Pilot Plant Case Studies And Performance Metrics Of Direct Lithium Extraction

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DLE Technology Background and Objectives

Direct Lithium Extraction (DLE) represents a paradigm shift in lithium production, emerging as an alternative to traditional evaporation pond methods that have dominated the industry for decades. The evolution of DLE technology can be traced back to the early 2000s, with significant advancements occurring in the past decade as global demand for lithium has surged due to the electric vehicle revolution and renewable energy storage requirements.

DLE technologies encompass a diverse range of approaches including adsorption, ion exchange, solvent extraction, and membrane processes, all aimed at selectively extracting lithium from brines while leaving other elements behind. The technological trajectory has been characterized by incremental improvements in selectivity, recovery rates, and process efficiency, with recent breakthroughs in material science enabling more effective lithium-selective sorbents and membranes.

The primary objective of DLE development is to establish economically viable processes that can extract lithium from various brine resources with higher recovery rates, reduced environmental footprint, and accelerated production timelines compared to conventional methods. Current pilot plant studies are focused on validating these technologies at scale and generating performance metrics that can justify commercial implementation.

Key technical goals include achieving lithium recovery rates exceeding 90%, reducing water consumption by over 70% compared to evaporation methods, minimizing chemical reagent usage, and developing processes capable of handling diverse brine chemistries across different geological formations. Additionally, there is emphasis on creating modular, scalable systems that can be deployed in various geographical contexts.

The technological evolution is increasingly driven by sustainability considerations, with emerging metrics focused not only on extraction efficiency but also on carbon footprint, water usage, land disturbance, and waste generation. This reflects the industry's recognition that future lithium production must align with environmental, social, and governance (ESG) principles to secure social license to operate and meet regulatory requirements.

Recent pilot plant case studies demonstrate promising progress, with several technologies achieving lithium concentration factors of 50-100x from initial brine concentrations, while maintaining high selectivity against competing ions such as sodium, magnesium, and calcium. These advancements suggest that DLE is approaching commercial viability for certain brine resources, though challenges remain in process optimization, energy efficiency, and long-term operational stability.

The technological trajectory indicates continued innovation in sorbent materials, process integration, and energy optimization, with the ultimate goal of establishing DLE as the predominant method for lithium production from brine resources globally by 2030.

DLE technologies encompass a diverse range of approaches including adsorption, ion exchange, solvent extraction, and membrane processes, all aimed at selectively extracting lithium from brines while leaving other elements behind. The technological trajectory has been characterized by incremental improvements in selectivity, recovery rates, and process efficiency, with recent breakthroughs in material science enabling more effective lithium-selective sorbents and membranes.

The primary objective of DLE development is to establish economically viable processes that can extract lithium from various brine resources with higher recovery rates, reduced environmental footprint, and accelerated production timelines compared to conventional methods. Current pilot plant studies are focused on validating these technologies at scale and generating performance metrics that can justify commercial implementation.

Key technical goals include achieving lithium recovery rates exceeding 90%, reducing water consumption by over 70% compared to evaporation methods, minimizing chemical reagent usage, and developing processes capable of handling diverse brine chemistries across different geological formations. Additionally, there is emphasis on creating modular, scalable systems that can be deployed in various geographical contexts.

The technological evolution is increasingly driven by sustainability considerations, with emerging metrics focused not only on extraction efficiency but also on carbon footprint, water usage, land disturbance, and waste generation. This reflects the industry's recognition that future lithium production must align with environmental, social, and governance (ESG) principles to secure social license to operate and meet regulatory requirements.

Recent pilot plant case studies demonstrate promising progress, with several technologies achieving lithium concentration factors of 50-100x from initial brine concentrations, while maintaining high selectivity against competing ions such as sodium, magnesium, and calcium. These advancements suggest that DLE is approaching commercial viability for certain brine resources, though challenges remain in process optimization, energy efficiency, and long-term operational stability.

The technological trajectory indicates continued innovation in sorbent materials, process integration, and energy optimization, with the ultimate goal of establishing DLE as the predominant method for lithium production from brine resources globally by 2030.

Market Analysis for Direct Lithium Extraction

The global lithium market is experiencing unprecedented growth, driven primarily by the rapid expansion of electric vehicle (EV) production and energy storage systems. Direct Lithium Extraction (DLE) technologies have emerged as a revolutionary approach to lithium production, offering significant advantages over traditional extraction methods. The market for DLE is projected to grow at a CAGR of 30% between 2023-2030, reaching a market value of $5.7 billion by 2030.

Demand for lithium is expected to increase fourfold by 2030, with EVs accounting for approximately 75% of total lithium consumption. This surge in demand has created a substantial supply gap that conventional extraction methods cannot adequately address. DLE technologies offer a promising solution to this supply-demand imbalance, with the potential to unlock previously uneconomical lithium resources.

Geographically, the DLE market shows distinct regional characteristics. North America leads in technology development and implementation, with several pilot plants operational in the United States and Canada. South America, particularly the "Lithium Triangle" (Argentina, Bolivia, and Chile), represents the largest potential market for DLE applications due to its vast lithium brine resources. Asia-Pacific, led by China, is rapidly adopting DLE technologies to secure domestic lithium supply chains.

Market segmentation reveals that ion exchange and adsorption-based DLE technologies currently dominate the market, accounting for approximately 60% of pilot implementations. Membrane-based and solvent extraction technologies represent emerging segments with significant growth potential. The market is further segmented by end-users, with battery manufacturers constituting the largest customer segment (65%), followed by glass and ceramics industries (20%).

Key market drivers include increasing lithium prices, environmental regulations limiting traditional extraction methods, and technological advancements improving DLE efficiency. The average production cost using DLE technologies has decreased by 35% over the past five years, enhancing commercial viability. Additionally, DLE offers significant environmental benefits, reducing water consumption by up to 90% compared to evaporation ponds.

Market barriers include high initial capital requirements, technological uncertainties in scaling from pilot to commercial operations, and competition from established extraction methods. The average capital expenditure for a commercial-scale DLE plant remains 30-40% higher than conventional operations, though this gap is narrowing as technologies mature.

Customer adoption patterns indicate increasing acceptance of DLE-sourced lithium, with major battery manufacturers incorporating sustainability metrics into their sourcing decisions. This trend is expected to accelerate as ESG considerations become more prominent in investment decisions throughout the lithium value chain.

Demand for lithium is expected to increase fourfold by 2030, with EVs accounting for approximately 75% of total lithium consumption. This surge in demand has created a substantial supply gap that conventional extraction methods cannot adequately address. DLE technologies offer a promising solution to this supply-demand imbalance, with the potential to unlock previously uneconomical lithium resources.

Geographically, the DLE market shows distinct regional characteristics. North America leads in technology development and implementation, with several pilot plants operational in the United States and Canada. South America, particularly the "Lithium Triangle" (Argentina, Bolivia, and Chile), represents the largest potential market for DLE applications due to its vast lithium brine resources. Asia-Pacific, led by China, is rapidly adopting DLE technologies to secure domestic lithium supply chains.

Market segmentation reveals that ion exchange and adsorption-based DLE technologies currently dominate the market, accounting for approximately 60% of pilot implementations. Membrane-based and solvent extraction technologies represent emerging segments with significant growth potential. The market is further segmented by end-users, with battery manufacturers constituting the largest customer segment (65%), followed by glass and ceramics industries (20%).

Key market drivers include increasing lithium prices, environmental regulations limiting traditional extraction methods, and technological advancements improving DLE efficiency. The average production cost using DLE technologies has decreased by 35% over the past five years, enhancing commercial viability. Additionally, DLE offers significant environmental benefits, reducing water consumption by up to 90% compared to evaporation ponds.

Market barriers include high initial capital requirements, technological uncertainties in scaling from pilot to commercial operations, and competition from established extraction methods. The average capital expenditure for a commercial-scale DLE plant remains 30-40% higher than conventional operations, though this gap is narrowing as technologies mature.

Customer adoption patterns indicate increasing acceptance of DLE-sourced lithium, with major battery manufacturers incorporating sustainability metrics into their sourcing decisions. This trend is expected to accelerate as ESG considerations become more prominent in investment decisions throughout the lithium value chain.

Global DLE Technology Status and Challenges

Direct Lithium Extraction (DLE) technologies have gained significant momentum globally as the demand for lithium continues to surge with the expansion of electric vehicle markets and energy storage systems. Currently, DLE technologies are at varying stages of development across different regions, with North America, Australia, and parts of Europe leading in research and pilot implementations.

The conventional lithium extraction methods from brines involve evaporation ponds that are time-consuming (12-18 months), land-intensive, and weather-dependent, with recovery rates typically below 50%. In contrast, DLE technologies promise extraction times of hours to days, significantly reduced land footprint, and potential recovery rates of 70-90%.

Despite these promising advantages, DLE faces several critical challenges. Technical barriers include the selectivity of sorbents in complex brine chemistries, where high concentrations of competing ions like sodium, magnesium, and calcium can interfere with lithium adsorption. Many DLE technologies struggle with maintaining performance consistency when processing brines with varying lithium concentrations and impurity profiles.

Water consumption remains a significant concern, particularly in water-stressed regions like Chile's Atacama Desert and Argentina's lithium triangle. Some DLE methods require substantial freshwater for processing and regeneration cycles, creating environmental sustainability challenges in these arid regions.

Energy requirements present another hurdle, as many DLE technologies demand considerable electricity for operations, potentially offsetting their environmental benefits if powered by fossil fuels. The economic viability of DLE is further complicated by high capital expenditure requirements and operational costs compared to traditional methods.

Geographically, DLE development shows distinct patterns. North American companies are focusing on adsorption and ion exchange technologies, while European research centers emphasize membrane-based approaches. Chinese entities are advancing electrochemical methods at accelerated rates, supported by government initiatives.

Regulatory frameworks vary significantly across regions, with some countries expediting permitting processes for DLE projects due to their reduced environmental footprint, while others maintain stringent requirements regardless of extraction methodology. This regulatory inconsistency creates additional challenges for global technology deployment.

The scalability from laboratory to commercial operations represents perhaps the most significant challenge, with many promising technologies failing to maintain performance metrics when scaled up. This scale-up gap has resulted in numerous pilot projects demonstrating excellent results in controlled environments but struggling to achieve comparable outcomes in field conditions.

The conventional lithium extraction methods from brines involve evaporation ponds that are time-consuming (12-18 months), land-intensive, and weather-dependent, with recovery rates typically below 50%. In contrast, DLE technologies promise extraction times of hours to days, significantly reduced land footprint, and potential recovery rates of 70-90%.

Despite these promising advantages, DLE faces several critical challenges. Technical barriers include the selectivity of sorbents in complex brine chemistries, where high concentrations of competing ions like sodium, magnesium, and calcium can interfere with lithium adsorption. Many DLE technologies struggle with maintaining performance consistency when processing brines with varying lithium concentrations and impurity profiles.

Water consumption remains a significant concern, particularly in water-stressed regions like Chile's Atacama Desert and Argentina's lithium triangle. Some DLE methods require substantial freshwater for processing and regeneration cycles, creating environmental sustainability challenges in these arid regions.

Energy requirements present another hurdle, as many DLE technologies demand considerable electricity for operations, potentially offsetting their environmental benefits if powered by fossil fuels. The economic viability of DLE is further complicated by high capital expenditure requirements and operational costs compared to traditional methods.

Geographically, DLE development shows distinct patterns. North American companies are focusing on adsorption and ion exchange technologies, while European research centers emphasize membrane-based approaches. Chinese entities are advancing electrochemical methods at accelerated rates, supported by government initiatives.

Regulatory frameworks vary significantly across regions, with some countries expediting permitting processes for DLE projects due to their reduced environmental footprint, while others maintain stringent requirements regardless of extraction methodology. This regulatory inconsistency creates additional challenges for global technology deployment.

The scalability from laboratory to commercial operations represents perhaps the most significant challenge, with many promising technologies failing to maintain performance metrics when scaled up. This scale-up gap has resulted in numerous pilot projects demonstrating excellent results in controlled environments but struggling to achieve comparable outcomes in field conditions.

Current DLE Pilot Plant Solutions

01 Efficiency and selectivity metrics in DLE processes

Direct Lithium Extraction (DLE) processes are evaluated based on their efficiency and selectivity metrics. These metrics measure how effectively lithium can be extracted from brine solutions while minimizing the co-extraction of other elements. Key performance indicators include lithium recovery rate, selectivity ratio (lithium vs. other ions), and adsorption capacity. Advanced DLE technologies employ specialized adsorbents or ion exchange materials that can selectively capture lithium ions from complex brine compositions, significantly improving extraction efficiency compared to traditional evaporation methods.- Efficiency and selectivity metrics in DLE processes: Direct Lithium Extraction (DLE) processes are evaluated based on efficiency and selectivity metrics. These metrics measure how effectively lithium is extracted from brine solutions while minimizing the extraction of unwanted elements. Key performance indicators include lithium recovery rate, selectivity ratio (lithium vs. other ions), and adsorption capacity. Advanced DLE technologies employ specialized adsorbents and ion exchange materials that can selectively capture lithium ions from complex brine compositions, significantly improving extraction efficiency compared to traditional evaporation methods.

- Energy consumption and environmental impact assessment: Energy consumption is a critical performance metric for DLE technologies, directly affecting operational costs and environmental sustainability. Modern DLE systems are evaluated based on kWh per kilogram of lithium extracted, carbon footprint, and water usage efficiency. Environmental impact assessments track metrics such as water consumption, land use, chemical reagent requirements, and waste generation. Advanced DLE methods aim to minimize energy requirements through process optimization, heat recovery systems, and renewable energy integration, while reducing environmental impacts compared to traditional evaporation pond methods.

- Process cycle time and throughput optimization: Cycle time and throughput are key performance metrics that determine the commercial viability of DLE operations. These metrics measure how quickly lithium can be processed and the volume that can be handled per unit time. Performance indicators include adsorption-desorption cycle duration, brine processing rate, and lithium production capacity. Advanced DLE technologies focus on optimizing these parameters through improved sorbent materials, efficient fluid handling systems, and automated process control. Continuous flow systems and parallel processing configurations are employed to maximize throughput while maintaining extraction efficiency.

- Sorbent performance and regeneration metrics: The performance of sorbent materials is crucial in DLE processes and is measured through various metrics including adsorption capacity, selectivity coefficient, kinetics, and cycle stability. Key performance indicators track how many cycles a sorbent can undergo before requiring replacement, regeneration efficiency, and chemical stability in various brine compositions. Advanced DLE technologies employ innovative sorbent materials such as ion-sieves, functionalized polymers, and inorganic ion exchangers that can maintain high performance over numerous cycles, thereby reducing operational costs and improving process economics.

- Real-time monitoring and process optimization systems: Advanced DLE operations implement real-time monitoring and process optimization systems to continuously track and improve performance metrics. These systems collect data on parameters such as flow rates, pressure, temperature, pH, and ion concentrations throughout the extraction process. Performance metrics include system response time, control precision, and optimization effectiveness. Machine learning algorithms and predictive analytics are employed to identify optimal operating conditions, detect anomalies, and implement adaptive control strategies. These monitoring systems enable operators to maximize lithium recovery while minimizing resource consumption and operational costs.

02 Energy consumption and environmental impact assessment

Energy consumption is a critical performance metric for DLE technologies, directly affecting operational costs and environmental sustainability. Modern DLE systems are evaluated based on their energy requirements per unit of lithium produced, carbon footprint, and overall environmental impact. Performance metrics in this category include kWh per kg of lithium extracted, greenhouse gas emissions, and water usage efficiency. Innovative DLE approaches aim to minimize energy consumption through process optimization, heat recovery systems, and integration of renewable energy sources to create more sustainable lithium production methods.Expand Specific Solutions03 Process cycle time and throughput optimization

The speed and volume capacity of DLE operations are crucial performance metrics that determine commercial viability. Key indicators include adsorption-desorption cycle time, processing volume per unit time, and continuous operation capability. Advanced DLE technologies focus on optimizing these parameters through improved system design, enhanced mass transfer, and automated process control. Reducing cycle times while maintaining high lithium recovery rates enables higher throughput, making DLE more competitive with traditional extraction methods while accommodating variable brine compositions and flow rates.Expand Specific Solutions04 Real-time monitoring and performance analytics

Modern DLE systems incorporate sophisticated monitoring and analytics capabilities to track performance metrics in real-time. These systems collect data on extraction efficiency, system conditions, and operational parameters to enable continuous optimization. Key performance indicators include sensor accuracy, data processing speed, and predictive maintenance capabilities. Advanced analytics platforms use machine learning algorithms to identify performance trends, predict maintenance needs, and automatically adjust process parameters to maintain optimal extraction conditions across varying brine compositions and environmental factors.Expand Specific Solutions05 Economic performance and scalability metrics

Economic viability is assessed through comprehensive cost metrics that evaluate DLE technologies based on capital expenditure, operational expenses, and return on investment. Key performance indicators include cost per ton of lithium carbonate equivalent produced, payback period, and scalability potential. Advanced DLE systems aim to minimize reagent consumption, reduce waste treatment costs, and optimize equipment lifespan. Scalability metrics evaluate how effectively a DLE technology can be expanded from pilot to commercial scale while maintaining performance efficiency and economic advantages over conventional extraction methods.Expand Specific Solutions

Key Industry Players in DLE Technology

The direct lithium extraction (DLE) technology landscape is currently in an early growth phase, characterized by increasing pilot plant deployments but limited commercial-scale operations. The global lithium market, valued at approximately $7 billion, is projected to grow significantly due to electric vehicle battery demand. From a technical maturity perspective, companies are at varying development stages. Koch Technology Solutions and Schlumberger have leveraged their industrial process expertise to advance DLE technologies, while academic institutions like The University of Manchester and Chinese Academy of Sciences contribute fundamental research. Emerging players like Lilac Solutions and International Battery Metals are demonstrating promising pilot results. Established lithium producers such as Ganfeng Lithium and BYD are increasingly investing in DLE to complement traditional extraction methods, indicating the technology's growing strategic importance.

Schlumberger Technologies, Inc.

Technical Solution: Schlumberger has leveraged its extensive experience in oilfield technologies to develop a direct lithium extraction platform called "NeoLith Energy." This technology utilizes a selective extraction process based on advanced ion-exchange materials specifically designed for lithium selectivity in complex brine environments. Their pilot plant in Clayton Valley, Nevada has demonstrated the ability to process lithium brines with concentrations ranging from 100-400 mg/L, achieving lithium recovery rates of 85-90% with minimal impurity co-extraction. The NeoLith system employs a continuous flow design where brine passes through specialized extraction columns containing the proprietary ion-exchange media, allowing for lithium capture within hours rather than months. After extraction, a controlled elution process produces a concentrated lithium chloride solution that can be further processed into battery-grade materials. Performance metrics from their pilot operations indicate a 90% reduction in land use compared to evaporation ponds, water consumption reduced by approximately 85%, and processing time shortened from months to days. Their modular system architecture enables scalable deployment with the ability to adjust capacity based on project requirements.

Strengths: Exceptional lithium selectivity even in complex brine compositions; significantly reduced environmental footprint; rapid processing timeframe; high lithium recovery rates; modular and scalable design; leverages existing expertise in fluid handling and processing from oil and gas operations. Weaknesses: Higher energy requirements compared to traditional evaporation methods; more complex operational requirements necessitating specialized technical expertise; technology still scaling to full commercial implementation; potential challenges with ion-exchange material durability in continuous operations.

Ganfeng Lithium Group Co., Ltd.

Technical Solution: Ganfeng Lithium has developed a comprehensive direct lithium extraction technology portfolio that includes both adsorption and membrane-based systems tailored for different brine chemistries. Their primary DLE technology utilizes proprietary lithium-selective adsorption materials that can effectively extract lithium from brines with concentrations as low as 50 mg/L. Pilot plant operations in Tibet and Qinghai salt lakes have demonstrated lithium recovery rates of 80-85% with processing times reduced to days rather than the 12-18 months required for traditional evaporation methods. Their system employs a continuous countercurrent extraction process where the lithium-selective adsorbent contacts the brine in multiple stages, maximizing lithium recovery while minimizing reagent consumption. The company has also developed complementary membrane concentration technologies that can further concentrate lithium solutions prior to conversion to lithium carbonate or hydroxide. Pilot operations have shown that their integrated approach can achieve lithium product purities exceeding 99.5% battery grade specifications while reducing water consumption by approximately 70% compared to evaporation methods.

Strengths: Versatile technology applicable to diverse brine chemistries; high lithium selectivity with minimal impurity co-extraction; significantly reduced processing time; substantially lower water footprint; modular design allowing for scalable implementation; integrated approach from extraction to final product. Weaknesses: Higher energy consumption compared to traditional evaporation methods; more complex operational requirements; potential challenges with adsorbent material longevity in continuous operations; higher capital expenditure requirements for initial plant construction.

Critical Patents and Technical Literature Analysis

Process and product

PatentPendingUS20250161879A1

Innovation

- The process involves contacting an aqueous lithium solution with a lithium sorbent to absorb lithium, followed by separation of the loaded sorbent and depleted solution, and subsequent treatment to regenerate the sorbent. This process utilizes pH control to maintain the lithium depleted solution at a pH of about 3 to 7 and employs ultrafiltration or nanofiltration membranes for separation.

Lithium ion adsorbents

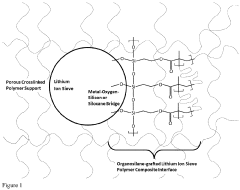

PatentPendingEP4223409A1

Innovation

- Development of an organosilane-grafted lithium ion sieve covalently incorporated into a porous crosslinked polymeric support scaffold, enhancing selectivity and durability through improved porosity and resistance to degradation under turbulent and high-temperature conditions.

Environmental Impact Assessment of DLE Methods

Direct Lithium Extraction (DLE) technologies are increasingly recognized for their potential to revolutionize lithium production with reduced environmental footprints compared to traditional methods. However, comprehensive environmental impact assessments of various DLE methods are essential for sustainable implementation and regulatory compliance.

Water usage represents a critical environmental consideration for DLE operations. While conventional evaporation ponds consume 500-2,000 cubic meters of water per tonne of lithium carbonate equivalent (LCE), pilot studies demonstrate that advanced DLE methods can reduce water consumption by 50-90%. The E3 Metals pilot plant in Alberta reported water usage of approximately 390 cubic meters per tonne of LCE, representing a significant improvement over traditional methods.

Land disturbance metrics from pilot operations reveal another environmental advantage of DLE technologies. Standard Solar Evaporation requires approximately 2,000-4,000 hectares per 20,000 tonnes of annual LCE production, whereas DLE facilities documented in pilot studies require only 10-50 hectares for equivalent production capacity. This dramatic reduction in land footprint minimizes habitat disruption and biodiversity impacts in sensitive ecosystems.

Carbon emissions associated with DLE operations vary significantly based on energy sources and process efficiency. Pilot plant data indicates that DLE methods powered by conventional energy sources generate 5-15 tonnes of CO2 per tonne of LCE. However, facilities implementing renewable energy integration have demonstrated potential reductions to 2-7 tonnes of CO2 per tonne of LCE. Lilac Solutions' pilot operations reported a 62% reduction in carbon footprint compared to traditional extraction methods.

Chemical usage and waste generation present ongoing environmental challenges for DLE implementation. Pilot operations typically utilize sorbents, solvents, or membranes that require periodic replacement and proper disposal. Standard Lithium's Arkansas demonstration plant documented a 90% reduction in reagent consumption compared to conventional processes, while achieving 94% lithium recovery rates.

Brine reinjection practices significantly impact groundwater systems and require careful monitoring. Pilot studies indicate that properly managed DLE operations can maintain hydrogeological balance by returning 85-95% of extracted brine to source aquifers. However, potential concerns regarding temperature differentials and chemical alterations in reinjected brines require ongoing assessment and mitigation strategies.

Regulatory frameworks for DLE environmental impacts remain under development in most jurisdictions. Pilot operations have been instrumental in establishing baseline environmental performance metrics that inform emerging standards. The International Energy Agency has recommended standardized environmental reporting protocols based on pilot plant case studies to facilitate meaningful comparisons between different DLE technologies and conventional extraction methods.

Water usage represents a critical environmental consideration for DLE operations. While conventional evaporation ponds consume 500-2,000 cubic meters of water per tonne of lithium carbonate equivalent (LCE), pilot studies demonstrate that advanced DLE methods can reduce water consumption by 50-90%. The E3 Metals pilot plant in Alberta reported water usage of approximately 390 cubic meters per tonne of LCE, representing a significant improvement over traditional methods.

Land disturbance metrics from pilot operations reveal another environmental advantage of DLE technologies. Standard Solar Evaporation requires approximately 2,000-4,000 hectares per 20,000 tonnes of annual LCE production, whereas DLE facilities documented in pilot studies require only 10-50 hectares for equivalent production capacity. This dramatic reduction in land footprint minimizes habitat disruption and biodiversity impacts in sensitive ecosystems.

Carbon emissions associated with DLE operations vary significantly based on energy sources and process efficiency. Pilot plant data indicates that DLE methods powered by conventional energy sources generate 5-15 tonnes of CO2 per tonne of LCE. However, facilities implementing renewable energy integration have demonstrated potential reductions to 2-7 tonnes of CO2 per tonne of LCE. Lilac Solutions' pilot operations reported a 62% reduction in carbon footprint compared to traditional extraction methods.

Chemical usage and waste generation present ongoing environmental challenges for DLE implementation. Pilot operations typically utilize sorbents, solvents, or membranes that require periodic replacement and proper disposal. Standard Lithium's Arkansas demonstration plant documented a 90% reduction in reagent consumption compared to conventional processes, while achieving 94% lithium recovery rates.

Brine reinjection practices significantly impact groundwater systems and require careful monitoring. Pilot studies indicate that properly managed DLE operations can maintain hydrogeological balance by returning 85-95% of extracted brine to source aquifers. However, potential concerns regarding temperature differentials and chemical alterations in reinjected brines require ongoing assessment and mitigation strategies.

Regulatory frameworks for DLE environmental impacts remain under development in most jurisdictions. Pilot operations have been instrumental in establishing baseline environmental performance metrics that inform emerging standards. The International Energy Agency has recommended standardized environmental reporting protocols based on pilot plant case studies to facilitate meaningful comparisons between different DLE technologies and conventional extraction methods.

Scalability and Commercialization Pathways

The scalability of Direct Lithium Extraction (DLE) technologies from pilot to commercial scale represents a critical pathway for meeting the growing global demand for lithium. Current pilot plant case studies demonstrate varying degrees of success in scaling operations, with several key factors influencing commercial viability.

Technical scalability assessments indicate that membrane-based DLE systems have shown promising results in maintaining extraction efficiency when scaled from laboratory (1-10 L/day) to pilot scale (1,000-10,000 L/day). However, the transition to commercial scale (100,000+ L/day) introduces significant engineering challenges related to membrane fouling and replacement frequency, which directly impacts operational costs.

Ion-exchange based DLE technologies have demonstrated more consistent performance metrics during scale-up, with several pilot plants reporting lithium recovery rates of 80-90% maintained across different operational scales. The Standard Lithium pilot plant in Arkansas and Lilac Solutions' field demonstrations provide valuable data points showing that selective adsorption technologies can maintain performance during scale-up when properly engineered.

Economic pathway analysis reveals that capital expenditure requirements increase non-linearly with scale, with pilot plants typically costing $5-15 million while commercial facilities require $50-200 million investments. The economic inflection point appears to occur at approximately 20,000 tons LCE annual production capacity, where economies of scale begin to significantly reduce per-unit production costs.

Commercialization timelines based on current pilot projects suggest a 3-5 year development cycle from successful pilot demonstration to commercial operation. This includes 12-18 months for engineering design, 18-24 months for construction, and 6-12 months for commissioning and performance verification. Companies with established pilot plants showing consistent performance metrics over 6+ months of continuous operation are best positioned for commercial scale-up.

Regulatory pathways vary significantly by jurisdiction, with projects in established mining regions experiencing more streamlined permitting processes. Environmental performance metrics from pilot operations, particularly regarding water usage, chemical consumption, and waste management, have become critical factors in securing approvals for commercial-scale facilities.

Strategic partnerships between technology developers and established lithium producers have emerged as a dominant commercialization model, allowing for risk sharing and leveraging complementary capabilities. These partnerships typically involve technology licensing arrangements with performance-based milestone payments tied to specific extraction efficiency and production volume metrics demonstrated at pilot scale.

Technical scalability assessments indicate that membrane-based DLE systems have shown promising results in maintaining extraction efficiency when scaled from laboratory (1-10 L/day) to pilot scale (1,000-10,000 L/day). However, the transition to commercial scale (100,000+ L/day) introduces significant engineering challenges related to membrane fouling and replacement frequency, which directly impacts operational costs.

Ion-exchange based DLE technologies have demonstrated more consistent performance metrics during scale-up, with several pilot plants reporting lithium recovery rates of 80-90% maintained across different operational scales. The Standard Lithium pilot plant in Arkansas and Lilac Solutions' field demonstrations provide valuable data points showing that selective adsorption technologies can maintain performance during scale-up when properly engineered.

Economic pathway analysis reveals that capital expenditure requirements increase non-linearly with scale, with pilot plants typically costing $5-15 million while commercial facilities require $50-200 million investments. The economic inflection point appears to occur at approximately 20,000 tons LCE annual production capacity, where economies of scale begin to significantly reduce per-unit production costs.

Commercialization timelines based on current pilot projects suggest a 3-5 year development cycle from successful pilot demonstration to commercial operation. This includes 12-18 months for engineering design, 18-24 months for construction, and 6-12 months for commissioning and performance verification. Companies with established pilot plants showing consistent performance metrics over 6+ months of continuous operation are best positioned for commercial scale-up.

Regulatory pathways vary significantly by jurisdiction, with projects in established mining regions experiencing more streamlined permitting processes. Environmental performance metrics from pilot operations, particularly regarding water usage, chemical consumption, and waste management, have become critical factors in securing approvals for commercial-scale facilities.

Strategic partnerships between technology developers and established lithium producers have emerged as a dominant commercialization model, allowing for risk sharing and leveraging complementary capabilities. These partnerships typically involve technology licensing arrangements with performance-based milestone payments tied to specific extraction efficiency and production volume metrics demonstrated at pilot scale.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!