Non-Destructive Detection of HE Damage: Acoustic Emission, Microstructure and NDT Approaches

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HE Damage Detection Background and Objectives

Hydrogen embrittlement (HE) damage is a critical concern in various industries, particularly in aerospace, automotive, and energy sectors. The detection and assessment of HE damage have become increasingly important due to the growing use of high-strength materials in these fields. The evolution of HE damage detection techniques has been driven by the need for more accurate, reliable, and non-destructive methods to ensure the safety and integrity of structures and components.

The primary objective of HE damage detection is to identify and characterize the presence, extent, and progression of hydrogen-induced degradation in materials without compromising their structural integrity. This goal has led to the development of various non-destructive testing (NDT) approaches, with acoustic emission, microstructural analysis, and other NDT techniques emerging as promising solutions.

Historically, the detection of HE damage relied heavily on destructive testing methods, which were time-consuming, costly, and often required the sacrifice of valuable components. As industries demanded more efficient and less invasive inspection techniques, research efforts shifted towards non-destructive approaches. This transition marked a significant milestone in the field of materials science and engineering, paving the way for more sophisticated and sensitive detection methodologies.

The acoustic emission technique has gained considerable attention in recent years due to its ability to detect and monitor the dynamic processes associated with HE damage in real-time. This method relies on the detection of stress waves generated by the formation and growth of microcracks and other defects caused by hydrogen embrittlement. The development of advanced sensors and signal processing algorithms has greatly enhanced the sensitivity and reliability of acoustic emission-based HE damage detection.

Microstructural analysis techniques have also played a crucial role in understanding the mechanisms of HE damage at the microscopic level. Advanced imaging technologies, such as electron microscopy and X-ray tomography, have enabled researchers to visualize and quantify the effects of hydrogen on material microstructure. These insights have been instrumental in developing more accurate predictive models and improving the interpretation of NDT results.

The integration of multiple NDT approaches has emerged as a promising strategy to overcome the limitations of individual techniques and provide a more comprehensive assessment of HE damage. This multi-modal approach combines the strengths of various methods, such as acoustic emission, ultrasonic testing, and electromagnetic techniques, to enhance the accuracy and reliability of damage detection and characterization.

As the field of HE damage detection continues to evolve, researchers and industry professionals are focusing on developing more sensitive, reliable, and cost-effective techniques. The ultimate goal is to create a robust and versatile toolset for early detection and accurate assessment of hydrogen embrittlement damage, thereby improving the safety, performance, and longevity of critical components and structures across various industries.

The primary objective of HE damage detection is to identify and characterize the presence, extent, and progression of hydrogen-induced degradation in materials without compromising their structural integrity. This goal has led to the development of various non-destructive testing (NDT) approaches, with acoustic emission, microstructural analysis, and other NDT techniques emerging as promising solutions.

Historically, the detection of HE damage relied heavily on destructive testing methods, which were time-consuming, costly, and often required the sacrifice of valuable components. As industries demanded more efficient and less invasive inspection techniques, research efforts shifted towards non-destructive approaches. This transition marked a significant milestone in the field of materials science and engineering, paving the way for more sophisticated and sensitive detection methodologies.

The acoustic emission technique has gained considerable attention in recent years due to its ability to detect and monitor the dynamic processes associated with HE damage in real-time. This method relies on the detection of stress waves generated by the formation and growth of microcracks and other defects caused by hydrogen embrittlement. The development of advanced sensors and signal processing algorithms has greatly enhanced the sensitivity and reliability of acoustic emission-based HE damage detection.

Microstructural analysis techniques have also played a crucial role in understanding the mechanisms of HE damage at the microscopic level. Advanced imaging technologies, such as electron microscopy and X-ray tomography, have enabled researchers to visualize and quantify the effects of hydrogen on material microstructure. These insights have been instrumental in developing more accurate predictive models and improving the interpretation of NDT results.

The integration of multiple NDT approaches has emerged as a promising strategy to overcome the limitations of individual techniques and provide a more comprehensive assessment of HE damage. This multi-modal approach combines the strengths of various methods, such as acoustic emission, ultrasonic testing, and electromagnetic techniques, to enhance the accuracy and reliability of damage detection and characterization.

As the field of HE damage detection continues to evolve, researchers and industry professionals are focusing on developing more sensitive, reliable, and cost-effective techniques. The ultimate goal is to create a robust and versatile toolset for early detection and accurate assessment of hydrogen embrittlement damage, thereby improving the safety, performance, and longevity of critical components and structures across various industries.

Market Demand for NDT in HE Damage Assessment

The market demand for Non-Destructive Testing (NDT) in Hydrogen Embrittlement (HE) damage assessment has been steadily growing in recent years, driven by the increasing use of high-strength materials in critical applications across various industries. As industries such as aerospace, automotive, and energy sectors continue to push the boundaries of material performance, the need for reliable and accurate HE damage detection methods has become paramount.

In the aerospace industry, where safety is of utmost importance, there is a significant demand for NDT techniques to assess HE damage in critical components such as landing gear, fasteners, and structural elements. The ability to detect and monitor HE damage without compromising the integrity of these components is crucial for maintaining aircraft safety and extending their operational lifespan.

The automotive sector has also seen a surge in demand for NDT methods to evaluate HE damage, particularly in the context of hydrogen fuel cell vehicles. As the automotive industry transitions towards more sustainable transportation solutions, the need to ensure the long-term reliability and safety of hydrogen storage systems and related components has become a key driver for NDT market growth in this sector.

In the energy sector, particularly in oil and gas industries, the demand for NDT techniques to assess HE damage in pipelines, pressure vessels, and offshore structures has been on the rise. The harsh operating conditions and exposure to hydrogen-rich environments in these applications necessitate regular and thorough inspections to prevent catastrophic failures and ensure operational safety.

The market for NDT in HE damage assessment is also being propelled by stringent regulatory requirements and industry standards. Governing bodies and certification agencies are increasingly mandating the use of advanced NDT techniques to ensure the structural integrity of critical components and systems, further driving the demand for innovative and reliable inspection methods.

Furthermore, the growing awareness of the economic impact of HE-related failures has led many companies to invest in preventive maintenance strategies. This shift towards proactive asset management has created a substantial market opportunity for NDT service providers and equipment manufacturers specializing in HE damage detection.

As the demand for lightweight and high-strength materials continues to grow across industries, the market for NDT in HE damage assessment is expected to expand further. This trend is likely to drive innovation in NDT technologies, leading to the development of more sensitive, accurate, and cost-effective inspection methods tailored specifically for HE damage detection and monitoring.

In the aerospace industry, where safety is of utmost importance, there is a significant demand for NDT techniques to assess HE damage in critical components such as landing gear, fasteners, and structural elements. The ability to detect and monitor HE damage without compromising the integrity of these components is crucial for maintaining aircraft safety and extending their operational lifespan.

The automotive sector has also seen a surge in demand for NDT methods to evaluate HE damage, particularly in the context of hydrogen fuel cell vehicles. As the automotive industry transitions towards more sustainable transportation solutions, the need to ensure the long-term reliability and safety of hydrogen storage systems and related components has become a key driver for NDT market growth in this sector.

In the energy sector, particularly in oil and gas industries, the demand for NDT techniques to assess HE damage in pipelines, pressure vessels, and offshore structures has been on the rise. The harsh operating conditions and exposure to hydrogen-rich environments in these applications necessitate regular and thorough inspections to prevent catastrophic failures and ensure operational safety.

The market for NDT in HE damage assessment is also being propelled by stringent regulatory requirements and industry standards. Governing bodies and certification agencies are increasingly mandating the use of advanced NDT techniques to ensure the structural integrity of critical components and systems, further driving the demand for innovative and reliable inspection methods.

Furthermore, the growing awareness of the economic impact of HE-related failures has led many companies to invest in preventive maintenance strategies. This shift towards proactive asset management has created a substantial market opportunity for NDT service providers and equipment manufacturers specializing in HE damage detection.

As the demand for lightweight and high-strength materials continues to grow across industries, the market for NDT in HE damage assessment is expected to expand further. This trend is likely to drive innovation in NDT technologies, leading to the development of more sensitive, accurate, and cost-effective inspection methods tailored specifically for HE damage detection and monitoring.

Current Challenges in Non-Destructive HE Damage Detection

The non-destructive detection of hydrogen embrittlement (HE) damage presents several significant challenges that researchers and industry professionals are actively working to overcome. One of the primary difficulties lies in the subtle nature of HE damage, which often occurs at the microstructural level without visible surface indications. This makes traditional visual inspection methods inadequate for early detection and necessitates more advanced techniques.

Acoustic emission (AE) methods, while promising, face challenges in signal interpretation and noise discrimination. The acoustic signals generated by HE damage can be weak and easily masked by background noise from operational environments. Developing robust algorithms for signal processing and pattern recognition is crucial to improve the reliability of AE-based detection systems.

Microstructural analysis techniques, such as electron microscopy and X-ray diffraction, offer high-resolution insights but are often limited by their ex-situ nature. The need for sample preparation and the inability to perform real-time monitoring in operational conditions restrict their applicability for continuous HE damage assessment in industrial settings.

Non-destructive testing (NDT) approaches like ultrasonic testing and eddy current inspection face challenges in detecting early-stage HE damage before it progresses to critical levels. The sensitivity of these methods to subtle material changes induced by hydrogen needs significant enhancement to provide early warning capabilities.

Another major challenge is the development of standardized procedures and acceptance criteria for HE damage detection. The lack of universally accepted standards makes it difficult to compare results across different studies and implement consistent inspection protocols in industry.

The complex geometry of many industrial components further complicates HE damage detection. Curved surfaces, welds, and hard-to-reach areas can create blind spots for many NDT techniques, necessitating the development of more versatile and adaptable inspection methods.

Environmental factors, such as temperature fluctuations and corrosive atmospheres, can interfere with detection methods and lead to false positives or negatives. Developing robust techniques that remain accurate under varying operational conditions is a significant challenge.

Lastly, the integration of multiple NDT techniques to create a comprehensive HE damage detection system poses both technical and data management challenges. Combining data from various sensors and methods requires sophisticated data fusion algorithms and interpretation frameworks to provide actionable insights for maintenance and safety decisions.

Acoustic emission (AE) methods, while promising, face challenges in signal interpretation and noise discrimination. The acoustic signals generated by HE damage can be weak and easily masked by background noise from operational environments. Developing robust algorithms for signal processing and pattern recognition is crucial to improve the reliability of AE-based detection systems.

Microstructural analysis techniques, such as electron microscopy and X-ray diffraction, offer high-resolution insights but are often limited by their ex-situ nature. The need for sample preparation and the inability to perform real-time monitoring in operational conditions restrict their applicability for continuous HE damage assessment in industrial settings.

Non-destructive testing (NDT) approaches like ultrasonic testing and eddy current inspection face challenges in detecting early-stage HE damage before it progresses to critical levels. The sensitivity of these methods to subtle material changes induced by hydrogen needs significant enhancement to provide early warning capabilities.

Another major challenge is the development of standardized procedures and acceptance criteria for HE damage detection. The lack of universally accepted standards makes it difficult to compare results across different studies and implement consistent inspection protocols in industry.

The complex geometry of many industrial components further complicates HE damage detection. Curved surfaces, welds, and hard-to-reach areas can create blind spots for many NDT techniques, necessitating the development of more versatile and adaptable inspection methods.

Environmental factors, such as temperature fluctuations and corrosive atmospheres, can interfere with detection methods and lead to false positives or negatives. Developing robust techniques that remain accurate under varying operational conditions is a significant challenge.

Lastly, the integration of multiple NDT techniques to create a comprehensive HE damage detection system poses both technical and data management challenges. Combining data from various sensors and methods requires sophisticated data fusion algorithms and interpretation frameworks to provide actionable insights for maintenance and safety decisions.

Existing NDT Solutions for HE Damage Assessment

01 Shaped charge design for enhanced damage

Shaped charges are designed to focus explosive energy in a specific direction, maximizing damage to the target. This involves careful engineering of the explosive cavity, liner material, and overall geometry to create a high-velocity jet of metal particles upon detonation. The design aims to increase penetration depth and overall destructive power against armored targets or structures.- Shaped charge design for enhanced explosive damage: Shaped charges are designed to focus explosive energy in a specific direction, increasing the effectiveness of high explosive damage. This design typically involves a conical or hemispherical liner that collapses under detonation, creating a high-velocity jet of metal particles. The shape and material of the liner, as well as the explosive composition, are crucial factors in optimizing the damage potential.

- Fragmentation enhancement techniques: Various methods are employed to enhance fragmentation effects of high explosives, increasing their damage potential. These techniques include pre-formed fragmentation patterns, use of specific materials for casing, and controlled fragmentation designs. The goal is to create a more uniform and effective distribution of fragments upon detonation, maximizing the damage radius and impact.

- Explosive composition optimization: The formulation of high explosive compositions is crucial for maximizing damage potential. This involves selecting and combining different explosive materials, binders, and additives to achieve desired detonation characteristics such as velocity, pressure, and temperature. Advanced compositions may include nanomaterials or energetic polymers to enhance performance and stability.

- Detonation wave shaping and control: Techniques for shaping and controlling the detonation wave are developed to optimize explosive damage. This includes the use of multiple detonation points, precise timing circuits, and specialized initiators. By manipulating the detonation wave, the explosive energy can be directed more effectively, enhancing the overall damage potential of the high explosive device.

- Damage assessment and modeling: Advanced computational models and simulation techniques are used to assess and predict high explosive damage. These models take into account factors such as explosive yield, target characteristics, and environmental conditions. By accurately predicting damage patterns, these tools aid in the design and optimization of high explosive devices for specific applications.

02 Fragmentation enhancement techniques

Various methods are employed to enhance fragmentation effects of high explosives. These include using pre-formed fragments, scoring the casing, or incorporating special materials to create more lethal shrapnel upon detonation. The goal is to increase the effective radius of damage and improve lethality against personnel or lightly armored targets.Expand Specific Solutions03 Blast wave optimization

Techniques are developed to optimize the blast wave generated by high explosives. This involves manipulating the explosive composition, detonation sequence, and containment to enhance the overpressure and impulse of the blast. The aim is to maximize structural damage and increase the effective range of the explosion.Expand Specific Solutions04 Thermobaric and fuel-air explosive effects

Thermobaric and fuel-air explosives are designed to create prolonged high-temperature explosions and enhanced blast effects. These weapons disperse an aerosol cloud of fuel before detonation, utilizing atmospheric oxygen to create a more powerful and sustained explosion. The result is increased damage to structures and personnel within enclosed spaces.Expand Specific Solutions05 Underwater and subterranean explosion damage

Specialized high explosives are developed for underwater and subterranean applications. These explosives are designed to maximize damage in these unique environments by optimizing the shock wave propagation through water or soil. The focus is on creating powerful pressure waves that can damage submerged targets or underground structures effectively.Expand Specific Solutions

Key Players in NDT and HE Damage Detection Industry

The non-destructive detection of HE damage is an evolving field with increasing market potential. The industry is in a growth phase, driven by rising demand for safety and quality assurance across sectors like aerospace, energy, and manufacturing. The global non-destructive testing market is projected to reach significant size in the coming years. Technologically, acoustic emission, microstructure analysis, and other NDT approaches are advancing, with varying levels of maturity. Companies like Baker Hughes, Olympus IMS, and Leonardo SpA are at the forefront, offering sophisticated solutions. Academic institutions such as Carnegie Mellon University and research agencies like A*STAR are contributing to technological advancements, indicating a collaborative ecosystem driving innovation in this space.

Baker Hughes Co.

Technical Solution: Baker Hughes has developed advanced acoustic emission (AE) technology for non-destructive detection of high-energy (HE) damage in oil and gas equipment. Their system utilizes an array of piezoelectric sensors to detect and localize micro-fractures and crack growth in real-time. The AE data is processed using machine learning algorithms to differentiate between different types of damage mechanisms. Baker Hughes has also integrated this technology with other NDT methods like ultrasonic testing for comprehensive structural health monitoring[1][3]. Their approach allows for early detection of HE damage before it leads to catastrophic failure, improving safety and reducing downtime in oil and gas operations.

Strengths: Comprehensive solution combining multiple NDT techniques, real-time monitoring capability, and machine learning-enhanced data analysis. Weaknesses: May require significant initial investment and expertise to implement and interpret results effectively.

Olympus IMS

Technical Solution: Olympus Industrial Solutions has developed a multi-modal approach to non-destructive detection of HE damage, combining phased array ultrasonic testing (PAUT) with advanced imaging techniques. Their OmniScan X3 flaw detector utilizes Total Focusing Method (TFM) to create high-resolution images of internal structures, allowing for precise identification and characterization of HE-induced defects[2]. The system also incorporates adaptive focal law technology to optimize beam focusing in complex geometries. Olympus has further enhanced their solution by integrating acoustic emission sensors for continuous monitoring, enabling the detection of active crack growth during operation[4]. This comprehensive approach provides a more complete picture of material integrity and damage progression.

Strengths: High-resolution imaging capabilities, versatile application across various materials and geometries, and integration of multiple NDT techniques. Weaknesses: Potentially higher cost compared to single-method solutions and may require specialized training for operators.

Innovations in Acoustic Emission and Microstructure Analysis

Method and apparatus for acoustic emission non- destructive testing

PatentInactiveUS3858439A

Innovation

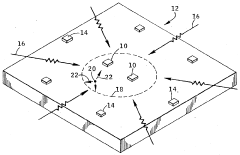

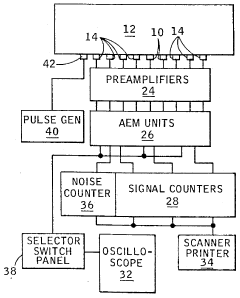

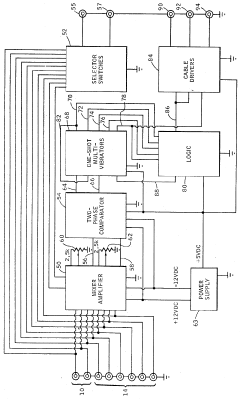

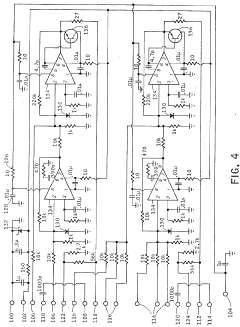

- A spatial filtering method using an array of sensors and logic circuits, where 'master' sensors are surrounded by 'slave' sensors, with an electronic gating system that ignores noise signals originating outside the inspection area, allowing only acoustic emissions within the region to be detected, and frequency filters are used to eliminate low-frequency noise.

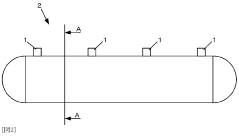

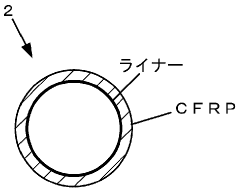

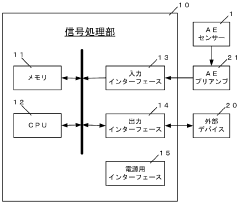

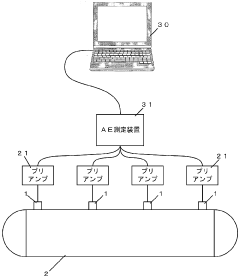

High-pressure tank damage detecting method and device therefor

PatentWO2009008515A1

Innovation

- A non-destructive damage detection method using acoustic emission sensors to monitor AE hit rates, which detects signs of destruction by identifying saturation in AE hit rates as high-pressure tanks are filled, indicating potential failure.

Standardization and Certification in NDT for HE Damage

Standardization and certification play a crucial role in ensuring the reliability and consistency of Non-Destructive Testing (NDT) methods for Hydrogen Embrittlement (HE) damage detection. As the field of NDT for HE damage continues to evolve, there is an increasing need for unified standards and certification processes to maintain quality and safety across industries.

International organizations such as the International Organization for Standardization (ISO) and the American Society for Testing and Materials (ASTM) have been at the forefront of developing standards for NDT techniques. These standards provide guidelines for equipment calibration, testing procedures, and result interpretation, ensuring that NDT methods for HE damage detection are performed consistently across different facilities and operators.

For acoustic emission testing, standards such as ASTM E1139 and ISO 12716 provide guidelines for the detection and evaluation of acoustic emissions in metallic materials. These standards outline procedures for sensor placement, data acquisition, and signal analysis, which are essential for accurately detecting HE-induced damage.

In the realm of microstructure analysis, standards like ASTM E3 and ISO 17639 offer guidance on metallographic sample preparation and examination. These standards are crucial for ensuring that microstructural changes due to HE damage are accurately identified and characterized across different laboratories and research institutions.

Certification programs for NDT professionals specializing in HE damage detection have also been developed by organizations such as the American Society for Nondestructive Testing (ASNT) and the British Institute of Non-Destructive Testing (BINDT). These programs typically involve a combination of theoretical knowledge and practical skills assessment, ensuring that certified professionals possess the necessary expertise to perform reliable HE damage detection using various NDT methods.

As new NDT techniques for HE damage detection emerge, such as advanced ultrasonic methods and electromagnetic techniques, there is an ongoing effort to develop and update standards and certification processes. This continuous evolution helps to incorporate the latest technological advancements and ensures that NDT practices remain effective in detecting and characterizing HE damage across various materials and applications.

The standardization and certification processes also contribute to the overall quality assurance and risk management in industries where HE damage is a concern, such as aerospace, automotive, and energy sectors. By adhering to established standards and employing certified professionals, companies can demonstrate their commitment to safety and reliability, which is crucial for regulatory compliance and customer confidence.

International organizations such as the International Organization for Standardization (ISO) and the American Society for Testing and Materials (ASTM) have been at the forefront of developing standards for NDT techniques. These standards provide guidelines for equipment calibration, testing procedures, and result interpretation, ensuring that NDT methods for HE damage detection are performed consistently across different facilities and operators.

For acoustic emission testing, standards such as ASTM E1139 and ISO 12716 provide guidelines for the detection and evaluation of acoustic emissions in metallic materials. These standards outline procedures for sensor placement, data acquisition, and signal analysis, which are essential for accurately detecting HE-induced damage.

In the realm of microstructure analysis, standards like ASTM E3 and ISO 17639 offer guidance on metallographic sample preparation and examination. These standards are crucial for ensuring that microstructural changes due to HE damage are accurately identified and characterized across different laboratories and research institutions.

Certification programs for NDT professionals specializing in HE damage detection have also been developed by organizations such as the American Society for Nondestructive Testing (ASNT) and the British Institute of Non-Destructive Testing (BINDT). These programs typically involve a combination of theoretical knowledge and practical skills assessment, ensuring that certified professionals possess the necessary expertise to perform reliable HE damage detection using various NDT methods.

As new NDT techniques for HE damage detection emerge, such as advanced ultrasonic methods and electromagnetic techniques, there is an ongoing effort to develop and update standards and certification processes. This continuous evolution helps to incorporate the latest technological advancements and ensures that NDT practices remain effective in detecting and characterizing HE damage across various materials and applications.

The standardization and certification processes also contribute to the overall quality assurance and risk management in industries where HE damage is a concern, such as aerospace, automotive, and energy sectors. By adhering to established standards and employing certified professionals, companies can demonstrate their commitment to safety and reliability, which is crucial for regulatory compliance and customer confidence.

Environmental Impact of NDT Methods for HE Damage Detection

The environmental impact of Non-Destructive Testing (NDT) methods for Hydrogen Embrittlement (HE) damage detection is an important consideration in the development and application of these technologies. While NDT methods are generally considered less invasive than destructive testing, they still have potential environmental implications that need to be carefully evaluated.

Acoustic Emission (AE) testing, one of the primary NDT methods for HE damage detection, has a relatively low environmental impact. The technique relies on detecting and analyzing stress waves generated by material deformation, requiring minimal energy input and producing no waste materials. However, the sensors and equipment used in AE testing may contain electronic components that require proper disposal at the end of their lifecycle.

Microstructural analysis techniques, such as scanning electron microscopy (SEM) and transmission electron microscopy (TEM), have a more significant environmental footprint. These methods often require sample preparation, which may involve chemical etching or polishing processes. The chemicals used in these processes need careful handling and disposal to prevent environmental contamination. Additionally, electron microscopes consume substantial amounts of electricity and may use coolants that require periodic replacement and proper disposal.

Other NDT methods, like ultrasonic testing and eddy current testing, generally have low direct environmental impacts. However, the production and disposal of specialized equipment and probes used in these techniques should be considered in their overall environmental assessment.

The use of radiographic testing for HE damage detection raises more significant environmental concerns. This method involves ionizing radiation, which requires strict safety protocols and specialized disposal procedures for radioactive sources. While the radiation levels used in NDT are typically low, proper shielding and waste management are crucial to minimize environmental risks.

Emerging NDT technologies, such as thermography and digital image correlation, offer promising alternatives with potentially lower environmental impacts. These methods often rely on non-contact, non-invasive techniques that require minimal consumables and produce little to no waste.

In assessing the environmental impact of NDT methods for HE damage detection, it is essential to consider the entire lifecycle of the equipment and materials used. This includes the environmental costs of manufacturing specialized instruments, the energy consumption during operation, and the disposal or recycling of equipment at the end of its useful life.

Furthermore, the indirect environmental benefits of effective NDT methods should not be overlooked. By enabling early detection of HE damage, these techniques can prevent catastrophic failures in critical infrastructure, potentially averting significant environmental disasters associated with structural collapses or industrial accidents.

Acoustic Emission (AE) testing, one of the primary NDT methods for HE damage detection, has a relatively low environmental impact. The technique relies on detecting and analyzing stress waves generated by material deformation, requiring minimal energy input and producing no waste materials. However, the sensors and equipment used in AE testing may contain electronic components that require proper disposal at the end of their lifecycle.

Microstructural analysis techniques, such as scanning electron microscopy (SEM) and transmission electron microscopy (TEM), have a more significant environmental footprint. These methods often require sample preparation, which may involve chemical etching or polishing processes. The chemicals used in these processes need careful handling and disposal to prevent environmental contamination. Additionally, electron microscopes consume substantial amounts of electricity and may use coolants that require periodic replacement and proper disposal.

Other NDT methods, like ultrasonic testing and eddy current testing, generally have low direct environmental impacts. However, the production and disposal of specialized equipment and probes used in these techniques should be considered in their overall environmental assessment.

The use of radiographic testing for HE damage detection raises more significant environmental concerns. This method involves ionizing radiation, which requires strict safety protocols and specialized disposal procedures for radioactive sources. While the radiation levels used in NDT are typically low, proper shielding and waste management are crucial to minimize environmental risks.

Emerging NDT technologies, such as thermography and digital image correlation, offer promising alternatives with potentially lower environmental impacts. These methods often rely on non-contact, non-invasive techniques that require minimal consumables and produce little to no waste.

In assessing the environmental impact of NDT methods for HE damage detection, it is essential to consider the entire lifecycle of the equipment and materials used. This includes the environmental costs of manufacturing specialized instruments, the energy consumption during operation, and the disposal or recycling of equipment at the end of its useful life.

Furthermore, the indirect environmental benefits of effective NDT methods should not be overlooked. By enabling early detection of HE damage, these techniques can prevent catastrophic failures in critical infrastructure, potentially averting significant environmental disasters associated with structural collapses or industrial accidents.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!