Selectivity And Capacity Of Ion Sieve Sorbents For Direct Lithium Extraction

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ion Sieve Technology Background and Objectives

Ion sieve technology represents a significant advancement in the field of selective ion extraction, particularly for lithium recovery from various sources. The concept of ion sieves emerged in the 1970s, initially developed for applications in water treatment and rare earth element separation. Over the past five decades, this technology has evolved substantially, with a marked acceleration in research and development efforts focused on lithium extraction during the last decade, driven by the growing demand for lithium in battery technologies.

The fundamental principle of ion sieves involves the creation of host materials with specific cavity sizes and chemical environments that preferentially adsorb target ions while excluding others. For lithium extraction, manganese oxide-based ion sieves have historically dominated the field, with λ-MnO2 structures derived from lithium manganese oxides being particularly prominent due to their lithium-specific adsorption sites.

Recent technological evolution has expanded beyond manganese-based materials to include titanium-based sorbents, vanadium-based compounds, and various metal organic frameworks (MOFs). Each generation of materials has addressed specific limitations of previous iterations, such as improved stability in acidic environments, enhanced cycling performance, and increased lithium uptake capacity.

The global trajectory of ion sieve technology development shows a clear shift from laboratory-scale proof-of-concept studies toward pilot-scale demonstrations and commercial implementations. This progression reflects the maturation of the technology and its increasing readiness for industrial application in direct lithium extraction (DLE) processes.

The primary technical objectives for ion sieve sorbents in lithium extraction applications include achieving high selectivity for lithium over competing ions (particularly sodium, potassium, magnesium, and calcium), maximizing adsorption capacity, ensuring rapid kinetics for efficient processing, maintaining stability over multiple adsorption-desorption cycles, and developing cost-effective synthesis methods suitable for large-scale production.

Additionally, environmental considerations have become increasingly important in technology development goals, with emphasis on reducing chemical consumption, minimizing waste generation, and lowering the overall energy footprint of the extraction process. These objectives align with broader sustainability goals in critical mineral recovery.

Looking forward, the technology aims to enable economically viable extraction of lithium from unconventional sources such as geothermal brines, oilfield produced waters, and seawater, which contain significantly lower lithium concentrations than traditional brine resources but represent vastly larger potential reserves. Success in these applications would fundamentally transform global lithium supply chains and potentially alleviate resource constraints for the expanding electric vehicle and energy storage markets.

The fundamental principle of ion sieves involves the creation of host materials with specific cavity sizes and chemical environments that preferentially adsorb target ions while excluding others. For lithium extraction, manganese oxide-based ion sieves have historically dominated the field, with λ-MnO2 structures derived from lithium manganese oxides being particularly prominent due to their lithium-specific adsorption sites.

Recent technological evolution has expanded beyond manganese-based materials to include titanium-based sorbents, vanadium-based compounds, and various metal organic frameworks (MOFs). Each generation of materials has addressed specific limitations of previous iterations, such as improved stability in acidic environments, enhanced cycling performance, and increased lithium uptake capacity.

The global trajectory of ion sieve technology development shows a clear shift from laboratory-scale proof-of-concept studies toward pilot-scale demonstrations and commercial implementations. This progression reflects the maturation of the technology and its increasing readiness for industrial application in direct lithium extraction (DLE) processes.

The primary technical objectives for ion sieve sorbents in lithium extraction applications include achieving high selectivity for lithium over competing ions (particularly sodium, potassium, magnesium, and calcium), maximizing adsorption capacity, ensuring rapid kinetics for efficient processing, maintaining stability over multiple adsorption-desorption cycles, and developing cost-effective synthesis methods suitable for large-scale production.

Additionally, environmental considerations have become increasingly important in technology development goals, with emphasis on reducing chemical consumption, minimizing waste generation, and lowering the overall energy footprint of the extraction process. These objectives align with broader sustainability goals in critical mineral recovery.

Looking forward, the technology aims to enable economically viable extraction of lithium from unconventional sources such as geothermal brines, oilfield produced waters, and seawater, which contain significantly lower lithium concentrations than traditional brine resources but represent vastly larger potential reserves. Success in these applications would fundamentally transform global lithium supply chains and potentially alleviate resource constraints for the expanding electric vehicle and energy storage markets.

Market Analysis for Lithium Extraction Technologies

The global lithium market has experienced unprecedented growth in recent years, primarily driven by the rapid expansion of electric vehicle (EV) production and renewable energy storage systems. The market value for lithium extraction technologies reached approximately $1.7 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 12.3% through 2030, potentially reaching $4.3 billion by that time.

Traditional lithium extraction methods, including hard rock mining and evaporative brine processing, currently dominate the market with over 80% market share. However, Direct Lithium Extraction (DLE) technologies, particularly ion sieve sorbents, are gaining significant traction due to their environmental advantages and efficiency improvements. Market analysis indicates that DLE technologies could capture up to 25% of the lithium extraction market by 2028.

The demand for high-selectivity ion sieve sorbents is particularly strong in regions with complex brine compositions, such as South America's "Lithium Triangle" (Argentina, Bolivia, and Chile) and salt lakes in China. These regions collectively hold approximately 70% of the world's lithium reserves but face challenges with traditional extraction methods due to high magnesium-to-lithium ratios.

Key market drivers for selective ion sieve technologies include increasingly stringent environmental regulations, water conservation requirements, and the push for faster production cycles. The market premium for technologies that can achieve lithium recovery rates above 90% with minimal water usage is estimated at 30-40% compared to conventional methods.

Industry analysis reveals that automotive and battery manufacturers are increasingly investing directly in lithium extraction technologies to secure supply chains. In 2022 alone, over $2.5 billion was invested in DLE startups and research initiatives, with approximately 40% focused specifically on improving ion sieve selectivity and capacity.

The competitive landscape shows a mix of established mining companies adapting their processes and specialized technology startups focusing exclusively on advanced sorbent development. The market is currently fragmented, with no single technology holding more than 15% market share in the DLE segment.

Regional market analysis indicates that North America is experiencing the fastest growth in DLE technology adoption (18% annually), followed by Asia-Pacific (15%) and Europe (12%). This growth pattern correlates strongly with regional EV production forecasts and government initiatives supporting domestic lithium production capabilities.

Traditional lithium extraction methods, including hard rock mining and evaporative brine processing, currently dominate the market with over 80% market share. However, Direct Lithium Extraction (DLE) technologies, particularly ion sieve sorbents, are gaining significant traction due to their environmental advantages and efficiency improvements. Market analysis indicates that DLE technologies could capture up to 25% of the lithium extraction market by 2028.

The demand for high-selectivity ion sieve sorbents is particularly strong in regions with complex brine compositions, such as South America's "Lithium Triangle" (Argentina, Bolivia, and Chile) and salt lakes in China. These regions collectively hold approximately 70% of the world's lithium reserves but face challenges with traditional extraction methods due to high magnesium-to-lithium ratios.

Key market drivers for selective ion sieve technologies include increasingly stringent environmental regulations, water conservation requirements, and the push for faster production cycles. The market premium for technologies that can achieve lithium recovery rates above 90% with minimal water usage is estimated at 30-40% compared to conventional methods.

Industry analysis reveals that automotive and battery manufacturers are increasingly investing directly in lithium extraction technologies to secure supply chains. In 2022 alone, over $2.5 billion was invested in DLE startups and research initiatives, with approximately 40% focused specifically on improving ion sieve selectivity and capacity.

The competitive landscape shows a mix of established mining companies adapting their processes and specialized technology startups focusing exclusively on advanced sorbent development. The market is currently fragmented, with no single technology holding more than 15% market share in the DLE segment.

Regional market analysis indicates that North America is experiencing the fastest growth in DLE technology adoption (18% annually), followed by Asia-Pacific (15%) and Europe (12%). This growth pattern correlates strongly with regional EV production forecasts and government initiatives supporting domestic lithium production capabilities.

Current Challenges in Ion Sieve Sorbent Development

Despite significant advancements in ion sieve sorbent technology for direct lithium extraction (DLE), several critical challenges continue to impede widespread commercial implementation. The most pressing issue remains the trade-off between selectivity and capacity. Current ion sieve materials that demonstrate high lithium selectivity often suffer from limited adsorption capacity, while those with higher capacity typically show reduced selectivity in complex brine environments containing competing ions such as sodium, potassium, magnesium, and calcium.

Structural stability presents another significant challenge, particularly during repeated adsorption-desorption cycles. Many promising ion sieve materials experience framework collapse or significant performance degradation after multiple regeneration cycles, substantially reducing their operational lifespan and economic viability. This instability is especially pronounced in manganese-based ion sieves, which can lose up to 30-40% of their capacity within the first 5-10 cycles.

Kinetic limitations also hinder practical applications, with many current materials exhibiting slow lithium uptake rates. This sluggish kinetic performance necessitates longer contact times, reducing throughput and increasing operational costs in industrial settings. The slow diffusion of lithium ions within the sorbent structure remains a fundamental barrier to achieving commercially viable extraction rates.

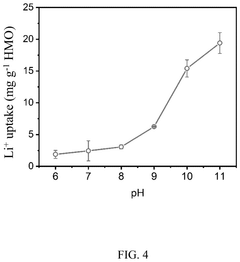

Environmental factors significantly impact performance, with most ion sieves showing marked sensitivity to pH variations, temperature fluctuations, and the presence of organic contaminants in brine sources. These sensitivities necessitate additional pre-treatment steps, further complicating process design and increasing operational costs.

Manufacturing scalability represents a substantial hurdle, as many laboratory-developed materials rely on complex synthesis procedures involving expensive precursors or environmentally problematic reagents. The transition from laboratory to industrial-scale production often results in quality inconsistencies and reduced performance metrics.

Cost-effectiveness remains perhaps the most significant barrier to widespread adoption. Current high-performance ion sieves typically incorporate expensive components such as titanium dioxide, lithium manganese oxide, or specialized polymeric frameworks. The economic viability of DLE technologies depends critically on reducing material costs while maintaining performance characteristics.

Regeneration efficiency presents ongoing challenges, with most ion sieves requiring harsh chemical conditions or significant energy inputs for effective lithium desorption and material regeneration. These requirements not only increase operational costs but also raise environmental concerns regarding chemical waste management and energy consumption.

Structural stability presents another significant challenge, particularly during repeated adsorption-desorption cycles. Many promising ion sieve materials experience framework collapse or significant performance degradation after multiple regeneration cycles, substantially reducing their operational lifespan and economic viability. This instability is especially pronounced in manganese-based ion sieves, which can lose up to 30-40% of their capacity within the first 5-10 cycles.

Kinetic limitations also hinder practical applications, with many current materials exhibiting slow lithium uptake rates. This sluggish kinetic performance necessitates longer contact times, reducing throughput and increasing operational costs in industrial settings. The slow diffusion of lithium ions within the sorbent structure remains a fundamental barrier to achieving commercially viable extraction rates.

Environmental factors significantly impact performance, with most ion sieves showing marked sensitivity to pH variations, temperature fluctuations, and the presence of organic contaminants in brine sources. These sensitivities necessitate additional pre-treatment steps, further complicating process design and increasing operational costs.

Manufacturing scalability represents a substantial hurdle, as many laboratory-developed materials rely on complex synthesis procedures involving expensive precursors or environmentally problematic reagents. The transition from laboratory to industrial-scale production often results in quality inconsistencies and reduced performance metrics.

Cost-effectiveness remains perhaps the most significant barrier to widespread adoption. Current high-performance ion sieves typically incorporate expensive components such as titanium dioxide, lithium manganese oxide, or specialized polymeric frameworks. The economic viability of DLE technologies depends critically on reducing material costs while maintaining performance characteristics.

Regeneration efficiency presents ongoing challenges, with most ion sieves requiring harsh chemical conditions or significant energy inputs for effective lithium desorption and material regeneration. These requirements not only increase operational costs but also raise environmental concerns regarding chemical waste management and energy consumption.

Current Ion Sieve Sorbent Solutions and Mechanisms

01 Metal ion selectivity in ion sieve sorbents

Ion sieve sorbents can be designed with specific structures to selectively adsorb target metal ions based on ionic radius, charge, and coordination chemistry. These materials often contain engineered cavities or functional groups that preferentially bind to certain ions while excluding others. The selectivity can be enhanced through modification of the sieve's framework composition, pore size distribution, and surface chemistry, allowing for efficient separation of similar metal ions even in complex solutions.- Metal ion selective sorbents: Ion sieve sorbents can be designed with specific selectivity for target metal ions, particularly for rare earth elements and heavy metals. These sorbents utilize molecular recognition principles to create binding sites that match the ionic radius and coordination preferences of specific ions. The selectivity can be enhanced through chemical modification of the sorbent surface or by incorporating specific functional groups that preferentially interact with target ions, allowing for efficient separation even in complex mixtures.

- Lithium extraction technologies: Specialized ion sieve sorbents have been developed for lithium extraction from brines and seawater. These materials often feature manganese oxide structures with lithium ion-sized cavities that enable high selectivity for lithium over competing ions like sodium and potassium. The capacity and selectivity of these lithium-specific sorbents can be optimized through controlled synthesis conditions, doping with other elements, or post-synthesis treatments to enhance the stability and regeneration capabilities of the material.

- Novel composite materials for enhanced capacity: Composite ion sieve materials combine different components to achieve superior adsorption capacity while maintaining selectivity. These may include polymer-inorganic hybrids, carbon-based composites, or layered structures. The synergistic effects between components can create multiple adsorption sites, improve mass transfer kinetics, and enhance mechanical stability. These composite sorbents often demonstrate higher capacity than single-component materials while allowing for tailored selectivity through careful design of the interface between components.

- Regeneration and reusability optimization: Enhancing the regeneration capabilities of ion sieve sorbents is crucial for their practical application. Various approaches have been developed to improve reusability while maintaining selectivity and capacity over multiple cycles. These include designing robust structures that resist degradation during regeneration processes, incorporating pH-responsive functional groups that facilitate ion release, and developing mild elution conditions that preserve the sorbent structure. Optimized regeneration protocols can significantly extend the operational lifetime of ion sieve materials.

- Environmental applications and scale-up: Ion sieve sorbents have been adapted for environmental remediation applications, including wastewater treatment and recovery of valuable resources from industrial effluents. These applications require consideration of selectivity and capacity under real-world conditions with competing ions and potential fouling agents. Scale-up strategies focus on maintaining the high performance of laboratory-developed materials in larger systems, including fixed-bed columns, fluidized beds, or membrane-assisted processes, while addressing challenges related to pressure drop, flow distribution, and mass transfer limitations.

02 Adsorption capacity enhancement techniques

Various methods can be employed to increase the adsorption capacity of ion sieve sorbents, including surface area optimization, introduction of additional binding sites, and structural modifications. Techniques such as template-assisted synthesis, hydrothermal treatment, and incorporation of functional groups can significantly improve the number of available adsorption sites. Additionally, controlling the crystallinity, particle size, and porosity of the sorbent material can lead to enhanced capacity for target ions.Expand Specific Solutions03 Lithium-selective ion sieve materials

Specialized ion sieve sorbents have been developed for selective lithium recovery from various sources including brines, seawater, and geothermal fluids. These materials often utilize manganese oxide structures with spinel or layered configurations that can selectively extract lithium ions based on size exclusion principles. The selectivity for lithium over competing ions such as sodium, potassium, and magnesium is achieved through precise control of the sieve's interlayer spacing and coordination environment.Expand Specific Solutions04 Regeneration and reusability of ion sieves

The economic viability of ion sieve sorbents depends significantly on their regeneration capabilities and cycle stability. Various regeneration methods have been developed, including acid treatment, ion exchange, and electrochemical approaches, to desorb captured ions and restore the sorbent's capacity. The regeneration process must be optimized to maintain the structural integrity and selectivity of the sorbent over multiple adsorption-desorption cycles, thereby extending its operational lifetime and improving cost-effectiveness.Expand Specific Solutions05 Novel composite ion sieve materials

Composite ion sieve materials combine different components to achieve enhanced selectivity and capacity compared to traditional single-phase sorbents. These composites may incorporate polymers, carbon materials, metal-organic frameworks, or inorganic matrices to create synergistic effects. The integration of multiple functional components can provide improved mechanical stability, faster kinetics, and resistance to fouling, while maintaining or enhancing the selective ion capture properties. These advanced materials often demonstrate superior performance in challenging environments with complex ion mixtures.Expand Specific Solutions

Key Industry Players in Lithium Extraction Technology

The direct lithium extraction (DLE) market using ion sieve sorbents is in an early growth phase, characterized by rapid technological innovation and increasing commercial interest. The global market is expanding significantly as demand for lithium in battery applications surges, with projections indicating substantial growth over the next decade. Technologically, ion sieve sorbents are advancing from laboratory to commercial scale, with varying degrees of maturity. Leading players like Lilac Solutions and Summit Nanotech are pioneering commercial DLE technologies with enhanced selectivity and capacity, while established companies such as BYD and Siemens are investing in related technologies. Academic institutions including Central South University and Beijing University of Chemical Technology are contributing fundamental research to improve sorbent performance. Chinese companies like Guangdong Bangpu and SDIC Xinjiang Luobupo are leveraging their expertise in lithium processing to develop competitive extraction technologies.

XTRALIT LTD

Technical Solution: XTRALIT has developed a novel class of nanostructured ion-sieve materials specifically engineered for direct lithium extraction from diverse brine resources. Their technology centers on composite metal oxide frameworks with precisely controlled pore architectures that enable exceptional lithium selectivity through both size exclusion and chemical affinity mechanisms. The company's proprietary sorbents feature a core-shell structure with lithium-selective functional groups strategically positioned to maximize adsorption capacity while maintaining rapid kinetics. XTRALIT's extraction process operates through a pressure-driven flow system where brine passes through columns packed with their specialized sorbent material, allowing for continuous lithium capture with minimal energy requirements. The technology demonstrates remarkable selectivity coefficients, with Li/Mg selectivity ratios exceeding 60:1 and Li/Na selectivity above 100:1 even in challenging mixed-salt environments[5]. Their sorbent materials achieve lithium extraction capacities of 25-35 mg/g with over 95% recovery efficiency from feed brines. XTRALIT has developed an innovative regeneration approach that uses significantly reduced volumes of regenerant solution compared to conventional methods, resulting in highly concentrated lithium products suitable for direct conversion to battery-grade materials.

Strengths: Exceptional lithium selectivity even in complex brine compositions; rapid adsorption kinetics enabling high throughput processing; efficient regeneration with minimal chemical consumption; stable performance over extended cycling (1000+ cycles). Weaknesses: Limited commercial-scale deployment history; potential sensitivity to certain trace contaminants in brines; higher manufacturing complexity of advanced nanostructured sorbents compared to conventional materials.

Qinghai Institute of Salt Lakes, Chinese Academy of Sciences

Technical Solution: The Qinghai Institute of Salt Lakes has pioneered advanced manganese oxide-based ion-sieve materials for direct lithium extraction from salt lake brines. Their technology focuses on spinel-type lithium manganese oxide (LiMn2O4) and its derivatives, which undergo an ion-exchange process where lithium ions in the crystal structure are replaced with hydrogen ions, creating highly selective lithium extraction sites. These H-form sieves demonstrate exceptional selectivity for lithium over sodium, potassium, magnesium, and calcium ions commonly found in salt lake brines. The institute has developed a comprehensive process involving sorbent synthesis, activation, adsorption-desorption cycling, and regeneration protocols specifically optimized for the high-magnesium brines characteristic of Chinese salt lakes. Their latest generation materials achieve lithium extraction capacities of 30-40 mg/g with Mg/Li selectivity coefficients exceeding 50:1[2]. The institute has successfully scaled this technology from laboratory to pilot plant operations, demonstrating continuous extraction capabilities with minimal sorbent degradation over hundreds of cycles when proper regeneration protocols are followed.

Strengths: Exceptional selectivity for lithium in high-magnesium brines typical of Chinese salt lakes; well-developed regeneration protocols; proven technology at pilot scale with extensive field testing. Weaknesses: Relatively slow kinetics compared to some newer materials; potential manganese leaching during repeated cycling; sensitivity to certain impurities in brine that can cause premature degradation of sorbent materials.

Critical Patents and Research in Ion Sieve Technology

Method of obtaining inorganic sorbents for extraction of lithium from lithium-containing natural and technological brines

PatentActiveUS11260366B2

Innovation

- A method involving a series of steps to produce a selective inorganic sorbent by contacting a soluble manganese (II) salt with an alkali solution and aluminum (III) salt, followed by oxidation, granulation, and calcination, resulting in a hydrated mixed oxide of manganese and aluminum, which is then converted into a lithium-form and finally treated with an acid to achieve high selectivity and stability.

Method for preparing lithium extraction absorbent and its application

PatentPendingUS20240307848A1

Innovation

- A method for preparing a lithium extraction adsorbent by forming a homogeneous casting liquid with a metal-based lithium ion sieve, an organic carrier, and a functional material, followed by solidification, washing, crosslinking, and freeze-drying, which includes activating the adsorbent with an alkali activator to create an alkaline microenvironment, enhancing adsorption capacity and selectivity under natural conditions without altering the water's pH.

Environmental Impact Assessment of DLE Technologies

The environmental impact of Direct Lithium Extraction (DLE) technologies, particularly those utilizing ion sieve sorbents, requires comprehensive assessment to ensure sustainable implementation. These technologies offer promising alternatives to traditional evaporation pond methods, potentially reducing the ecological footprint of lithium production.

Water usage represents a critical environmental consideration for DLE technologies. While conventional lithium extraction methods consume approximately 500,000 gallons of water per ton of lithium produced, ion sieve sorbent-based DLE systems can achieve significant reductions, with some advanced systems reporting up to 90% less water consumption. This efficiency becomes particularly valuable in water-stressed regions where lithium resources are abundant.

Land disturbance metrics also favor ion sieve sorbent technologies. Traditional evaporation ponds require extensive surface area—approximately 2-3 square kilometers per 20,000 tons of annual lithium carbonate production. In contrast, DLE facilities utilizing selective sorbents can operate with a physical footprint reduced by 50-70%, minimizing habitat disruption and preserving natural landscapes.

Chemical usage patterns differ substantially between extraction methods. Ion sieve sorbents typically require regeneration chemicals, including acids and bases, which necessitate careful handling and disposal protocols. Environmental monitoring data indicates that closed-loop systems can recycle up to 95% of these chemicals, though residual discharge must still be managed according to stringent environmental standards.

Greenhouse gas emissions associated with ion sieve DLE operations primarily stem from energy requirements for pumping and regeneration processes. Life cycle assessments indicate emissions of 5-15 kg CO2e per kilogram of lithium carbonate equivalent (LCE) produced—significantly lower than the 15-25 kg CO2e/kg LCE from traditional methods. Implementation of renewable energy sources can further reduce this carbon footprint.

Waste management challenges persist despite technological advances. Spent ion sieve materials require proper disposal or recycling, while process effluents may contain trace metals and salts. Current best practices include precipitation and filtration systems that can remove over 99% of potential contaminants before any discharge occurs.

Groundwater protection remains paramount, as DLE operations interact directly with subsurface brine resources. Monitoring data from pilot projects utilizing ion sieve technologies demonstrates minimal impact on surrounding aquifer quality when appropriate well construction and operational protocols are followed. However, long-term studies are still needed to verify sustained environmental performance across diverse geological settings.

Biodiversity impacts appear substantially reduced with ion sieve DLE technologies compared to evaporation pond methods, which have documented negative effects on migratory birds and local ecosystems. The concentrated operational footprint of sorbent-based systems minimizes habitat fragmentation and ecosystem disruption.

Water usage represents a critical environmental consideration for DLE technologies. While conventional lithium extraction methods consume approximately 500,000 gallons of water per ton of lithium produced, ion sieve sorbent-based DLE systems can achieve significant reductions, with some advanced systems reporting up to 90% less water consumption. This efficiency becomes particularly valuable in water-stressed regions where lithium resources are abundant.

Land disturbance metrics also favor ion sieve sorbent technologies. Traditional evaporation ponds require extensive surface area—approximately 2-3 square kilometers per 20,000 tons of annual lithium carbonate production. In contrast, DLE facilities utilizing selective sorbents can operate with a physical footprint reduced by 50-70%, minimizing habitat disruption and preserving natural landscapes.

Chemical usage patterns differ substantially between extraction methods. Ion sieve sorbents typically require regeneration chemicals, including acids and bases, which necessitate careful handling and disposal protocols. Environmental monitoring data indicates that closed-loop systems can recycle up to 95% of these chemicals, though residual discharge must still be managed according to stringent environmental standards.

Greenhouse gas emissions associated with ion sieve DLE operations primarily stem from energy requirements for pumping and regeneration processes. Life cycle assessments indicate emissions of 5-15 kg CO2e per kilogram of lithium carbonate equivalent (LCE) produced—significantly lower than the 15-25 kg CO2e/kg LCE from traditional methods. Implementation of renewable energy sources can further reduce this carbon footprint.

Waste management challenges persist despite technological advances. Spent ion sieve materials require proper disposal or recycling, while process effluents may contain trace metals and salts. Current best practices include precipitation and filtration systems that can remove over 99% of potential contaminants before any discharge occurs.

Groundwater protection remains paramount, as DLE operations interact directly with subsurface brine resources. Monitoring data from pilot projects utilizing ion sieve technologies demonstrates minimal impact on surrounding aquifer quality when appropriate well construction and operational protocols are followed. However, long-term studies are still needed to verify sustained environmental performance across diverse geological settings.

Biodiversity impacts appear substantially reduced with ion sieve DLE technologies compared to evaporation pond methods, which have documented negative effects on migratory birds and local ecosystems. The concentrated operational footprint of sorbent-based systems minimizes habitat fragmentation and ecosystem disruption.

Scalability and Economic Feasibility Analysis

The scalability of ion sieve sorbents for direct lithium extraction (DLE) represents a critical factor in determining their commercial viability. Current laboratory-scale demonstrations have shown promising results, with selective lithium extraction rates of 80-95% from various brine sources. However, transitioning these technologies to industrial scale presents significant engineering challenges, particularly in maintaining selectivity and capacity during continuous operation cycles.

Economic analysis indicates that DLE technologies using ion sieve sorbents could potentially reduce lithium production costs by 30-40% compared to traditional evaporation pond methods, primarily through decreased processing time and land requirements. The capital expenditure for a commercial-scale DLE facility (5,000-10,000 tons LCE/year) is estimated at $50-80 million, with operational costs ranging from $2,500-4,000 per ton of lithium carbonate equivalent.

Material durability presents a key economic consideration, as most ion sieve sorbents demonstrate performance degradation after 200-500 extraction cycles. This necessitates periodic replacement, adding approximately $800-1,200 per ton to production costs. Research indicates that extending sorbent lifespan to 1,000+ cycles would significantly improve economic feasibility, potentially reducing this cost component by 60-70%.

Water consumption metrics reveal that ion sieve-based DLE processes require 30-50 cubic meters of water per ton of lithium produced, substantially lower than the 500+ cubic meters needed for evaporation methods. This water efficiency becomes increasingly valuable in water-stressed regions where many lithium resources are located.

Energy requirements for ion sieve regeneration and processing represent another critical economic factor. Current technologies consume 5-8 MWh per ton of lithium produced, contributing approximately $500-800 to production costs depending on regional energy prices. Innovations in regeneration chemistry and process optimization could potentially reduce this energy demand by 25-35%.

Supply chain considerations for specialized ion sieve materials must also be evaluated. Many advanced sorbents incorporate rare earth elements or specialized polymers with limited production capacity. Scaling production would require significant investment in material manufacturing infrastructure, estimated at $15-25 million for materials production facilities capable of supporting commercial DLE operations.

Return on investment calculations suggest that ion sieve-based DLE facilities could achieve payback periods of 4-6 years at current lithium market prices, compared to 7-9 years for traditional extraction methods. This favorable economic profile is driving increased investment, with over $1.2 billion allocated to DLE technologies in 2022 alone, representing a 300% increase from 2020 levels.

Economic analysis indicates that DLE technologies using ion sieve sorbents could potentially reduce lithium production costs by 30-40% compared to traditional evaporation pond methods, primarily through decreased processing time and land requirements. The capital expenditure for a commercial-scale DLE facility (5,000-10,000 tons LCE/year) is estimated at $50-80 million, with operational costs ranging from $2,500-4,000 per ton of lithium carbonate equivalent.

Material durability presents a key economic consideration, as most ion sieve sorbents demonstrate performance degradation after 200-500 extraction cycles. This necessitates periodic replacement, adding approximately $800-1,200 per ton to production costs. Research indicates that extending sorbent lifespan to 1,000+ cycles would significantly improve economic feasibility, potentially reducing this cost component by 60-70%.

Water consumption metrics reveal that ion sieve-based DLE processes require 30-50 cubic meters of water per ton of lithium produced, substantially lower than the 500+ cubic meters needed for evaporation methods. This water efficiency becomes increasingly valuable in water-stressed regions where many lithium resources are located.

Energy requirements for ion sieve regeneration and processing represent another critical economic factor. Current technologies consume 5-8 MWh per ton of lithium produced, contributing approximately $500-800 to production costs depending on regional energy prices. Innovations in regeneration chemistry and process optimization could potentially reduce this energy demand by 25-35%.

Supply chain considerations for specialized ion sieve materials must also be evaluated. Many advanced sorbents incorporate rare earth elements or specialized polymers with limited production capacity. Scaling production would require significant investment in material manufacturing infrastructure, estimated at $15-25 million for materials production facilities capable of supporting commercial DLE operations.

Return on investment calculations suggest that ion sieve-based DLE facilities could achieve payback periods of 4-6 years at current lithium market prices, compared to 7-9 years for traditional extraction methods. This favorable economic profile is driving increased investment, with over $1.2 billion allocated to DLE technologies in 2022 alone, representing a 300% increase from 2020 levels.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!