Chemical Sensors Developed from Sulphanilic Acid: Sensitivity and Selectivity Studies

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sulphanilic Acid Sensors: Background and Objectives

Chemical sensors developed from sulphanilic acid have emerged as a promising field in analytical chemistry, offering potential solutions for sensitive and selective detection of various analytes. The evolution of these sensors can be traced back to the early 20th century when sulphanilic acid was first synthesized and its chemical properties were explored. Over the decades, researchers have recognized the unique characteristics of sulphanilic acid, particularly its ability to form diazonium salts and undergo coupling reactions, which make it an excellent candidate for sensor development.

The primary objective of developing chemical sensors based on sulphanilic acid is to create highly sensitive and selective detection methods for a wide range of analytes, including environmental pollutants, biological molecules, and industrial chemicals. These sensors aim to provide rapid, accurate, and cost-effective analysis in various fields such as environmental monitoring, healthcare diagnostics, and quality control in manufacturing processes.

The technological progression in this area has been driven by the need for more efficient and reliable sensing methods. Traditional analytical techniques often require complex instrumentation, time-consuming sample preparation, and skilled operators. Sulphanilic acid-based sensors offer the potential to overcome these limitations by providing simple, portable, and user-friendly detection systems.

Recent advancements in nanotechnology and materials science have further accelerated the development of sulphanilic acid sensors. The integration of nanomaterials, such as carbon nanotubes, graphene, and metal nanoparticles, with sulphanilic acid has led to enhanced sensitivity and selectivity. These hybrid materials exploit the unique properties of both components, resulting in improved sensor performance.

The current research focus in this field is on optimizing the sensor design to achieve lower detection limits, broader dynamic ranges, and higher specificity for target analytes. Scientists are exploring various modification strategies, including surface functionalization, molecular imprinting, and the incorporation of recognition elements such as aptamers and antibodies.

As we look towards the future, the development of sulphanilic acid-based chemical sensors is expected to contribute significantly to the advancement of point-of-care diagnostics, environmental monitoring systems, and industrial process control. The ultimate goal is to create robust, reliable, and versatile sensing platforms that can address the growing demand for rapid and accurate chemical analysis in diverse applications.

The primary objective of developing chemical sensors based on sulphanilic acid is to create highly sensitive and selective detection methods for a wide range of analytes, including environmental pollutants, biological molecules, and industrial chemicals. These sensors aim to provide rapid, accurate, and cost-effective analysis in various fields such as environmental monitoring, healthcare diagnostics, and quality control in manufacturing processes.

The technological progression in this area has been driven by the need for more efficient and reliable sensing methods. Traditional analytical techniques often require complex instrumentation, time-consuming sample preparation, and skilled operators. Sulphanilic acid-based sensors offer the potential to overcome these limitations by providing simple, portable, and user-friendly detection systems.

Recent advancements in nanotechnology and materials science have further accelerated the development of sulphanilic acid sensors. The integration of nanomaterials, such as carbon nanotubes, graphene, and metal nanoparticles, with sulphanilic acid has led to enhanced sensitivity and selectivity. These hybrid materials exploit the unique properties of both components, resulting in improved sensor performance.

The current research focus in this field is on optimizing the sensor design to achieve lower detection limits, broader dynamic ranges, and higher specificity for target analytes. Scientists are exploring various modification strategies, including surface functionalization, molecular imprinting, and the incorporation of recognition elements such as aptamers and antibodies.

As we look towards the future, the development of sulphanilic acid-based chemical sensors is expected to contribute significantly to the advancement of point-of-care diagnostics, environmental monitoring systems, and industrial process control. The ultimate goal is to create robust, reliable, and versatile sensing platforms that can address the growing demand for rapid and accurate chemical analysis in diverse applications.

Market Analysis for Chemical Sensor Applications

The chemical sensor market has experienced significant growth in recent years, driven by increasing demand across various industries such as environmental monitoring, healthcare, and industrial processes. The global chemical sensor market was valued at approximately $20 billion in 2020 and is projected to reach $30 billion by 2025, with a compound annual growth rate (CAGR) of around 8%.

Chemical sensors developed from sulphanilic acid have garnered particular interest due to their potential for enhanced sensitivity and selectivity. These sensors are finding applications in diverse fields, including water quality monitoring, food safety testing, and medical diagnostics. The market for sulphanilic acid-based chemical sensors is expected to grow at a faster rate than the overall chemical sensor market, with a CAGR of 10-12% over the next five years.

One of the key drivers for the growth of sulphanilic acid-based chemical sensors is the increasing need for real-time and accurate detection of various chemical compounds in environmental and industrial settings. Governments worldwide are implementing stricter regulations on pollutant monitoring, creating a strong demand for advanced sensing technologies. Additionally, the healthcare sector is showing growing interest in these sensors for point-of-care diagnostics and continuous health monitoring applications.

The food and beverage industry is another significant market for sulphanilic acid-based chemical sensors. With rising concerns about food safety and quality, there is a growing need for rapid and reliable detection of contaminants and adulterants in food products. These sensors offer the potential for on-site testing, reducing the time and cost associated with traditional laboratory analysis.

In terms of geographical distribution, North America and Europe currently dominate the market for advanced chemical sensors, including those based on sulphanilic acid. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, increasing environmental concerns, and growing investments in healthcare infrastructure.

Despite the promising market outlook, there are challenges that need to be addressed. These include the need for further improvements in sensor stability and longevity, as well as reducing production costs to make these sensors more accessible for widespread adoption. Additionally, the development of standardized testing and calibration protocols will be crucial for ensuring the reliability and comparability of sensor measurements across different applications and industries.

Chemical sensors developed from sulphanilic acid have garnered particular interest due to their potential for enhanced sensitivity and selectivity. These sensors are finding applications in diverse fields, including water quality monitoring, food safety testing, and medical diagnostics. The market for sulphanilic acid-based chemical sensors is expected to grow at a faster rate than the overall chemical sensor market, with a CAGR of 10-12% over the next five years.

One of the key drivers for the growth of sulphanilic acid-based chemical sensors is the increasing need for real-time and accurate detection of various chemical compounds in environmental and industrial settings. Governments worldwide are implementing stricter regulations on pollutant monitoring, creating a strong demand for advanced sensing technologies. Additionally, the healthcare sector is showing growing interest in these sensors for point-of-care diagnostics and continuous health monitoring applications.

The food and beverage industry is another significant market for sulphanilic acid-based chemical sensors. With rising concerns about food safety and quality, there is a growing need for rapid and reliable detection of contaminants and adulterants in food products. These sensors offer the potential for on-site testing, reducing the time and cost associated with traditional laboratory analysis.

In terms of geographical distribution, North America and Europe currently dominate the market for advanced chemical sensors, including those based on sulphanilic acid. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, increasing environmental concerns, and growing investments in healthcare infrastructure.

Despite the promising market outlook, there are challenges that need to be addressed. These include the need for further improvements in sensor stability and longevity, as well as reducing production costs to make these sensors more accessible for widespread adoption. Additionally, the development of standardized testing and calibration protocols will be crucial for ensuring the reliability and comparability of sensor measurements across different applications and industries.

Current Challenges in Sulphanilic Acid-based Sensors

Despite the promising potential of sulphanilic acid-based chemical sensors, several significant challenges currently hinder their widespread adoption and optimal performance. One of the primary obstacles is the limited sensitivity of these sensors, particularly when detecting low concentrations of target analytes. This issue stems from the inherent chemical properties of sulphanilic acid and its derivatives, which may not always provide sufficiently strong or specific interactions with certain molecules of interest.

Selectivity remains another critical challenge for sulphanilic acid-based sensors. In complex sample matrices, these sensors often struggle to discriminate between structurally similar compounds, leading to potential false positives or inaccurate measurements. This lack of specificity can be particularly problematic in applications requiring precise identification of specific analytes amidst a mixture of interfering substances.

The stability and longevity of sulphanilic acid-based sensors pose additional concerns. Environmental factors such as temperature, humidity, and pH can significantly affect the sensor's performance and reliability over time. This instability may result in drift, reduced sensitivity, or even complete loss of functionality, necessitating frequent recalibration or replacement of sensor components.

Reproducibility in sensor fabrication and performance is another hurdle that researchers and manufacturers face. Variations in the synthesis and immobilization of sulphanilic acid derivatives can lead to inconsistencies in sensor behavior, making it challenging to achieve uniform and reliable results across different batches or production runs.

The response time of sulphanilic acid-based sensors is often slower than desired for real-time monitoring applications. This limitation can be attributed to the kinetics of the chemical reactions involved in the sensing mechanism, as well as the diffusion rates of analytes through the sensor matrix. Improving the speed of detection without compromising accuracy remains a significant challenge in the field.

Furthermore, the integration of sulphanilic acid-based sensors into miniaturized and portable devices presents technical difficulties. Scaling down the sensor components while maintaining their performance characteristics requires innovative approaches in materials science and engineering. Additionally, ensuring the compatibility of these sensors with existing electronic systems and data processing algorithms adds another layer of complexity to their development and implementation.

Lastly, the cost-effectiveness of sulphanilic acid-based sensors compared to alternative sensing technologies is a concern for commercial viability. While sulphanilic acid itself is relatively inexpensive, the overall production costs, including specialized equipment and skilled labor for sensor fabrication, may limit their competitiveness in certain market segments.

Selectivity remains another critical challenge for sulphanilic acid-based sensors. In complex sample matrices, these sensors often struggle to discriminate between structurally similar compounds, leading to potential false positives or inaccurate measurements. This lack of specificity can be particularly problematic in applications requiring precise identification of specific analytes amidst a mixture of interfering substances.

The stability and longevity of sulphanilic acid-based sensors pose additional concerns. Environmental factors such as temperature, humidity, and pH can significantly affect the sensor's performance and reliability over time. This instability may result in drift, reduced sensitivity, or even complete loss of functionality, necessitating frequent recalibration or replacement of sensor components.

Reproducibility in sensor fabrication and performance is another hurdle that researchers and manufacturers face. Variations in the synthesis and immobilization of sulphanilic acid derivatives can lead to inconsistencies in sensor behavior, making it challenging to achieve uniform and reliable results across different batches or production runs.

The response time of sulphanilic acid-based sensors is often slower than desired for real-time monitoring applications. This limitation can be attributed to the kinetics of the chemical reactions involved in the sensing mechanism, as well as the diffusion rates of analytes through the sensor matrix. Improving the speed of detection without compromising accuracy remains a significant challenge in the field.

Furthermore, the integration of sulphanilic acid-based sensors into miniaturized and portable devices presents technical difficulties. Scaling down the sensor components while maintaining their performance characteristics requires innovative approaches in materials science and engineering. Additionally, ensuring the compatibility of these sensors with existing electronic systems and data processing algorithms adds another layer of complexity to their development and implementation.

Lastly, the cost-effectiveness of sulphanilic acid-based sensors compared to alternative sensing technologies is a concern for commercial viability. While sulphanilic acid itself is relatively inexpensive, the overall production costs, including specialized equipment and skilled labor for sensor fabrication, may limit their competitiveness in certain market segments.

Existing Sulphanilic Acid Sensor Designs

01 Sulphanilic acid-based chemical sensors for enhanced sensitivity

Chemical sensors developed using sulphanilic acid as a key component demonstrate improved sensitivity for detecting various analytes. These sensors utilize the unique properties of sulphanilic acid to enhance the detection capabilities, allowing for more accurate and reliable measurements in various applications.- Sulphanilic acid-based chemical sensors for enhanced sensitivity: Chemical sensors developed using sulphanilic acid as a key component demonstrate improved sensitivity for detecting various analytes. These sensors utilize the unique properties of sulphanilic acid to enhance the detection capabilities, allowing for more accurate and reliable measurements in various applications.

- Selective detection methods using sulphanilic acid derivatives: Sensors incorporating sulphanilic acid derivatives exhibit high selectivity for specific target molecules. These sensors are designed to discriminate between different analytes, reducing interference from other substances and improving the accuracy of detection in complex sample matrices.

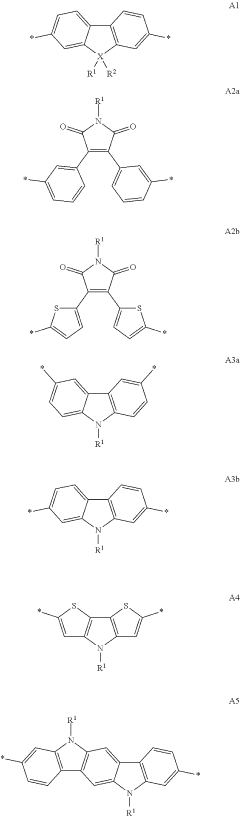

- Nanostructured sulphanilic acid-based sensors for improved performance: Nanostructured materials incorporating sulphanilic acid are used to develop chemical sensors with enhanced sensitivity and selectivity. These sensors leverage the increased surface area and unique properties of nanomaterials to improve detection limits and response times.

- Electrochemical sensors utilizing sulphanilic acid: Electrochemical sensors based on sulphanilic acid and its derivatives are developed for various applications. These sensors exploit the electrochemical properties of sulphanilic acid to achieve sensitive and selective detection of target analytes through electrochemical reactions.

- Functionalization of sulphanilic acid for tailored sensor properties: Chemical modification and functionalization of sulphanilic acid are employed to tailor the properties of sensors for specific applications. These modifications enhance the sensitivity, selectivity, and stability of the sensors, allowing for customized detection capabilities in various environments.

02 Selectivity improvement in sulphanilic acid sensors

Researchers have developed methods to enhance the selectivity of chemical sensors based on sulphanilic acid. These improvements allow the sensors to discriminate between different analytes more effectively, reducing interference from other substances and increasing the accuracy of measurements in complex environments.Expand Specific Solutions03 Nanostructured sulphanilic acid sensors for increased performance

Incorporating nanostructures into sulphanilic acid-based chemical sensors has led to significant improvements in both sensitivity and selectivity. These nanostructured sensors offer larger surface areas and unique properties that enhance their detection capabilities and overall performance.Expand Specific Solutions04 Functionalization of sulphanilic acid for specific analyte detection

Chemical modification and functionalization of sulphanilic acid have been employed to create sensors tailored for specific analyte detection. This approach allows for the development of highly selective sensors for targeted applications in various fields, including environmental monitoring and medical diagnostics.Expand Specific Solutions05 Integration of sulphanilic acid sensors in electronic devices

Sulphanilic acid-based chemical sensors have been successfully integrated into electronic devices and systems. This integration enables real-time monitoring and analysis, making these sensors suitable for a wide range of applications, from portable diagnostic tools to industrial process control systems.Expand Specific Solutions

Key Players in Chemical Sensor Industry

The development of chemical sensors from sulphanilic acid is in an early stage of industry growth, with a relatively small but expanding market. The technology's maturity is still evolving, as evidenced by ongoing research at institutions like Shandong Agricultural University and the University of Jinan. Major players such as Caterpillar Inc. and Sony Group Corp. are likely exploring applications in their respective industries. Specialized companies like N5 Sensors, Inc. are focusing on sensor development, while research organizations like Fraunhofer-Gesellschaft and the Industrial Technology Research Institute are contributing to advancements in this field. The involvement of diverse entities suggests growing interest and potential for future market expansion in chemical sensor technology.

N5 Sensors, Inc.

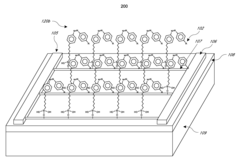

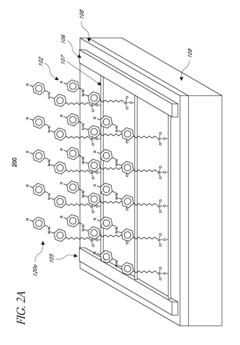

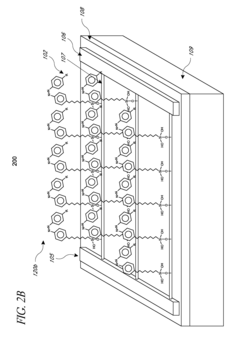

Technical Solution: N5 Sensors has developed a proprietary chemical sensing platform that incorporates sulphanilic acid-based materials. Their technology utilizes an array of nanoscale sensors, each functionalized with different sulphanilic acid derivatives to detect a wide range of chemical species. The company's approach combines advanced MEMS fabrication techniques with novel surface chemistry to create highly sensitive and selective sensors. N5 Sensors' devices can detect multiple gases simultaneously at parts-per-billion levels, with response times under 10 seconds [6]. The sensors are integrated into compact, low-power modules suitable for portable and wearable applications. N5 Sensors has also developed proprietary algorithms for signal processing and pattern recognition, enabling their sensors to operate effectively in complex environments with multiple interferents [7].

Strengths: Miniaturization and integration capabilities, multi-gas detection, and advanced signal processing. Weaknesses: Potential high production costs and need for periodic recalibration in long-term deployments.

Council of Scientific & Industrial Research

Technical Solution: The Council of Scientific & Industrial Research (CSIR) has developed advanced chemical sensors using sulphanilic acid as a key component. Their approach involves the synthesis of sulphanilic acid-based nanocomposites, which are then integrated into electrochemical sensing platforms. These sensors demonstrate high sensitivity and selectivity towards various analytes, including heavy metals and organic pollutants. CSIR's technology utilizes a combination of surface modification techniques and novel electrode designs to enhance the sensor's performance. The sensors exhibit rapid response times, typically under 30 seconds, and low detection limits in the parts-per-billion range [1][3]. Additionally, CSIR has implemented machine learning algorithms to improve the sensor's data processing capabilities, enabling real-time analysis and pattern recognition in complex chemical environments [2].

Strengths: High sensitivity and selectivity, rapid response times, and integration of advanced data processing. Weaknesses: Potential challenges in large-scale manufacturing and long-term stability in harsh environments.

Core Innovations in Sensitivity and Selectivity

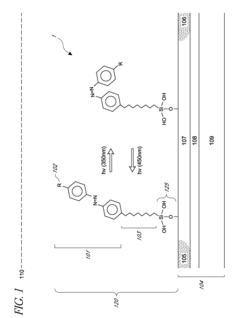

Dynamic chemical sensors

PatentInactiveUS20160187274A1

Innovation

- A dynamic chemical sensor utilizing azobenzene compounds that can change hydrophobicity upon radiation or temperature exposure, allowing a single sensor to detect both hydrophobic and hydrophilic analytes by altering its surface properties, which are coupled to a channel in a field effect transistor configuration.

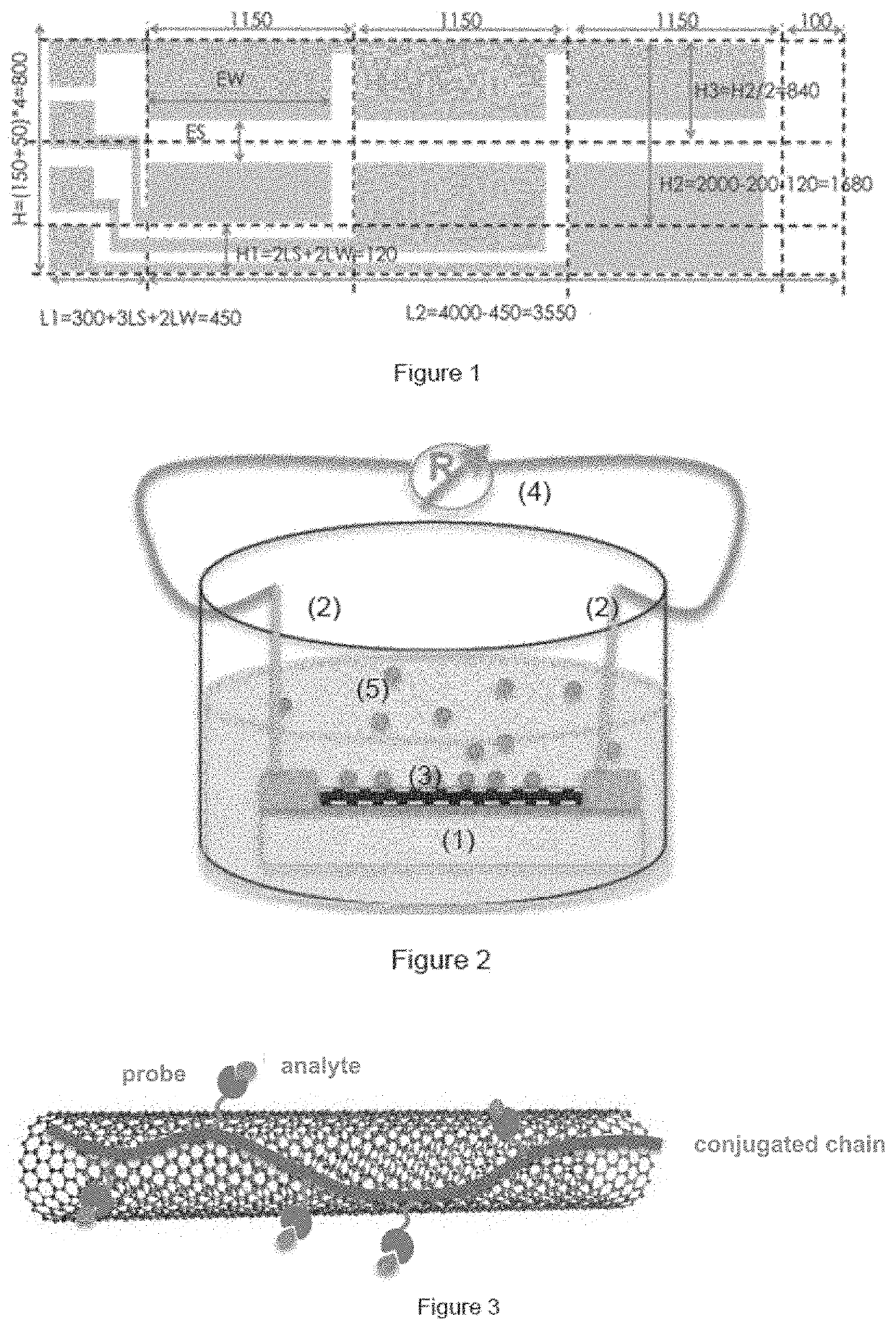

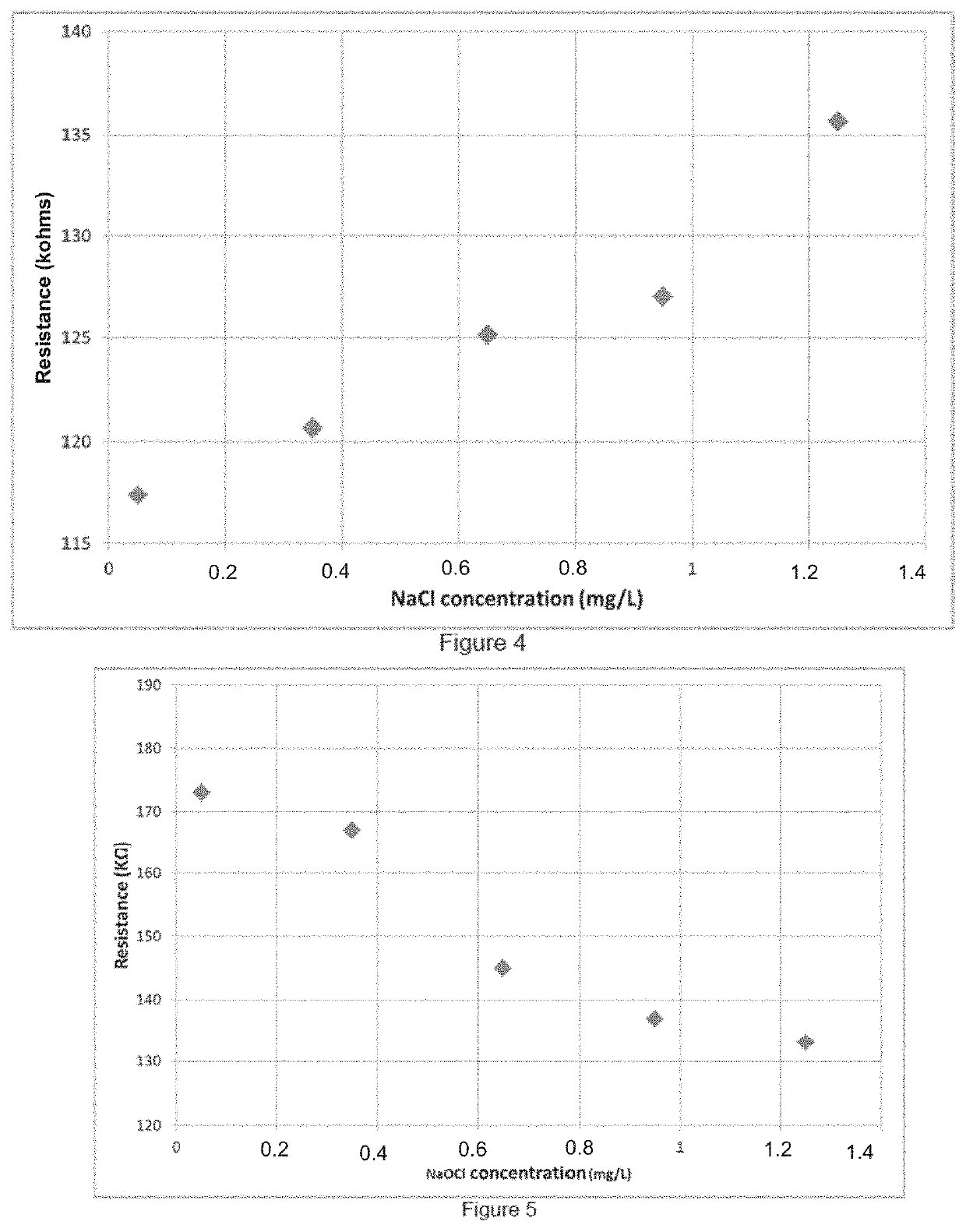

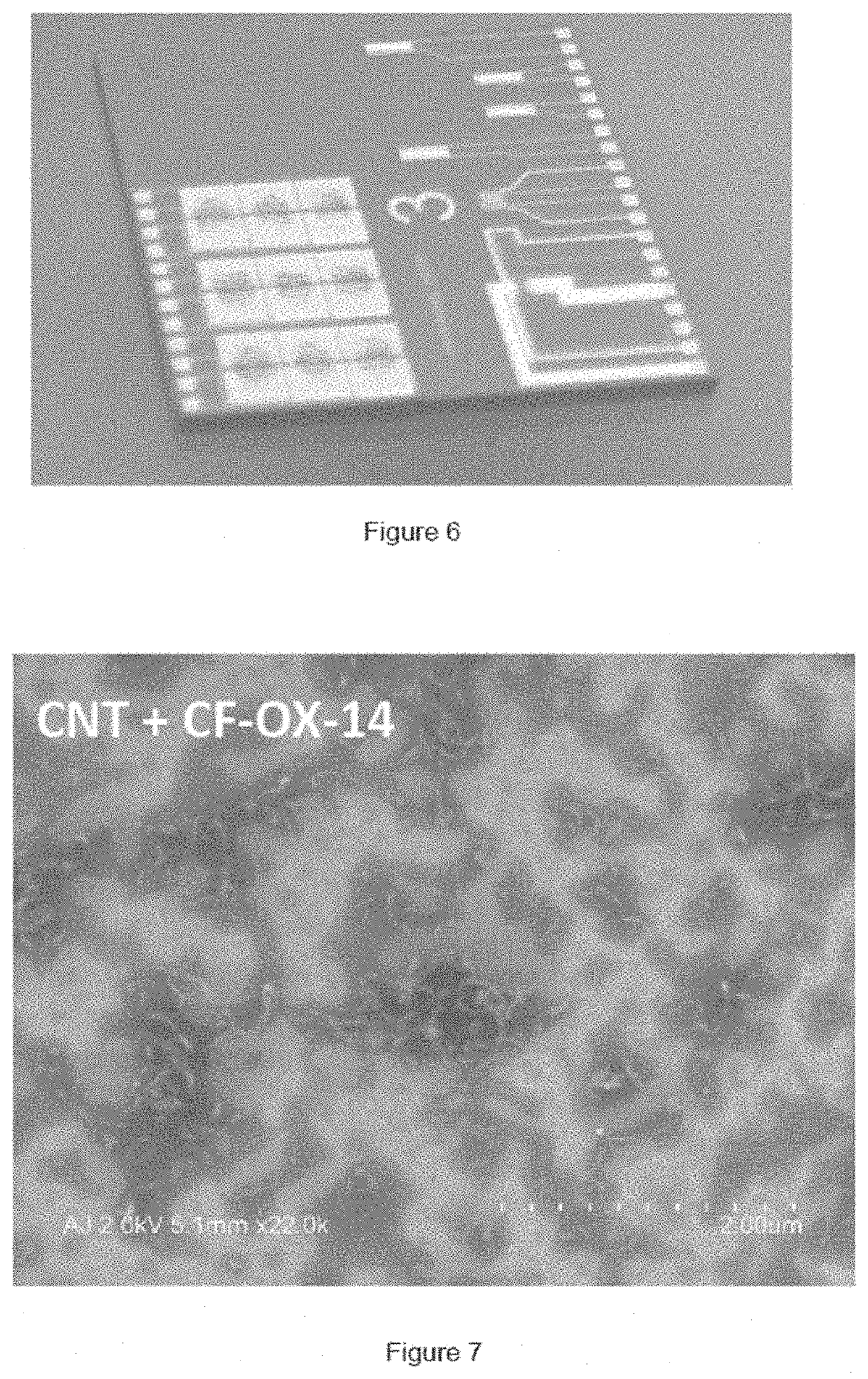

Chemical sensors based on carbon nanotubes functionalised by conjugated polymers for analysis in aqueous medium

PatentActiveUS20210130540A1

Innovation

- Development of a chemical sensor using carbon nanotubes functionalized with novel conjugated polymers that enhance electron transfer and interaction with specific analytes, allowing for selective detection and quantification of ionic compounds in a fluid, enabling real-time monitoring without the need for sample collection.

Environmental Impact of Sensor Materials

The development and widespread use of chemical sensors based on sulphanilic acid raise important considerations regarding their environmental impact. These sensors, while offering significant benefits in terms of sensitivity and selectivity for various applications, also present potential environmental challenges that must be carefully evaluated.

The primary environmental concern associated with sulphanilic acid-based sensors is the potential for chemical leaching or degradation over time. As these sensors are exposed to various environmental conditions, there is a risk that small amounts of sulphanilic acid or its derivatives may be released into the surrounding ecosystem. This could potentially affect aquatic life and soil microorganisms, particularly in areas where these sensors are deployed in large numbers or for extended periods.

Another aspect to consider is the end-of-life disposal of these sensors. As with many electronic devices, improper disposal can lead to the release of harmful substances into the environment. The sulphanilic acid components, along with other materials used in sensor construction, may require specialized recycling or disposal methods to minimize environmental impact.

The manufacturing process of these sensors also warrants attention from an environmental perspective. The production of sulphanilic acid and its incorporation into sensor materials may involve chemical processes that generate waste products or emissions. Ensuring that these manufacturing processes adhere to strict environmental regulations and employ best practices for waste management is crucial to mitigating potential negative impacts.

On the positive side, the high sensitivity and selectivity of sulphanilic acid-based sensors can contribute to environmental protection efforts. By enabling more accurate and reliable detection of pollutants or harmful substances, these sensors can play a vital role in environmental monitoring and early warning systems. This improved detection capability may lead to more timely and effective responses to environmental threats, potentially offsetting some of the environmental costs associated with their production and use.

The durability and lifespan of these sensors also factor into their overall environmental impact. Sensors that maintain their performance over longer periods reduce the frequency of replacement, thereby decreasing the cumulative environmental footprint associated with manufacturing and disposal. Research into improving the longevity and stability of sulphanilic acid-based sensors could significantly enhance their environmental sustainability.

In conclusion, while chemical sensors developed from sulphanilic acid offer promising advancements in sensitivity and selectivity, their environmental impact must be carefully managed. Balancing the benefits of improved detection capabilities against potential environmental risks requires ongoing research, responsible manufacturing practices, and thoughtful consideration of the entire lifecycle of these sensors.

The primary environmental concern associated with sulphanilic acid-based sensors is the potential for chemical leaching or degradation over time. As these sensors are exposed to various environmental conditions, there is a risk that small amounts of sulphanilic acid or its derivatives may be released into the surrounding ecosystem. This could potentially affect aquatic life and soil microorganisms, particularly in areas where these sensors are deployed in large numbers or for extended periods.

Another aspect to consider is the end-of-life disposal of these sensors. As with many electronic devices, improper disposal can lead to the release of harmful substances into the environment. The sulphanilic acid components, along with other materials used in sensor construction, may require specialized recycling or disposal methods to minimize environmental impact.

The manufacturing process of these sensors also warrants attention from an environmental perspective. The production of sulphanilic acid and its incorporation into sensor materials may involve chemical processes that generate waste products or emissions. Ensuring that these manufacturing processes adhere to strict environmental regulations and employ best practices for waste management is crucial to mitigating potential negative impacts.

On the positive side, the high sensitivity and selectivity of sulphanilic acid-based sensors can contribute to environmental protection efforts. By enabling more accurate and reliable detection of pollutants or harmful substances, these sensors can play a vital role in environmental monitoring and early warning systems. This improved detection capability may lead to more timely and effective responses to environmental threats, potentially offsetting some of the environmental costs associated with their production and use.

The durability and lifespan of these sensors also factor into their overall environmental impact. Sensors that maintain their performance over longer periods reduce the frequency of replacement, thereby decreasing the cumulative environmental footprint associated with manufacturing and disposal. Research into improving the longevity and stability of sulphanilic acid-based sensors could significantly enhance their environmental sustainability.

In conclusion, while chemical sensors developed from sulphanilic acid offer promising advancements in sensitivity and selectivity, their environmental impact must be carefully managed. Balancing the benefits of improved detection capabilities against potential environmental risks requires ongoing research, responsible manufacturing practices, and thoughtful consideration of the entire lifecycle of these sensors.

Regulatory Framework for Chemical Sensors

The regulatory framework for chemical sensors plays a crucial role in ensuring the safety, reliability, and standardization of these devices across various industries. In the context of chemical sensors developed from sulphanilic acid, several regulatory bodies and standards are particularly relevant.

The International Organization for Standardization (ISO) has established guidelines for chemical sensors, including ISO 11843 for calibration and detection capabilities. These standards are essential for validating the sensitivity and selectivity of sulphanilic acid-based sensors, ensuring consistent performance across different applications.

In the United States, the Environmental Protection Agency (EPA) regulates chemical sensors used for environmental monitoring. The EPA's Method 40 CFR Part 60 outlines performance specifications for continuous emission monitoring systems, which may incorporate sulphanilic acid-based sensors for detecting specific pollutants.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation impacts the development and use of chemical sensors. Manufacturers must ensure that sulphanilic acid and any other materials used in sensor production comply with REACH requirements, particularly concerning safety and environmental impact.

For medical applications, the Food and Drug Administration (FDA) in the United States oversees the regulation of chemical sensors used in diagnostic devices. The FDA's 510(k) clearance process is often required for new sensor technologies, including those based on sulphanilic acid, to demonstrate their safety and efficacy.

In the workplace, the Occupational Safety and Health Administration (OSHA) sets standards for chemical exposure monitoring. Sensors developed from sulphanilic acid for detecting hazardous substances must meet OSHA's requirements for accuracy and reliability to ensure worker safety.

The International Electrotechnical Commission (IEC) provides standards specific to electrochemical sensors, which may be applicable to certain sulphanilic acid-based sensors. IEC 61010-2-033, for instance, covers safety requirements for handheld multimeters and other measuring instruments.

As the field of chemical sensors continues to evolve, regulatory frameworks are adapting to address new technologies and applications. Manufacturers and researchers working with sulphanilic acid-based sensors must stay informed about these evolving regulations to ensure compliance and market acceptance of their products.

The International Organization for Standardization (ISO) has established guidelines for chemical sensors, including ISO 11843 for calibration and detection capabilities. These standards are essential for validating the sensitivity and selectivity of sulphanilic acid-based sensors, ensuring consistent performance across different applications.

In the United States, the Environmental Protection Agency (EPA) regulates chemical sensors used for environmental monitoring. The EPA's Method 40 CFR Part 60 outlines performance specifications for continuous emission monitoring systems, which may incorporate sulphanilic acid-based sensors for detecting specific pollutants.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation impacts the development and use of chemical sensors. Manufacturers must ensure that sulphanilic acid and any other materials used in sensor production comply with REACH requirements, particularly concerning safety and environmental impact.

For medical applications, the Food and Drug Administration (FDA) in the United States oversees the regulation of chemical sensors used in diagnostic devices. The FDA's 510(k) clearance process is often required for new sensor technologies, including those based on sulphanilic acid, to demonstrate their safety and efficacy.

In the workplace, the Occupational Safety and Health Administration (OSHA) sets standards for chemical exposure monitoring. Sensors developed from sulphanilic acid for detecting hazardous substances must meet OSHA's requirements for accuracy and reliability to ensure worker safety.

The International Electrotechnical Commission (IEC) provides standards specific to electrochemical sensors, which may be applicable to certain sulphanilic acid-based sensors. IEC 61010-2-033, for instance, covers safety requirements for handheld multimeters and other measuring instruments.

As the field of chemical sensors continues to evolve, regulatory frameworks are adapting to address new technologies and applications. Manufacturers and researchers working with sulphanilic acid-based sensors must stay informed about these evolving regulations to ensure compliance and market acceptance of their products.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!