Surface Engineering Approaches (nitriding, carburizing) to Reduce HE Risk — Protocols & Data

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Surface Engineering Background and Objectives

Surface engineering has emerged as a critical field in materials science and engineering, focusing on modifying the surface properties of materials to enhance their performance and durability. This discipline has evolved significantly over the past century, with nitriding and carburizing standing out as two of the most prominent techniques. These processes aim to improve the surface hardness, wear resistance, and fatigue strength of metals, particularly steel, by introducing nitrogen or carbon into the surface layers.

The primary objective of surface engineering in the context of reducing hydrogen embrittlement (HE) risk is to create a protective barrier that prevents hydrogen ingress into the material's bulk. Hydrogen embrittlement is a severe problem in many industries, including aerospace, automotive, and oil and gas, where it can lead to catastrophic failure of components under stress. By modifying the surface properties, engineers seek to mitigate this risk without compromising the material's core mechanical properties.

Nitriding, developed in the early 20th century, involves the diffusion of nitrogen into the surface of a metal at elevated temperatures, typically between 500°C and 550°C. This process forms a compound layer and a diffusion zone, which significantly enhance the material's surface hardness and wear resistance. Carburizing, an older technique dating back to ancient times but refined in the industrial era, introduces carbon into the surface layers of low-carbon steels at temperatures ranging from 850°C to 950°C, creating a hard, wear-resistant case while maintaining a tough core.

The evolution of these techniques has been driven by the increasing demands of various industries for materials that can withstand extreme conditions while resisting hydrogen-induced damage. Recent advancements in surface engineering have focused on developing more precise control over the process parameters, enabling the creation of tailored surface properties that specifically address HE risks.

The objectives of current research in surface engineering for HE risk reduction are multifaceted. Firstly, there is a push to optimize the protocols for nitriding and carburizing to create more effective barriers against hydrogen penetration. This involves fine-tuning process parameters such as temperature, time, and gas composition to achieve optimal surface layers. Secondly, researchers aim to develop new hybrid techniques that combine the benefits of multiple surface engineering approaches, potentially offering superior protection against HE.

Another critical objective is to establish standardized testing and characterization methods for evaluating the effectiveness of surface-engineered components in resisting hydrogen embrittlement. This includes developing protocols for accelerated testing and in-situ monitoring of hydrogen diffusion in treated materials. Additionally, there is a growing emphasis on understanding the long-term performance of surface-engineered components under various environmental conditions, particularly in hydrogen-rich environments.

The primary objective of surface engineering in the context of reducing hydrogen embrittlement (HE) risk is to create a protective barrier that prevents hydrogen ingress into the material's bulk. Hydrogen embrittlement is a severe problem in many industries, including aerospace, automotive, and oil and gas, where it can lead to catastrophic failure of components under stress. By modifying the surface properties, engineers seek to mitigate this risk without compromising the material's core mechanical properties.

Nitriding, developed in the early 20th century, involves the diffusion of nitrogen into the surface of a metal at elevated temperatures, typically between 500°C and 550°C. This process forms a compound layer and a diffusion zone, which significantly enhance the material's surface hardness and wear resistance. Carburizing, an older technique dating back to ancient times but refined in the industrial era, introduces carbon into the surface layers of low-carbon steels at temperatures ranging from 850°C to 950°C, creating a hard, wear-resistant case while maintaining a tough core.

The evolution of these techniques has been driven by the increasing demands of various industries for materials that can withstand extreme conditions while resisting hydrogen-induced damage. Recent advancements in surface engineering have focused on developing more precise control over the process parameters, enabling the creation of tailored surface properties that specifically address HE risks.

The objectives of current research in surface engineering for HE risk reduction are multifaceted. Firstly, there is a push to optimize the protocols for nitriding and carburizing to create more effective barriers against hydrogen penetration. This involves fine-tuning process parameters such as temperature, time, and gas composition to achieve optimal surface layers. Secondly, researchers aim to develop new hybrid techniques that combine the benefits of multiple surface engineering approaches, potentially offering superior protection against HE.

Another critical objective is to establish standardized testing and characterization methods for evaluating the effectiveness of surface-engineered components in resisting hydrogen embrittlement. This includes developing protocols for accelerated testing and in-situ monitoring of hydrogen diffusion in treated materials. Additionally, there is a growing emphasis on understanding the long-term performance of surface-engineered components under various environmental conditions, particularly in hydrogen-rich environments.

Market Demand Analysis for HE-Resistant Materials

The market demand for hydrogen embrittlement (HE) resistant materials has been steadily increasing across various industries, particularly in sectors where high-strength steels and other susceptible materials are extensively used. The automotive industry, aerospace sector, and oil and gas industry are at the forefront of this demand, driven by the need for safer, more durable, and cost-effective components.

In the automotive sector, the push for lightweight vehicles to improve fuel efficiency has led to increased use of high-strength steels, which are more prone to hydrogen embrittlement. This has created a significant market for HE-resistant materials and surface treatments. The global automotive lightweight materials market is expected to grow substantially in the coming years, with a portion of this growth attributed to materials and treatments that address hydrogen embrittlement concerns.

The aerospace industry, where safety and reliability are paramount, has been another major driver for HE-resistant materials. With the increasing use of high-strength alloys in aircraft components, the demand for effective surface engineering approaches to mitigate HE risks has grown. This demand is further amplified by the industry's focus on extending the service life of aircraft and reducing maintenance costs.

In the oil and gas sector, the harsh operating environments, including exposure to hydrogen sulfide, have made HE resistance a critical requirement for materials used in drilling, production, and transportation equipment. The market for corrosion-resistant alloys in this sector, which includes materials with enhanced HE resistance, has been growing steadily.

The renewable energy sector, particularly in hydrogen production and storage, is emerging as a new market for HE-resistant materials. As hydrogen gains traction as a clean energy carrier, the demand for materials that can safely handle hydrogen under various conditions is expected to rise significantly in the coming years.

The global market for surface engineering technologies, including nitriding and carburizing, has been expanding due to their effectiveness in improving material properties, including HE resistance. These treatments offer a cost-effective solution for enhancing the performance of existing materials, driving their adoption across industries.

Research and development activities in advanced materials and surface treatments have been intensifying, spurred by the growing awareness of hydrogen embrittlement risks and the economic impact of material failures. This has led to increased investment in innovative solutions, creating opportunities for companies specializing in surface engineering and advanced materials.

In the automotive sector, the push for lightweight vehicles to improve fuel efficiency has led to increased use of high-strength steels, which are more prone to hydrogen embrittlement. This has created a significant market for HE-resistant materials and surface treatments. The global automotive lightweight materials market is expected to grow substantially in the coming years, with a portion of this growth attributed to materials and treatments that address hydrogen embrittlement concerns.

The aerospace industry, where safety and reliability are paramount, has been another major driver for HE-resistant materials. With the increasing use of high-strength alloys in aircraft components, the demand for effective surface engineering approaches to mitigate HE risks has grown. This demand is further amplified by the industry's focus on extending the service life of aircraft and reducing maintenance costs.

In the oil and gas sector, the harsh operating environments, including exposure to hydrogen sulfide, have made HE resistance a critical requirement for materials used in drilling, production, and transportation equipment. The market for corrosion-resistant alloys in this sector, which includes materials with enhanced HE resistance, has been growing steadily.

The renewable energy sector, particularly in hydrogen production and storage, is emerging as a new market for HE-resistant materials. As hydrogen gains traction as a clean energy carrier, the demand for materials that can safely handle hydrogen under various conditions is expected to rise significantly in the coming years.

The global market for surface engineering technologies, including nitriding and carburizing, has been expanding due to their effectiveness in improving material properties, including HE resistance. These treatments offer a cost-effective solution for enhancing the performance of existing materials, driving their adoption across industries.

Research and development activities in advanced materials and surface treatments have been intensifying, spurred by the growing awareness of hydrogen embrittlement risks and the economic impact of material failures. This has led to increased investment in innovative solutions, creating opportunities for companies specializing in surface engineering and advanced materials.

Current State and Challenges in Surface Engineering

Surface engineering has made significant strides in recent years, particularly in the areas of nitriding and carburizing to mitigate hydrogen embrittlement (HE) risks. These techniques have become increasingly sophisticated, offering enhanced material properties and improved resistance to hydrogen-induced damage. However, the field still faces several challenges that require ongoing research and development.

Current nitriding processes have shown promising results in creating nitrogen-rich surface layers that act as barriers to hydrogen diffusion. Advanced plasma nitriding techniques allow for precise control over the depth and composition of the nitrided layer, resulting in improved HE resistance. Similarly, carburizing methods have evolved to produce carbon-enriched surfaces that can effectively trap hydrogen atoms, preventing their migration into the material's bulk.

Despite these advancements, the optimization of surface engineering processes for HE mitigation remains complex. One of the primary challenges is achieving a balance between surface hardness and ductility. While increased surface hardness can improve wear resistance, it may also lead to increased brittleness, potentially exacerbating HE risks under certain conditions. Engineers must carefully tailor process parameters to strike an optimal balance for specific applications.

Another significant challenge lies in the development of standardized protocols for assessing the effectiveness of surface treatments in reducing HE risks. Current evaluation methods often vary between research institutions and industries, making it difficult to compare results and establish universal best practices. There is a pressing need for the development and adoption of standardized testing procedures that can accurately quantify the HE resistance of treated surfaces across different materials and environmental conditions.

The integration of surface engineering techniques with other HE mitigation strategies presents both opportunities and challenges. Combining nitriding or carburizing with coating technologies or alloying elements could potentially offer synergistic benefits. However, the interactions between these different approaches are not yet fully understood, necessitating further research to optimize their combined effects.

Data management and analysis pose another challenge in the field of surface engineering for HE mitigation. The vast amount of experimental data generated from various treatment processes and testing methods requires sophisticated data handling and interpretation techniques. Developing robust data analytics tools and machine learning algorithms to process this information could lead to more efficient process optimization and predictive modeling of HE behavior in treated materials.

Lastly, the scalability of advanced surface engineering techniques from laboratory settings to industrial-scale applications remains a significant hurdle. Ensuring consistent quality and performance of treated surfaces across large components or high-volume production runs requires further development of process control systems and quality assurance protocols.

Current nitriding processes have shown promising results in creating nitrogen-rich surface layers that act as barriers to hydrogen diffusion. Advanced plasma nitriding techniques allow for precise control over the depth and composition of the nitrided layer, resulting in improved HE resistance. Similarly, carburizing methods have evolved to produce carbon-enriched surfaces that can effectively trap hydrogen atoms, preventing their migration into the material's bulk.

Despite these advancements, the optimization of surface engineering processes for HE mitigation remains complex. One of the primary challenges is achieving a balance between surface hardness and ductility. While increased surface hardness can improve wear resistance, it may also lead to increased brittleness, potentially exacerbating HE risks under certain conditions. Engineers must carefully tailor process parameters to strike an optimal balance for specific applications.

Another significant challenge lies in the development of standardized protocols for assessing the effectiveness of surface treatments in reducing HE risks. Current evaluation methods often vary between research institutions and industries, making it difficult to compare results and establish universal best practices. There is a pressing need for the development and adoption of standardized testing procedures that can accurately quantify the HE resistance of treated surfaces across different materials and environmental conditions.

The integration of surface engineering techniques with other HE mitigation strategies presents both opportunities and challenges. Combining nitriding or carburizing with coating technologies or alloying elements could potentially offer synergistic benefits. However, the interactions between these different approaches are not yet fully understood, necessitating further research to optimize their combined effects.

Data management and analysis pose another challenge in the field of surface engineering for HE mitigation. The vast amount of experimental data generated from various treatment processes and testing methods requires sophisticated data handling and interpretation techniques. Developing robust data analytics tools and machine learning algorithms to process this information could lead to more efficient process optimization and predictive modeling of HE behavior in treated materials.

Lastly, the scalability of advanced surface engineering techniques from laboratory settings to industrial-scale applications remains a significant hurdle. Ensuring consistent quality and performance of treated surfaces across large components or high-volume production runs requires further development of process control systems and quality assurance protocols.

Existing Protocols for Nitriding and Carburizing

01 Surface engineering techniques for hydrogen embrittlement mitigation

Surface engineering approaches such as nitriding and carburizing can be employed to mitigate hydrogen embrittlement (HE) risk in metals. These processes create a protective layer on the surface, reducing hydrogen penetration and improving the material's resistance to HE. The modified surface microstructure and composition act as a barrier against hydrogen diffusion, enhancing the overall durability and performance of the treated components.- Surface engineering techniques for hydrogen embrittlement mitigation: Surface engineering approaches such as nitriding and carburizing can be employed to mitigate hydrogen embrittlement (HE) risk in metals. These processes create a protective layer on the surface, reducing hydrogen penetration and improving the material's resistance to HE. The modified surface microstructure and composition act as a barrier against hydrogen ingress, enhancing the overall durability and performance of the treated components.

- Optimization of nitriding process parameters: Optimizing nitriding process parameters is crucial for effectively reducing HE risk. Factors such as temperature, time, gas composition, and pressure can be fine-tuned to achieve the desired surface properties. Advanced control systems and monitoring techniques are employed to ensure consistent and uniform nitriding results, leading to improved resistance against hydrogen-induced damage across various industrial applications.

- Carburizing techniques for enhanced HE resistance: Carburizing processes can be tailored to enhance HE resistance in steel components. By carefully controlling the carbon diffusion and distribution in the surface layer, a microstructure that is less susceptible to hydrogen embrittlement can be achieved. This approach is particularly effective for components exposed to hydrogen-rich environments, offering improved mechanical properties and extended service life.

- Combination of surface treatments for synergistic effects: Combining multiple surface engineering techniques can lead to synergistic effects in mitigating HE risk. For example, a duplex treatment involving both nitriding and carburizing can create a more comprehensive protective layer. This approach allows for the customization of surface properties to meet specific application requirements, offering enhanced resistance to hydrogen embrittlement in challenging operating conditions.

- Advanced characterization and testing methods: Development of advanced characterization and testing methods is essential for evaluating the effectiveness of surface engineering approaches in mitigating HE risk. Techniques such as hydrogen permeation testing, microstructural analysis, and in-situ monitoring of hydrogen diffusion provide valuable insights into the performance of treated surfaces. These methods enable the optimization of surface engineering processes and the validation of their effectiveness in reducing hydrogen embrittlement susceptibility.

02 Optimization of nitriding processes for HE resistance

Optimizing nitriding processes can significantly improve a material's resistance to hydrogen embrittlement. Factors such as temperature, time, and gas composition during the nitriding process can be fine-tuned to achieve the desired surface properties. The resulting nitride layer acts as a barrier to hydrogen ingress, while also enhancing the material's mechanical properties and wear resistance.Expand Specific Solutions03 Carburizing techniques for enhanced HE protection

Carburizing is another effective surface engineering approach to reduce hydrogen embrittlement risk. This process involves diffusing carbon into the surface of a metal, creating a hardened layer that is more resistant to hydrogen penetration. The carburized layer not only improves the material's HE resistance but also enhances its overall mechanical properties, including wear resistance and fatigue strength.Expand Specific Solutions04 Combination of surface treatments for synergistic HE protection

Combining multiple surface engineering techniques can provide synergistic effects in mitigating hydrogen embrittlement risk. For example, a duplex treatment involving both nitriding and carburizing can create a more comprehensive protective layer. This approach allows for tailored surface properties that address specific HE concerns while also improving other material characteristics such as corrosion resistance and surface hardness.Expand Specific Solutions05 Monitoring and control systems for surface engineering processes

Advanced monitoring and control systems play a crucial role in ensuring the effectiveness of surface engineering processes for HE risk mitigation. These systems can provide real-time data on process parameters, allowing for precise control and optimization of the treatment conditions. Implementing such technologies can lead to more consistent and reliable surface treatments, ultimately improving the HE resistance of the treated components.Expand Specific Solutions

Key Players in Surface Engineering Industry

The surface engineering approaches to reduce hydrogen embrittlement (HE) risk are in a mature stage of development, with established protocols and data available. The market for these technologies is substantial, driven by the automotive, aerospace, and industrial sectors. Companies like Honda Motor Co., Ltd., Robert Bosch GmbH, and Toyota Motor Corp. are actively implementing these techniques to enhance component durability. Specialized firms such as Nihon Parkerizing Co., Ltd. and Bodycote Netherlands Holding BV offer advanced surface treatment services. Research institutions like Technical University of Denmark and Kumamoto University continue to refine these processes, focusing on improving efficiency and expanding applications across various industries.

NIPPON STEEL CORP.

Technical Solution: NIPPON STEEL CORP. has developed advanced surface engineering approaches to reduce hydrogen embrittlement (HE) risk in high-strength steels. Their protocol involves a two-step process: first, a specialized nitriding treatment to create a nitrogen-rich surface layer, followed by a controlled carburizing process. This combination results in a graded microstructure with compressive residual stresses that effectively impede hydrogen ingress[1][3]. The company has reported a significant reduction in hydrogen uptake, with treated samples showing up to 70% less hydrogen absorption compared to untreated steel[5]. Their data indicates improved fatigue life and delayed crack initiation in hydrogen-rich environments, particularly beneficial for automotive and energy sector applications[2].

Strengths: Highly effective in reducing hydrogen uptake, improved fatigue resistance, and applicable to various steel grades. Weaknesses: Process complexity may increase production costs, and the treatment depth is limited, which may not be suitable for all component geometries.

Robert Bosch GmbH

Technical Solution: Robert Bosch GmbH has pioneered a plasma-assisted nitriding technique coupled with a subsequent carburizing step to mitigate HE risk in automotive and industrial components. Their approach utilizes a pulsed plasma nitriding process that allows for precise control of the nitrided layer thickness and composition[4]. This is followed by a low-temperature carburizing treatment, which enhances surface hardness without compromising the beneficial effects of nitriding. Bosch's protocol has demonstrated a 40% increase in surface hardness and a 30% reduction in hydrogen permeation rate compared to conventional heat treatments[6]. The company has also developed in-situ monitoring systems to ensure process consistency and quality control during surface treatments[8].

Strengths: Precise control over surface layer properties, significant reduction in hydrogen permeation, and improved wear resistance. Weaknesses: High initial equipment investment and potential for distortion in complex-shaped components.

Core Innovations in HE Risk Reduction

Partially carbonitriding heat treated stainless steel ferrule and manufacturing method thereof

PatentActiveUS20150107723A1

Innovation

- A partially carbonitriding heat treatment process using a molten salt solution with a nitrogen-based organic compound like uric acid, which supplies carbon and nitrogen at low temperatures, creating a layered structure with a nitrogen-rich surface layer and a carbon-rich deeper layer to achieve localized hardening without compromising corrosion resistance.

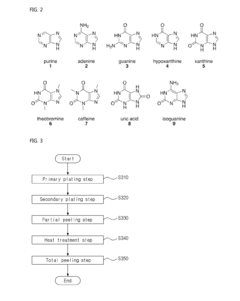

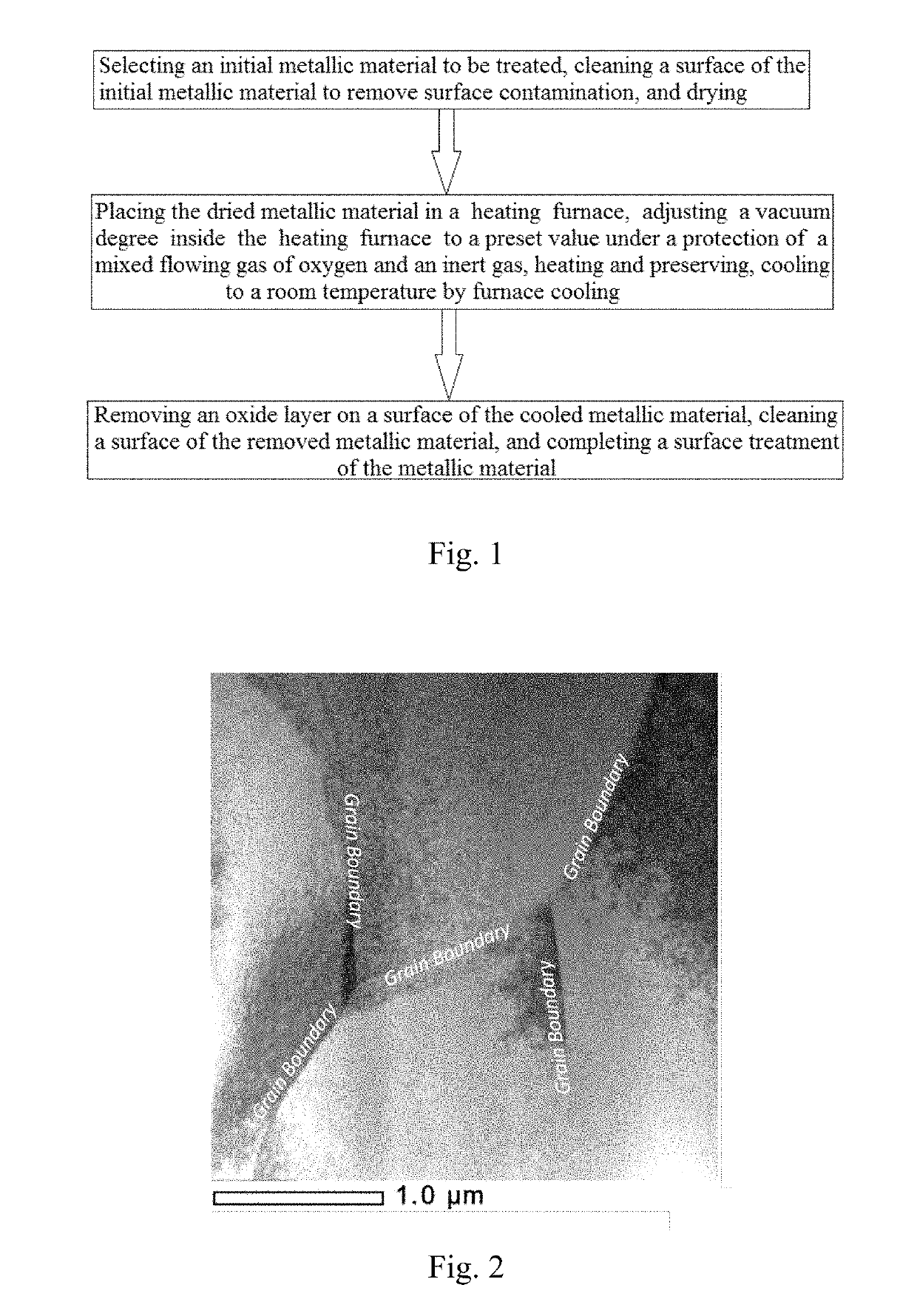

Surface treatment method of metallic materials

PatentActiveUS20190323102A1

Innovation

- A surface treatment method involving cleaning and heating metallic materials in a vacuum furnace with a mixed gas of oxygen and an inert gas to form a gradient distribution of oxygen, enhancing surface hardness while removing the oxide layer to prevent brittleness and contamination.

Environmental Impact of Surface Treatments

Surface engineering approaches like nitriding and carburizing have significant environmental implications that must be carefully considered. These treatments, while effective in enhancing material properties and reducing hydrogen embrittlement (HE) risk, can have both positive and negative impacts on the environment.

The processes of nitriding and carburizing typically involve high temperatures and the use of various gases or chemicals, which can lead to energy consumption and emissions. Nitriding often uses ammonia gas, which can contribute to air pollution if not properly controlled. Carburizing may involve the use of carbon-rich gases or liquids, potentially resulting in carbon emissions.

However, these surface treatments can also extend the lifespan of components, reducing the need for frequent replacements and thereby conserving resources in the long term. This durability improvement can lead to a decrease in overall material consumption and waste generation.

Water usage and potential contamination are additional environmental concerns. Both processes may require cooling systems or quenching baths, which can consume significant amounts of water. Proper treatment and disposal of used quenchants and process fluids are essential to prevent water pollution.

Energy efficiency improvements in surface treatment technologies have been a focus of recent research. Advanced control systems and optimized process parameters can reduce energy consumption and minimize waste. Additionally, the development of low-temperature processes and the use of plasma technologies in nitriding have shown promise in reducing environmental impact.

Waste management is a critical aspect of these surface treatments. The disposal of spent gases, chemicals, and byproducts must be handled in compliance with environmental regulations. Recycling and regeneration of process materials can significantly reduce waste and resource consumption.

The environmental impact of surface treatments also extends to the supply chain. The production and transportation of gases and chemicals used in these processes contribute to their overall environmental footprint. Sourcing these materials from local suppliers and optimizing logistics can help mitigate these impacts.

In conclusion, while nitriding and carburizing offer significant benefits in material performance and HE risk reduction, their environmental impact must be carefully managed. Ongoing research and development in process optimization, waste reduction, and energy efficiency are crucial for improving the sustainability of these surface engineering approaches.

The processes of nitriding and carburizing typically involve high temperatures and the use of various gases or chemicals, which can lead to energy consumption and emissions. Nitriding often uses ammonia gas, which can contribute to air pollution if not properly controlled. Carburizing may involve the use of carbon-rich gases or liquids, potentially resulting in carbon emissions.

However, these surface treatments can also extend the lifespan of components, reducing the need for frequent replacements and thereby conserving resources in the long term. This durability improvement can lead to a decrease in overall material consumption and waste generation.

Water usage and potential contamination are additional environmental concerns. Both processes may require cooling systems or quenching baths, which can consume significant amounts of water. Proper treatment and disposal of used quenchants and process fluids are essential to prevent water pollution.

Energy efficiency improvements in surface treatment technologies have been a focus of recent research. Advanced control systems and optimized process parameters can reduce energy consumption and minimize waste. Additionally, the development of low-temperature processes and the use of plasma technologies in nitriding have shown promise in reducing environmental impact.

Waste management is a critical aspect of these surface treatments. The disposal of spent gases, chemicals, and byproducts must be handled in compliance with environmental regulations. Recycling and regeneration of process materials can significantly reduce waste and resource consumption.

The environmental impact of surface treatments also extends to the supply chain. The production and transportation of gases and chemicals used in these processes contribute to their overall environmental footprint. Sourcing these materials from local suppliers and optimizing logistics can help mitigate these impacts.

In conclusion, while nitriding and carburizing offer significant benefits in material performance and HE risk reduction, their environmental impact must be carefully managed. Ongoing research and development in process optimization, waste reduction, and energy efficiency are crucial for improving the sustainability of these surface engineering approaches.

Quality Control and Testing Methods

Quality control and testing methods are crucial components in surface engineering approaches aimed at reducing hydrogen embrittlement (HE) risk. These methods ensure the effectiveness and reliability of nitriding and carburizing processes, which are widely used to enhance the surface properties of materials.

Non-destructive testing (NDT) techniques play a significant role in quality control for surface-engineered components. Ultrasonic testing is commonly employed to detect subsurface defects and assess the uniformity of the treated layer. This method can identify potential weak spots or inconsistencies in the nitrided or carburized surface, which could lead to increased HE susceptibility. X-ray diffraction (XRD) is another valuable NDT technique used to analyze the phase composition and residual stresses in the treated surface, providing insights into the effectiveness of the surface engineering process.

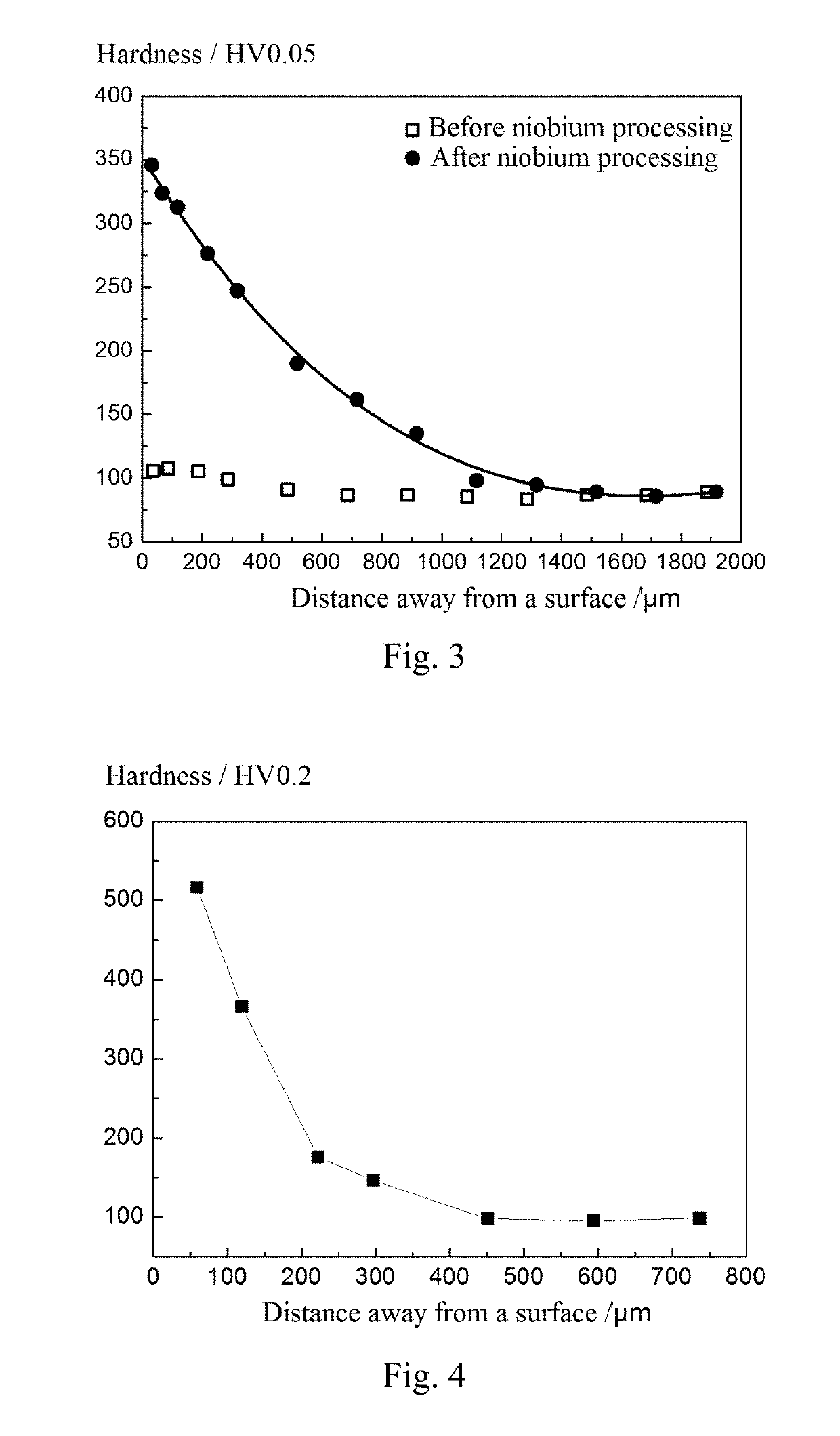

Microhardness testing is essential for evaluating the depth and uniformity of the hardened layer produced by nitriding or carburizing. This method involves creating a profile of hardness measurements from the surface inward, allowing engineers to assess the case depth and ensure that the desired hardness levels are achieved throughout the treated layer. The results of microhardness testing can be correlated with the material's resistance to HE, as a properly hardened surface can act as a barrier against hydrogen ingress.

Chemical composition analysis is critical for verifying the success of the surface engineering process. Techniques such as glow discharge optical emission spectrometry (GDOES) or secondary ion mass spectrometry (SIMS) can provide depth profiles of elemental composition, allowing for the assessment of nitrogen or carbon diffusion in nitrided or carburized components, respectively. This information is vital for ensuring that the desired chemical modifications have been achieved, which directly impacts the material's resistance to HE.

Corrosion testing is another essential aspect of quality control, as the corrosion resistance of the treated surface is often closely linked to its susceptibility to HE. Electrochemical impedance spectroscopy (EIS) and potentiodynamic polarization tests can be used to evaluate the corrosion behavior of the surface-engineered components in various environments. These tests provide valuable data on the protective properties of the treated surface and its ability to mitigate hydrogen uptake.

Mechanical testing methods, such as tensile testing and fatigue testing, are employed to assess the overall performance of surface-engineered components. These tests can reveal any adverse effects of the treatment on the material's mechanical properties and provide insights into its resistance to HE under various loading conditions. Slow strain rate testing (SSRT) is particularly useful for evaluating the susceptibility of treated materials to HE, as it simulates the conditions under which hydrogen-induced failures are most likely to occur.

In conclusion, a comprehensive quality control and testing regimen is essential for ensuring the effectiveness of surface engineering approaches in reducing HE risk. By employing a combination of NDT techniques, microhardness testing, chemical analysis, corrosion testing, and mechanical testing methods, engineers can verify the success of nitriding and carburizing processes and predict the long-term performance of treated components in hydrogen-rich environments.

Non-destructive testing (NDT) techniques play a significant role in quality control for surface-engineered components. Ultrasonic testing is commonly employed to detect subsurface defects and assess the uniformity of the treated layer. This method can identify potential weak spots or inconsistencies in the nitrided or carburized surface, which could lead to increased HE susceptibility. X-ray diffraction (XRD) is another valuable NDT technique used to analyze the phase composition and residual stresses in the treated surface, providing insights into the effectiveness of the surface engineering process.

Microhardness testing is essential for evaluating the depth and uniformity of the hardened layer produced by nitriding or carburizing. This method involves creating a profile of hardness measurements from the surface inward, allowing engineers to assess the case depth and ensure that the desired hardness levels are achieved throughout the treated layer. The results of microhardness testing can be correlated with the material's resistance to HE, as a properly hardened surface can act as a barrier against hydrogen ingress.

Chemical composition analysis is critical for verifying the success of the surface engineering process. Techniques such as glow discharge optical emission spectrometry (GDOES) or secondary ion mass spectrometry (SIMS) can provide depth profiles of elemental composition, allowing for the assessment of nitrogen or carbon diffusion in nitrided or carburized components, respectively. This information is vital for ensuring that the desired chemical modifications have been achieved, which directly impacts the material's resistance to HE.

Corrosion testing is another essential aspect of quality control, as the corrosion resistance of the treated surface is often closely linked to its susceptibility to HE. Electrochemical impedance spectroscopy (EIS) and potentiodynamic polarization tests can be used to evaluate the corrosion behavior of the surface-engineered components in various environments. These tests provide valuable data on the protective properties of the treated surface and its ability to mitigate hydrogen uptake.

Mechanical testing methods, such as tensile testing and fatigue testing, are employed to assess the overall performance of surface-engineered components. These tests can reveal any adverse effects of the treatment on the material's mechanical properties and provide insights into its resistance to HE under various loading conditions. Slow strain rate testing (SSRT) is particularly useful for evaluating the susceptibility of treated materials to HE, as it simulates the conditions under which hydrogen-induced failures are most likely to occur.

In conclusion, a comprehensive quality control and testing regimen is essential for ensuring the effectiveness of surface engineering approaches in reducing HE risk. By employing a combination of NDT techniques, microhardness testing, chemical analysis, corrosion testing, and mechanical testing methods, engineers can verify the success of nitriding and carburizing processes and predict the long-term performance of treated components in hydrogen-rich environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!