Surface Coatings for HE Mitigation: Metallic, Ceramic and Polymer Options — Comparative Data

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Surface Coatings HE Mitigation Background

Surface coatings for high-energy (HE) mitigation have emerged as a critical area of research and development in materials science and engineering. These coatings serve as protective layers designed to mitigate the effects of high-energy impacts, explosions, and other extreme events. The evolution of this technology can be traced back to the mid-20th century, with significant advancements occurring in recent decades due to increasing demands in defense, aerospace, and industrial applications.

The primary objective of HE mitigation coatings is to absorb, dissipate, or redirect the energy from high-impact events, thereby reducing damage to underlying structures and enhancing overall safety. This field has seen a convergence of various materials science disciplines, including metallurgy, ceramics, and polymer science, each contributing unique properties and advantages to the development of effective coating solutions.

Historically, metallic coatings were among the first to be explored for HE mitigation. These coatings, often based on high-strength alloys, offered excellent impact resistance and energy absorption capabilities. However, their relatively high weight and cost led researchers to investigate alternative materials.

Ceramic coatings gained prominence in the latter part of the 20th century, offering superior hardness and thermal resistance. These properties made them particularly suitable for applications involving extreme temperatures and abrasive environments. The development of advanced ceramics, such as boron carbide and silicon carbide, further expanded the potential of these coatings in HE mitigation.

Polymer-based coatings represent the most recent frontier in this field. The advent of high-performance polymers and composite materials has opened new possibilities for lightweight, flexible, and highly effective HE mitigation solutions. These coatings often incorporate energy-absorbing mechanisms at the molecular level, providing enhanced protection while maintaining low weight and thickness.

The technological trajectory in this field is moving towards multi-layered and hybrid coating systems that combine the strengths of different materials. This approach aims to create synergistic effects, maximizing protection against a wide range of high-energy threats while minimizing drawbacks associated with single-material solutions.

As research continues, the focus is increasingly shifting towards nano-engineered coatings and smart materials that can adapt to different types of impacts. These advanced coatings promise not only superior protection but also the ability to self-heal and provide real-time monitoring of structural integrity.

The primary objective of HE mitigation coatings is to absorb, dissipate, or redirect the energy from high-impact events, thereby reducing damage to underlying structures and enhancing overall safety. This field has seen a convergence of various materials science disciplines, including metallurgy, ceramics, and polymer science, each contributing unique properties and advantages to the development of effective coating solutions.

Historically, metallic coatings were among the first to be explored for HE mitigation. These coatings, often based on high-strength alloys, offered excellent impact resistance and energy absorption capabilities. However, their relatively high weight and cost led researchers to investigate alternative materials.

Ceramic coatings gained prominence in the latter part of the 20th century, offering superior hardness and thermal resistance. These properties made them particularly suitable for applications involving extreme temperatures and abrasive environments. The development of advanced ceramics, such as boron carbide and silicon carbide, further expanded the potential of these coatings in HE mitigation.

Polymer-based coatings represent the most recent frontier in this field. The advent of high-performance polymers and composite materials has opened new possibilities for lightweight, flexible, and highly effective HE mitigation solutions. These coatings often incorporate energy-absorbing mechanisms at the molecular level, providing enhanced protection while maintaining low weight and thickness.

The technological trajectory in this field is moving towards multi-layered and hybrid coating systems that combine the strengths of different materials. This approach aims to create synergistic effects, maximizing protection against a wide range of high-energy threats while minimizing drawbacks associated with single-material solutions.

As research continues, the focus is increasingly shifting towards nano-engineered coatings and smart materials that can adapt to different types of impacts. These advanced coatings promise not only superior protection but also the ability to self-heal and provide real-time monitoring of structural integrity.

Market Analysis for HE Mitigation Coatings

The market for High Energy (HE) mitigation coatings has experienced significant growth in recent years, driven by increasing concerns over safety and protection in various industries. These coatings play a crucial role in mitigating the effects of high-energy impacts, explosions, and other potentially destructive events.

The global HE mitigation coatings market is primarily segmented into three main categories: metallic, ceramic, and polymer-based coatings. Each type offers unique properties and advantages, catering to different application requirements and industry needs. The market demand for these coatings spans across multiple sectors, including defense, aerospace, construction, and industrial applications.

In the defense sector, HE mitigation coatings are extensively used in military vehicles, aircraft, and naval vessels to enhance personnel and equipment protection. The aerospace industry also relies heavily on these coatings to improve the safety and durability of aircraft structures and components. The construction sector utilizes HE mitigation coatings in critical infrastructure projects, such as government buildings, bridges, and tunnels, to enhance their resilience against potential threats.

The industrial sector represents another significant market for HE mitigation coatings, particularly in oil and gas, chemical, and manufacturing facilities. These coatings are employed to protect equipment, storage tanks, and structures from potential explosions or high-energy impacts, thereby ensuring workplace safety and minimizing potential damage to assets.

Market trends indicate a growing preference for lightweight, high-performance coatings that offer superior protection without compromising on weight or flexibility. This trend is particularly evident in the aerospace and defense sectors, where weight reduction is a critical factor in improving overall system performance.

The market for HE mitigation coatings is also influenced by ongoing research and development efforts aimed at enhancing coating properties and performance. Innovations in nanotechnology and advanced materials science are driving the development of next-generation coatings with improved durability, impact resistance, and multi-functional capabilities.

Geographically, North America and Europe currently dominate the HE mitigation coatings market, primarily due to their strong defense and aerospace industries. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by increasing defense spending, rapid industrialization, and growing awareness of safety measures in emerging economies.

The global HE mitigation coatings market is primarily segmented into three main categories: metallic, ceramic, and polymer-based coatings. Each type offers unique properties and advantages, catering to different application requirements and industry needs. The market demand for these coatings spans across multiple sectors, including defense, aerospace, construction, and industrial applications.

In the defense sector, HE mitigation coatings are extensively used in military vehicles, aircraft, and naval vessels to enhance personnel and equipment protection. The aerospace industry also relies heavily on these coatings to improve the safety and durability of aircraft structures and components. The construction sector utilizes HE mitigation coatings in critical infrastructure projects, such as government buildings, bridges, and tunnels, to enhance their resilience against potential threats.

The industrial sector represents another significant market for HE mitigation coatings, particularly in oil and gas, chemical, and manufacturing facilities. These coatings are employed to protect equipment, storage tanks, and structures from potential explosions or high-energy impacts, thereby ensuring workplace safety and minimizing potential damage to assets.

Market trends indicate a growing preference for lightweight, high-performance coatings that offer superior protection without compromising on weight or flexibility. This trend is particularly evident in the aerospace and defense sectors, where weight reduction is a critical factor in improving overall system performance.

The market for HE mitigation coatings is also influenced by ongoing research and development efforts aimed at enhancing coating properties and performance. Innovations in nanotechnology and advanced materials science are driving the development of next-generation coatings with improved durability, impact resistance, and multi-functional capabilities.

Geographically, North America and Europe currently dominate the HE mitigation coatings market, primarily due to their strong defense and aerospace industries. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by increasing defense spending, rapid industrialization, and growing awareness of safety measures in emerging economies.

Current Challenges in Surface Coating Technologies

Surface coating technologies have made significant strides in recent years, yet several challenges persist in their development and application for high-energy (HE) mitigation. One of the primary obstacles is achieving optimal adhesion between the coating and substrate materials. This is particularly crucial in high-stress environments where coatings are subjected to extreme temperatures, pressures, and mechanical forces. The interface between the coating and substrate must maintain integrity under these conditions to ensure effective protection.

Another significant challenge lies in developing coatings with uniform thickness and composition across large surface areas. Inconsistencies in coating application can lead to weak points or areas of reduced effectiveness, compromising the overall protective capabilities of the system. This issue is especially pronounced when dealing with complex geometries or intricate surface features.

The durability and longevity of surface coatings in harsh environments remain areas of concern. While many coatings perform well initially, their effectiveness can degrade over time due to factors such as thermal cycling, chemical exposure, and mechanical wear. Developing coatings that maintain their protective properties throughout the intended lifespan of the component is an ongoing challenge.

Balancing multiple performance requirements is another hurdle in surface coating technologies. Coatings must often provide not only HE mitigation but also resistance to corrosion, erosion, and other environmental factors. Achieving this multi-functionality without compromising the primary protective role is a complex task that requires careful material selection and design.

The environmental impact and sustainability of coating materials and processes are becoming increasingly important considerations. Many traditional coating technologies involve the use of hazardous substances or energy-intensive processes. Developing eco-friendly alternatives that maintain or improve upon the performance of existing coatings is a pressing challenge in the field.

Cost-effectiveness and scalability of coating technologies also present significant obstacles. While some advanced coatings offer superior performance, their widespread adoption may be hindered by high production costs or difficulties in scaling up manufacturing processes. Bridging the gap between laboratory-scale innovations and commercially viable, large-scale production remains a key challenge.

Lastly, the characterization and testing of coatings for HE mitigation pose unique challenges. Developing standardized methods for evaluating coating performance under extreme conditions and predicting long-term behavior is crucial for advancing the field. This includes the need for improved non-destructive testing techniques and accelerated aging protocols that accurately simulate real-world conditions.

Another significant challenge lies in developing coatings with uniform thickness and composition across large surface areas. Inconsistencies in coating application can lead to weak points or areas of reduced effectiveness, compromising the overall protective capabilities of the system. This issue is especially pronounced when dealing with complex geometries or intricate surface features.

The durability and longevity of surface coatings in harsh environments remain areas of concern. While many coatings perform well initially, their effectiveness can degrade over time due to factors such as thermal cycling, chemical exposure, and mechanical wear. Developing coatings that maintain their protective properties throughout the intended lifespan of the component is an ongoing challenge.

Balancing multiple performance requirements is another hurdle in surface coating technologies. Coatings must often provide not only HE mitigation but also resistance to corrosion, erosion, and other environmental factors. Achieving this multi-functionality without compromising the primary protective role is a complex task that requires careful material selection and design.

The environmental impact and sustainability of coating materials and processes are becoming increasingly important considerations. Many traditional coating technologies involve the use of hazardous substances or energy-intensive processes. Developing eco-friendly alternatives that maintain or improve upon the performance of existing coatings is a pressing challenge in the field.

Cost-effectiveness and scalability of coating technologies also present significant obstacles. While some advanced coatings offer superior performance, their widespread adoption may be hindered by high production costs or difficulties in scaling up manufacturing processes. Bridging the gap between laboratory-scale innovations and commercially viable, large-scale production remains a key challenge.

Lastly, the characterization and testing of coatings for HE mitigation pose unique challenges. Developing standardized methods for evaluating coating performance under extreme conditions and predicting long-term behavior is crucial for advancing the field. This includes the need for improved non-destructive testing techniques and accelerated aging protocols that accurately simulate real-world conditions.

Existing HE Mitigation Coating Solutions

01 Protective coatings for high-energy (HE) mitigation

Specialized surface coatings are developed to mitigate the effects of high-energy events. These coatings are designed to absorb, deflect, or dissipate energy from explosions or other high-energy impacts, providing protection to underlying structures or components.- Protective coatings for high-energy environments: Specialized surface coatings are developed to mitigate the effects of high-energy (HE) environments. These coatings are designed to protect underlying materials from damage caused by extreme temperatures, radiation, or chemical exposure. The coatings often incorporate advanced materials and application techniques to enhance durability and performance in harsh conditions.

- Nanostructured coatings for HE mitigation: Nanostructured coatings are utilized to enhance surface protection against high-energy impacts. These coatings leverage the unique properties of nanomaterials to create highly resistant surfaces. The nanostructure can help dissipate energy, reduce heat transfer, and improve overall durability of the coated surface in high-energy environments.

- Thermal barrier coatings for HE applications: Thermal barrier coatings are specifically formulated to protect surfaces from extreme heat in high-energy environments. These coatings typically consist of ceramic materials with low thermal conductivity. They are designed to reduce heat transfer to the underlying substrate, thereby protecting it from thermal damage and extending its operational life in high-temperature conditions.

- Electromagnetic shielding coatings: Surface coatings are developed to provide electromagnetic shielding in high-energy environments. These coatings are designed to absorb or reflect electromagnetic radiation, protecting sensitive components from interference or damage. The coatings often incorporate conductive materials or specialized compounds to effectively mitigate electromagnetic effects.

- Self-healing coatings for HE protection: Advanced self-healing coatings are engineered to automatically repair minor damage caused by high-energy impacts or environmental stress. These coatings contain microcapsules or other mechanisms that release healing agents when the coating is damaged. This self-repair capability helps maintain the protective properties of the coating over time, even in harsh high-energy environments.

02 Electromagnetic shielding coatings

Surface coatings are formulated to provide electromagnetic shielding, protecting sensitive electronic components from electromagnetic interference (EMI) and high-energy electromagnetic pulses. These coatings typically incorporate conductive materials or specialized compounds to absorb or reflect electromagnetic radiation.Expand Specific Solutions03 Thermal management coatings for HE applications

Advanced coatings are developed to manage heat generated during high-energy events. These coatings can dissipate heat rapidly, provide insulation, or change properties under extreme temperatures to protect underlying materials from thermal damage.Expand Specific Solutions04 Nanostructured coatings for enhanced HE protection

Nanostructured materials are incorporated into surface coatings to enhance their protective properties against high-energy impacts. These coatings leverage the unique properties of nanomaterials to improve energy absorption, strength, and resilience.Expand Specific Solutions05 Self-healing coatings for prolonged HE protection

Innovative self-healing coatings are designed to repair damage caused by high-energy events automatically. These coatings contain microcapsules or other mechanisms that release healing agents when damaged, maintaining their protective properties over time and multiple impacts.Expand Specific Solutions

Key Players in Surface Coating Industry

The surface coatings market for high-energy (HE) mitigation is in a growth phase, driven by increasing demand for advanced protective solutions in defense and industrial applications. The market size is expanding, with a diverse range of players offering metallic, ceramic, and polymer coating options. Technologically, the field is advancing rapidly, with companies like Nihon Parkerizing, BASF, and RTX Corp leading innovation in their respective specialties. General Electric and Toshiba are leveraging their extensive R&D capabilities to develop cutting-edge solutions, while specialized firms like EPG AG focus on nanotech-based coatings. The competitive landscape is characterized by a mix of established industrial giants and niche players, each contributing to the evolving technological landscape in HE mitigation surface coatings.

General Electric Company

Technical Solution: General Electric has focused on developing metallic coatings for HE mitigation, particularly for use in turbine engines and aerospace applications. Their approach involves using advanced alloys, such as nickel-based superalloys and titanium aluminides, applied through methods like electron beam physical vapor deposition (EB-PVD). These coatings are designed to withstand extreme temperatures and provide protection against high-energy impacts. GE's metallic coatings typically range from 75-250 μm in thickness and can operate at temperatures up to 1200°C[7]. The company has also incorporated thermal barrier coatings (TBCs) into their systems, which can reduce the surface temperature of the base metal by up to 150°C[9]. GE's latest developments include self-healing metallic coatings that can repair micro-cracks at high temperatures, significantly extending the lifespan of protected components[8].

Strengths: Excellent high-temperature performance, good adhesion to metal substrates, and potential for self-healing properties. Weaknesses: Can be heavy compared to other coating types, and may be susceptible to oxidation in certain environments.

BASF Corp.

Technical Solution: BASF has developed advanced polymer coatings for high-energy (HE) mitigation. Their approach involves using specially formulated polyurethane-based coatings that incorporate energy-absorbing additives. These coatings are designed to dissipate shock waves and reduce the impact of high-energy events. BASF's polymer coatings utilize a multi-layer system, with each layer serving a specific purpose in energy absorption and dispersion[1]. The company has also integrated nano-materials into their coatings to enhance their protective properties, improving resistance to fragmentation and thermal effects[3]. BASF's coatings have been tested to withstand pressures up to 100 MPa and temperatures exceeding 1000°C in simulated high-energy environments[5].

Strengths: Excellent energy absorption, high temperature resistance, and versatility in application. Weaknesses: May require frequent reapplication in harsh environments, and potential for higher costs compared to traditional coatings.

Core Innovations in Coating Materials

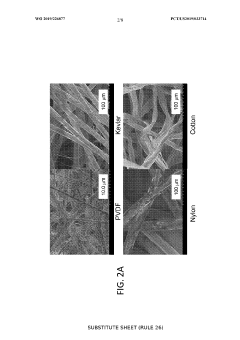

Self-healing, hydrobphobic composites and related methods

PatentWO2019226877A1

Innovation

- Self-healing hydrophobic composites are developed by infusing hydrophobic phase change materials into a network of polymer fibers, which provide enhanced mechanical properties and increased hydrophobicity upon mechanical damage, with the ability to restore surface morphology and wettability through local temperature control.

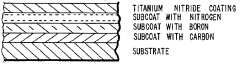

Surface coatings and subcoats

PatentInactiveUS4556607A

Innovation

- Application of novel metal coatings comprising 20-70% cobalt or nickel, 8-35% chromium, 3-20% molybdenum or tungsten, and 0.5-10% carbon, nitrogen, or boron, forming microcrystalline, single-phase solid solutions, which are used as subcoats to enhance the bonding and physical properties of nitrides, carbides, and borides of titanium, hafnium, and zirconium coatings.

Environmental Impact of Coating Materials

The environmental impact of coating materials used for high explosive (HE) mitigation is a critical consideration in the development and application of surface coatings. Metallic, ceramic, and polymer options each present unique environmental challenges and benefits throughout their lifecycle, from production to disposal.

Metallic coatings, such as those based on aluminum or zinc, often require energy-intensive manufacturing processes, contributing to increased carbon emissions. However, many metals used in these coatings are recyclable, potentially reducing their long-term environmental footprint. The durability of metallic coatings can also lead to extended product lifespans, minimizing waste generation.

Ceramic coatings, while generally inert and non-toxic, may involve the use of rare earth elements in their production. The extraction of these materials can have significant environmental consequences, including habitat destruction and water pollution. On the positive side, ceramic coatings often provide excellent thermal insulation properties, which can contribute to energy savings in various applications.

Polymer-based coatings present a mixed environmental profile. Many polymers are derived from petrochemicals, raising concerns about resource depletion and greenhouse gas emissions. However, advancements in bio-based and biodegradable polymers offer more sustainable alternatives. These eco-friendly options can reduce the environmental impact of coating disposal and potentially contribute to carbon sequestration.

The application methods for these coatings also factor into their environmental impact. Spray application, common for many coating types, can result in volatile organic compound (VOC) emissions, contributing to air pollution and potential health hazards. Water-based and powder coating technologies have emerged as more environmentally friendly alternatives, significantly reducing VOC emissions.

End-of-life considerations are crucial when assessing the environmental impact of coating materials. While some coatings can be recycled or safely disposed of, others may leach harmful substances into the environment if not properly managed. The development of easily separable or biodegradable coatings is an active area of research aimed at mitigating these concerns.

In the context of HE mitigation, the protective properties of these coatings must be balanced against their environmental impact. Coatings that effectively contain or suppress explosive events may indirectly contribute to environmental protection by preventing large-scale contamination from explosive materials. However, this benefit must be weighed against the potential environmental costs of coating production and disposal.

Metallic coatings, such as those based on aluminum or zinc, often require energy-intensive manufacturing processes, contributing to increased carbon emissions. However, many metals used in these coatings are recyclable, potentially reducing their long-term environmental footprint. The durability of metallic coatings can also lead to extended product lifespans, minimizing waste generation.

Ceramic coatings, while generally inert and non-toxic, may involve the use of rare earth elements in their production. The extraction of these materials can have significant environmental consequences, including habitat destruction and water pollution. On the positive side, ceramic coatings often provide excellent thermal insulation properties, which can contribute to energy savings in various applications.

Polymer-based coatings present a mixed environmental profile. Many polymers are derived from petrochemicals, raising concerns about resource depletion and greenhouse gas emissions. However, advancements in bio-based and biodegradable polymers offer more sustainable alternatives. These eco-friendly options can reduce the environmental impact of coating disposal and potentially contribute to carbon sequestration.

The application methods for these coatings also factor into their environmental impact. Spray application, common for many coating types, can result in volatile organic compound (VOC) emissions, contributing to air pollution and potential health hazards. Water-based and powder coating technologies have emerged as more environmentally friendly alternatives, significantly reducing VOC emissions.

End-of-life considerations are crucial when assessing the environmental impact of coating materials. While some coatings can be recycled or safely disposed of, others may leach harmful substances into the environment if not properly managed. The development of easily separable or biodegradable coatings is an active area of research aimed at mitigating these concerns.

In the context of HE mitigation, the protective properties of these coatings must be balanced against their environmental impact. Coatings that effectively contain or suppress explosive events may indirectly contribute to environmental protection by preventing large-scale contamination from explosive materials. However, this benefit must be weighed against the potential environmental costs of coating production and disposal.

Cost-Benefit Analysis of Coating Options

The cost-benefit analysis of coating options for high-energy (HE) mitigation is a critical aspect of decision-making in various industries, including aerospace, defense, and energy sectors. This analysis involves evaluating the economic feasibility and performance advantages of different coating materials and application methods.

Metallic coatings, such as nickel-based alloys or titanium, offer excellent thermal resistance and durability. However, they often come with higher initial costs due to expensive raw materials and complex application processes. The long-term benefits of metallic coatings include extended equipment lifespan and reduced maintenance frequency, potentially offsetting the higher upfront investment.

Ceramic coatings, like zirconia or alumina, provide superior thermal insulation and wear resistance. While generally less expensive than metallic options, ceramic coatings may require more frequent reapplication in high-stress environments. The cost-benefit ratio for ceramics often favors applications where extreme temperature resistance is crucial, and the coating's longevity can be assured through proper maintenance schedules.

Polymer-based coatings, such as epoxy or polyurethane, present a more economical initial investment. They offer good chemical resistance and are easier to apply, reducing labor costs. However, their performance in extreme conditions may be limited, potentially leading to more frequent replacement and higher long-term expenses in demanding applications.

The selection of coating options must consider factors beyond direct costs. These include application time, which affects production downtime, and the coating's impact on the substrate material's properties. Environmental regulations and disposal costs for coating materials and byproducts should also be factored into the overall cost-benefit equation.

Lifecycle cost analysis is essential in determining the true value of each coating option. This involves calculating not only the initial application costs but also factoring in maintenance, repair, and replacement expenses over the expected service life of the coated component. In some cases, a higher initial investment in a more durable coating may result in significant long-term savings through reduced maintenance and extended equipment life.

Performance metrics such as thermal efficiency, erosion resistance, and impact on overall system performance must be quantified and translated into economic terms. This allows for a comprehensive comparison of different coating options, considering both their protective capabilities and their effect on operational efficiency.

Metallic coatings, such as nickel-based alloys or titanium, offer excellent thermal resistance and durability. However, they often come with higher initial costs due to expensive raw materials and complex application processes. The long-term benefits of metallic coatings include extended equipment lifespan and reduced maintenance frequency, potentially offsetting the higher upfront investment.

Ceramic coatings, like zirconia or alumina, provide superior thermal insulation and wear resistance. While generally less expensive than metallic options, ceramic coatings may require more frequent reapplication in high-stress environments. The cost-benefit ratio for ceramics often favors applications where extreme temperature resistance is crucial, and the coating's longevity can be assured through proper maintenance schedules.

Polymer-based coatings, such as epoxy or polyurethane, present a more economical initial investment. They offer good chemical resistance and are easier to apply, reducing labor costs. However, their performance in extreme conditions may be limited, potentially leading to more frequent replacement and higher long-term expenses in demanding applications.

The selection of coating options must consider factors beyond direct costs. These include application time, which affects production downtime, and the coating's impact on the substrate material's properties. Environmental regulations and disposal costs for coating materials and byproducts should also be factored into the overall cost-benefit equation.

Lifecycle cost analysis is essential in determining the true value of each coating option. This involves calculating not only the initial application costs but also factoring in maintenance, repair, and replacement expenses over the expected service life of the coated component. In some cases, a higher initial investment in a more durable coating may result in significant long-term savings through reduced maintenance and extended equipment life.

Performance metrics such as thermal efficiency, erosion resistance, and impact on overall system performance must be quantified and translated into economic terms. This allows for a comprehensive comparison of different coating options, considering both their protective capabilities and their effect on operational efficiency.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!