How to Select Fasteners for Hydrogen Service: Materials, Coatings and Testing Guidelines

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogen Fastener Selection Background and Objectives

The selection of fasteners for hydrogen service has become increasingly critical as the world shifts towards a hydrogen-based economy. This technological challenge stems from the unique properties of hydrogen and its interaction with various materials, particularly metals. Hydrogen, being the smallest element, can easily penetrate many materials, leading to embrittlement and potential failure of components under stress.

The evolution of this technology field has been driven by the growing demand for clean energy solutions and the expansion of hydrogen applications in industries such as aerospace, automotive, and energy production. As hydrogen infrastructure expands, the need for reliable and safe fastening solutions has become paramount, pushing the boundaries of materials science and engineering.

The primary objective of this technical research is to establish comprehensive guidelines for selecting appropriate fasteners for hydrogen service. This involves a multifaceted approach, addressing materials selection, surface treatments, coatings, and testing methodologies. The goal is to ensure the long-term integrity and safety of hydrogen systems across various applications and operating conditions.

Key technological trends in this field include the development of advanced alloys resistant to hydrogen embrittlement, innovative coating technologies to create barrier layers against hydrogen penetration, and the refinement of testing protocols to accurately predict fastener performance in hydrogen environments. These advancements are crucial for enabling the widespread adoption of hydrogen technologies while maintaining the highest safety standards.

The research aims to bridge the gap between theoretical understanding of hydrogen-material interactions and practical engineering solutions. This involves synthesizing knowledge from materials science, mechanical engineering, and chemical engineering to create a holistic approach to fastener selection. By doing so, we seek to overcome current limitations in fastener performance and reliability in hydrogen service.

Furthermore, this research endeavors to anticipate future challenges as hydrogen technologies evolve. This includes considering higher pressure and temperature requirements, new material combinations, and novel application scenarios. The ultimate aim is to develop a robust framework that can adapt to emerging needs in the hydrogen economy, ensuring that fastener selection remains ahead of the curve in terms of safety, efficiency, and durability.

The evolution of this technology field has been driven by the growing demand for clean energy solutions and the expansion of hydrogen applications in industries such as aerospace, automotive, and energy production. As hydrogen infrastructure expands, the need for reliable and safe fastening solutions has become paramount, pushing the boundaries of materials science and engineering.

The primary objective of this technical research is to establish comprehensive guidelines for selecting appropriate fasteners for hydrogen service. This involves a multifaceted approach, addressing materials selection, surface treatments, coatings, and testing methodologies. The goal is to ensure the long-term integrity and safety of hydrogen systems across various applications and operating conditions.

Key technological trends in this field include the development of advanced alloys resistant to hydrogen embrittlement, innovative coating technologies to create barrier layers against hydrogen penetration, and the refinement of testing protocols to accurately predict fastener performance in hydrogen environments. These advancements are crucial for enabling the widespread adoption of hydrogen technologies while maintaining the highest safety standards.

The research aims to bridge the gap between theoretical understanding of hydrogen-material interactions and practical engineering solutions. This involves synthesizing knowledge from materials science, mechanical engineering, and chemical engineering to create a holistic approach to fastener selection. By doing so, we seek to overcome current limitations in fastener performance and reliability in hydrogen service.

Furthermore, this research endeavors to anticipate future challenges as hydrogen technologies evolve. This includes considering higher pressure and temperature requirements, new material combinations, and novel application scenarios. The ultimate aim is to develop a robust framework that can adapt to emerging needs in the hydrogen economy, ensuring that fastener selection remains ahead of the curve in terms of safety, efficiency, and durability.

Market Demand for Hydrogen-Compatible Fasteners

The market demand for hydrogen-compatible fasteners is experiencing significant growth, driven by the expanding hydrogen economy and the increasing adoption of hydrogen as a clean energy source. As industries transition towards sustainable energy solutions, the need for specialized fasteners capable of withstanding hydrogen environments has become paramount.

The automotive sector, particularly in the development of fuel cell electric vehicles (FCEVs), represents a major driver for hydrogen-compatible fasteners. As automakers invest heavily in FCEV technology, the demand for fasteners that can maintain structural integrity in hydrogen-rich environments has surged. This trend is expected to continue as more automotive manufacturers commit to hydrogen-powered vehicle production.

The aerospace industry is another key market for hydrogen-compatible fasteners. With the aviation sector exploring hydrogen as a potential fuel for future aircraft, the demand for fasteners that can withstand hydrogen exposure at high altitudes and extreme temperatures is on the rise. Space exploration initiatives, including hydrogen-powered rockets and spacecraft, further contribute to the growing market for specialized fasteners.

In the energy sector, the push for green hydrogen production and storage facilities has created a substantial market for hydrogen-compatible fasteners. These components are crucial in ensuring the safety and reliability of hydrogen infrastructure, including electrolyzers, storage tanks, and distribution pipelines. As countries invest in large-scale hydrogen projects, the demand for suitable fasteners is expected to increase significantly.

The industrial sector, particularly in chemical processing and refining, represents another important market for hydrogen-compatible fasteners. As these industries adopt hydrogen as a feedstock or process gas, the need for fasteners that can withstand hydrogen embrittlement and maintain structural integrity in corrosive environments has grown.

Market analysts project robust growth in the hydrogen-compatible fastener market over the coming years. Factors such as government initiatives promoting hydrogen adoption, increasing investments in hydrogen infrastructure, and the growing focus on decarbonization across industries are expected to drive demand. Additionally, the development of new materials and coatings specifically designed for hydrogen service is likely to expand the market further.

However, challenges such as the high cost of specialized materials and the need for rigorous testing and certification processes may impact market growth. Manufacturers and end-users must carefully balance performance requirements with cost considerations, potentially leading to opportunities for innovation in material science and manufacturing processes.

The automotive sector, particularly in the development of fuel cell electric vehicles (FCEVs), represents a major driver for hydrogen-compatible fasteners. As automakers invest heavily in FCEV technology, the demand for fasteners that can maintain structural integrity in hydrogen-rich environments has surged. This trend is expected to continue as more automotive manufacturers commit to hydrogen-powered vehicle production.

The aerospace industry is another key market for hydrogen-compatible fasteners. With the aviation sector exploring hydrogen as a potential fuel for future aircraft, the demand for fasteners that can withstand hydrogen exposure at high altitudes and extreme temperatures is on the rise. Space exploration initiatives, including hydrogen-powered rockets and spacecraft, further contribute to the growing market for specialized fasteners.

In the energy sector, the push for green hydrogen production and storage facilities has created a substantial market for hydrogen-compatible fasteners. These components are crucial in ensuring the safety and reliability of hydrogen infrastructure, including electrolyzers, storage tanks, and distribution pipelines. As countries invest in large-scale hydrogen projects, the demand for suitable fasteners is expected to increase significantly.

The industrial sector, particularly in chemical processing and refining, represents another important market for hydrogen-compatible fasteners. As these industries adopt hydrogen as a feedstock or process gas, the need for fasteners that can withstand hydrogen embrittlement and maintain structural integrity in corrosive environments has grown.

Market analysts project robust growth in the hydrogen-compatible fastener market over the coming years. Factors such as government initiatives promoting hydrogen adoption, increasing investments in hydrogen infrastructure, and the growing focus on decarbonization across industries are expected to drive demand. Additionally, the development of new materials and coatings specifically designed for hydrogen service is likely to expand the market further.

However, challenges such as the high cost of specialized materials and the need for rigorous testing and certification processes may impact market growth. Manufacturers and end-users must carefully balance performance requirements with cost considerations, potentially leading to opportunities for innovation in material science and manufacturing processes.

Current Challenges in Hydrogen Fastener Technology

The selection of fasteners for hydrogen service presents several significant challenges due to the unique properties of hydrogen and its interaction with materials. One of the primary concerns is hydrogen embrittlement, a phenomenon where hydrogen atoms diffuse into the metal structure, leading to a reduction in ductility and load-bearing capacity. This can result in unexpected and catastrophic failures, particularly in high-strength materials commonly used in fasteners.

Another challenge lies in the small molecular size of hydrogen, which allows it to penetrate through microscopic gaps and defects in materials. This property necessitates extremely tight tolerances and specialized sealing techniques to prevent hydrogen leakage, which is both a safety concern and an efficiency issue in hydrogen systems.

The wide range of operating conditions in hydrogen service further complicates fastener selection. Fasteners must maintain their integrity across a broad spectrum of temperatures and pressures, from cryogenic conditions in liquid hydrogen storage to high-temperature environments in fuel cells or hydrogen-powered engines. This variability demands materials and coatings that can withstand extreme thermal cycling without degradation.

Corrosion resistance is another critical factor, as many hydrogen production and storage environments involve the presence of other corrosive substances. Fasteners must resist not only hydrogen-induced degradation but also withstand potential chemical attacks from impurities or byproducts in the hydrogen stream.

The lack of comprehensive long-term performance data for materials in hydrogen service poses a significant challenge. While accelerated testing methods exist, they may not fully capture the cumulative effects of prolonged hydrogen exposure under real-world conditions. This knowledge gap complicates risk assessment and material selection processes.

Standardization and certification of fasteners for hydrogen service are still evolving, creating uncertainty in the industry. The absence of universally accepted testing protocols and performance criteria makes it difficult for manufacturers to validate their products and for end-users to make informed selections.

Lastly, the cost-effectiveness of specialized hydrogen-resistant fasteners remains a challenge. The need for advanced materials, coatings, and rigorous testing procedures often results in higher production costs, which can impact the economic viability of hydrogen technologies in competitive markets.

Another challenge lies in the small molecular size of hydrogen, which allows it to penetrate through microscopic gaps and defects in materials. This property necessitates extremely tight tolerances and specialized sealing techniques to prevent hydrogen leakage, which is both a safety concern and an efficiency issue in hydrogen systems.

The wide range of operating conditions in hydrogen service further complicates fastener selection. Fasteners must maintain their integrity across a broad spectrum of temperatures and pressures, from cryogenic conditions in liquid hydrogen storage to high-temperature environments in fuel cells or hydrogen-powered engines. This variability demands materials and coatings that can withstand extreme thermal cycling without degradation.

Corrosion resistance is another critical factor, as many hydrogen production and storage environments involve the presence of other corrosive substances. Fasteners must resist not only hydrogen-induced degradation but also withstand potential chemical attacks from impurities or byproducts in the hydrogen stream.

The lack of comprehensive long-term performance data for materials in hydrogen service poses a significant challenge. While accelerated testing methods exist, they may not fully capture the cumulative effects of prolonged hydrogen exposure under real-world conditions. This knowledge gap complicates risk assessment and material selection processes.

Standardization and certification of fasteners for hydrogen service are still evolving, creating uncertainty in the industry. The absence of universally accepted testing protocols and performance criteria makes it difficult for manufacturers to validate their products and for end-users to make informed selections.

Lastly, the cost-effectiveness of specialized hydrogen-resistant fasteners remains a challenge. The need for advanced materials, coatings, and rigorous testing procedures often results in higher production costs, which can impact the economic viability of hydrogen technologies in competitive markets.

Existing Fastener Solutions for Hydrogen Service

01 Corrosion-resistant coatings for fasteners

Various coatings are applied to fasteners to enhance their corrosion resistance. These coatings can include metallic layers, organic compounds, or a combination of both. The coatings protect the underlying fastener material from environmental factors, extending the lifespan and maintaining the structural integrity of the fastened components.- Corrosion-resistant coatings for fasteners: Various coatings are applied to fasteners to enhance their corrosion resistance. These coatings can include metallic layers, organic compounds, or a combination of both. The coatings protect the underlying fastener material from environmental factors that could lead to degradation or failure.

- Advanced materials for fastener construction: Innovative materials are being used in fastener manufacturing to improve strength, durability, and performance. These materials can include high-strength alloys, composite materials, or specially engineered polymers that offer superior mechanical properties compared to traditional fastener materials.

- Self-locking and vibration-resistant fasteners: Fasteners are designed with features that provide self-locking capabilities and resistance to vibration-induced loosening. These designs may incorporate special thread profiles, locking inserts, or deformable elements that increase friction and maintain tension under dynamic loads.

- Surface treatments for improved adhesion: Various surface treatments are applied to fasteners to enhance adhesion of coatings or improve bonding with other materials. These treatments can include chemical etching, plasma treatment, or the application of primers that promote better adhesion of subsequent coatings or adhesives.

- Smart fasteners with embedded sensors: Advanced fasteners are being developed with embedded sensors or smart materials that can monitor stress, strain, or environmental conditions. These smart fasteners can provide real-time data on the structural integrity of joints or alert users to potential failures before they occur.

02 Advanced materials for high-performance fasteners

High-performance fasteners are manufactured using advanced materials such as titanium alloys, superalloys, or composite materials. These materials offer superior strength-to-weight ratios, heat resistance, and durability, making them suitable for demanding applications in aerospace, automotive, and other industries.Expand Specific Solutions03 Self-locking and anti-loosening fastener designs

Innovative fastener designs incorporate self-locking and anti-loosening features. These designs may include special thread profiles, locking inserts, or deformable elements that prevent unintended loosening due to vibration or thermal cycling. Such fasteners are crucial in applications where safety and reliability are paramount.Expand Specific Solutions04 Environmentally friendly coating processes for fasteners

Eco-friendly coating processes for fasteners are being developed to reduce environmental impact. These processes may use water-based coatings, powder coatings, or other low-VOC (Volatile Organic Compound) formulations. The focus is on maintaining or improving fastener performance while minimizing harmful emissions and waste.Expand Specific Solutions05 Smart fasteners with embedded sensors or RFID technology

Advanced fasteners are being developed with embedded sensors or RFID (Radio-Frequency Identification) technology. These smart fasteners can provide real-time data on their condition, including tension, temperature, or potential failure modes. This technology enables predictive maintenance and enhances safety in critical applications.Expand Specific Solutions

Key Players in Hydrogen Fastener Industry

The hydrogen fastener technology landscape is in a growth phase, with increasing market size driven by the expanding hydrogen economy. The technology maturity varies across different aspects, with established players like Illinois Tool Works and Nylok Corp. leading in traditional fastener solutions. Emerging players such as Pegasus Solar and Airbus Operations are pushing innovations in specialized applications. The market is seeing a blend of industrial giants like Siemens AG and General Electric Company investing in hydrogen-related technologies, alongside specialized fastener companies. Research institutions like Zhejiang University and Tsinghua University are contributing to advancing material science and testing methodologies for hydrogen service, indicating ongoing technological development in this field.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a comprehensive approach for selecting fasteners in hydrogen service environments. Their method involves using high-strength, low-alloy steels with carefully controlled chemical compositions to minimize hydrogen embrittlement[1]. They employ advanced surface treatments, including phosphating and electroplating with zinc or nickel, to enhance corrosion resistance[2]. Sinopec also implements rigorous testing protocols, including slow strain rate testing (SSRT) and hydrogen permeation measurements, to evaluate material performance under hydrogen exposure[3]. Additionally, they have developed proprietary coatings that act as hydrogen barriers, significantly reducing hydrogen uptake in fasteners[4].

Strengths: Extensive experience in hydrogen environments, advanced material science capabilities, and comprehensive testing facilities. Weaknesses: Potential higher costs due to specialized materials and treatments, and possible limitations in extreme temperature applications.

China National Petroleum Corp.

Technical Solution: China National Petroleum Corp. (CNPC) has implemented a multi-faceted approach to fastener selection for hydrogen service. They prioritize the use of austenitic stainless steels, particularly grades 316 and 321, due to their superior resistance to hydrogen embrittlement[1]. CNPC has developed a proprietary heat treatment process that optimizes the microstructure of these alloys, further enhancing their performance in hydrogen environments[2]. For coating solutions, they utilize a combination of PTFE-based coatings and specialized ceramic-metallic (cermet) coatings to provide both corrosion protection and hydrogen barrier properties[3]. CNPC also employs advanced non-destructive testing techniques, including acoustic emission and ultrasonic testing, to monitor fastener integrity during service[4].

Strengths: Strong focus on material optimization, innovative coating technologies, and advanced in-service monitoring capabilities. Weaknesses: Potential limitations in high-temperature applications and possible increased maintenance requirements due to specialized coatings.

Core Innovations in Hydrogen-Compatible Materials

Fastening element

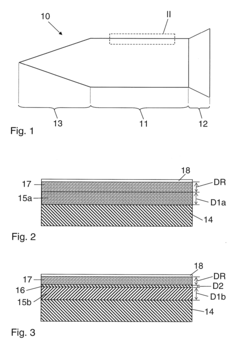

PatentInactiveEP2033773A2

Innovation

- Incorporating a low-carbon steel intermediate zone between the core and surface zones, with specific metallurgical compositions and thicknesses, to create a barrier against hydrogen ingress and enhance corrosion resistance, while using a ferritic or austenitic steel alloy with varying alloy metal concentrations, and applying an anti-corrosion coating.

High-pressure, low-temperature coating for hydrogen service environments

PatentPendingGB2629505A8

Innovation

- Development of a hydrogen-resistant coating specifically designed for corrosive service environments.

- Utilization of a ferrous base metal that maintains structural strength in hydrogen service conditions.

- Creation of a coated structure combining a strong base metal with a protective hydrogen-resistant coating.

Safety Standards for Hydrogen Service Components

Safety standards for hydrogen service components are crucial for ensuring the safe and reliable operation of systems involving hydrogen. These standards encompass a wide range of requirements, including material selection, design specifications, testing protocols, and operational guidelines. The primary focus is on preventing hydrogen embrittlement, which can lead to catastrophic failures in metal components exposed to hydrogen environments.

International standards organizations, such as ISO and ASME, have developed specific codes for hydrogen service components. These standards provide comprehensive guidelines for the selection of materials, design considerations, and testing procedures. For instance, ISO 11114-4 outlines test methods for selecting metallic materials resistant to hydrogen embrittlement, while ASME B31.12 provides detailed requirements for hydrogen piping and pipeline systems.

Material selection is a critical aspect of safety standards for hydrogen service components. Austenitic stainless steels, nickel alloys, and aluminum alloys are commonly recommended due to their resistance to hydrogen embrittlement. However, the specific grade and composition must be carefully chosen based on the operating conditions, such as pressure, temperature, and hydrogen concentration.

Design specifications in these safety standards often include requirements for minimum wall thickness, stress analysis, and fatigue resistance. Components must be designed to withstand the high pressures and potential temperature fluctuations associated with hydrogen service. Additionally, standards may specify requirements for joints, welds, and seals to ensure leak-tight connections and minimize the risk of hydrogen permeation.

Testing protocols are an integral part of safety standards for hydrogen service components. These may include pressure tests, leak tests, and specific tests for hydrogen compatibility. For example, the ASTM F1940 standard describes a test method for measuring the permeation of gaseous hydrogen through materials used in hydrogen service.

Operational guidelines within these standards typically cover aspects such as inspection intervals, maintenance procedures, and monitoring requirements. Regular inspections are crucial for detecting any signs of material degradation or hydrogen-induced damage. Standards may also specify requirements for purging procedures, ventilation systems, and emergency shutdown mechanisms to mitigate risks associated with hydrogen leaks or accumulation.

Compliance with these safety standards is often mandatory for industries working with hydrogen, such as aerospace, automotive, and energy sectors. Regulatory bodies in various countries may adopt or reference these international standards in their national regulations, ensuring a consistent approach to hydrogen safety across different industries and geographical regions.

International standards organizations, such as ISO and ASME, have developed specific codes for hydrogen service components. These standards provide comprehensive guidelines for the selection of materials, design considerations, and testing procedures. For instance, ISO 11114-4 outlines test methods for selecting metallic materials resistant to hydrogen embrittlement, while ASME B31.12 provides detailed requirements for hydrogen piping and pipeline systems.

Material selection is a critical aspect of safety standards for hydrogen service components. Austenitic stainless steels, nickel alloys, and aluminum alloys are commonly recommended due to their resistance to hydrogen embrittlement. However, the specific grade and composition must be carefully chosen based on the operating conditions, such as pressure, temperature, and hydrogen concentration.

Design specifications in these safety standards often include requirements for minimum wall thickness, stress analysis, and fatigue resistance. Components must be designed to withstand the high pressures and potential temperature fluctuations associated with hydrogen service. Additionally, standards may specify requirements for joints, welds, and seals to ensure leak-tight connections and minimize the risk of hydrogen permeation.

Testing protocols are an integral part of safety standards for hydrogen service components. These may include pressure tests, leak tests, and specific tests for hydrogen compatibility. For example, the ASTM F1940 standard describes a test method for measuring the permeation of gaseous hydrogen through materials used in hydrogen service.

Operational guidelines within these standards typically cover aspects such as inspection intervals, maintenance procedures, and monitoring requirements. Regular inspections are crucial for detecting any signs of material degradation or hydrogen-induced damage. Standards may also specify requirements for purging procedures, ventilation systems, and emergency shutdown mechanisms to mitigate risks associated with hydrogen leaks or accumulation.

Compliance with these safety standards is often mandatory for industries working with hydrogen, such as aerospace, automotive, and energy sectors. Regulatory bodies in various countries may adopt or reference these international standards in their national regulations, ensuring a consistent approach to hydrogen safety across different industries and geographical regions.

Environmental Impact of Hydrogen Fastener Production

The production of fasteners for hydrogen service has significant environmental implications that must be considered in the context of sustainable manufacturing practices. The primary materials used in these fasteners, such as high-strength steels, nickel alloys, and titanium, require extensive energy inputs during extraction and processing. Mining operations for these raw materials can lead to habitat disruption, soil erosion, and water pollution if not managed responsibly.

The manufacturing process of hydrogen-compatible fasteners involves multiple stages, including forging, machining, heat treatment, and surface finishing. Each of these steps contributes to the overall environmental footprint through energy consumption and potential emissions. Heat treatment processes, in particular, are energy-intensive and may result in the release of greenhouse gases if not optimized or powered by renewable energy sources.

Surface treatments and coatings applied to enhance hydrogen compatibility, such as electroplating or physical vapor deposition, can introduce additional environmental concerns. These processes often involve the use of chemicals and solvents that, if not properly managed, can lead to air and water pollution. Proper waste management and recycling systems are crucial to mitigate these impacts.

The production of specialized coatings for hydrogen fasteners may also have unique environmental considerations. For instance, the synthesis of advanced materials like diamond-like carbon coatings or nanostructured composites may require rare elements or energy-intensive processes, potentially increasing the overall environmental burden of fastener production.

However, it is important to note that the environmental impact of hydrogen fastener production should be balanced against the potential benefits of hydrogen as a clean energy carrier. Fasteners that enable safe and efficient hydrogen systems contribute to the broader goal of reducing global carbon emissions by facilitating the transition to hydrogen-based technologies in various sectors.

To minimize the environmental impact, manufacturers are increasingly adopting cleaner production techniques, such as using recycled materials, implementing energy-efficient processes, and developing closed-loop systems for water and chemical use. Additionally, life cycle assessments are becoming more common in the fastener industry to identify and address environmental hotspots throughout the production chain.

As the demand for hydrogen-compatible fasteners grows, there is an opportunity to innovate in materials and manufacturing processes that not only meet the stringent requirements for hydrogen service but also align with principles of sustainable production. This may include the development of bio-based or recyclable materials for non-critical components, as well as the integration of additive manufacturing techniques that can reduce material waste and energy consumption.

The manufacturing process of hydrogen-compatible fasteners involves multiple stages, including forging, machining, heat treatment, and surface finishing. Each of these steps contributes to the overall environmental footprint through energy consumption and potential emissions. Heat treatment processes, in particular, are energy-intensive and may result in the release of greenhouse gases if not optimized or powered by renewable energy sources.

Surface treatments and coatings applied to enhance hydrogen compatibility, such as electroplating or physical vapor deposition, can introduce additional environmental concerns. These processes often involve the use of chemicals and solvents that, if not properly managed, can lead to air and water pollution. Proper waste management and recycling systems are crucial to mitigate these impacts.

The production of specialized coatings for hydrogen fasteners may also have unique environmental considerations. For instance, the synthesis of advanced materials like diamond-like carbon coatings or nanostructured composites may require rare elements or energy-intensive processes, potentially increasing the overall environmental burden of fastener production.

However, it is important to note that the environmental impact of hydrogen fastener production should be balanced against the potential benefits of hydrogen as a clean energy carrier. Fasteners that enable safe and efficient hydrogen systems contribute to the broader goal of reducing global carbon emissions by facilitating the transition to hydrogen-based technologies in various sectors.

To minimize the environmental impact, manufacturers are increasingly adopting cleaner production techniques, such as using recycled materials, implementing energy-efficient processes, and developing closed-loop systems for water and chemical use. Additionally, life cycle assessments are becoming more common in the fastener industry to identify and address environmental hotspots throughout the production chain.

As the demand for hydrogen-compatible fasteners grows, there is an opportunity to innovate in materials and manufacturing processes that not only meet the stringent requirements for hydrogen service but also align with principles of sustainable production. This may include the development of bio-based or recyclable materials for non-critical components, as well as the integration of additive manufacturing techniques that can reduce material waste and energy consumption.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!