How to Design Heat Treatments to Improve HE Resistance in 4140 and Similar Steels

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HE Resistance in 4140 Steel: Background and Objectives

The development of high-strength steels, particularly AISI 4140 and similar alloys, has been crucial in various industries due to their excellent mechanical properties. However, these steels are susceptible to hydrogen embrittlement (HE), a phenomenon that can lead to catastrophic failure in critical applications. The primary objective of this technical research is to explore and design heat treatment processes that can enhance the resistance to hydrogen embrittlement in 4140 and similar steels.

Hydrogen embrittlement has been a significant concern in the steel industry for decades. It occurs when atomic hydrogen diffuses into the steel microstructure, leading to a reduction in ductility and load-bearing capacity. This issue is particularly prevalent in high-strength steels due to their susceptibility to hydrogen trapping and the presence of residual stresses from manufacturing processes.

The evolution of heat treatment techniques for improving HE resistance has seen significant advancements over the years. Early approaches focused on reducing hydrogen content through baking processes. However, as our understanding of microstructural effects on HE resistance grew, more sophisticated heat treatment strategies emerged. These include tailored quenching and tempering processes, as well as the development of novel multi-stage heat treatments.

Current research aims to optimize the microstructure of 4140 and similar steels to minimize hydrogen trapping sites and enhance overall resistance to embrittlement. This involves a deep understanding of the relationship between heat treatment parameters, resulting microstructures, and their impact on hydrogen diffusion and trapping mechanisms.

The technical goals of this research include developing heat treatment protocols that can significantly improve HE resistance without compromising the desirable mechanical properties of these steels. This involves investigating the effects of various heat treatment temperatures, holding times, and cooling rates on the steel's microstructure and its subsequent interaction with hydrogen.

Furthermore, the research aims to establish quantitative relationships between heat treatment parameters and HE resistance metrics. This will enable more precise control and prediction of material performance in hydrogen-rich environments. Additionally, there is a focus on developing heat treatment processes that are both effective and economically viable for industrial-scale implementation.

By addressing these objectives, the research seeks to contribute to the broader field of materials science and engineering, potentially leading to safer and more reliable high-strength steel components in critical applications across various industries, including oil and gas, automotive, and aerospace sectors.

Hydrogen embrittlement has been a significant concern in the steel industry for decades. It occurs when atomic hydrogen diffuses into the steel microstructure, leading to a reduction in ductility and load-bearing capacity. This issue is particularly prevalent in high-strength steels due to their susceptibility to hydrogen trapping and the presence of residual stresses from manufacturing processes.

The evolution of heat treatment techniques for improving HE resistance has seen significant advancements over the years. Early approaches focused on reducing hydrogen content through baking processes. However, as our understanding of microstructural effects on HE resistance grew, more sophisticated heat treatment strategies emerged. These include tailored quenching and tempering processes, as well as the development of novel multi-stage heat treatments.

Current research aims to optimize the microstructure of 4140 and similar steels to minimize hydrogen trapping sites and enhance overall resistance to embrittlement. This involves a deep understanding of the relationship between heat treatment parameters, resulting microstructures, and their impact on hydrogen diffusion and trapping mechanisms.

The technical goals of this research include developing heat treatment protocols that can significantly improve HE resistance without compromising the desirable mechanical properties of these steels. This involves investigating the effects of various heat treatment temperatures, holding times, and cooling rates on the steel's microstructure and its subsequent interaction with hydrogen.

Furthermore, the research aims to establish quantitative relationships between heat treatment parameters and HE resistance metrics. This will enable more precise control and prediction of material performance in hydrogen-rich environments. Additionally, there is a focus on developing heat treatment processes that are both effective and economically viable for industrial-scale implementation.

By addressing these objectives, the research seeks to contribute to the broader field of materials science and engineering, potentially leading to safer and more reliable high-strength steel components in critical applications across various industries, including oil and gas, automotive, and aerospace sectors.

Market Demand for HE-Resistant 4140 Steel

The market demand for HE-resistant 4140 steel has been steadily increasing across various industries, driven by the growing need for high-performance materials in critical applications. The oil and gas sector, in particular, has shown a significant appetite for improved 4140 steel with enhanced hydrogen embrittlement (HE) resistance. This demand stems from the harsh operating conditions in deep-sea drilling, where components are exposed to high pressures, corrosive environments, and hydrogen-rich atmospheres.

Aerospace and automotive industries have also contributed to the rising demand for HE-resistant 4140 steel. In aerospace, the material is crucial for landing gear components and structural parts that require high strength and resistance to environmental factors. The automotive sector utilizes this steel in drivetrain components, where improved HE resistance can lead to enhanced durability and safety.

Market analysis indicates that the global demand for high-strength, HE-resistant steels is expected to grow at a compound annual growth rate (CAGR) of 5-7% over the next five years. This growth is primarily attributed to the expansion of offshore oil and gas exploration activities and the increasing adoption of advanced materials in the transportation sector.

The power generation industry, especially in the realm of nuclear and renewable energy, has emerged as another significant consumer of HE-resistant 4140 steel. As power plants strive for higher efficiency and longer operational lifespans, the need for materials that can withstand extreme conditions and resist hydrogen-induced degradation has intensified.

Furthermore, the construction and infrastructure sectors have shown interest in HE-resistant 4140 steel for applications in bridges, high-rise buildings, and other large-scale structures. The material's improved resistance to environmental factors and its high strength-to-weight ratio make it an attractive option for engineers and architects seeking to enhance the longevity and safety of their designs.

The market demand is not limited to specific geographical regions. While North America and Europe have traditionally been strong markets for advanced steel products, emerging economies in Asia-Pacific and the Middle East are showing rapid growth in demand. This global distribution of demand is driven by industrialization, infrastructure development, and the expansion of energy exploration activities in these regions.

As industries continue to push the boundaries of material performance, the demand for HE-resistant 4140 steel is expected to evolve. Manufacturers and researchers are focusing on developing heat treatment processes that can further enhance the material's properties, potentially opening up new market opportunities and applications.

Aerospace and automotive industries have also contributed to the rising demand for HE-resistant 4140 steel. In aerospace, the material is crucial for landing gear components and structural parts that require high strength and resistance to environmental factors. The automotive sector utilizes this steel in drivetrain components, where improved HE resistance can lead to enhanced durability and safety.

Market analysis indicates that the global demand for high-strength, HE-resistant steels is expected to grow at a compound annual growth rate (CAGR) of 5-7% over the next five years. This growth is primarily attributed to the expansion of offshore oil and gas exploration activities and the increasing adoption of advanced materials in the transportation sector.

The power generation industry, especially in the realm of nuclear and renewable energy, has emerged as another significant consumer of HE-resistant 4140 steel. As power plants strive for higher efficiency and longer operational lifespans, the need for materials that can withstand extreme conditions and resist hydrogen-induced degradation has intensified.

Furthermore, the construction and infrastructure sectors have shown interest in HE-resistant 4140 steel for applications in bridges, high-rise buildings, and other large-scale structures. The material's improved resistance to environmental factors and its high strength-to-weight ratio make it an attractive option for engineers and architects seeking to enhance the longevity and safety of their designs.

The market demand is not limited to specific geographical regions. While North America and Europe have traditionally been strong markets for advanced steel products, emerging economies in Asia-Pacific and the Middle East are showing rapid growth in demand. This global distribution of demand is driven by industrialization, infrastructure development, and the expansion of energy exploration activities in these regions.

As industries continue to push the boundaries of material performance, the demand for HE-resistant 4140 steel is expected to evolve. Manufacturers and researchers are focusing on developing heat treatment processes that can further enhance the material's properties, potentially opening up new market opportunities and applications.

Current Challenges in HE Resistance for 4140 Steel

The current challenges in hydrogen embrittlement (HE) resistance for 4140 steel and similar alloys are multifaceted and complex. One of the primary issues is the inherent susceptibility of high-strength steels to hydrogen-induced cracking. As the strength of the steel increases, its resistance to HE typically decreases, creating a delicate balance between mechanical properties and environmental resistance.

The microstructure of 4140 steel, particularly after heat treatment, plays a crucial role in its HE resistance. The presence of martensite, while beneficial for strength, can increase susceptibility to hydrogen embrittlement. Controlling the formation and distribution of martensite during heat treatment is challenging, as it requires precise temperature control and cooling rates.

Another significant challenge is the presence of non-metallic inclusions and carbides in the steel matrix. These features can act as hydrogen traps, leading to localized accumulation of hydrogen and potential crack initiation sites. Minimizing and controlling the size and distribution of these inclusions is a complex metallurgical problem that requires careful consideration during both the steelmaking and heat treatment processes.

The heat treatment process itself presents several challenges in improving HE resistance. Achieving the optimal balance between strength, toughness, and hydrogen resistance often requires multiple heat treatment steps, including quenching and tempering. The precise control of temperature, time, and cooling rates during these processes is critical but can be difficult to maintain consistently, especially in large or complex parts.

Surface conditions and residual stresses introduced during manufacturing and heat treatment also significantly impact HE resistance. Decarburization, oxidation, and the formation of surface defects during heat treatment can create preferential pathways for hydrogen ingress. Managing these surface-related issues while maintaining the desired bulk properties adds another layer of complexity to the heat treatment design.

Furthermore, the interaction between alloying elements and hydrogen is not fully understood, making it challenging to predict and optimize the HE resistance through compositional adjustments. The role of elements like chromium, molybdenum, and vanadium in trapping or facilitating hydrogen diffusion needs further investigation to develop more effective heat treatment strategies.

Lastly, the lack of standardized testing methods for HE resistance specific to heat-treated 4140 steel complicates the evaluation and comparison of different heat treatment approaches. Developing reliable and reproducible testing protocols that accurately simulate service conditions remains an ongoing challenge in the field.

The microstructure of 4140 steel, particularly after heat treatment, plays a crucial role in its HE resistance. The presence of martensite, while beneficial for strength, can increase susceptibility to hydrogen embrittlement. Controlling the formation and distribution of martensite during heat treatment is challenging, as it requires precise temperature control and cooling rates.

Another significant challenge is the presence of non-metallic inclusions and carbides in the steel matrix. These features can act as hydrogen traps, leading to localized accumulation of hydrogen and potential crack initiation sites. Minimizing and controlling the size and distribution of these inclusions is a complex metallurgical problem that requires careful consideration during both the steelmaking and heat treatment processes.

The heat treatment process itself presents several challenges in improving HE resistance. Achieving the optimal balance between strength, toughness, and hydrogen resistance often requires multiple heat treatment steps, including quenching and tempering. The precise control of temperature, time, and cooling rates during these processes is critical but can be difficult to maintain consistently, especially in large or complex parts.

Surface conditions and residual stresses introduced during manufacturing and heat treatment also significantly impact HE resistance. Decarburization, oxidation, and the formation of surface defects during heat treatment can create preferential pathways for hydrogen ingress. Managing these surface-related issues while maintaining the desired bulk properties adds another layer of complexity to the heat treatment design.

Furthermore, the interaction between alloying elements and hydrogen is not fully understood, making it challenging to predict and optimize the HE resistance through compositional adjustments. The role of elements like chromium, molybdenum, and vanadium in trapping or facilitating hydrogen diffusion needs further investigation to develop more effective heat treatment strategies.

Lastly, the lack of standardized testing methods for HE resistance specific to heat-treated 4140 steel complicates the evaluation and comparison of different heat treatment approaches. Developing reliable and reproducible testing protocols that accurately simulate service conditions remains an ongoing challenge in the field.

Existing Heat Treatment Solutions for 4140 Steel

01 Composition modifications for improved HE resistance

Altering the chemical composition of 4140 and similar steels can enhance their resistance to hydrogen embrittlement (HE). This may involve adjusting the levels of alloying elements such as chromium, molybdenum, and nickel, or introducing new elements that improve HE resistance. These modifications can help to reduce hydrogen diffusion and trapping in the steel microstructure.- Composition modifications for improved HE resistance: Altering the chemical composition of 4140 and similar steels can enhance their resistance to hydrogen embrittlement (HE). This may involve adjusting the levels of alloying elements such as chromium, molybdenum, and nickel, or introducing new elements to create a more HE-resistant microstructure.

- Heat treatment processes for HE resistance: Specialized heat treatment processes can be employed to improve the HE resistance of 4140 and similar steels. These may include controlled cooling rates, tempering at specific temperatures, or multi-stage heat treatments designed to optimize the microstructure for HE resistance.

- Surface treatments to mitigate HE: Various surface treatments can be applied to 4140 and similar steels to enhance their resistance to hydrogen embrittlement. These may include coatings, nitriding, carburizing, or other surface modification techniques that create a barrier to hydrogen ingress or alter the surface properties of the steel.

- Microstructure engineering for HE resistance: Controlling and optimizing the microstructure of 4140 and similar steels can significantly improve their resistance to hydrogen embrittlement. This may involve techniques to refine grain size, control precipitate distribution, or create specific phase compositions that are less susceptible to HE.

- Testing and evaluation methods for HE resistance: Developing and implementing effective testing and evaluation methods is crucial for assessing the HE resistance of 4140 and similar steels. This includes standardized test procedures, in-situ monitoring techniques, and advanced analytical methods to understand the mechanisms of hydrogen embrittlement and quantify the effectiveness of various resistance strategies.

02 Heat treatment processes for HE resistance

Specialized heat treatment processes can be applied to 4140 and similar steels to enhance their resistance to hydrogen embrittlement. These processes may include controlled cooling rates, tempering at specific temperatures, or multi-stage heat treatments. The goal is to create a microstructure that is less susceptible to hydrogen-induced damage.Expand Specific Solutions03 Surface treatments to mitigate HE

Various surface treatments can be applied to 4140 and similar steels to improve their resistance to hydrogen embrittlement. These may include coatings, nitriding, carburizing, or other surface modification techniques that create a barrier to hydrogen ingress or alter the surface properties to reduce hydrogen absorption.Expand Specific Solutions04 Microstructure engineering for HE resistance

Controlling and optimizing the microstructure of 4140 and similar steels can significantly improve their resistance to hydrogen embrittlement. This may involve techniques to refine grain size, modify the distribution and morphology of carbides, or create specific phase compositions that are less susceptible to hydrogen-induced damage.Expand Specific Solutions05 Testing and evaluation methods for HE resistance

Developing and implementing effective testing and evaluation methods is crucial for assessing the hydrogen embrittlement resistance of 4140 and similar steels. This may include standardized test procedures, in-situ monitoring techniques, or advanced analytical methods to quantify hydrogen content and its effects on the material properties.Expand Specific Solutions

Key Players in 4140 Steel Heat Treatment Industry

The competitive landscape for improving hydrogen embrittlement (HE) resistance in 4140 and similar steels through heat treatments is in a mature stage, with established players and ongoing research. The market size is significant, given the widespread use of these steels in critical applications. Technologically, the field is moderately mature, with continuous advancements being made. Key players like NIPPON STEEL CORP., POSCO Holdings, and JFE Steel Corp. are at the forefront, leveraging their extensive R&D capabilities. Research institutions such as the Central Iron & Steel Research Institute and universities like Harbin Institute of Technology contribute to technological progress. Companies like Honda Motor Co., Ltd. and Cummins, Inc. drive demand as end-users in automotive and industrial sectors.

NIPPON STEEL CORP.

Technical Solution: NIPPON STEEL CORP. has developed advanced heat treatment processes for improving hydrogen embrittlement (HE) resistance in 4140 and similar steels. Their approach involves a multi-stage heat treatment process, including quenching and tempering, followed by a specialized hydrogen trapping treatment. This process creates a fine-grained microstructure with optimized carbide distribution, enhancing the steel's ability to trap hydrogen and prevent its diffusion to critical areas[1]. The company has also implemented controlled cooling rates and precise temperature control during heat treatment to minimize residual stresses and improve overall mechanical properties[3]. Additionally, NIPPON STEEL has developed proprietary alloying techniques to introduce fine dispersions of titanium and vanadium carbides, which act as effective hydrogen traps[5].

Strengths: Improved HE resistance, enhanced mechanical properties, and reduced risk of delayed fracture. Weaknesses: Potentially higher production costs and longer processing times compared to conventional heat treatments.

POSCO Holdings, Inc.

Technical Solution: POSCO Holdings has developed a novel heat treatment approach for 4140 and similar steels to enhance HE resistance. Their method involves a two-stage tempering process combined with controlled cooling rates. The first tempering stage is performed at a higher temperature to promote the formation of stable carbides, while the second stage is conducted at a lower temperature to refine the microstructure and optimize hydrogen trapping sites[2]. POSCO has also incorporated surface treatment techniques, such as shot peening or carburizing, to create a compressive stress layer on the steel surface, further improving HE resistance[4]. The company has invested in advanced heat treatment facilities with precise temperature and atmosphere control, allowing for consistent and reproducible results in large-scale production[6].

Strengths: Improved HE resistance, enhanced surface properties, and scalability for industrial production. Weaknesses: May require specialized equipment and longer processing times, potentially increasing production costs.

Core Innovations in HE Resistance Enhancement

COMPOSITION DESIGN AND PROCESSING METHODS OF HIGH STRENGTH, HIGH DUCTILITY, AND HIGH CORROSION RESISTANCE FeMnAlC ALLOYS

PatentActiveUS20170107588A1

Innovation

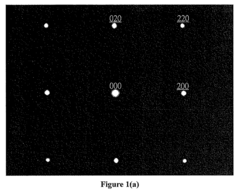

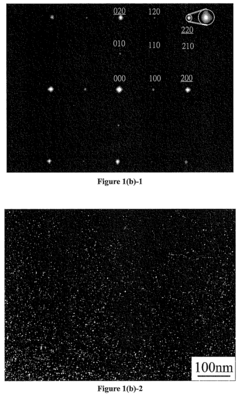

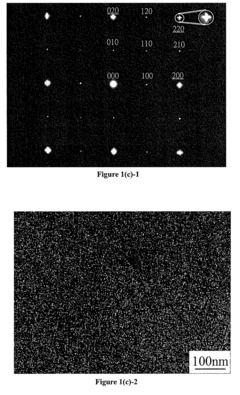

- The alloy composition is optimized with a carbon concentration between 1.4% and 2.2% to form a high density of fine κ′-carbides through spinodal decomposition during quenching, and nitriding treatments are applied at 450-550°C to enhance mechanical strength and corrosion resistance, resulting in a microstructure of austenite+fine κ′-carbides without grain boundary precipitates.

Environmental Impact of Heat Treatment Processes

Heat treatment processes, while essential for improving the mechanical properties of steels, can have significant environmental impacts. The environmental footprint of heat treatment operations primarily stems from energy consumption, emissions, and resource utilization. Energy-intensive processes such as austenitizing, quenching, and tempering contribute to greenhouse gas emissions, particularly when fossil fuels are used as energy sources. The high temperatures required for heat treatment can lead to substantial energy losses through radiation and convection, further exacerbating the environmental impact.

Quenching media, often consisting of oil-based or polymer-based solutions, pose potential environmental hazards if not properly managed. These fluids can contaminate soil and water sources if leaked or improperly disposed of. Additionally, the vaporization of quenchants during the rapid cooling process can release volatile organic compounds (VOCs) into the atmosphere, contributing to air pollution and potentially affecting worker health.

The use of protective atmospheres in heat treatment furnaces, such as nitrogen or argon, can lead to the depletion of non-renewable resources. Furthermore, the production and transportation of these gases contribute to the overall carbon footprint of the heat treatment process. In some cases, the use of salt baths for heat treatment can generate hazardous waste that requires specialized disposal methods to prevent environmental contamination.

Water consumption is another environmental concern in heat treatment processes, particularly in quenching operations. Large volumes of water may be required for cooling, and the resulting wastewater can contain contaminants that need proper treatment before discharge. This puts additional strain on water resources and wastewater treatment facilities.

To mitigate these environmental impacts, the heat treatment industry is increasingly focusing on developing more sustainable practices. Energy efficiency improvements, such as better insulation, heat recovery systems, and the use of renewable energy sources, can significantly reduce the carbon footprint of heat treatment operations. Advanced furnace designs and process optimization techniques help minimize energy waste and improve overall efficiency.

The adoption of cleaner quenching technologies, such as high-pressure gas quenching or salt bath quenching with environmentally friendly salts, can reduce the reliance on oil-based quenchants and minimize associated environmental risks. Closed-loop systems for quenchant recycling and filtration can further reduce waste generation and resource consumption.

As environmental regulations become more stringent, heat treatment facilities are also implementing advanced emission control technologies to reduce air pollutants and greenhouse gas emissions. This includes the use of scrubbers, thermal oxidizers, and other air pollution control devices to capture and treat exhaust gases before release into the atmosphere.

Quenching media, often consisting of oil-based or polymer-based solutions, pose potential environmental hazards if not properly managed. These fluids can contaminate soil and water sources if leaked or improperly disposed of. Additionally, the vaporization of quenchants during the rapid cooling process can release volatile organic compounds (VOCs) into the atmosphere, contributing to air pollution and potentially affecting worker health.

The use of protective atmospheres in heat treatment furnaces, such as nitrogen or argon, can lead to the depletion of non-renewable resources. Furthermore, the production and transportation of these gases contribute to the overall carbon footprint of the heat treatment process. In some cases, the use of salt baths for heat treatment can generate hazardous waste that requires specialized disposal methods to prevent environmental contamination.

Water consumption is another environmental concern in heat treatment processes, particularly in quenching operations. Large volumes of water may be required for cooling, and the resulting wastewater can contain contaminants that need proper treatment before discharge. This puts additional strain on water resources and wastewater treatment facilities.

To mitigate these environmental impacts, the heat treatment industry is increasingly focusing on developing more sustainable practices. Energy efficiency improvements, such as better insulation, heat recovery systems, and the use of renewable energy sources, can significantly reduce the carbon footprint of heat treatment operations. Advanced furnace designs and process optimization techniques help minimize energy waste and improve overall efficiency.

The adoption of cleaner quenching technologies, such as high-pressure gas quenching or salt bath quenching with environmentally friendly salts, can reduce the reliance on oil-based quenchants and minimize associated environmental risks. Closed-loop systems for quenchant recycling and filtration can further reduce waste generation and resource consumption.

As environmental regulations become more stringent, heat treatment facilities are also implementing advanced emission control technologies to reduce air pollutants and greenhouse gas emissions. This includes the use of scrubbers, thermal oxidizers, and other air pollution control devices to capture and treat exhaust gases before release into the atmosphere.

Quality Control Measures for Heat-Treated 4140 Steel

Quality control measures are crucial for ensuring the consistency and reliability of heat-treated 4140 steel, particularly when aiming to improve hydrogen embrittlement (HE) resistance. These measures typically involve a combination of process monitoring, testing procedures, and documentation practices throughout the heat treatment process.

Temperature control is a critical aspect of quality assurance in heat treatment. Precise monitoring and regulation of furnace temperatures are essential to achieve the desired microstructure and properties. This often involves the use of calibrated thermocouples and advanced temperature control systems. Regular calibration and maintenance of these systems are necessary to maintain accuracy.

Time management is equally important in heat treatment processes. Accurate timing of heating, soaking, and cooling stages is crucial for achieving the desired metallurgical transformations. Automated systems with precise timing controls are often employed to ensure consistency across batches.

Atmosphere control within the heat treatment furnace is another key factor. For 4140 steel, controlling the carbon potential of the atmosphere is particularly important to prevent decarburization or carburization, which can affect the steel's properties and HE resistance. Regular monitoring and adjustment of furnace atmospheres are necessary.

Post-heat treatment testing is an integral part of quality control. This typically includes hardness testing, microstructure analysis, and mechanical property testing. For HE resistance, specific tests such as slow strain rate testing or hydrogen charging experiments may be conducted on sample pieces from each batch.

Non-destructive testing methods, such as ultrasonic testing or magnetic particle inspection, can be employed to detect any internal defects or surface imperfections that may have developed during the heat treatment process. These tests help ensure the structural integrity of the heat-treated components.

Documentation and traceability are essential elements of quality control. Detailed records of heat treatment parameters, test results, and any deviations from standard procedures should be maintained for each batch. This documentation aids in troubleshooting, process improvement, and compliance with industry standards.

Statistical process control techniques can be applied to monitor trends in heat treatment outcomes over time. This approach helps identify any drift in process parameters or results, allowing for proactive adjustments to maintain consistent quality.

Regular audits and reviews of the heat treatment process and quality control measures should be conducted. These reviews can help identify areas for improvement and ensure that all procedures are up to date with the latest industry standards and best practices for improving HE resistance in 4140 steel.

Temperature control is a critical aspect of quality assurance in heat treatment. Precise monitoring and regulation of furnace temperatures are essential to achieve the desired microstructure and properties. This often involves the use of calibrated thermocouples and advanced temperature control systems. Regular calibration and maintenance of these systems are necessary to maintain accuracy.

Time management is equally important in heat treatment processes. Accurate timing of heating, soaking, and cooling stages is crucial for achieving the desired metallurgical transformations. Automated systems with precise timing controls are often employed to ensure consistency across batches.

Atmosphere control within the heat treatment furnace is another key factor. For 4140 steel, controlling the carbon potential of the atmosphere is particularly important to prevent decarburization or carburization, which can affect the steel's properties and HE resistance. Regular monitoring and adjustment of furnace atmospheres are necessary.

Post-heat treatment testing is an integral part of quality control. This typically includes hardness testing, microstructure analysis, and mechanical property testing. For HE resistance, specific tests such as slow strain rate testing or hydrogen charging experiments may be conducted on sample pieces from each batch.

Non-destructive testing methods, such as ultrasonic testing or magnetic particle inspection, can be employed to detect any internal defects or surface imperfections that may have developed during the heat treatment process. These tests help ensure the structural integrity of the heat-treated components.

Documentation and traceability are essential elements of quality control. Detailed records of heat treatment parameters, test results, and any deviations from standard procedures should be maintained for each batch. This documentation aids in troubleshooting, process improvement, and compliance with industry standards.

Statistical process control techniques can be applied to monitor trends in heat treatment outcomes over time. This approach helps identify any drift in process parameters or results, allowing for proactive adjustments to maintain consistent quality.

Regular audits and reviews of the heat treatment process and quality control measures should be conducted. These reviews can help identify areas for improvement and ensure that all procedures are up to date with the latest industry standards and best practices for improving HE resistance in 4140 steel.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!