Stress Corrosion Cracking vs HE: Distinguishing Features and Test Protocols

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SCC and HE Background

Stress Corrosion Cracking (SCC) and Hydrogen Embrittlement (HE) are two significant degradation mechanisms that affect the integrity and reliability of metallic materials in various industrial applications. These phenomena have been extensively studied for decades due to their detrimental effects on structural components, particularly in corrosive environments and under stress conditions.

SCC is a form of environmentally assisted cracking that occurs when a susceptible material is subjected to both tensile stress and a specific corrosive environment. This process involves the simultaneous action of mechanical stress and electrochemical corrosion, leading to the formation and propagation of cracks. SCC can result in sudden and catastrophic failures, making it a critical concern in industries such as oil and gas, nuclear power, and aerospace.

Hydrogen Embrittlement, on the other hand, is a process by which hydrogen atoms penetrate the metal lattice, causing a reduction in ductility and load-bearing capacity. This phenomenon can occur through various mechanisms, including hydrogen absorption during manufacturing processes, corrosion reactions, or exposure to hydrogen-containing environments. HE is particularly problematic in high-strength steels and other alloys used in critical applications.

Both SCC and HE share some similarities in their manifestation, as they both lead to the degradation of material properties and can result in unexpected failures. However, their underlying mechanisms and the specific conditions required for their occurrence differ significantly. Understanding these distinctions is crucial for developing effective prevention and mitigation strategies.

The historical context of SCC and HE research dates back to the early 20th century, with significant advancements made during World War II and the subsequent decades. The development of advanced materials and the expansion of industries operating in harsh environments have further intensified the need for comprehensive understanding and control of these phenomena.

In recent years, the focus has shifted towards developing more sophisticated testing methods and predictive models to assess the susceptibility of materials to SCC and HE. This includes the use of advanced characterization techniques, such as in-situ electron microscopy and synchrotron-based X-ray diffraction, to observe crack initiation and propagation at the microscopic level.

The impact of SCC and HE extends beyond material failure, affecting the economics and safety of various industries. Consequently, significant research efforts are directed towards developing resistant materials, protective coatings, and inhibitors to mitigate these issues. Additionally, the integration of these considerations into design processes and risk assessment methodologies has become increasingly important in ensuring the long-term reliability of critical infrastructure and components.

SCC is a form of environmentally assisted cracking that occurs when a susceptible material is subjected to both tensile stress and a specific corrosive environment. This process involves the simultaneous action of mechanical stress and electrochemical corrosion, leading to the formation and propagation of cracks. SCC can result in sudden and catastrophic failures, making it a critical concern in industries such as oil and gas, nuclear power, and aerospace.

Hydrogen Embrittlement, on the other hand, is a process by which hydrogen atoms penetrate the metal lattice, causing a reduction in ductility and load-bearing capacity. This phenomenon can occur through various mechanisms, including hydrogen absorption during manufacturing processes, corrosion reactions, or exposure to hydrogen-containing environments. HE is particularly problematic in high-strength steels and other alloys used in critical applications.

Both SCC and HE share some similarities in their manifestation, as they both lead to the degradation of material properties and can result in unexpected failures. However, their underlying mechanisms and the specific conditions required for their occurrence differ significantly. Understanding these distinctions is crucial for developing effective prevention and mitigation strategies.

The historical context of SCC and HE research dates back to the early 20th century, with significant advancements made during World War II and the subsequent decades. The development of advanced materials and the expansion of industries operating in harsh environments have further intensified the need for comprehensive understanding and control of these phenomena.

In recent years, the focus has shifted towards developing more sophisticated testing methods and predictive models to assess the susceptibility of materials to SCC and HE. This includes the use of advanced characterization techniques, such as in-situ electron microscopy and synchrotron-based X-ray diffraction, to observe crack initiation and propagation at the microscopic level.

The impact of SCC and HE extends beyond material failure, affecting the economics and safety of various industries. Consequently, significant research efforts are directed towards developing resistant materials, protective coatings, and inhibitors to mitigate these issues. Additionally, the integration of these considerations into design processes and risk assessment methodologies has become increasingly important in ensuring the long-term reliability of critical infrastructure and components.

Market Demand Analysis

The market demand for technologies to distinguish and test Stress Corrosion Cracking (SCC) and Hydrogen Embrittlement (HE) has been steadily growing across various industries. This demand is primarily driven by the critical need to ensure the safety and reliability of materials used in high-stress environments, particularly in sectors such as oil and gas, aerospace, automotive, and nuclear power.

In the oil and gas industry, the market for SCC and HE testing solutions is expected to expand significantly due to the increasing exploration and production activities in harsh environments. Offshore platforms and subsea pipelines are especially vulnerable to these forms of corrosion, necessitating advanced testing protocols to prevent catastrophic failures.

The aerospace sector also presents a substantial market opportunity for SCC and HE testing technologies. With the growing emphasis on lightweight materials and high-strength alloys in aircraft manufacturing, the risk of SCC and HE increases. This has led to a rising demand for sophisticated testing methods to ensure the long-term integrity of critical components.

In the automotive industry, the shift towards electric vehicles and the use of advanced materials in lightweight construction have created new challenges in material integrity. As a result, there is an increasing need for reliable SCC and HE testing protocols to validate the safety and durability of these new materials and designs.

The nuclear power industry, with its stringent safety requirements, continues to be a significant driver for SCC and HE testing technologies. The aging infrastructure of many nuclear plants worldwide has heightened the importance of accurate material degradation assessment, further boosting the demand for advanced testing solutions.

Moreover, the global focus on sustainability and environmental protection has indirectly influenced the market for SCC and HE testing. As industries strive to extend the lifespan of existing infrastructure and equipment, there is a growing emphasis on preventive maintenance and early detection of material degradation, which relies heavily on these testing technologies.

The market is also seeing a trend towards non-destructive testing methods for SCC and HE, as these allow for in-situ monitoring without compromising the integrity of the structures. This shift is creating new opportunities for innovative testing technologies that can provide real-time, accurate assessments of material conditions.

In the oil and gas industry, the market for SCC and HE testing solutions is expected to expand significantly due to the increasing exploration and production activities in harsh environments. Offshore platforms and subsea pipelines are especially vulnerable to these forms of corrosion, necessitating advanced testing protocols to prevent catastrophic failures.

The aerospace sector also presents a substantial market opportunity for SCC and HE testing technologies. With the growing emphasis on lightweight materials and high-strength alloys in aircraft manufacturing, the risk of SCC and HE increases. This has led to a rising demand for sophisticated testing methods to ensure the long-term integrity of critical components.

In the automotive industry, the shift towards electric vehicles and the use of advanced materials in lightweight construction have created new challenges in material integrity. As a result, there is an increasing need for reliable SCC and HE testing protocols to validate the safety and durability of these new materials and designs.

The nuclear power industry, with its stringent safety requirements, continues to be a significant driver for SCC and HE testing technologies. The aging infrastructure of many nuclear plants worldwide has heightened the importance of accurate material degradation assessment, further boosting the demand for advanced testing solutions.

Moreover, the global focus on sustainability and environmental protection has indirectly influenced the market for SCC and HE testing. As industries strive to extend the lifespan of existing infrastructure and equipment, there is a growing emphasis on preventive maintenance and early detection of material degradation, which relies heavily on these testing technologies.

The market is also seeing a trend towards non-destructive testing methods for SCC and HE, as these allow for in-situ monitoring without compromising the integrity of the structures. This shift is creating new opportunities for innovative testing technologies that can provide real-time, accurate assessments of material conditions.

Current Challenges

The current challenges in distinguishing features and test protocols for Stress Corrosion Cracking (SCC) and Hydrogen Embrittlement (HE) are multifaceted and complex. One of the primary difficulties lies in the similarity of their macroscopic effects on materials, making it challenging to differentiate between the two phenomena based on visual inspection alone. Both SCC and HE can lead to sudden, catastrophic failures in metallic structures, often with little to no visible warning signs.

A significant challenge is the lack of standardized test protocols that can definitively distinguish between SCC and HE. While various testing methods exist for each phenomenon individually, there is a scarcity of comprehensive protocols that can simultaneously evaluate and differentiate between the two. This gap in testing methodologies hampers the ability of engineers and researchers to accurately diagnose the root cause of material failures in corrosive environments.

The time-dependent nature of both SCC and HE poses another challenge. These processes can occur over extended periods, making it difficult to replicate real-world conditions in laboratory settings. Accelerated testing methods, while useful for rapid assessment, may not always accurately represent the long-term behavior of materials under actual service conditions.

Environmental factors play a crucial role in both SCC and HE, but their effects can be highly variable and difficult to control in experimental setups. Factors such as temperature, pH, electrolyte composition, and stress state can significantly influence the occurrence and progression of these phenomena. Replicating these complex environmental conditions consistently across different test protocols remains a considerable challenge.

The microstructural complexity of modern alloys further complicates the distinction between SCC and HE. Advanced materials often have intricate microstructures that can respond differently to environmental stresses and hydrogen ingress. This variability makes it challenging to develop universal test protocols that are applicable across a wide range of materials.

Another significant challenge is the interaction between SCC and HE mechanisms. In many real-world scenarios, both phenomena can occur simultaneously or sequentially, making it difficult to isolate and study their individual effects. This interplay between SCC and HE mechanisms adds another layer of complexity to the development of effective distinguishing features and test protocols.

Lastly, the development of in-situ monitoring techniques for early detection and differentiation of SCC and HE remains a significant challenge. Current non-destructive testing methods often lack the sensitivity to detect these phenomena in their early stages, limiting the ability to prevent failures proactively.

A significant challenge is the lack of standardized test protocols that can definitively distinguish between SCC and HE. While various testing methods exist for each phenomenon individually, there is a scarcity of comprehensive protocols that can simultaneously evaluate and differentiate between the two. This gap in testing methodologies hampers the ability of engineers and researchers to accurately diagnose the root cause of material failures in corrosive environments.

The time-dependent nature of both SCC and HE poses another challenge. These processes can occur over extended periods, making it difficult to replicate real-world conditions in laboratory settings. Accelerated testing methods, while useful for rapid assessment, may not always accurately represent the long-term behavior of materials under actual service conditions.

Environmental factors play a crucial role in both SCC and HE, but their effects can be highly variable and difficult to control in experimental setups. Factors such as temperature, pH, electrolyte composition, and stress state can significantly influence the occurrence and progression of these phenomena. Replicating these complex environmental conditions consistently across different test protocols remains a considerable challenge.

The microstructural complexity of modern alloys further complicates the distinction between SCC and HE. Advanced materials often have intricate microstructures that can respond differently to environmental stresses and hydrogen ingress. This variability makes it challenging to develop universal test protocols that are applicable across a wide range of materials.

Another significant challenge is the interaction between SCC and HE mechanisms. In many real-world scenarios, both phenomena can occur simultaneously or sequentially, making it difficult to isolate and study their individual effects. This interplay between SCC and HE mechanisms adds another layer of complexity to the development of effective distinguishing features and test protocols.

Lastly, the development of in-situ monitoring techniques for early detection and differentiation of SCC and HE remains a significant challenge. Current non-destructive testing methods often lack the sensitivity to detect these phenomena in their early stages, limiting the ability to prevent failures proactively.

Existing Test Protocols

01 Distinguishing features of SCC and HE

Stress Corrosion Cracking (SCC) and Hydrogen Embrittlement (HE) are distinct phenomena with different mechanisms. SCC occurs due to the combined action of tensile stress and a corrosive environment, while HE results from hydrogen absorption into the metal structure. SCC typically shows branching cracks, whereas HE often exhibits straight, transgranular cracks. The presence of specific environmental factors and the nature of the fracture surface can help differentiate between these two mechanisms.- Distinguishing features between SCC and HE: Stress Corrosion Cracking (SCC) and Hydrogen Embrittlement (HE) are distinct phenomena with different mechanisms. SCC typically occurs in specific corrosive environments under tensile stress, while HE is caused by the absorption of hydrogen into the metal structure. SCC often shows branching cracks, whereas HE tends to result in more brittle fractures. Understanding these differences is crucial for accurate diagnosis and prevention strategies.

- Test protocols for SCC detection: Various test protocols are used to detect and evaluate Stress Corrosion Cracking. These may include slow strain rate testing, constant load testing, and U-bend tests in specific corrosive environments. Electrochemical techniques, such as potentiodynamic polarization, can also be employed to assess susceptibility to SCC. These tests often involve exposing stressed specimens to simulated service environments and monitoring for crack initiation and propagation.

- Test protocols for HE detection: Hydrogen Embrittlement is typically evaluated using methods that involve hydrogen charging of specimens. Common test protocols include the slow strain rate test under hydrogen charging conditions, thermal desorption spectroscopy, and the use of pre-cracked specimens in hydrogen environments. Permeation tests and hydrogen analysis techniques are also employed to quantify hydrogen content and diffusion in materials.

- Environmental factors influencing SCC and HE: The susceptibility to both Stress Corrosion Cracking and Hydrogen Embrittlement is heavily influenced by environmental factors. For SCC, these include the presence of specific corrosive species, pH, temperature, and electrochemical potential. For HE, factors such as hydrogen partial pressure, temperature, and the presence of hydrogen-promoting elements or compounds play crucial roles. Understanding these environmental influences is essential for developing effective prevention strategies.

- Prevention and mitigation strategies: Preventing and mitigating Stress Corrosion Cracking and Hydrogen Embrittlement involve various strategies. These may include material selection, surface treatments, cathodic protection, use of inhibitors, and control of environmental conditions. For HE specifically, techniques such as baking to remove hydrogen and the application of barrier coatings are often employed. Regular inspection and monitoring of susceptible components are also crucial for early detection and prevention of both phenomena.

02 Test protocols for SCC

SCC test protocols often involve exposing stressed specimens to specific corrosive environments. Common methods include constant load tests, slow strain rate tests, and U-bend tests. These tests are typically conducted in environments that simulate service conditions, such as chloride solutions for austenitic stainless steels or caustic solutions for carbon steels. The time to failure and the nature of the fracture surface are key indicators in SCC testing.Expand Specific Solutions03 Test protocols for HE

HE test protocols focus on introducing hydrogen into the material and evaluating its effects on mechanical properties. Common methods include hydrogen charging tests, slow strain rate tests in hydrogen environments, and thermal desorption spectroscopy. These tests often involve measuring changes in ductility, tensile strength, or fracture toughness after hydrogen exposure. Microstructural analysis is also crucial in identifying hydrogen-induced damage.Expand Specific Solutions04 Environmental factors influencing SCC and HE

Environmental factors play a crucial role in both SCC and HE. For SCC, factors such as temperature, pH, and specific ion concentrations are critical. In contrast, HE is influenced by hydrogen sources, such as cathodic protection systems, corrosion reactions, or high-pressure hydrogen gas. Understanding these environmental factors is essential for developing effective prevention strategies and conducting accurate tests for both phenomena.Expand Specific Solutions05 Advanced techniques for SCC and HE analysis

Advanced techniques are being developed to improve the detection and analysis of SCC and HE. These include in-situ monitoring methods, such as acoustic emission testing and electrochemical noise analysis, which can detect crack initiation and propagation in real-time. Additionally, advanced microscopy techniques, including high-resolution transmission electron microscopy and atom probe tomography, are being used to study the microstructural aspects of SCC and HE at the atomic level.Expand Specific Solutions

Key Industry Players

The competitive landscape for Stress Corrosion Cracking (SCC) and Hydrogen Embrittlement (HE) research is characterized by a mature industry with significant market potential. The global market for corrosion prevention and control is estimated to be worth billions of dollars annually, driven by the need to protect critical infrastructure in industries such as oil and gas, power generation, and aerospace. Technologically, the field is well-established but continues to evolve, with companies like The Japan Steel Works, NIPPON STEEL, and Tata Steel leading in materials development. Research institutions such as Huazhong University of Science & Technology and the Electric Power Research Institute contribute to advancing testing protocols and understanding of these phenomena. Specialized firms like Wuhan Corrtest Instruments focus on developing sophisticated monitoring equipment, indicating a high level of technical maturity in this domain.

NIPPON STEEL CORP.

Technical Solution: NIPPON STEEL CORP. has developed advanced testing protocols for distinguishing Stress Corrosion Cracking (SCC) and Hydrogen Embrittlement (HE). Their approach involves a combination of electrochemical and mechanical testing methods. For SCC, they employ Slow Strain Rate Testing (SSRT) in simulated environments, coupled with in-situ electrochemical measurements to monitor crack initiation and propagation[1]. For HE, they utilize hydrogen charging techniques followed by mechanical testing, including tensile and fatigue tests under various loading conditions[3]. They have also implemented advanced imaging techniques such as high-resolution SEM and TEM to analyze fracture surfaces and microstructural changes associated with both SCC and HE[5].

Strengths: Comprehensive testing protocols, advanced imaging capabilities, and extensive experience in steel manufacturing. Weaknesses: Primarily focused on steel alloys, which may limit applicability to other materials.

Holtec International, Inc.

Technical Solution: Holtec International has developed specialized test protocols for SCC and HE in nuclear applications. Their approach focuses on simulating real-world conditions in nuclear power plants. For SCC, they use autoclave testing with controlled water chemistry and stress conditions, mimicking reactor environments[2]. They employ electrochemical potential measurements to differentiate between SCC and general corrosion. For HE, Holtec uses thermal desorption spectroscopy (TDS) to quantify hydrogen content and distribution in materials[4]. They have also developed a unique in-situ crack growth monitoring system using potential drop techniques, allowing real-time observation of crack propagation in both SCC and HE scenarios[6].

Strengths: Specialized expertise in nuclear applications, advanced in-situ monitoring capabilities. Weaknesses: Testing protocols may be overly specific to nuclear industry, potentially limiting broader application.

Core Innovations

A new cost effective material for the emitting wire of electro static precipitator

PatentInactiveIN490KOL2009A

Innovation

- A material composition for emitting electrode wires is developed using high Mn-N austenitic steels, where nickel is replaced by manganese and nitrogen, with optional cobalt addition, to reduce costs and prevent stress corrosion cracking, maintaining the necessary mechanical and corrosion-resistant properties.

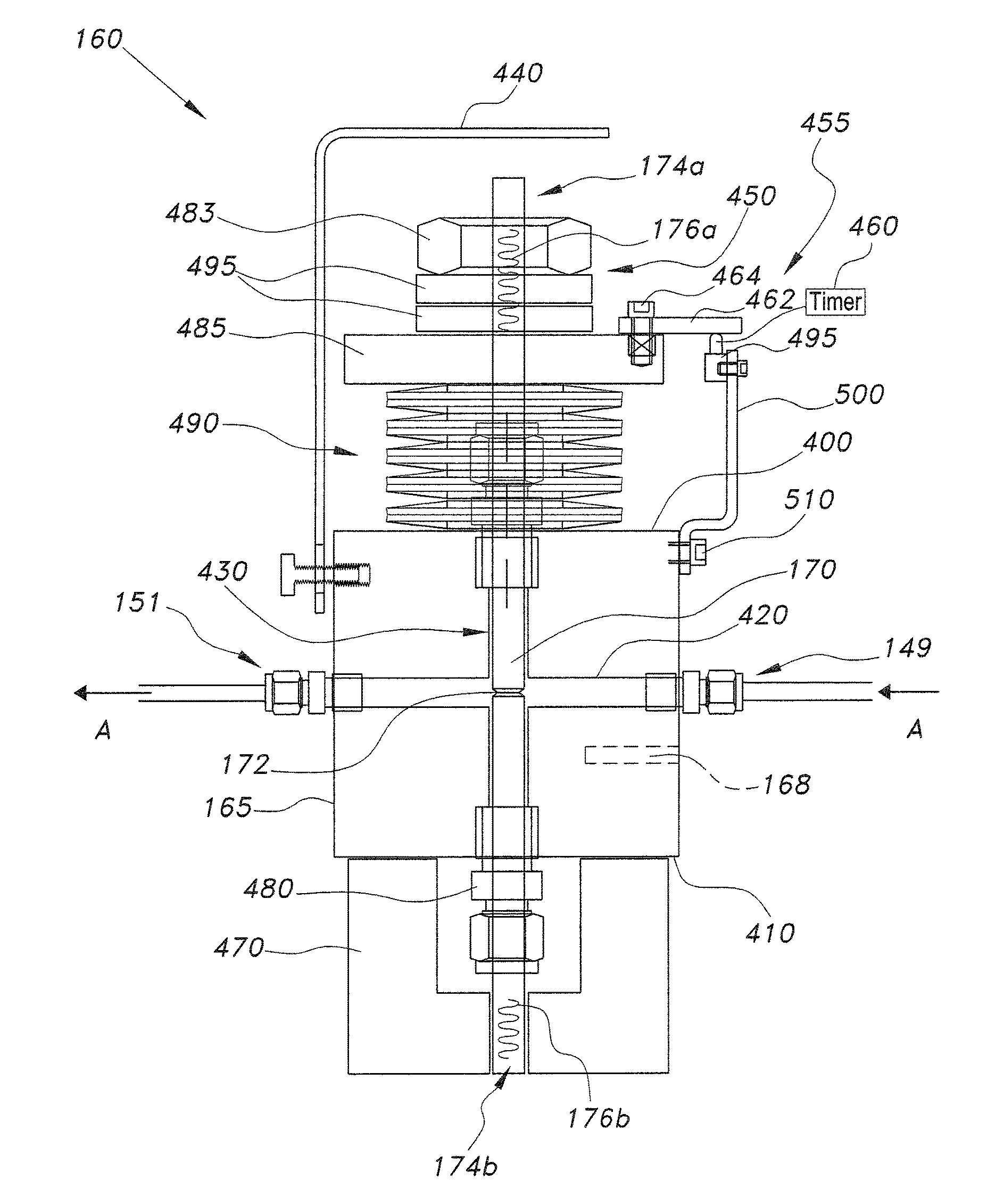

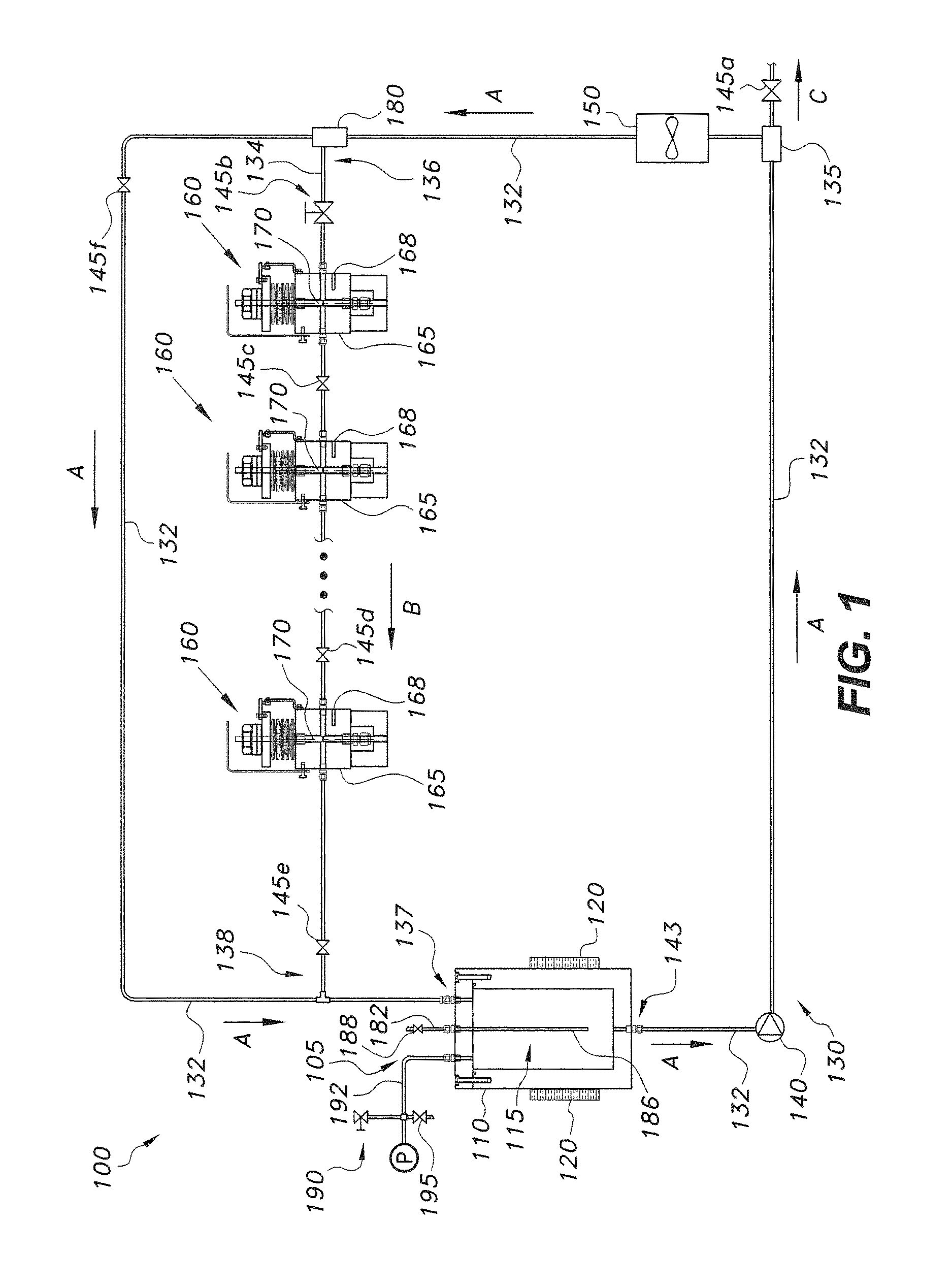

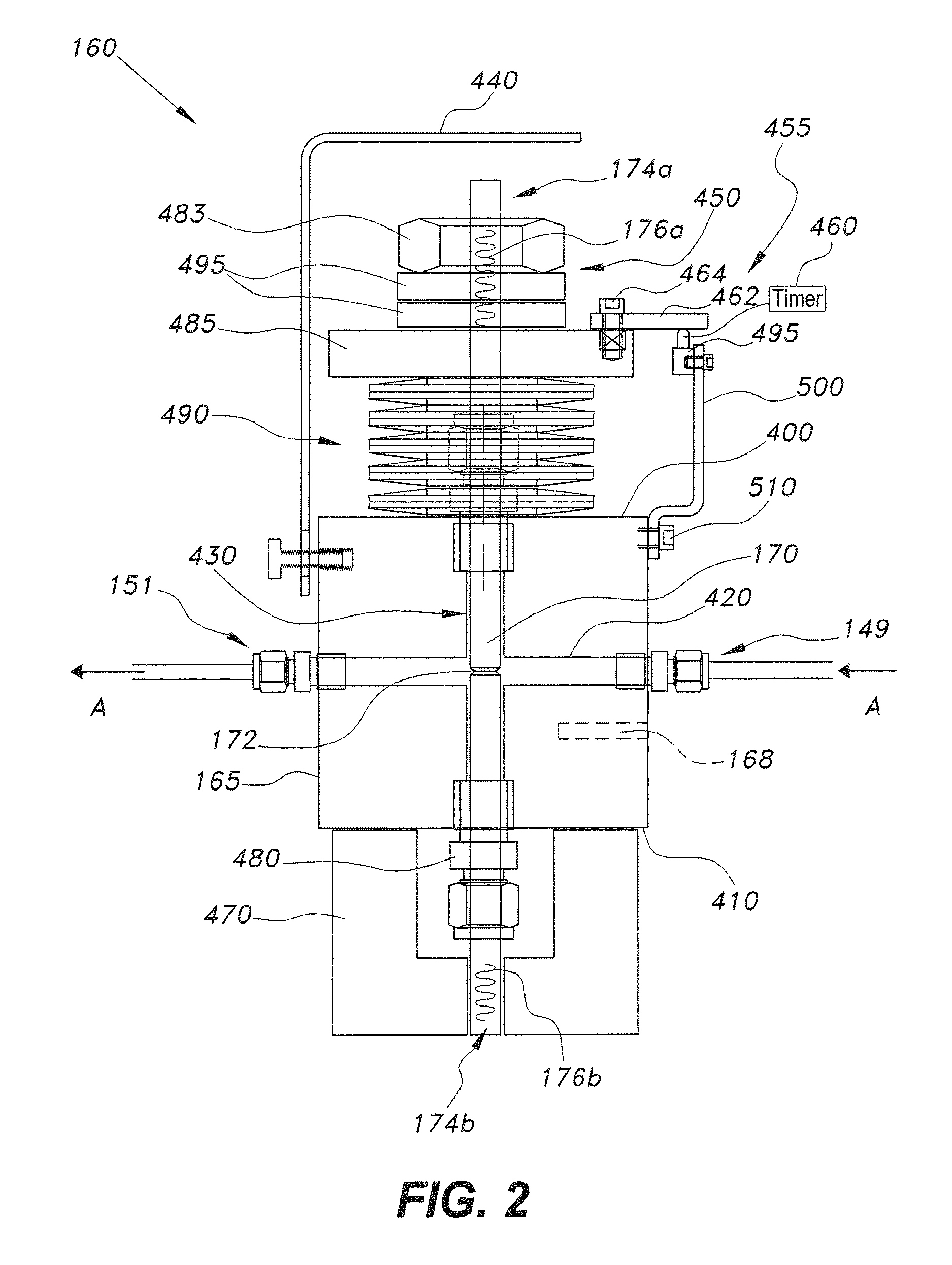

System for testing stress corrosion cracking

PatentInactiveUS9541485B1

Innovation

- A system comprising an autoclave with heating elements, a circulation assembly for circulating corrosive fluids, and multiple test sections that can be exposed to pressurized gases and liquids, allowing for simultaneous testing of specimens in a flowing corrosive environment, with control valves and a pressure assembly to manage temperature and pressure.

Regulatory Considerations

Regulatory considerations play a crucial role in the management and prevention of Stress Corrosion Cracking (SCC) and Hydrogen Embrittlement (HE) in various industries. These phenomena pose significant risks to structural integrity and safety, necessitating comprehensive regulatory frameworks to ensure proper testing, monitoring, and mitigation strategies.

In the oil and gas industry, regulatory bodies such as the American Petroleum Institute (API) and the National Association of Corrosion Engineers (NACE) have established standards and recommended practices for addressing SCC and HE. These guidelines outline specific test protocols, material selection criteria, and inspection requirements to minimize the occurrence of these degradation mechanisms.

The aerospace sector, governed by entities like the Federal Aviation Administration (FAA) and the European Union Aviation Safety Agency (EASA), has implemented stringent regulations regarding the use of materials susceptible to SCC and HE. These regulations mandate rigorous testing procedures and quality control measures to ensure the safety and reliability of aircraft components.

In the nuclear power industry, regulatory agencies such as the Nuclear Regulatory Commission (NRC) in the United States and the International Atomic Energy Agency (IAEA) have developed comprehensive guidelines for managing SCC and HE in nuclear power plant components. These regulations emphasize the importance of material selection, water chemistry control, and periodic inspections to maintain the integrity of critical systems.

The automotive industry has also recognized the importance of addressing SCC and HE, particularly in the context of hydrogen fuel cell vehicles. Regulatory bodies like the Society of Automotive Engineers (SAE) have developed standards for testing and qualifying materials used in hydrogen storage and delivery systems to mitigate the risks associated with these phenomena.

Regulatory considerations extend beyond industry-specific guidelines to encompass broader environmental and safety regulations. For instance, the Occupational Safety and Health Administration (OSHA) in the United States has established requirements for workplace safety that indirectly address the risks associated with SCC and HE in industrial settings.

As the understanding of SCC and HE mechanisms continues to evolve, regulatory bodies are adapting their guidelines to incorporate new findings and technologies. This includes the development of more sophisticated test protocols that can better distinguish between SCC and HE, as well as the implementation of advanced monitoring techniques to detect early signs of material degradation.

The global nature of many industries has led to efforts to harmonize regulatory standards across different regions. Organizations such as the International Organization for Standardization (ISO) are working to develop unified guidelines for testing and managing SCC and HE, facilitating international collaboration and ensuring consistent safety standards worldwide.

In the oil and gas industry, regulatory bodies such as the American Petroleum Institute (API) and the National Association of Corrosion Engineers (NACE) have established standards and recommended practices for addressing SCC and HE. These guidelines outline specific test protocols, material selection criteria, and inspection requirements to minimize the occurrence of these degradation mechanisms.

The aerospace sector, governed by entities like the Federal Aviation Administration (FAA) and the European Union Aviation Safety Agency (EASA), has implemented stringent regulations regarding the use of materials susceptible to SCC and HE. These regulations mandate rigorous testing procedures and quality control measures to ensure the safety and reliability of aircraft components.

In the nuclear power industry, regulatory agencies such as the Nuclear Regulatory Commission (NRC) in the United States and the International Atomic Energy Agency (IAEA) have developed comprehensive guidelines for managing SCC and HE in nuclear power plant components. These regulations emphasize the importance of material selection, water chemistry control, and periodic inspections to maintain the integrity of critical systems.

The automotive industry has also recognized the importance of addressing SCC and HE, particularly in the context of hydrogen fuel cell vehicles. Regulatory bodies like the Society of Automotive Engineers (SAE) have developed standards for testing and qualifying materials used in hydrogen storage and delivery systems to mitigate the risks associated with these phenomena.

Regulatory considerations extend beyond industry-specific guidelines to encompass broader environmental and safety regulations. For instance, the Occupational Safety and Health Administration (OSHA) in the United States has established requirements for workplace safety that indirectly address the risks associated with SCC and HE in industrial settings.

As the understanding of SCC and HE mechanisms continues to evolve, regulatory bodies are adapting their guidelines to incorporate new findings and technologies. This includes the development of more sophisticated test protocols that can better distinguish between SCC and HE, as well as the implementation of advanced monitoring techniques to detect early signs of material degradation.

The global nature of many industries has led to efforts to harmonize regulatory standards across different regions. Organizations such as the International Organization for Standardization (ISO) are working to develop unified guidelines for testing and managing SCC and HE, facilitating international collaboration and ensuring consistent safety standards worldwide.

Environmental Factors

Environmental factors play a crucial role in the occurrence and progression of both Stress Corrosion Cracking (SCC) and Hydrogen Embrittlement (HE). These phenomena, while distinct, share some common environmental influences that can significantly impact their development and severity.

For SCC, the presence of specific corrosive agents in the environment is a primary factor. Chlorides, hydroxides, and sulfides are among the most common culprits. The concentration of these corrosive species, along with temperature and pH levels, can greatly influence the rate and extent of SCC. Elevated temperatures typically accelerate the SCC process, while pH levels can affect the stability of protective oxide films on metal surfaces.

In contrast, HE is primarily influenced by the availability of hydrogen in the environment. This can occur through various sources, including cathodic protection systems, corrosion reactions, or exposure to hydrogen-containing gases. The rate of hydrogen absorption into the metal is affected by factors such as temperature, pressure, and the presence of hydrogen-promoting elements like sulfur or phosphorus.

Both SCC and HE are sensitive to mechanical stress levels in the material. However, the interaction between stress and environmental factors differs for each phenomenon. In SCC, the combination of tensile stress and a corrosive environment leads to localized corrosion and crack propagation. For HE, stress can enhance hydrogen diffusion into the material and promote the formation of brittle hydrides.

The electrochemical potential of the metal surface is another critical environmental factor. In SCC, this potential can influence the stability of protective films and the kinetics of corrosion reactions. For HE, the electrochemical potential affects the rate of hydrogen generation and absorption at the metal surface.

Time of exposure is a significant factor for both phenomena. SCC typically requires a certain incubation period before visible cracks appear, while HE can occur more rapidly under suitable conditions. The duration of exposure to the aggressive environment can determine the extent of damage and the likelihood of failure.

Lastly, the presence of inhibitors or accelerators in the environment can significantly impact both SCC and HE. Certain chemical species can retard the corrosion processes leading to SCC or reduce hydrogen absorption in the case of HE. Conversely, some environmental contaminants can accelerate these degradation mechanisms, making the material more susceptible to failure.

For SCC, the presence of specific corrosive agents in the environment is a primary factor. Chlorides, hydroxides, and sulfides are among the most common culprits. The concentration of these corrosive species, along with temperature and pH levels, can greatly influence the rate and extent of SCC. Elevated temperatures typically accelerate the SCC process, while pH levels can affect the stability of protective oxide films on metal surfaces.

In contrast, HE is primarily influenced by the availability of hydrogen in the environment. This can occur through various sources, including cathodic protection systems, corrosion reactions, or exposure to hydrogen-containing gases. The rate of hydrogen absorption into the metal is affected by factors such as temperature, pressure, and the presence of hydrogen-promoting elements like sulfur or phosphorus.

Both SCC and HE are sensitive to mechanical stress levels in the material. However, the interaction between stress and environmental factors differs for each phenomenon. In SCC, the combination of tensile stress and a corrosive environment leads to localized corrosion and crack propagation. For HE, stress can enhance hydrogen diffusion into the material and promote the formation of brittle hydrides.

The electrochemical potential of the metal surface is another critical environmental factor. In SCC, this potential can influence the stability of protective films and the kinetics of corrosion reactions. For HE, the electrochemical potential affects the rate of hydrogen generation and absorption at the metal surface.

Time of exposure is a significant factor for both phenomena. SCC typically requires a certain incubation period before visible cracks appear, while HE can occur more rapidly under suitable conditions. The duration of exposure to the aggressive environment can determine the extent of damage and the likelihood of failure.

Lastly, the presence of inhibitors or accelerators in the environment can significantly impact both SCC and HE. Certain chemical species can retard the corrosion processes leading to SCC or reduce hydrogen absorption in the case of HE. Conversely, some environmental contaminants can accelerate these degradation mechanisms, making the material more susceptible to failure.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!