processes require substantial freshwater inputs for regeneration cycles and washing steps. This creates sustainability concerns, particularly in water-scarce regions where many lithium resources are located. The water footprint of DLE operations can undermine the environmental benefits these technologies promise compared to traditional evaporation methods.

Energy requirements pose additional challenges, with many DLE technologies demanding considerable electrical or thermal energy inputs. This increases operational costs and potentially diminishes the environmental advantages of DLE processes, especially when power sources are carbon-intensive. The energy intensity varies significantly between different DLE approaches, with electrochemical methods typically requiring more energy than adsorption-based systems.

Sorbent performance limitations represent a critical technical barrier. Current lithium-selective sorbents and ion exchange materials often suffer from capacity degradation over multiple cycles, reducing their economic viability. Additionally, many sorbents demonstrate insufficient selectivity for lithium over competing ions, particularly in high-magnesium brines, necessitating additional purification steps.

Process scalability remains problematic, with many promising laboratory-scale technologies facing significant engineering challenges during scale-up. Continuous operation at commercial volumes introduces complexities in fluid dynamics, mass transfer, and process control that are not evident in smaller-scale demonstrations.

Meeting battery-grade specifications consistently presents perhaps the most significant commercial challenge. Battery manufacturers require lithium compounds with 99.5% or higher purity and strict limits on specific impurities like sodium (<20 ppm), potassium (<10 ppm), calcium (<5 ppm), and magnesium (<5 ppm). Current DLE processes often struggle to achieve these specifications without additional downstream processing steps, which add cost and complexity.

Waste management also poses significant operational challenges. The regeneration chemicals, spent sorbents, and rejected brine streams require proper handling and disposal. These waste streams may contain concentrated levels of potentially harmful elements that were present in the original brine, creating environmental management challenges.

Water consumption represents another significant limitation, as many DLE processes require substantial freshwater inputs for regeneration cycles and washing steps. This creates sustainability concerns, particularly in water-scarce regions where many lithium resources are located. The water footprint of DLE operations can undermine the environmental benefits these technologies promise compared to traditional evaporation methods.

Energy requirements pose additional challenges, with many DLE technologies demanding considerable electrical or thermal energy inputs. This increases operational costs and potentially diminishes the environmental advantages of DLE processes, especially when power sources are carbon-intensive. The energy intensity varies significantly between different DLE approaches, with electrochemical methods typically requiring more energy than adsorption-based systems.

Sorbent performance limitations represent a critical technical barrier. Current lithium-selective sorbents and ion exchange materials often suffer from capacity degradation over multiple cycles, reducing their economic viability. Additionally, many sorbents demonstrate insufficient selectivity for lithium over competing ions, particularly in high-magnesium brines, necessitating additional purification steps.

Process scalability remains problematic, with many promising laboratory-scale technologies facing significant engineering challenges during scale-up. Continuous operation at commercial volumes introduces complexities in fluid dynamics, mass transfer, and process control that are not evident in smaller-scale demonstrations.

Meeting battery-grade specifications consistently presents perhaps the most significant commercial challenge. Battery manufacturers require lithium compounds with 99.5% or higher purity and strict limits on specific impurities like sodium (<20 ppm), potassium (<10 ppm), calcium (<5 ppm), and magnesium (<5 ppm). Current DLE processes often struggle to achieve these specifications without additional downstream processing steps, which add cost and complexity.

Waste management also poses significant operational challenges. The regeneration chemicals, spent sorbents, and rejected brine streams require proper handling and disposal. These waste streams may contain concentrated levels of potentially harmful elements that were present in the original brine, creating environmental management challenges.

Current DLE Product Quality Solutions

01 Battery-grade lithium purity specifications

Battery-grade lithium compounds require high purity levels to ensure optimal battery performance. Direct Lithium Extraction (DLE) processes must achieve specific purity thresholds, typically 99.5% or higher for lithium carbonate and lithium hydroxide. These specifications include strict limits on impurities such as sodium, potassium, calcium, magnesium, and heavy metals that can negatively impact battery efficiency and lifespan. Advanced purification techniques are employed to meet these stringent requirements for use in high-performance lithium-ion batteries.- Battery-grade lithium purity specifications: Battery-grade lithium compounds require high purity levels to ensure optimal battery performance. Direct Lithium Extraction (DLE) processes must produce lithium products with minimal impurities, typically 99.5% or higher purity for battery applications. Key specifications include low levels of sodium, potassium, calcium, magnesium, and heavy metals. These stringent requirements are essential for preventing degradation of battery performance and ensuring consistent electrochemical properties in lithium-ion batteries.

- DLE purification technologies for battery-grade lithium: Various purification technologies are employed in DLE processes to achieve battery-grade specifications. These include ion exchange resins, selective adsorption materials, membrane filtration, and electrochemical methods. Advanced purification steps often involve multiple stages to progressively remove impurities and concentrate lithium compounds. These technologies are specifically designed to handle the unique challenges of different lithium-rich brines and to efficiently separate lithium from competing ions while minimizing environmental impact.

- Quality control and testing methods for DLE products: Rigorous quality control protocols are essential for ensuring DLE products meet battery-grade specifications. Testing methods include inductively coupled plasma (ICP) spectroscopy, atomic absorption spectroscopy, X-ray diffraction, and electrochemical performance testing. Continuous monitoring throughout the extraction and purification process helps maintain consistent product quality. These analytical techniques verify the chemical composition, crystalline structure, and electrochemical behavior of the lithium compounds to ensure they meet the strict requirements for battery applications.

- Process optimization for battery-grade lithium production: Optimizing DLE processes is crucial for consistently achieving battery-grade specifications. This involves careful control of process parameters such as temperature, pH, residence time, and reagent concentrations. Advanced process control systems, including real-time monitoring and automated adjustments, help maintain optimal extraction conditions. Process optimization also focuses on minimizing reagent consumption, reducing energy requirements, and increasing lithium recovery rates while ensuring the final product meets battery-grade purity standards.

- Conversion processes for battery-grade lithium compounds: After initial extraction and purification, DLE products often require conversion into specific lithium compounds suitable for battery applications. These conversion processes transform lithium chloride or lithium sulfate into battery-grade lithium carbonate, lithium hydroxide, or lithium phosphate. The conversion steps must be carefully controlled to maintain product purity and achieve the desired physical properties, such as particle size and morphology, which significantly impact battery performance. Advanced crystallization and precipitation techniques are employed to ensure consistent product quality.

02 DLE purification technologies for battery-grade lithium

Various purification technologies are employed in DLE processes to achieve battery-grade lithium quality. These include ion exchange resins, selective adsorption materials, membrane filtration, and solvent extraction methods. Each technology offers specific advantages in removing particular impurities from lithium-rich solutions. Multi-stage purification processes are often implemented to progressively eliminate contaminants and achieve the high purity levels required for battery applications. The selection of purification technology depends on the source brine composition and target product specifications.Expand Specific Solutions03 Quality control and testing methods for DLE lithium products

Rigorous quality control protocols and testing methods are essential for ensuring DLE lithium products meet battery-grade specifications. These include inductively coupled plasma (ICP) spectroscopy, atomic absorption spectroscopy, X-ray diffraction, and particle size analysis. Continuous monitoring throughout the production process helps maintain consistent quality. Testing focuses on chemical composition, crystal structure, particle morphology, and electrochemical performance to verify suitability for battery applications. Standardized testing procedures ensure compliance with industry specifications and customer requirements.Expand Specific Solutions04 Process optimization for battery-grade lithium production

Optimizing DLE processes is crucial for consistently producing battery-grade lithium compounds. This involves precise control of extraction parameters such as temperature, pH, residence time, and reagent concentrations. Advanced process control systems with real-time monitoring capabilities help maintain optimal operating conditions. Process integration strategies minimize contamination risks and energy consumption while maximizing lithium recovery rates. Continuous improvement methodologies are implemented to enhance product quality and production efficiency, ensuring consistent compliance with battery-grade specifications.Expand Specific Solutions05 Sustainable DLE approaches for high-quality lithium production

Sustainable DLE approaches focus on environmentally responsible methods for producing battery-grade lithium. These include water-efficient extraction techniques, renewable energy integration, and closed-loop systems that minimize waste generation. Advanced recovery methods reduce chemical consumption and environmental footprint while maintaining high product quality. Eco-friendly reagents and processes are developed to achieve sustainability goals without compromising lithium purity. These approaches address growing industry demands for environmentally responsible battery materials while meeting stringent quality specifications.Expand Specific Solutions

Key Industry Players in DLE Technology

Direct Lithium Extraction (DLE) technology is currently in an early growth phase, with the global market expected to expand significantly due to increasing demand for high-quality battery-grade lithium. The competitive landscape features established battery manufacturers like GS Yuasa, CATL, and Samsung SDI alongside specialized extraction technology developers such as Vulcan Energy, Watercycle Technologies, and Terralithium. Technical challenges remain in achieving consistent battery-grade specifications, with companies focusing on improving extraction efficiency, purity levels, and environmental sustainability. CATL's subsidiary Guangdong Bangpu Recycling is advancing recycling technologies, while academic institutions like Penn State Research Foundation and Karlsruhe Institute of Technology are contributing fundamental research. The industry is transitioning from pilot projects to commercial-scale operations, with significant investment flowing into technologies that can meet stringent battery-grade lithium specifications while reducing environmental impact.

Orocobre Ltd.

Technical Solution: Orocobre (现已更名为Allkem)开发了先进的吸附剂技术用于直接锂提取,专注于从盐湖卤水中高效提取锂。其技术方案采用专有的选择性吸附材料,能在不依赖传统蒸发池的情况下从卤水中分离锂离子。该系统使用可再生的吸附剂,通过多级柱状反应器实现连续处理,显著减少了水消耗(约减少90%)和土地占用(减少约60%)[1]。Orocobre的DLE技术特别适用于锂含量较低但杂质含量高的卤水资源,能够生产符合电池级规格(99.5%纯度)的碳酸锂产品,同时实现了从提取到最终产品的全流程质量控制[3]。

优势:水足迹显著降低,生产周期从传统方法的18个月缩短至几天,适应性强,可处理多种卤水成分。提取效率高达90%以上,远超传统蒸发法的40-50%。劣势:初始资本投入较高,能源消耗相对较大,技术在大规模商业化应用方面仍需进一步验证。

Vulcan Energie Ressourcen GmbH

Technical Solution: Vulcan Energy开发了一种创新的"零碳锂"提取技术,结合地热能源与直接锂提取。其技术方案利用深层地热卤水作为锂源,同时利用地热能为提取过程提供可再生能源。该系统采用专利的吸附剂技术(SORPTION),能够选择性地从地热卤水中捕获锂离子,而不提取其他元素[2]。Vulcan的工艺流程包括:从4-5公里深处抽取富含锂的地热卤水,通过热交换器产生可再生电力,然后将卤水通过DLE装置提取锂,最后将处理后的卤水重新注入地下。该技术能生产纯度超过99.9%的电池级氢氧化锂,完全符合电池制造商的严格规格要求[4][5]。整个过程实现了碳中和,无需大量淡水消耗,也不产生采矿废料。

优势:碳足迹极低,实现了真正的零碳锂生产;生产效率高,从提取到最终产品仅需几天时间;资源利用高效,同时生产可再生能源和锂产品。劣势:技术依赖特定的地质条件(需要合适的地热卤水资源);初期资本支出高;技术相对较新,大规模商业化验证仍在进行中。

Critical Patents and Innovations in DLE Processes

Process and product

PatentPendingUS20250161879A1

Innovation

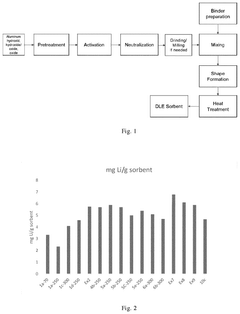

- The process involves contacting an aqueous lithium solution with a lithium sorbent to absorb lithium, followed by separation of the loaded sorbent and depleted solution, and subsequent treatment to regenerate the sorbent. This process utilizes pH control to maintain the lithium depleted solution at a pH of about 3 to 7 and employs ultrafiltration or nanofiltration membranes for separation.

Direct lithium extraction compositions and methods

PatentActiveUS12285740B1

Innovation

- The development of a sorbent composition comprising a lithiated aluminum component, such as lithiated aluminum trihydroxide, combined with an inorganic binder, which is shaped into particles with a controlled size and surface area, and heat-treated to enhance lithium adsorption capacity and stability.

Environmental Impact Assessment of DLE Methods

Direct Lithium Extraction (DLE) technologies, while promising for lithium production efficiency, carry significant environmental implications that require thorough assessment. Traditional lithium extraction methods such as evaporation ponds and hard rock mining have well-documented environmental impacts including extensive water consumption, land disturbance, and chemical pollution. DLE methods present both potential improvements and new environmental challenges that must be evaluated comprehensively.

Water usage represents a critical environmental factor in DLE operations. While many DLE technologies claim reduced water consumption compared to evaporation ponds, the actual water footprint varies significantly between different DLE methods. Adsorption-based systems typically require water for regeneration cycles, while membrane systems need water for maintenance and cleaning. Quantitative analysis indicates that advanced DLE systems can achieve 30-65% reduction in water usage compared to traditional methods, though this efficiency depends heavily on system design and local water availability.

Chemical usage in DLE processes presents another environmental consideration. Most DLE methods require sorbents, ion exchange resins, or membrane systems that involve chemical regeneration. The environmental impact of these chemicals depends on their toxicity, biodegradability, and potential for recovery and reuse. Recent advancements in green chemistry have led to the development of more environmentally benign sorbents, though their commercial viability remains under investigation.

Energy consumption represents a significant environmental factor for DLE operations. The energy intensity of DLE varies by technology type, with electrochemical systems typically requiring more energy than passive adsorption systems. Life cycle assessments indicate that the carbon footprint of DLE operations is heavily influenced by the energy source, with renewable energy integration offering substantial environmental benefits. Studies suggest that DLE powered by renewable energy can reduce greenhouse gas emissions by 40-80% compared to conventional extraction methods.

Waste management considerations include the handling of spent sorbents, membranes, and process residues. The environmental sustainability of DLE depends significantly on establishing effective recycling pathways for these materials. Current research focuses on extending sorbent lifespans and developing closed-loop systems that minimize waste generation.

Land use impacts of DLE are generally less extensive than traditional extraction methods, representing a potential environmental advantage. DLE facilities typically require 70-90% less land area than equivalent-capacity evaporation pond operations, reducing habitat disruption and biodiversity impacts. However, the construction of DLE facilities in sensitive ecosystems still requires careful environmental planning and mitigation strategies.

Water usage represents a critical environmental factor in DLE operations. While many DLE technologies claim reduced water consumption compared to evaporation ponds, the actual water footprint varies significantly between different DLE methods. Adsorption-based systems typically require water for regeneration cycles, while membrane systems need water for maintenance and cleaning. Quantitative analysis indicates that advanced DLE systems can achieve 30-65% reduction in water usage compared to traditional methods, though this efficiency depends heavily on system design and local water availability.

Chemical usage in DLE processes presents another environmental consideration. Most DLE methods require sorbents, ion exchange resins, or membrane systems that involve chemical regeneration. The environmental impact of these chemicals depends on their toxicity, biodegradability, and potential for recovery and reuse. Recent advancements in green chemistry have led to the development of more environmentally benign sorbents, though their commercial viability remains under investigation.

Energy consumption represents a significant environmental factor for DLE operations. The energy intensity of DLE varies by technology type, with electrochemical systems typically requiring more energy than passive adsorption systems. Life cycle assessments indicate that the carbon footprint of DLE operations is heavily influenced by the energy source, with renewable energy integration offering substantial environmental benefits. Studies suggest that DLE powered by renewable energy can reduce greenhouse gas emissions by 40-80% compared to conventional extraction methods.

Waste management considerations include the handling of spent sorbents, membranes, and process residues. The environmental sustainability of DLE depends significantly on establishing effective recycling pathways for these materials. Current research focuses on extending sorbent lifespans and developing closed-loop systems that minimize waste generation.

Land use impacts of DLE are generally less extensive than traditional extraction methods, representing a potential environmental advantage. DLE facilities typically require 70-90% less land area than equivalent-capacity evaporation pond operations, reducing habitat disruption and biodiversity impacts. However, the construction of DLE facilities in sensitive ecosystems still requires careful environmental planning and mitigation strategies.

Regulatory Framework for Lithium Production Standards

The regulatory landscape for lithium production is becoming increasingly complex as the demand for battery-grade lithium continues to surge globally. International standards organizations such as ISO and ASTM International have developed specific guidelines for lithium compounds used in battery applications, establishing threshold requirements for impurity levels, particle size distribution, and chemical composition. These standards serve as benchmarks for manufacturers and provide a common language for quality assessment across the supply chain.

In the United States, the Department of Energy has implemented the Federal Battery Research and Development Act, which includes provisions for standardizing battery materials including lithium compounds. The Environmental Protection Agency also regulates extraction processes through the Resource Conservation and Recovery Act, particularly focusing on waste management and environmental impact of extraction technologies.

The European Union has established more stringent frameworks through the European Chemicals Agency (ECHA) and REACH regulations, which mandate comprehensive documentation of chemical properties and potential hazards. The EU Battery Directive specifically addresses battery material standards and is currently being updated to include more detailed specifications for lithium extraction and processing methods.

In Asia, China has emerged as a leader in establishing national standards for battery-grade lithium through its GB/T framework. The China National Technical Committee of Standardization for Batteries has published detailed specifications for lithium carbonate and lithium hydroxide purity levels, which often exceed international requirements. These standards have significant global influence due to China's dominant position in the lithium processing industry.

Industry consortia also play a crucial role in standard-setting. The Global Battery Alliance and the International Lithium Association have developed voluntary standards and certification programs that are increasingly being adopted by major manufacturers and suppliers. These industry-led initiatives often precede formal regulatory requirements and help establish best practices for quality control.

Emerging regulatory trends indicate a move toward lifecycle assessment requirements, where producers must demonstrate environmental sustainability across the entire production chain. Several jurisdictions are developing frameworks that will require lithium producers to quantify carbon footprints, water usage efficiency, and land restoration plans as part of their compliance documentation.

For Direct Lithium Extraction technologies specifically, regulatory frameworks are still evolving, with many countries developing specialized standards that address the unique characteristics of these newer extraction methods compared to traditional evaporation pond techniques.

In the United States, the Department of Energy has implemented the Federal Battery Research and Development Act, which includes provisions for standardizing battery materials including lithium compounds. The Environmental Protection Agency also regulates extraction processes through the Resource Conservation and Recovery Act, particularly focusing on waste management and environmental impact of extraction technologies.

The European Union has established more stringent frameworks through the European Chemicals Agency (ECHA) and REACH regulations, which mandate comprehensive documentation of chemical properties and potential hazards. The EU Battery Directive specifically addresses battery material standards and is currently being updated to include more detailed specifications for lithium extraction and processing methods.

In Asia, China has emerged as a leader in establishing national standards for battery-grade lithium through its GB/T framework. The China National Technical Committee of Standardization for Batteries has published detailed specifications for lithium carbonate and lithium hydroxide purity levels, which often exceed international requirements. These standards have significant global influence due to China's dominant position in the lithium processing industry.

Industry consortia also play a crucial role in standard-setting. The Global Battery Alliance and the International Lithium Association have developed voluntary standards and certification programs that are increasingly being adopted by major manufacturers and suppliers. These industry-led initiatives often precede formal regulatory requirements and help establish best practices for quality control.

Emerging regulatory trends indicate a move toward lifecycle assessment requirements, where producers must demonstrate environmental sustainability across the entire production chain. Several jurisdictions are developing frameworks that will require lithium producers to quantify carbon footprints, water usage efficiency, and land restoration plans as part of their compliance documentation.

For Direct Lithium Extraction technologies specifically, regulatory frameworks are still evolving, with many countries developing specialized standards that address the unique characteristics of these newer extraction methods compared to traditional evaporation pond techniques.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!