Water Balance Environmental And ESG Reporting For Direct Lithium Extraction

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DLE Water Balance Technology Background and Objectives

Direct Lithium Extraction (DLE) represents a paradigm shift in lithium production technology, evolving from traditional methods such as evaporation ponds and hard rock mining that dominated the industry for decades. The evolution of DLE technologies began in the early 2000s, with significant acceleration in development occurring over the past decade as demand for lithium has surged due to electric vehicle and energy storage applications. This technological trajectory has been driven by the need for more sustainable, efficient, and environmentally responsible extraction methods.

The water balance aspect of DLE technologies has emerged as a critical focus area, particularly as lithium production faces increasing scrutiny regarding its environmental footprint. Traditional lithium extraction methods consume vast quantities of water—approximately 500,000 gallons per ton of lithium produced in evaporation pond operations—creating significant environmental challenges in water-stressed regions such as the Lithium Triangle in South America.

Current technological objectives for DLE water balance systems center on developing closed-loop water management solutions that minimize freshwater consumption, reduce wastewater discharge, and enable effective water recovery and reuse. These objectives align with broader industry goals to decrease the water intensity of lithium production while maintaining economic viability and scalability.

The environmental and ESG (Environmental, Social, and Governance) reporting dimensions of DLE water balance technologies have gained prominence as investors, regulators, and consumers increasingly demand transparency regarding resource utilization and environmental impacts. This has catalyzed research into comprehensive water accounting methodologies and real-time monitoring systems specific to lithium extraction operations.

Looking forward, the technological trajectory points toward integrated water management systems that incorporate advanced filtration, selective adsorption, and membrane technologies to maximize water recovery rates while minimizing energy consumption. Emerging research also focuses on brine chemistry optimization to reduce scaling and fouling issues that impact water recycling efficiency.

The ultimate goal of DLE water balance technology development is to achieve near-zero liquid discharge operations while maintaining competitive production costs. This represents a significant technical challenge that requires interdisciplinary approaches combining hydrometallurgy, membrane science, process engineering, and digital monitoring technologies.

As global lithium demand is projected to increase by 40-fold by 2040, according to the International Energy Agency, developing water-efficient DLE technologies has become not just an environmental imperative but a strategic necessity for ensuring sustainable growth of the lithium supply chain critical to the clean energy transition.

The water balance aspect of DLE technologies has emerged as a critical focus area, particularly as lithium production faces increasing scrutiny regarding its environmental footprint. Traditional lithium extraction methods consume vast quantities of water—approximately 500,000 gallons per ton of lithium produced in evaporation pond operations—creating significant environmental challenges in water-stressed regions such as the Lithium Triangle in South America.

Current technological objectives for DLE water balance systems center on developing closed-loop water management solutions that minimize freshwater consumption, reduce wastewater discharge, and enable effective water recovery and reuse. These objectives align with broader industry goals to decrease the water intensity of lithium production while maintaining economic viability and scalability.

The environmental and ESG (Environmental, Social, and Governance) reporting dimensions of DLE water balance technologies have gained prominence as investors, regulators, and consumers increasingly demand transparency regarding resource utilization and environmental impacts. This has catalyzed research into comprehensive water accounting methodologies and real-time monitoring systems specific to lithium extraction operations.

Looking forward, the technological trajectory points toward integrated water management systems that incorporate advanced filtration, selective adsorption, and membrane technologies to maximize water recovery rates while minimizing energy consumption. Emerging research also focuses on brine chemistry optimization to reduce scaling and fouling issues that impact water recycling efficiency.

The ultimate goal of DLE water balance technology development is to achieve near-zero liquid discharge operations while maintaining competitive production costs. This represents a significant technical challenge that requires interdisciplinary approaches combining hydrometallurgy, membrane science, process engineering, and digital monitoring technologies.

As global lithium demand is projected to increase by 40-fold by 2040, according to the International Energy Agency, developing water-efficient DLE technologies has become not just an environmental imperative but a strategic necessity for ensuring sustainable growth of the lithium supply chain critical to the clean energy transition.

Market Analysis for Sustainable Lithium Extraction Solutions

The global market for sustainable lithium extraction solutions is experiencing unprecedented growth, driven by the surging demand for lithium-ion batteries in electric vehicles, renewable energy storage systems, and consumer electronics. Traditional lithium extraction methods, primarily evaporation ponds and hard rock mining, face significant environmental challenges including excessive water consumption, habitat disruption, and substantial carbon footprints. This has created a robust market opportunity for Direct Lithium Extraction (DLE) technologies that emphasize water conservation and environmental stewardship.

Market projections indicate that the global lithium market is expected to grow at a compound annual growth rate of 14% through 2027, with DLE technologies potentially capturing a significant portion of new production capacity. The emphasis on water balance and environmental reporting in DLE operations aligns with the broader ESG (Environmental, Social, and Governance) investment trend, which has seen capital flows to ESG-focused projects increase dramatically in recent years.

Consumer-facing industries, particularly automotive manufacturers, are increasingly demanding responsibly sourced materials for their supply chains. Major automakers have established sustainability commitments that cascade down to their raw material suppliers, creating premium market segments for environmentally responsible lithium. This market differentiation potential represents a significant value proposition for DLE operations with robust water management and ESG reporting frameworks.

Regional market analysis reveals varying drivers across geographies. In water-stressed regions like Chile's Atacama Desert and Argentina's lithium triangle, regulatory pressures and community concerns regarding water usage are accelerating the adoption of water-efficient extraction technologies. In North America and Europe, consumer and investor preferences for sustainable products are the primary market drivers.

The competitive landscape includes established mining companies pivoting toward DLE technologies, specialized technology providers, and innovative startups. Market consolidation through strategic partnerships and acquisitions is becoming increasingly common as companies seek to secure technological advantages in sustainable extraction methods.

Market barriers include the higher capital expenditure requirements for DLE facilities compared to traditional methods, technological uncertainties for scaled implementation, and the need for specialized expertise in water balance management and ESG reporting. However, these barriers are offset by the long-term operational benefits, regulatory advantages, and premium pricing potential for sustainably produced lithium.

Customer segmentation analysis reveals three primary buyer categories: battery manufacturers seeking ESG-compliant supply chains, automotive companies with sustainability commitments, and energy storage system developers addressing renewable energy integration challenges. Each segment presents distinct requirements for water management transparency and environmental performance documentation.

Market projections indicate that the global lithium market is expected to grow at a compound annual growth rate of 14% through 2027, with DLE technologies potentially capturing a significant portion of new production capacity. The emphasis on water balance and environmental reporting in DLE operations aligns with the broader ESG (Environmental, Social, and Governance) investment trend, which has seen capital flows to ESG-focused projects increase dramatically in recent years.

Consumer-facing industries, particularly automotive manufacturers, are increasingly demanding responsibly sourced materials for their supply chains. Major automakers have established sustainability commitments that cascade down to their raw material suppliers, creating premium market segments for environmentally responsible lithium. This market differentiation potential represents a significant value proposition for DLE operations with robust water management and ESG reporting frameworks.

Regional market analysis reveals varying drivers across geographies. In water-stressed regions like Chile's Atacama Desert and Argentina's lithium triangle, regulatory pressures and community concerns regarding water usage are accelerating the adoption of water-efficient extraction technologies. In North America and Europe, consumer and investor preferences for sustainable products are the primary market drivers.

The competitive landscape includes established mining companies pivoting toward DLE technologies, specialized technology providers, and innovative startups. Market consolidation through strategic partnerships and acquisitions is becoming increasingly common as companies seek to secure technological advantages in sustainable extraction methods.

Market barriers include the higher capital expenditure requirements for DLE facilities compared to traditional methods, technological uncertainties for scaled implementation, and the need for specialized expertise in water balance management and ESG reporting. However, these barriers are offset by the long-term operational benefits, regulatory advantages, and premium pricing potential for sustainably produced lithium.

Customer segmentation analysis reveals three primary buyer categories: battery manufacturers seeking ESG-compliant supply chains, automotive companies with sustainability commitments, and energy storage system developers addressing renewable energy integration challenges. Each segment presents distinct requirements for water management transparency and environmental performance documentation.

Current Challenges in DLE Water Management Technologies

Direct Lithium Extraction (DLE) technologies face significant water management challenges that impede their widespread adoption and environmental sustainability. The primary challenge lies in the substantial water consumption required for lithium extraction processes, particularly in water-scarce regions where many lithium deposits are located. Current DLE operations typically require between 10-15 cubic meters of water per ton of lithium carbonate equivalent produced, creating tension between resource extraction and water conservation objectives.

Water quality management presents another critical challenge, as DLE processes generate complex wastewater streams containing various contaminants including dissolved solids, heavy metals, and process chemicals. Conventional treatment technologies struggle to handle these mixed waste streams cost-effectively, often requiring multiple treatment stages that increase operational complexity and costs.

The circular water economy remains underdeveloped in DLE operations, with limited implementation of closed-loop systems. Most facilities still operate with linear water use patterns, where water is extracted, used, and discharged rather than recycled. This approach not only increases freshwater demand but also creates additional environmental liabilities through discharge management requirements.

Monitoring and reporting infrastructure for water usage in DLE operations is frequently inadequate, with inconsistent measurement methodologies and limited real-time data collection capabilities. This hampers accurate water footprint assessment and complicates ESG reporting requirements, which increasingly demand transparent water stewardship practices.

Regulatory compliance presents a moving target as environmental regulations governing water extraction and discharge continue to evolve, particularly in developing countries where many lithium resources are concentrated. Companies must navigate complex and sometimes contradictory regulatory frameworks across different jurisdictions, adding uncertainty to operational planning.

Energy-water nexus considerations further complicate DLE water management, as water treatment and recycling processes require significant energy inputs. This creates a challenging optimization problem where reducing water consumption may increase energy usage and associated carbon emissions, potentially undermining broader sustainability goals.

Technological limitations persist in brine concentration and purification processes, with current membrane and thermal technologies facing efficiency constraints when processing highly concentrated lithium brines. These limitations result in higher water consumption than theoretically necessary, highlighting the need for more advanced separation technologies.

Water quality management presents another critical challenge, as DLE processes generate complex wastewater streams containing various contaminants including dissolved solids, heavy metals, and process chemicals. Conventional treatment technologies struggle to handle these mixed waste streams cost-effectively, often requiring multiple treatment stages that increase operational complexity and costs.

The circular water economy remains underdeveloped in DLE operations, with limited implementation of closed-loop systems. Most facilities still operate with linear water use patterns, where water is extracted, used, and discharged rather than recycled. This approach not only increases freshwater demand but also creates additional environmental liabilities through discharge management requirements.

Monitoring and reporting infrastructure for water usage in DLE operations is frequently inadequate, with inconsistent measurement methodologies and limited real-time data collection capabilities. This hampers accurate water footprint assessment and complicates ESG reporting requirements, which increasingly demand transparent water stewardship practices.

Regulatory compliance presents a moving target as environmental regulations governing water extraction and discharge continue to evolve, particularly in developing countries where many lithium resources are concentrated. Companies must navigate complex and sometimes contradictory regulatory frameworks across different jurisdictions, adding uncertainty to operational planning.

Energy-water nexus considerations further complicate DLE water management, as water treatment and recycling processes require significant energy inputs. This creates a challenging optimization problem where reducing water consumption may increase energy usage and associated carbon emissions, potentially undermining broader sustainability goals.

Technological limitations persist in brine concentration and purification processes, with current membrane and thermal technologies facing efficiency constraints when processing highly concentrated lithium brines. These limitations result in higher water consumption than theoretically necessary, highlighting the need for more advanced separation technologies.

Current Water Balance Reporting Frameworks for DLE

01 Water recycling and reuse in DLE processes

Direct Lithium Extraction processes can be optimized through efficient water recycling and reuse systems. These systems help minimize freshwater consumption by treating and recirculating process water. Advanced filtration, reverse osmosis, and other purification technologies are employed to remove impurities from the water before reintroduction into the extraction cycle, significantly reducing the overall water footprint of lithium production operations.- Water recycling and reuse in DLE processes: Direct Lithium Extraction processes can be optimized through efficient water recycling and reuse systems. These systems help minimize freshwater consumption by treating and recirculating process water. Advanced filtration, reverse osmosis, and other purification technologies enable the removal of impurities from used process water, allowing it to be reintroduced into the extraction cycle. This approach significantly improves the water balance by reducing overall water requirements and minimizing discharge to the environment.

- Closed-loop water systems for DLE operations: Closed-loop water systems represent an advanced approach to water management in Direct Lithium Extraction. These systems are designed to capture, treat, and reuse virtually all process water, creating a near-zero discharge operation. By implementing sophisticated water treatment technologies and process integration, closed-loop systems effectively separate lithium from other components while maintaining water within the operational cycle. This approach minimizes environmental impact and reduces dependence on external water sources, particularly beneficial in water-scarce regions where lithium extraction often occurs.

- Brine management and water recovery techniques: Effective brine management is crucial for maintaining optimal water balance in Direct Lithium Extraction operations. Advanced techniques focus on maximizing lithium recovery while minimizing water losses from brine solutions. These include selective adsorption processes, membrane technologies, and evaporation control systems that enable efficient separation of lithium from the brine while preserving water content. By implementing sophisticated brine concentration and water recovery methods, DLE operations can significantly reduce freshwater requirements and improve overall process sustainability.

- Water treatment and purification for DLE processes: Water treatment and purification technologies play a vital role in maintaining water balance in Direct Lithium Extraction operations. These technologies focus on removing contaminants, adjusting pH levels, and conditioning water for reuse in the extraction process. Advanced filtration systems, ion exchange processes, and chemical treatments enable the conversion of wastewater into process-ready water. By implementing comprehensive water treatment protocols, DLE operations can maintain consistent water quality, reduce freshwater intake, and minimize environmental discharge while ensuring efficient lithium recovery.

- Water-efficient extraction technologies: Innovative water-efficient extraction technologies are being developed to address water balance challenges in Direct Lithium Extraction. These technologies focus on minimizing water consumption through advanced process designs that require less water per unit of lithium produced. Examples include selective adsorption materials, direct extraction from solid materials, and novel solvent systems that reduce water requirements. By implementing these water-efficient technologies, DLE operations can achieve higher lithium recovery rates while maintaining favorable water balance, particularly important in regions facing water scarcity issues.

02 Closed-loop water management systems

Closed-loop water management systems in DLE operations aim to minimize water losses and environmental impact. These systems capture, treat, and reuse process water within the extraction facility, reducing dependence on external water sources. The implementation of closed-loop systems includes water recovery from various process stages, treatment of wastewater, and monitoring of water quality parameters to maintain operational efficiency while addressing environmental concerns.Expand Specific Solutions03 Brine management and water conservation techniques

Effective brine management is crucial for water balance in DLE operations. Techniques include selective extraction of lithium while minimizing water removal from brines, efficient brine reinjection systems, and evaporation control methods. Advanced separation technologies allow for the extraction of lithium while maintaining the overall water balance of the brine resource. These approaches help preserve the natural hydrological conditions of lithium-rich aquifers and reduce environmental impact.Expand Specific Solutions04 Water treatment and purification for DLE operations

Water treatment and purification technologies play a vital role in maintaining water balance in DLE processes. These include membrane filtration, ion exchange, electrochemical treatment, and advanced oxidation processes to remove contaminants from process water. Effective water treatment enables the reuse of water in extraction operations, reduces discharge volumes, and helps meet environmental regulations while optimizing the overall water efficiency of lithium production.Expand Specific Solutions05 Integrated water and energy management in DLE

Integrated approaches to water and energy management in DLE processes focus on optimizing both resources simultaneously. These systems incorporate energy-efficient water treatment technologies, waste heat recovery for water processing, and renewable energy sources to power water management operations. By addressing water and energy needs together, these integrated systems improve the sustainability and economic viability of lithium extraction while minimizing environmental footprint and operational costs.Expand Specific Solutions

Key Industry Players in DLE Water Management

Direct Lithium Extraction (DLE) for water balance and ESG reporting is in an early growth phase, with market size expanding rapidly due to increasing demand for sustainable lithium production. The technology is approaching commercial maturity, with varying levels of advancement among key players. Schlumberger Technologies and Koch Technology Solutions are leveraging their energy sector expertise to develop industrial-scale DLE solutions, while specialized firms like Lilac Solutions and Saltworks Technologies focus on innovative extraction methods with reduced environmental footprints. Academic institutions including Central South University and Fraunhofer-Gesellschaft are advancing fundamental research, while companies such as Vulcan Energie Ressourcen and Evove are pioneering zero-carbon lithium production technologies. The competitive landscape is diversifying as both established energy corporations and specialized startups develop proprietary DLE technologies addressing water conservation and ESG compliance.

Schlumberger Technologies, Inc.

Technical Solution: Schlumberger has developed an integrated water balance and ESG reporting system specifically for Direct Lithium Extraction (DLE) operations. Their technology combines real-time monitoring sensors, advanced analytics, and cloud-based reporting platforms to provide comprehensive water management solutions. The system tracks water usage throughout the DLE process, measuring extraction rates, processing consumption, reinjection volumes, and evaporation losses with high precision. Schlumberger's solution incorporates AI-driven predictive analytics to optimize water usage and minimize environmental impact while maintaining extraction efficiency. Their platform generates automated ESG reports compliant with international standards such as SASB, GRI, and TCFD, providing transparent data on water consumption metrics, carbon footprint, and land use impacts associated with lithium extraction operations[1][3]. The technology integrates with their existing oilfield management systems, leveraging decades of experience in resource extraction monitoring to address the specific challenges of DLE water management.

Strengths: Leverages extensive experience in resource extraction monitoring; seamless integration with existing field operations; comprehensive real-time data collection capabilities; advanced predictive analytics for optimization. Weaknesses: Potentially higher implementation costs than simpler solutions; may require significant customization for different DLE technologies; relies on robust connectivity infrastructure that might be lacking in remote lithium operations.

Lilac Solutions, Inc.

Technical Solution: Lilac Solutions has pioneered an ion exchange technology for Direct Lithium Extraction that fundamentally transforms water management in lithium operations. Their proprietary ion exchange beads selectively extract lithium from brine while minimizing water consumption compared to traditional evaporation methods. The company's water balance system incorporates closed-loop processing that recovers approximately 98% of water used in operations, significantly reducing freshwater requirements[2]. Lilac's integrated environmental monitoring platform tracks water usage metrics, including withdrawal rates, recycling efficiency, and discharge quality in real-time. Their ESG reporting solution automatically generates compliance documentation showing water intensity per ton of lithium produced, enabling comparison against industry benchmarks. The technology includes specialized sensors that monitor potential contaminants in process water and surrounding groundwater systems to ensure environmental protection. Lilac's platform also calculates the water footprint reduction achieved compared to traditional evaporation pond methods, quantifying the environmental benefits for stakeholders and regulatory reporting[4].

Strengths: Revolutionary water efficiency compared to traditional methods; closed-loop system minimizes environmental impact; provides clear comparative metrics against conventional extraction; highly selective extraction reduces contamination risks. Weaknesses: Technology is relatively new with limited long-term operational data; may face challenges scaling to very large production volumes; higher upfront capital costs compared to traditional evaporation methods.

Technical Innovations in DLE Water Conservation

Accounting for sustainability: integrating environmental, social, and governance (ESG) factors in financial reporting

PatentPendingIN202311041296A

Innovation

- A comprehensive list of ESG keywords is compiled, categorized, and analyzed using textual analysis to transform qualitative insights into quantitative data, enabling deeper investigation and comparison of ESG reporting, particularly through the analysis of 10-K filings and proxy statements, facilitating decision-making and identifying trends in ESG metrics.

Method and electronic device for handling environmental, social, governance (ESG) data

PatentUndeterminedIN202221025639A

Innovation

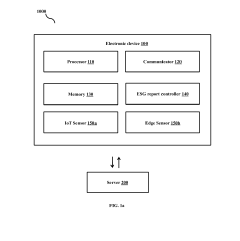

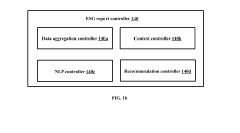

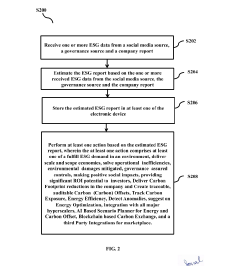

- An electronic device and method that receive and estimate ESG reports from social media, governance, and company sources using IoT and edge sensors, integrating AI for real-time analysis and blockchain-based storage, enabling actions such as carbon footprint reduction, energy optimization, and third-party integrations for improved reporting and stakeholder engagement.

Regulatory Compliance for DLE Water Usage

Direct Lithium Extraction (DLE) operations are subject to increasingly stringent regulatory frameworks governing water usage across different jurisdictions. These regulations stem from growing concerns about water scarcity and the environmental impact of lithium extraction activities, particularly in water-stressed regions such as the Lithium Triangle in South America and arid regions of North America and Australia.

At the federal level, most countries with significant lithium resources have established baseline requirements for water withdrawal permits, discharge standards, and monitoring protocols. In the United States, DLE operations must comply with the Clean Water Act, Safe Drinking Water Act, and specific Bureau of Land Management regulations when operating on federal lands. The Environmental Protection Agency (EPA) enforces strict reporting requirements regarding water quality parameters and consumption volumes.

Regional and state-level regulations often impose additional, more stringent requirements. For instance, in Nevada and California, water rights allocation systems require detailed justification for industrial water usage, with priority given to senior water rights holders. These jurisdictions have implemented mandatory water recycling targets specifically for mining operations, with some requiring up to 80% water recovery rates.

International frameworks add another layer of compliance requirements. The International Council on Mining and Metals (ICMM) has established water stewardship principles that many major lithium producers have voluntarily adopted. Additionally, countries like Chile and Argentina have implemented lithium-specific regulations, including water usage caps in sensitive areas such as the Salar de Atacama, where operators must demonstrate minimal impact on fragile hydrological systems.

ESG reporting standards related to water usage have evolved significantly, with frameworks such as the Global Reporting Initiative (GRI), Sustainability Accounting Standards Board (SASB), and Task Force on Climate-related Financial Disclosures (TCFD) requiring comprehensive water balance reporting. These standards mandate disclosure of total water withdrawal, consumption, recycling rates, and impacts on local water resources.

Compliance verification typically involves continuous monitoring systems, regular third-party audits, and community engagement processes. Many jurisdictions now require real-time water monitoring data to be made publicly available, increasing transparency and accountability. Non-compliance can result in substantial penalties, including fines, production restrictions, or even license revocation.

Forward-looking regulations are trending toward watershed-level management approaches rather than project-specific permits. This holistic approach considers cumulative impacts of multiple operations on regional water resources, requiring collaborative water management strategies among different stakeholders. Companies investing in DLE technologies must therefore anticipate increasingly complex regulatory landscapes that will demand sophisticated water accounting systems and adaptive management strategies.

At the federal level, most countries with significant lithium resources have established baseline requirements for water withdrawal permits, discharge standards, and monitoring protocols. In the United States, DLE operations must comply with the Clean Water Act, Safe Drinking Water Act, and specific Bureau of Land Management regulations when operating on federal lands. The Environmental Protection Agency (EPA) enforces strict reporting requirements regarding water quality parameters and consumption volumes.

Regional and state-level regulations often impose additional, more stringent requirements. For instance, in Nevada and California, water rights allocation systems require detailed justification for industrial water usage, with priority given to senior water rights holders. These jurisdictions have implemented mandatory water recycling targets specifically for mining operations, with some requiring up to 80% water recovery rates.

International frameworks add another layer of compliance requirements. The International Council on Mining and Metals (ICMM) has established water stewardship principles that many major lithium producers have voluntarily adopted. Additionally, countries like Chile and Argentina have implemented lithium-specific regulations, including water usage caps in sensitive areas such as the Salar de Atacama, where operators must demonstrate minimal impact on fragile hydrological systems.

ESG reporting standards related to water usage have evolved significantly, with frameworks such as the Global Reporting Initiative (GRI), Sustainability Accounting Standards Board (SASB), and Task Force on Climate-related Financial Disclosures (TCFD) requiring comprehensive water balance reporting. These standards mandate disclosure of total water withdrawal, consumption, recycling rates, and impacts on local water resources.

Compliance verification typically involves continuous monitoring systems, regular third-party audits, and community engagement processes. Many jurisdictions now require real-time water monitoring data to be made publicly available, increasing transparency and accountability. Non-compliance can result in substantial penalties, including fines, production restrictions, or even license revocation.

Forward-looking regulations are trending toward watershed-level management approaches rather than project-specific permits. This holistic approach considers cumulative impacts of multiple operations on regional water resources, requiring collaborative water management strategies among different stakeholders. Companies investing in DLE technologies must therefore anticipate increasingly complex regulatory landscapes that will demand sophisticated water accounting systems and adaptive management strategies.

ESG Performance Metrics and Standardization

In the rapidly evolving landscape of Direct Lithium Extraction (DLE), standardized ESG performance metrics have become increasingly critical for industry transparency and regulatory compliance. Currently, the sector faces significant challenges due to fragmented reporting frameworks, with companies utilizing various methodologies to measure water usage, carbon emissions, and community impact. This inconsistency creates difficulties for investors, regulators, and stakeholders when comparing performance across different lithium extraction operations.

The Global Reporting Initiative (GRI) and Sustainability Accounting Standards Board (SASB) have developed preliminary frameworks applicable to mining operations, but specific metrics tailored to DLE technologies remain underdeveloped. Key performance indicators should include water consumption per ton of lithium carbonate equivalent (LCE), percentage of water recycled, freshwater withdrawal impact on local aquifers, and brine reinjection rates.

Several industry leaders have begun implementing more comprehensive ESG reporting systems. Albemarle Corporation and SQM have pioneered water balance accounting systems that track inputs, outputs, and recycling rates with greater precision. These systems incorporate real-time monitoring technologies and blockchain verification to ensure data integrity, setting new benchmarks for the industry.

The International Organization for Standardization (ISO) is currently developing ISO 24444, specifically addressing water management in lithium extraction operations. This standard aims to harmonize reporting methodologies and establish minimum disclosure requirements, potentially becoming mandatory for operations in water-stressed regions. Similarly, the Initiative for Responsible Mining Assurance (IRMA) has expanded its certification program to include DLE-specific water management criteria.

Emerging technologies are enhancing the accuracy and reliability of ESG metrics collection. IoT sensor networks enable continuous monitoring of water flows throughout DLE processes, while AI-powered analytics platforms can identify optimization opportunities and predict potential environmental impacts before they occur. These technological advancements are gradually eliminating the subjectivity in ESG reporting.

For DLE operations to achieve meaningful ESG standardization, industry collaboration is essential. The newly formed Lithium Extraction Sustainability Coalition, comprising major producers, technology providers, and environmental organizations, is working to establish a unified reporting framework specifically designed for DLE operations, with water management as a central component. This initiative aims to create a certification system that would become the industry gold standard by 2025.

The Global Reporting Initiative (GRI) and Sustainability Accounting Standards Board (SASB) have developed preliminary frameworks applicable to mining operations, but specific metrics tailored to DLE technologies remain underdeveloped. Key performance indicators should include water consumption per ton of lithium carbonate equivalent (LCE), percentage of water recycled, freshwater withdrawal impact on local aquifers, and brine reinjection rates.

Several industry leaders have begun implementing more comprehensive ESG reporting systems. Albemarle Corporation and SQM have pioneered water balance accounting systems that track inputs, outputs, and recycling rates with greater precision. These systems incorporate real-time monitoring technologies and blockchain verification to ensure data integrity, setting new benchmarks for the industry.

The International Organization for Standardization (ISO) is currently developing ISO 24444, specifically addressing water management in lithium extraction operations. This standard aims to harmonize reporting methodologies and establish minimum disclosure requirements, potentially becoming mandatory for operations in water-stressed regions. Similarly, the Initiative for Responsible Mining Assurance (IRMA) has expanded its certification program to include DLE-specific water management criteria.

Emerging technologies are enhancing the accuracy and reliability of ESG metrics collection. IoT sensor networks enable continuous monitoring of water flows throughout DLE processes, while AI-powered analytics platforms can identify optimization opportunities and predict potential environmental impacts before they occur. These technological advancements are gradually eliminating the subjectivity in ESG reporting.

For DLE operations to achieve meaningful ESG standardization, industry collaboration is essential. The newly formed Lithium Extraction Sustainability Coalition, comprising major producers, technology providers, and environmental organizations, is working to establish a unified reporting framework specifically designed for DLE operations, with water management as a central component. This initiative aims to create a certification system that would become the industry gold standard by 2025.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!