Coating vs Material Selection: Effective Strategies to Mitigate Hydrogen Embrittlement in Pipelines

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HE Mitigation Background

Hydrogen embrittlement (HE) has been a significant concern in the pipeline industry for decades, posing severe threats to the integrity and safety of pipeline systems. This phenomenon occurs when hydrogen atoms penetrate the metal structure of pipelines, leading to a reduction in ductility and load-bearing capacity, ultimately resulting in premature failure of the material.

The issue of hydrogen embrittlement gained prominence in the mid-20th century as the demand for high-strength steels in pipeline construction increased. These materials, while offering improved mechanical properties, were found to be more susceptible to hydrogen-induced damage. The oil and gas industry, in particular, faced significant challenges as pipeline failures due to HE led to economic losses and environmental concerns.

Over the years, researchers and engineers have developed various strategies to mitigate the effects of hydrogen embrittlement in pipelines. These approaches can be broadly categorized into two main areas: coating technologies and material selection. Each of these strategies aims to address the root causes of HE and enhance the overall resilience of pipeline systems.

Coating technologies have evolved significantly, with early methods focusing on simple barrier coatings to more advanced multi-layer systems incorporating hydrogen trapping mechanisms. These coatings serve to prevent hydrogen ingress into the metal substrate, thereby reducing the risk of embrittlement. Concurrently, advancements in material science have led to the development of steel grades with improved resistance to hydrogen embrittlement, often achieved through careful control of microstructure and alloying elements.

The ongoing challenge in mitigating hydrogen embrittlement lies in balancing the need for high-strength materials with their inherent susceptibility to HE. This has driven continuous research and development efforts in both coating technologies and material science. Recent trends indicate a growing interest in nanotechnology-based coatings and the use of advanced computational models to predict and prevent HE in pipeline materials.

As the global energy landscape evolves, with increasing focus on hydrogen as a clean energy carrier, the importance of effective HE mitigation strategies has become even more critical. The potential for widespread hydrogen transportation through existing and new pipeline networks has reignited interest in developing robust solutions to combat hydrogen embrittlement.

In this context, the comparison between coating technologies and material selection approaches for HE mitigation represents a crucial area of study. Both strategies offer unique advantages and face distinct challenges in their implementation and effectiveness. Understanding the relative merits and limitations of these approaches is essential for developing comprehensive and sustainable solutions to ensure the long-term integrity and safety of pipeline infrastructure in an increasingly hydrogen-centric energy future.

The issue of hydrogen embrittlement gained prominence in the mid-20th century as the demand for high-strength steels in pipeline construction increased. These materials, while offering improved mechanical properties, were found to be more susceptible to hydrogen-induced damage. The oil and gas industry, in particular, faced significant challenges as pipeline failures due to HE led to economic losses and environmental concerns.

Over the years, researchers and engineers have developed various strategies to mitigate the effects of hydrogen embrittlement in pipelines. These approaches can be broadly categorized into two main areas: coating technologies and material selection. Each of these strategies aims to address the root causes of HE and enhance the overall resilience of pipeline systems.

Coating technologies have evolved significantly, with early methods focusing on simple barrier coatings to more advanced multi-layer systems incorporating hydrogen trapping mechanisms. These coatings serve to prevent hydrogen ingress into the metal substrate, thereby reducing the risk of embrittlement. Concurrently, advancements in material science have led to the development of steel grades with improved resistance to hydrogen embrittlement, often achieved through careful control of microstructure and alloying elements.

The ongoing challenge in mitigating hydrogen embrittlement lies in balancing the need for high-strength materials with their inherent susceptibility to HE. This has driven continuous research and development efforts in both coating technologies and material science. Recent trends indicate a growing interest in nanotechnology-based coatings and the use of advanced computational models to predict and prevent HE in pipeline materials.

As the global energy landscape evolves, with increasing focus on hydrogen as a clean energy carrier, the importance of effective HE mitigation strategies has become even more critical. The potential for widespread hydrogen transportation through existing and new pipeline networks has reignited interest in developing robust solutions to combat hydrogen embrittlement.

In this context, the comparison between coating technologies and material selection approaches for HE mitigation represents a crucial area of study. Both strategies offer unique advantages and face distinct challenges in their implementation and effectiveness. Understanding the relative merits and limitations of these approaches is essential for developing comprehensive and sustainable solutions to ensure the long-term integrity and safety of pipeline infrastructure in an increasingly hydrogen-centric energy future.

Market Demand Analysis

The market demand for effective strategies to mitigate hydrogen embrittlement in pipelines has been steadily increasing due to the growing importance of hydrogen as a clean energy carrier. As countries worldwide shift towards low-carbon economies, the need for safe and reliable hydrogen transportation infrastructure has become paramount.

The oil and gas industry, which has long been dealing with hydrogen-related issues, is experiencing a surge in demand for advanced coating technologies and material selection strategies. This is driven by the aging of existing pipeline networks and the need to repurpose them for hydrogen transport. The market for specialized coatings that can prevent hydrogen permeation is expected to grow significantly in the coming years.

In the emerging hydrogen economy, new pipeline projects are being planned and developed, creating a substantial market for materials and coatings that can withstand hydrogen embrittlement. This includes both metallic and non-metallic materials that offer superior resistance to hydrogen-induced damage.

The automotive and aerospace industries are also contributing to the market demand, as they seek solutions to protect high-strength steel components from hydrogen embrittlement. This has led to increased research and development in advanced coating technologies that can be applied to various metal substrates.

The renewable energy sector, particularly wind and solar power generation, is another key driver of market demand. As these industries expand, the need for hydrogen storage and transportation solutions that can resist embrittlement becomes more critical.

Geographically, regions with ambitious hydrogen strategies, such as the European Union, Japan, and parts of the United States, are expected to lead the market demand for hydrogen embrittlement mitigation technologies. These areas are investing heavily in hydrogen infrastructure and are likely to be early adopters of advanced coating and material selection strategies.

The market is also seeing increased demand from research institutions and testing facilities that are working on developing and validating new solutions for hydrogen embrittlement. This has created a niche market for specialized equipment and materials used in hydrogen embrittlement testing and analysis.

Overall, the market for hydrogen embrittlement mitigation strategies is poised for significant growth, driven by the global push towards decarbonization and the expansion of hydrogen as a key component of future energy systems. The demand spans across multiple industries and geographical regions, indicating a robust and diverse market landscape for the foreseeable future.

The oil and gas industry, which has long been dealing with hydrogen-related issues, is experiencing a surge in demand for advanced coating technologies and material selection strategies. This is driven by the aging of existing pipeline networks and the need to repurpose them for hydrogen transport. The market for specialized coatings that can prevent hydrogen permeation is expected to grow significantly in the coming years.

In the emerging hydrogen economy, new pipeline projects are being planned and developed, creating a substantial market for materials and coatings that can withstand hydrogen embrittlement. This includes both metallic and non-metallic materials that offer superior resistance to hydrogen-induced damage.

The automotive and aerospace industries are also contributing to the market demand, as they seek solutions to protect high-strength steel components from hydrogen embrittlement. This has led to increased research and development in advanced coating technologies that can be applied to various metal substrates.

The renewable energy sector, particularly wind and solar power generation, is another key driver of market demand. As these industries expand, the need for hydrogen storage and transportation solutions that can resist embrittlement becomes more critical.

Geographically, regions with ambitious hydrogen strategies, such as the European Union, Japan, and parts of the United States, are expected to lead the market demand for hydrogen embrittlement mitigation technologies. These areas are investing heavily in hydrogen infrastructure and are likely to be early adopters of advanced coating and material selection strategies.

The market is also seeing increased demand from research institutions and testing facilities that are working on developing and validating new solutions for hydrogen embrittlement. This has created a niche market for specialized equipment and materials used in hydrogen embrittlement testing and analysis.

Overall, the market for hydrogen embrittlement mitigation strategies is poised for significant growth, driven by the global push towards decarbonization and the expansion of hydrogen as a key component of future energy systems. The demand spans across multiple industries and geographical regions, indicating a robust and diverse market landscape for the foreseeable future.

Current HE Challenges

Hydrogen embrittlement (HE) remains a significant challenge in pipeline integrity management, particularly in the oil and gas industry. The current landscape of HE challenges is characterized by a complex interplay of material properties, environmental factors, and operational conditions.

One of the primary challenges is the difficulty in predicting and quantifying the extent of hydrogen-induced damage in pipeline materials. The mechanisms of hydrogen diffusion and trapping within the microstructure of steels are not fully understood, leading to uncertainties in risk assessment and maintenance planning. This knowledge gap hampers the development of accurate models for predicting the long-term behavior of pipelines exposed to hydrogen-rich environments.

The variability of hydrogen sources and concentrations in different operational scenarios further complicates the issue. Hydrogen can be introduced through various means, including cathodic protection systems, corrosive environments, and even during the manufacturing process. The synergistic effects of multiple hydrogen sources and their interaction with different pipeline materials create a multifaceted problem that requires comprehensive analysis and mitigation strategies.

Another significant challenge is the trade-off between material strength and HE resistance. High-strength steels, which are desirable for their mechanical properties and cost-effectiveness, are often more susceptible to hydrogen embrittlement. This creates a dilemma in material selection, where engineers must balance performance requirements with HE resistance.

The detection and monitoring of hydrogen-induced damage present additional challenges. Current non-destructive testing methods have limitations in identifying early-stage hydrogen damage, particularly in operating pipelines. The development of reliable in-situ monitoring techniques for hydrogen concentration and material degradation remains an active area of research and development.

Environmental factors, such as temperature fluctuations, pH variations, and the presence of other corrosive species, can significantly influence the severity of hydrogen embrittlement. These dynamic conditions make it difficult to establish standardized testing protocols and universally applicable mitigation strategies.

The economic implications of HE mitigation add another layer of complexity. Implementing comprehensive protection measures, such as advanced coatings or material upgrades, can be costly. Balancing these expenses against the potential risks and consequences of HE-related failures requires careful cost-benefit analysis and risk management strategies.

Lastly, the regulatory landscape surrounding hydrogen embrittlement in pipelines is evolving. As the understanding of HE mechanisms improves and new mitigation technologies emerge, industry standards and regulations must adapt. This creates challenges for pipeline operators in staying compliant while also implementing the most effective and economically viable solutions for HE mitigation.

One of the primary challenges is the difficulty in predicting and quantifying the extent of hydrogen-induced damage in pipeline materials. The mechanisms of hydrogen diffusion and trapping within the microstructure of steels are not fully understood, leading to uncertainties in risk assessment and maintenance planning. This knowledge gap hampers the development of accurate models for predicting the long-term behavior of pipelines exposed to hydrogen-rich environments.

The variability of hydrogen sources and concentrations in different operational scenarios further complicates the issue. Hydrogen can be introduced through various means, including cathodic protection systems, corrosive environments, and even during the manufacturing process. The synergistic effects of multiple hydrogen sources and their interaction with different pipeline materials create a multifaceted problem that requires comprehensive analysis and mitigation strategies.

Another significant challenge is the trade-off between material strength and HE resistance. High-strength steels, which are desirable for their mechanical properties and cost-effectiveness, are often more susceptible to hydrogen embrittlement. This creates a dilemma in material selection, where engineers must balance performance requirements with HE resistance.

The detection and monitoring of hydrogen-induced damage present additional challenges. Current non-destructive testing methods have limitations in identifying early-stage hydrogen damage, particularly in operating pipelines. The development of reliable in-situ monitoring techniques for hydrogen concentration and material degradation remains an active area of research and development.

Environmental factors, such as temperature fluctuations, pH variations, and the presence of other corrosive species, can significantly influence the severity of hydrogen embrittlement. These dynamic conditions make it difficult to establish standardized testing protocols and universally applicable mitigation strategies.

The economic implications of HE mitigation add another layer of complexity. Implementing comprehensive protection measures, such as advanced coatings or material upgrades, can be costly. Balancing these expenses against the potential risks and consequences of HE-related failures requires careful cost-benefit analysis and risk management strategies.

Lastly, the regulatory landscape surrounding hydrogen embrittlement in pipelines is evolving. As the understanding of HE mechanisms improves and new mitigation technologies emerge, industry standards and regulations must adapt. This creates challenges for pipeline operators in staying compliant while also implementing the most effective and economically viable solutions for HE mitigation.

Coating Solutions

01 Material selection for hydrogen pipelines

Choosing appropriate materials resistant to hydrogen embrittlement is crucial for pipeline construction. This includes selecting high-strength steels with specific microstructures and compositions that minimize susceptibility to hydrogen-induced cracking. Advanced alloys and coatings may also be employed to enhance resistance to hydrogen embrittlement in pipeline systems.- Material selection for hydrogen-resistant pipelines: Selecting appropriate materials that are resistant to hydrogen embrittlement is crucial for pipeline construction. This includes using high-strength steels with specific alloying elements or coatings that can withstand hydrogen permeation and reduce the risk of embrittlement. Advanced materials and surface treatments can significantly improve the pipeline's resistance to hydrogen-induced damage.

- Monitoring and detection techniques for hydrogen embrittlement: Implementing advanced monitoring and detection systems to identify early signs of hydrogen embrittlement in pipelines. This involves using sensors, non-destructive testing methods, and real-time data analysis to detect changes in material properties, crack initiation, or hydrogen concentration. Early detection allows for timely maintenance and prevention of catastrophic failures.

- Protective coatings and liners for hydrogen pipelines: Developing and applying specialized coatings or liners to the interior of pipelines to create a barrier against hydrogen permeation. These protective layers can be made from materials that are impermeable to hydrogen or can actively trap hydrogen molecules, preventing them from interacting with the base metal of the pipeline.

- Stress management and pipeline design optimization: Optimizing pipeline design to manage stress distribution and minimize areas of high stress concentration. This includes careful consideration of pipeline geometry, weld locations, and support structures. Implementing stress relief techniques and designing for flexibility can help reduce the risk of hydrogen embrittlement in critical areas of the pipeline system.

- Hydrogen purification and contaminant control: Implementing effective hydrogen purification systems and controlling contaminants in the pipeline environment. Removing impurities and managing moisture levels can significantly reduce the risk of hydrogen embrittlement. This includes using advanced filtration systems, desiccants, and maintaining proper operating conditions to ensure the purity of the hydrogen flowing through the pipeline.

02 Surface treatment and coating techniques

Various surface treatments and coating methods can be applied to pipeline materials to mitigate hydrogen embrittlement. These techniques may include nitriding, carburizing, or applying specialized coatings that act as barriers to hydrogen penetration. Such treatments can significantly improve the resistance of pipeline materials to hydrogen-induced damage.Expand Specific Solutions03 Monitoring and detection systems

Implementing advanced monitoring and detection systems is essential for managing hydrogen embrittlement in pipelines. These systems may include sensors, acoustic emission techniques, and other non-destructive testing methods to detect early signs of hydrogen-induced damage. Regular inspection and monitoring help prevent catastrophic failures due to embrittlement.Expand Specific Solutions04 Hydrogen pressure and temperature management

Controlling hydrogen pressure and temperature within pipelines is critical for minimizing embrittlement risks. This involves optimizing operating conditions, implementing pressure relief systems, and maintaining appropriate temperature ranges to reduce hydrogen diffusion and its detrimental effects on pipeline materials.Expand Specific Solutions05 Welding and joining techniques

Developing and implementing specialized welding and joining techniques is crucial for maintaining pipeline integrity in hydrogen transport systems. These methods focus on minimizing hydrogen uptake during welding processes, controlling heat-affected zones, and ensuring proper post-weld heat treatments to reduce susceptibility to hydrogen embrittlement at pipeline joints and connections.Expand Specific Solutions

Key Industry Players

The competitive landscape for mitigating hydrogen embrittlement in pipelines is characterized by a mature market with established players and ongoing research efforts. The industry is in a growth phase, driven by increasing demand for safer and more efficient pipeline infrastructure. Major companies like China National Petroleum Corp., Sinopec, and PetroChina are investing heavily in research and development, collaborating with academic institutions such as Zhejiang University and China University of Petroleum. The market size is substantial, given the critical importance of pipeline integrity in the oil and gas sector. Technologically, while coating and material selection strategies are well-established, there is continuous innovation to improve effectiveness and cost-efficiency, with companies like JFE Steel Corp. and Tata Steel Ltd. at the forefront of developing advanced materials and coatings.

JFE Steel Corp.

Technical Solution: JFE Steel Corp. has developed a novel approach to combat hydrogen embrittlement in pipelines through a combination of advanced coating technology and specialized material selection. Their coating strategy involves a proprietary multi-layer system that includes a chromium-based diffusion barrier layer, followed by a high-performance epoxy coating[1]. This combination effectively reduces hydrogen permeation into the steel substrate. For material selection, JFE Steel has focused on developing hydrogen-resistant steel grades, particularly for high-pressure hydrogen environments. Their HRX19™ steel, for instance, exhibits superior resistance to hydrogen embrittlement due to its optimized chemical composition and microstructure[2]. The steel contains carefully controlled amounts of chromium, molybdenum, and vanadium, which form stable carbides and nitrides that act as hydrogen traps, preventing hydrogen from accumulating at critical microstructural features[3]. Furthermore, JFE Steel has implemented advanced heat treatment processes to refine the grain structure and improve overall mechanical properties.

Strengths: Specialized hydrogen-resistant steel grades; innovative multi-layer coating system; extensive experience in pipeline materials. Weaknesses: Potentially higher production costs for specialized materials; may require adaptation of existing pipeline manufacturing processes.

Massachusetts Institute of Technology

Technical Solution: Researchers at the Massachusetts Institute of Technology (MIT) have developed innovative strategies to mitigate hydrogen embrittlement in pipelines, focusing on both coating technologies and advanced material selection. Their coating approach involves the use of graphene-based nanocomposite coatings that provide an exceptionally effective barrier against hydrogen permeation[1]. These coatings are applied using a novel plasma-enhanced chemical vapor deposition (PECVD) technique, which ensures uniform coverage and strong adhesion to the steel substrate. In terms of material selection, MIT scientists have pioneered the development of nanostructured steels with enhanced resistance to hydrogen embrittlement[2]. These materials feature a carefully engineered microstructure with a high density of nanoscale precipitates that act as hydrogen traps, effectively preventing hydrogen from accumulating at grain boundaries and other critical locations. Additionally, MIT researchers have developed advanced computational models to predict the behavior of materials under hydrogen-rich environments, allowing for rapid screening and optimization of potential pipeline materials[3].

Strengths: Cutting-edge research in nanomaterials and advanced coatings; strong focus on fundamental understanding of hydrogen embrittlement mechanisms; potential for breakthrough technologies. Weaknesses: Technologies may be at early stages of development, requiring further scaling and practical implementation; potential high costs associated with advanced materials and processes.

Material Selection

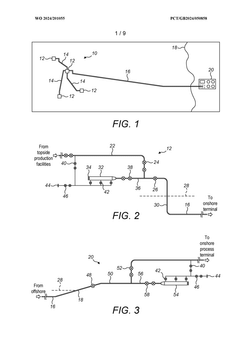

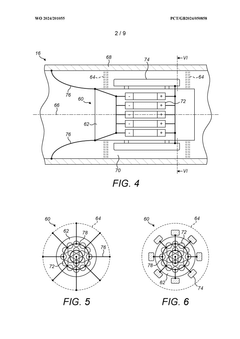

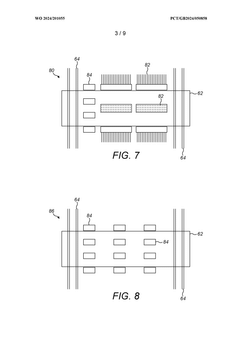

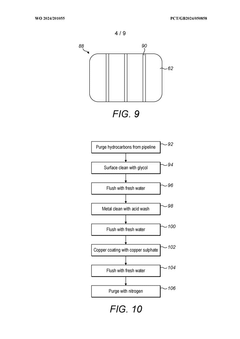

Adapting hydrocarbon pipelines to transport hydrogen

PatentWO2024201055A1

Innovation

- Electrodepositing a metallic coating, such as copper, onto the inner surface of steel pipelines using a pig that drives an electric current through an electrolyte fluid, creating a less absorbent barrier to restrict hydrogen absorption and mitigate embrittlement.

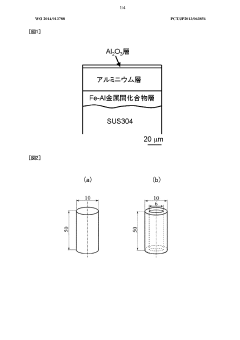

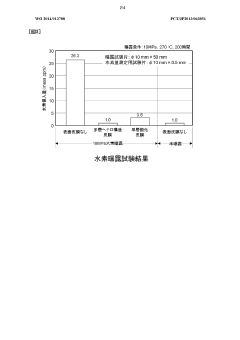

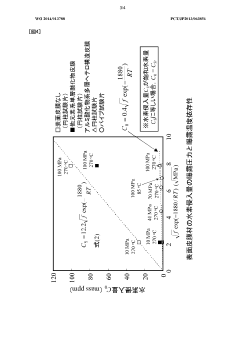

Base material for hydrogen apparatus

PatentWO2014013788A1

Innovation

- A multi-layer hetero film structure coating comprising an aluminum-based intermetallic compound layer, an aluminum layer, and an alumina layer is applied to the base material, which significantly reduces hydrogen penetration and embrittlement, allowing the use of less expensive materials while maintaining durability.

Environmental Impact

The environmental impact of strategies to mitigate hydrogen embrittlement in pipelines is a critical consideration in the ongoing debate between coating and material selection approaches. Both methods have significant implications for the surrounding ecosystem and long-term sustainability of pipeline operations.

Coating technologies, while effective in creating a barrier against hydrogen penetration, often involve the use of synthetic materials and chemical compounds. These substances may pose risks to soil and water quality if not properly managed throughout the pipeline's lifecycle. The production and application of coatings can result in emissions and waste that require careful handling and disposal. However, advancements in eco-friendly coating formulations are reducing these environmental concerns.

Material selection strategies, on the other hand, focus on using inherently resistant alloys or modified steel compositions. This approach generally has a lower direct environmental impact during operation, as it doesn't introduce additional substances to the ecosystem. The environmental footprint is primarily associated with the production and processing of these specialized materials, which may require more energy-intensive manufacturing processes.

From a lifecycle perspective, the durability and longevity of the chosen solution play a crucial role in determining its overall environmental impact. Coatings that require frequent reapplication or replacement can lead to increased maintenance activities, potentially disrupting local ecosystems. Conversely, well-selected materials with long-term resistance to hydrogen embrittlement may reduce the need for interventions and associated environmental disturbances.

The choice between coating and material selection also affects the pipeline's end-of-life considerations. Coated pipelines may present challenges in recycling or disposal due to the presence of multiple materials. In contrast, pipelines constructed with carefully selected materials may offer simpler and more environmentally friendly decommissioning options.

Energy efficiency is another important environmental factor. Some coating technologies can improve flow efficiency within the pipeline, potentially reducing energy consumption during operation. Material selection strategies may not offer this benefit but could contribute to energy savings through reduced maintenance and replacement needs.

Ultimately, the environmental impact of hydrogen embrittlement mitigation strategies extends beyond the immediate pipeline vicinity. It encompasses the entire supply chain, from raw material extraction to manufacturing, installation, operation, and eventual decommissioning. A comprehensive environmental assessment must consider these broader implications to make truly sustainable choices in pipeline infrastructure development.

Coating technologies, while effective in creating a barrier against hydrogen penetration, often involve the use of synthetic materials and chemical compounds. These substances may pose risks to soil and water quality if not properly managed throughout the pipeline's lifecycle. The production and application of coatings can result in emissions and waste that require careful handling and disposal. However, advancements in eco-friendly coating formulations are reducing these environmental concerns.

Material selection strategies, on the other hand, focus on using inherently resistant alloys or modified steel compositions. This approach generally has a lower direct environmental impact during operation, as it doesn't introduce additional substances to the ecosystem. The environmental footprint is primarily associated with the production and processing of these specialized materials, which may require more energy-intensive manufacturing processes.

From a lifecycle perspective, the durability and longevity of the chosen solution play a crucial role in determining its overall environmental impact. Coatings that require frequent reapplication or replacement can lead to increased maintenance activities, potentially disrupting local ecosystems. Conversely, well-selected materials with long-term resistance to hydrogen embrittlement may reduce the need for interventions and associated environmental disturbances.

The choice between coating and material selection also affects the pipeline's end-of-life considerations. Coated pipelines may present challenges in recycling or disposal due to the presence of multiple materials. In contrast, pipelines constructed with carefully selected materials may offer simpler and more environmentally friendly decommissioning options.

Energy efficiency is another important environmental factor. Some coating technologies can improve flow efficiency within the pipeline, potentially reducing energy consumption during operation. Material selection strategies may not offer this benefit but could contribute to energy savings through reduced maintenance and replacement needs.

Ultimately, the environmental impact of hydrogen embrittlement mitigation strategies extends beyond the immediate pipeline vicinity. It encompasses the entire supply chain, from raw material extraction to manufacturing, installation, operation, and eventual decommissioning. A comprehensive environmental assessment must consider these broader implications to make truly sustainable choices in pipeline infrastructure development.

Economic Feasibility

The economic feasibility of implementing strategies to mitigate hydrogen embrittlement in pipelines is a critical consideration for industry stakeholders. When comparing coating technologies with material selection approaches, several factors come into play that influence the overall cost-effectiveness and long-term economic viability of each solution.

Coating technologies often present a lower initial investment compared to material selection strategies. The application of protective coatings to existing pipeline infrastructure can be a cost-effective short-term solution, particularly for older systems that require immediate protection against hydrogen embrittlement. However, the long-term economic implications of coating solutions must be carefully evaluated, as they may require more frequent maintenance and reapplication, potentially increasing operational costs over time.

Material selection strategies, while potentially more expensive upfront, can offer significant long-term economic benefits. The use of advanced alloys or composite materials that are inherently resistant to hydrogen embrittlement may result in reduced maintenance requirements and extended pipeline lifespans. This approach can lead to substantial cost savings in the long run, particularly for new pipeline installations or major infrastructure upgrades.

The economic feasibility of both approaches is heavily influenced by factors such as the scale of implementation, geographical location, and regulatory requirements. Large-scale pipeline networks may benefit more from material selection strategies due to economies of scale, while smaller, localized systems might find coating solutions more economically viable. Additionally, the cost of raw materials, labor, and specialized equipment for each approach can vary significantly across different regions, impacting the overall economic calculus.

Regulatory compliance costs must also be factored into the economic assessment. As environmental and safety regulations become increasingly stringent, the long-term economic viability of different mitigation strategies may shift. Solutions that offer better compliance with future regulatory standards may prove more economically advantageous, even if they require higher initial investments.

The potential economic impact of pipeline failures due to hydrogen embrittlement cannot be overlooked. The costs associated with environmental remediation, legal liabilities, and reputational damage in the event of a failure can be astronomical. Therefore, the economic feasibility analysis must consider the risk mitigation potential of each approach, weighing the upfront and ongoing costs against the potential financial consequences of pipeline failures.

In conclusion, the economic feasibility of coating versus material selection strategies for mitigating hydrogen embrittlement in pipelines is a complex calculation that requires a comprehensive, long-term perspective. While coating technologies may offer more immediate economic benefits, material selection approaches could prove more cost-effective over extended periods. The optimal strategy from an economic standpoint will depend on a careful analysis of project-specific factors, regulatory landscapes, and risk assessments.

Coating technologies often present a lower initial investment compared to material selection strategies. The application of protective coatings to existing pipeline infrastructure can be a cost-effective short-term solution, particularly for older systems that require immediate protection against hydrogen embrittlement. However, the long-term economic implications of coating solutions must be carefully evaluated, as they may require more frequent maintenance and reapplication, potentially increasing operational costs over time.

Material selection strategies, while potentially more expensive upfront, can offer significant long-term economic benefits. The use of advanced alloys or composite materials that are inherently resistant to hydrogen embrittlement may result in reduced maintenance requirements and extended pipeline lifespans. This approach can lead to substantial cost savings in the long run, particularly for new pipeline installations or major infrastructure upgrades.

The economic feasibility of both approaches is heavily influenced by factors such as the scale of implementation, geographical location, and regulatory requirements. Large-scale pipeline networks may benefit more from material selection strategies due to economies of scale, while smaller, localized systems might find coating solutions more economically viable. Additionally, the cost of raw materials, labor, and specialized equipment for each approach can vary significantly across different regions, impacting the overall economic calculus.

Regulatory compliance costs must also be factored into the economic assessment. As environmental and safety regulations become increasingly stringent, the long-term economic viability of different mitigation strategies may shift. Solutions that offer better compliance with future regulatory standards may prove more economically advantageous, even if they require higher initial investments.

The potential economic impact of pipeline failures due to hydrogen embrittlement cannot be overlooked. The costs associated with environmental remediation, legal liabilities, and reputational damage in the event of a failure can be astronomical. Therefore, the economic feasibility analysis must consider the risk mitigation potential of each approach, weighing the upfront and ongoing costs against the potential financial consequences of pipeline failures.

In conclusion, the economic feasibility of coating versus material selection strategies for mitigating hydrogen embrittlement in pipelines is a complex calculation that requires a comprehensive, long-term perspective. While coating technologies may offer more immediate economic benefits, material selection approaches could prove more cost-effective over extended periods. The optimal strategy from an economic standpoint will depend on a careful analysis of project-specific factors, regulatory landscapes, and risk assessments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!