How to Measure Diffusible Hydrogen and Interpret Results for Failure Analysis

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogen Measurement Background and Objectives

The measurement of diffusible hydrogen and its interpretation for failure analysis has become increasingly crucial in materials science and engineering. This technology has evolved significantly over the past decades, driven by the need to understand and mitigate hydrogen-induced failures in various industries, including aerospace, automotive, and energy sectors.

The historical development of hydrogen measurement techniques can be traced back to the early 20th century when researchers first recognized the detrimental effects of hydrogen on metal properties. Initial methods were rudimentary, often relying on indirect measurements or destructive testing. As the understanding of hydrogen embrittlement grew, so did the sophistication of measurement techniques.

The evolution of hydrogen measurement technology has been marked by several key milestones. The introduction of gas chromatography in the 1950s provided a more accurate means of quantifying hydrogen content. The development of thermal desorption spectroscopy in the 1970s allowed for the differentiation between diffusible and residual hydrogen. More recently, advances in electrochemical techniques and mass spectrometry have further enhanced our ability to detect and measure hydrogen at increasingly lower concentrations.

Current technological trends in hydrogen measurement focus on improving sensitivity, accuracy, and real-time monitoring capabilities. There is a growing emphasis on non-destructive testing methods and in-situ measurements, which allow for the evaluation of hydrogen content without compromising the integrity of the material or component under investigation.

The primary objectives of modern hydrogen measurement techniques in the context of failure analysis are multifaceted. Firstly, they aim to accurately quantify the amount of diffusible hydrogen present in materials, as this form of hydrogen is particularly problematic due to its mobility and potential to accumulate at stress concentration points. Secondly, these techniques seek to establish correlations between hydrogen content and material properties, enabling better prediction of hydrogen-induced failures.

Furthermore, the goals extend to developing standardized methods for hydrogen measurement across different industries and applications. This standardization is crucial for ensuring consistency in failure analysis and for establishing reliable threshold values for safe hydrogen levels in various materials and components.

Another key objective is to enhance the interpretation of hydrogen measurement results in the context of failure analysis. This involves not only quantifying hydrogen content but also understanding its distribution, trapping mechanisms, and interaction with material microstructures. Advanced analytical techniques are being developed to provide a more comprehensive picture of hydrogen's role in material degradation and failure.

The historical development of hydrogen measurement techniques can be traced back to the early 20th century when researchers first recognized the detrimental effects of hydrogen on metal properties. Initial methods were rudimentary, often relying on indirect measurements or destructive testing. As the understanding of hydrogen embrittlement grew, so did the sophistication of measurement techniques.

The evolution of hydrogen measurement technology has been marked by several key milestones. The introduction of gas chromatography in the 1950s provided a more accurate means of quantifying hydrogen content. The development of thermal desorption spectroscopy in the 1970s allowed for the differentiation between diffusible and residual hydrogen. More recently, advances in electrochemical techniques and mass spectrometry have further enhanced our ability to detect and measure hydrogen at increasingly lower concentrations.

Current technological trends in hydrogen measurement focus on improving sensitivity, accuracy, and real-time monitoring capabilities. There is a growing emphasis on non-destructive testing methods and in-situ measurements, which allow for the evaluation of hydrogen content without compromising the integrity of the material or component under investigation.

The primary objectives of modern hydrogen measurement techniques in the context of failure analysis are multifaceted. Firstly, they aim to accurately quantify the amount of diffusible hydrogen present in materials, as this form of hydrogen is particularly problematic due to its mobility and potential to accumulate at stress concentration points. Secondly, these techniques seek to establish correlations between hydrogen content and material properties, enabling better prediction of hydrogen-induced failures.

Furthermore, the goals extend to developing standardized methods for hydrogen measurement across different industries and applications. This standardization is crucial for ensuring consistency in failure analysis and for establishing reliable threshold values for safe hydrogen levels in various materials and components.

Another key objective is to enhance the interpretation of hydrogen measurement results in the context of failure analysis. This involves not only quantifying hydrogen content but also understanding its distribution, trapping mechanisms, and interaction with material microstructures. Advanced analytical techniques are being developed to provide a more comprehensive picture of hydrogen's role in material degradation and failure.

Market Demand for Hydrogen Detection in Materials

The market demand for hydrogen detection in materials has been steadily growing across various industries, driven by the increasing awareness of hydrogen embrittlement and its detrimental effects on material integrity. The aerospace, automotive, and energy sectors are particularly invested in advanced hydrogen detection technologies to ensure the safety and reliability of their products and infrastructure.

In the aerospace industry, the demand for hydrogen detection is critical for maintaining the structural integrity of aircraft components. Manufacturers and maintenance facilities require precise measurement tools to detect diffusible hydrogen in high-strength steels and aluminum alloys used in aircraft structures. This demand is further amplified by the stringent safety regulations imposed by aviation authorities worldwide.

The automotive sector has also seen a surge in the need for hydrogen detection, especially with the rise of hydrogen fuel cell vehicles. As automakers invest heavily in hydrogen-powered transportation, the ability to accurately measure and control hydrogen levels in fuel cells and storage tanks becomes paramount. This has led to increased demand for sophisticated hydrogen detection systems that can ensure the safety and efficiency of hydrogen-powered vehicles.

In the energy sector, particularly in oil and gas industries, hydrogen detection plays a crucial role in preventing catastrophic failures in pipelines, storage tanks, and refinery equipment. The market for hydrogen detection technologies in this sector is driven by the need to mitigate risks associated with hydrogen-induced cracking and stress corrosion cracking.

The semiconductor industry represents another significant market for hydrogen detection. As chip manufacturers strive for higher performance and smaller form factors, the control of hydrogen contamination during the fabrication process becomes increasingly important. This has created a niche market for ultra-sensitive hydrogen detection tools capable of measuring trace amounts of hydrogen in clean room environments.

Research institutions and materials science laboratories contribute to the market demand as well, requiring advanced hydrogen detection capabilities for studying material properties and developing new alloys resistant to hydrogen embrittlement. This academic and research-driven demand fuels innovation in detection methodologies and instrumentation.

The global push towards a hydrogen-based economy has further expanded the market for hydrogen detection technologies. As countries invest in hydrogen infrastructure for energy storage and distribution, the need for reliable safety measures, including accurate hydrogen detection systems, has grown exponentially.

In the aerospace industry, the demand for hydrogen detection is critical for maintaining the structural integrity of aircraft components. Manufacturers and maintenance facilities require precise measurement tools to detect diffusible hydrogen in high-strength steels and aluminum alloys used in aircraft structures. This demand is further amplified by the stringent safety regulations imposed by aviation authorities worldwide.

The automotive sector has also seen a surge in the need for hydrogen detection, especially with the rise of hydrogen fuel cell vehicles. As automakers invest heavily in hydrogen-powered transportation, the ability to accurately measure and control hydrogen levels in fuel cells and storage tanks becomes paramount. This has led to increased demand for sophisticated hydrogen detection systems that can ensure the safety and efficiency of hydrogen-powered vehicles.

In the energy sector, particularly in oil and gas industries, hydrogen detection plays a crucial role in preventing catastrophic failures in pipelines, storage tanks, and refinery equipment. The market for hydrogen detection technologies in this sector is driven by the need to mitigate risks associated with hydrogen-induced cracking and stress corrosion cracking.

The semiconductor industry represents another significant market for hydrogen detection. As chip manufacturers strive for higher performance and smaller form factors, the control of hydrogen contamination during the fabrication process becomes increasingly important. This has created a niche market for ultra-sensitive hydrogen detection tools capable of measuring trace amounts of hydrogen in clean room environments.

Research institutions and materials science laboratories contribute to the market demand as well, requiring advanced hydrogen detection capabilities for studying material properties and developing new alloys resistant to hydrogen embrittlement. This academic and research-driven demand fuels innovation in detection methodologies and instrumentation.

The global push towards a hydrogen-based economy has further expanded the market for hydrogen detection technologies. As countries invest in hydrogen infrastructure for energy storage and distribution, the need for reliable safety measures, including accurate hydrogen detection systems, has grown exponentially.

Current Challenges in Diffusible Hydrogen Measurement

The measurement of diffusible hydrogen and its interpretation for failure analysis face several significant challenges in the current technological landscape. One of the primary obstacles is the lack of standardization in measurement techniques across different industries and laboratories. This inconsistency leads to difficulties in comparing results and establishing reliable benchmarks for hydrogen content in materials.

Another challenge lies in the sensitivity and accuracy of existing measurement methods. Diffusible hydrogen, being highly mobile, can easily escape from the material during sample preparation or measurement, leading to underestimation of the actual hydrogen content. This is particularly problematic for materials with low hydrogen concentrations, where even small losses can significantly impact the results.

The time-dependent nature of hydrogen diffusion poses additional complications. The hydrogen content in a material can change rapidly, especially at elevated temperatures or under stress. This dynamic behavior makes it challenging to obtain representative measurements, as the hydrogen distribution may alter between the time of failure and the time of analysis.

Sample preparation techniques also present hurdles in accurate hydrogen measurement. The methods used to extract samples from failed components can inadvertently introduce or remove hydrogen, skewing the results. Moreover, the sample size and geometry can influence the hydrogen distribution and diffusion rates, further complicating the measurement process.

Interpretation of the results presents its own set of challenges. Establishing a clear correlation between measured hydrogen levels and material failure is not always straightforward. Factors such as material microstructure, stress state, and environmental conditions all play roles in how hydrogen affects material properties and failure mechanisms. This complexity makes it difficult to determine critical hydrogen thresholds for different materials and applications.

Furthermore, the influence of trapping sites within materials adds another layer of complexity. These sites can temporarily or permanently bind hydrogen, affecting its mobility and distribution. Understanding and accounting for these trapping effects in measurement and interpretation is crucial but remains challenging.

Lastly, the development of in-situ measurement techniques for real-time monitoring of hydrogen content in operating components is an ongoing challenge. Such capabilities would greatly enhance our understanding of hydrogen-induced degradation processes but require overcoming significant technical hurdles in sensor design and data interpretation.

Another challenge lies in the sensitivity and accuracy of existing measurement methods. Diffusible hydrogen, being highly mobile, can easily escape from the material during sample preparation or measurement, leading to underestimation of the actual hydrogen content. This is particularly problematic for materials with low hydrogen concentrations, where even small losses can significantly impact the results.

The time-dependent nature of hydrogen diffusion poses additional complications. The hydrogen content in a material can change rapidly, especially at elevated temperatures or under stress. This dynamic behavior makes it challenging to obtain representative measurements, as the hydrogen distribution may alter between the time of failure and the time of analysis.

Sample preparation techniques also present hurdles in accurate hydrogen measurement. The methods used to extract samples from failed components can inadvertently introduce or remove hydrogen, skewing the results. Moreover, the sample size and geometry can influence the hydrogen distribution and diffusion rates, further complicating the measurement process.

Interpretation of the results presents its own set of challenges. Establishing a clear correlation between measured hydrogen levels and material failure is not always straightforward. Factors such as material microstructure, stress state, and environmental conditions all play roles in how hydrogen affects material properties and failure mechanisms. This complexity makes it difficult to determine critical hydrogen thresholds for different materials and applications.

Furthermore, the influence of trapping sites within materials adds another layer of complexity. These sites can temporarily or permanently bind hydrogen, affecting its mobility and distribution. Understanding and accounting for these trapping effects in measurement and interpretation is crucial but remains challenging.

Lastly, the development of in-situ measurement techniques for real-time monitoring of hydrogen content in operating components is an ongoing challenge. Such capabilities would greatly enhance our understanding of hydrogen-induced degradation processes but require overcoming significant technical hurdles in sensor design and data interpretation.

Existing Methods for Diffusible Hydrogen Measurement

01 Measurement techniques for diffusible hydrogen

Various techniques are employed to measure diffusible hydrogen in materials, particularly in welding applications. These methods include gas chromatography, mercury displacement, and hot extraction techniques. The measurements are crucial for assessing the potential for hydrogen embrittlement and ensuring the quality of welded joints.- Measurement methods for diffusible hydrogen: Various techniques are employed to measure diffusible hydrogen in materials, particularly in welding applications. These methods include gas chromatography, mercury displacement, and hot extraction techniques. The choice of method depends on the material being tested and the required accuracy of the measurement.

- Interpretation of diffusible hydrogen levels: The interpretation of diffusible hydrogen levels is crucial in assessing the quality and potential risks associated with welded joints. Factors such as material composition, welding parameters, and environmental conditions are considered when interpreting the results. Threshold values are often established to determine acceptable hydrogen levels for different applications.

- Equipment and devices for hydrogen measurement: Specialized equipment and devices are used for measuring diffusible hydrogen. These include hydrogen analyzers, gas chromatographs, and custom-designed apparatus for specific testing protocols. The development of portable and automated systems has improved the efficiency and accuracy of hydrogen measurements in field conditions.

- Factors affecting diffusible hydrogen content: Several factors influence the diffusible hydrogen content in materials, particularly in welding processes. These include electrode composition, flux type, welding parameters, environmental humidity, and material surface conditions. Understanding these factors is essential for controlling and minimizing hydrogen-induced cracking risks.

- Standards and procedures for hydrogen testing: Various international standards and procedures govern the testing and measurement of diffusible hydrogen. These standards provide guidelines for sample preparation, testing conditions, and result reporting. Adherence to these standards ensures consistency and comparability of hydrogen measurements across different laboratories and applications.

02 Interpretation of diffusible hydrogen data

The interpretation of diffusible hydrogen measurements involves analyzing the data to determine the hydrogen content in materials and its potential effects. This process includes comparing results to established standards, evaluating the risk of hydrogen-induced cracking, and making decisions about material suitability for specific applications.Expand Specific Solutions03 Equipment and devices for hydrogen measurement

Specialized equipment and devices are used for measuring diffusible hydrogen. These include hydrogen analyzers, gas chromatographs with specific detectors, and custom-designed apparatuses for sample preparation and hydrogen extraction. The choice of equipment depends on the material being tested and the required precision of measurement.Expand Specific Solutions04 Standards and procedures for hydrogen testing

Standardized procedures and methods are essential for accurate and reproducible diffusible hydrogen measurements. These standards define sample preparation, testing conditions, and data reporting requirements. They ensure consistency in hydrogen testing across different laboratories and industries, facilitating meaningful comparisons and interpretations of results.Expand Specific Solutions05 Applications of diffusible hydrogen analysis

Diffusible hydrogen analysis is applied in various fields, including welding, materials science, and manufacturing. It is particularly important in assessing the quality of welded joints, determining the suitability of materials for hydrogen-sensitive applications, and developing strategies to mitigate hydrogen-induced damage in metals and alloys.Expand Specific Solutions

Key Players in Hydrogen Analysis Industry

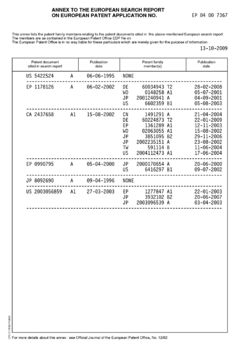

The competitive landscape for measuring diffusible hydrogen and interpreting results for failure analysis is characterized by a mature market with established players across various industries. The market size is significant, driven by the critical importance of hydrogen embrittlement prevention in sectors like automotive, oil and gas, and manufacturing. Technologically, the field is well-developed, with companies like NTN Corp., Saudi Aramco, and JFE Steel Corp. offering advanced solutions. Academic institutions such as Tianjin University and King Fahd University of Petroleum & Minerals contribute to ongoing research and development. The technology's maturity is evident in the diverse range of products and services offered by companies like Linde GmbH and Hach Lange GmbH, catering to specific industry needs.

JFE Steel Corp.

Technical Solution: JFE Steel Corp. has developed advanced techniques for measuring diffusible hydrogen in steel. They utilize a gas chromatography method that involves heating steel samples to extract hydrogen, which is then analyzed using a thermal conductivity detector. This method allows for precise measurement of hydrogen content as low as 0.1 ppm [1]. JFE Steel has also implemented an in-line hydrogen measurement system for continuous casting, enabling real-time monitoring and control of hydrogen levels during steel production [2]. Their approach combines high-temperature hydrogen extraction with mass spectrometry for rapid and accurate analysis, crucial for preventing hydrogen-induced cracking in high-strength steels [3].

Strengths: High precision measurements, real-time monitoring capability, and applicability to industrial-scale production. Weaknesses: Requires specialized equipment and expertise, potentially high implementation costs for smaller operations.

Kobe Steel, Ltd.

Technical Solution: Kobe Steel has pioneered the use of thermal desorption analysis (TDA) for measuring diffusible hydrogen in steel. Their method involves gradually heating steel samples and continuously measuring the released hydrogen using a mass spectrometer. This technique allows for the differentiation between various types of hydrogen traps in the steel microstructure [4]. Kobe Steel has also developed a novel electrochemical hydrogen permeation technique that enables the measurement of hydrogen diffusion coefficients in steel under simulated service conditions [5]. Their research extends to the use of secondary ion mass spectrometry (SIMS) for high-resolution mapping of hydrogen distribution in steel microstructures, providing crucial insights for failure analysis [6].

Strengths: Comprehensive analysis of hydrogen trapping and diffusion behavior, applicable to a wide range of steel grades. Weaknesses: Some techniques may be time-consuming and require highly specialized equipment.

Innovations in Hydrogen Detection Technologies

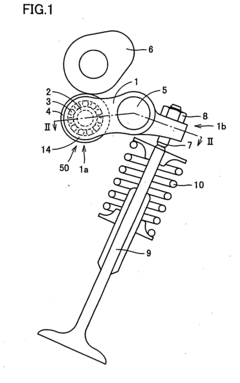

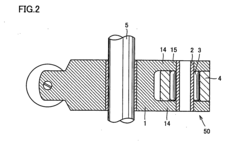

Roller cam follower for an engine

PatentInactiveEP1548145A1

Innovation

- A roller cam follower with a carbonitrided layer having austenite crystal grains larger than 10, combined with low-temperature secondary quenching to increase fracture stress and reduce hydrogen content, and a compression residual stress to enhance durability and hardness, along with a design that allows the roller shaft to have varying hardness for improved caulking and durability.

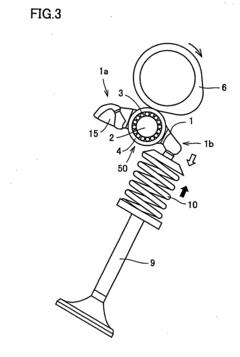

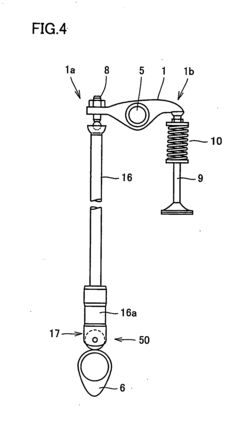

Compressor bearing and compressor component

PatentInactiveEP1462649A3

Innovation

- The solution involves carbonitriding steel at a temperature above the A1 transformation point, followed by cooling below it and subsequent reheating to a range above the A1 transformation point for quenching, resulting in a nitriding layer with a fracture stress value of at least 2650 MPa and austenite grain size exceeding 10, while maintaining a hydrogen content of 0.5 ppm or less to enhance anti-crack strength and stability.

Standardization of Hydrogen Measurement Procedures

The standardization of hydrogen measurement procedures is crucial for ensuring consistent and reliable results in failure analysis. This process involves establishing uniform methods for sample preparation, measurement techniques, and data interpretation across different laboratories and industries.

One key aspect of standardization is the development of precise protocols for sample collection and handling. This includes guidelines for extracting samples from specific locations within materials, as well as procedures for preserving the integrity of the samples during transportation and storage. Standardized sample preparation techniques, such as surface cleaning and degreasing, are also essential to minimize contamination and ensure accurate measurements.

Measurement techniques themselves must be standardized to allow for meaningful comparisons between different studies and laboratories. This involves specifying the exact equipment to be used, such as gas chromatographs or mass spectrometers, and detailing the operating parameters for these instruments. Calibration procedures using certified reference materials are also crucial to ensure the accuracy and traceability of measurements.

Data analysis and interpretation methods are another critical component of standardization. This includes establishing uniform calculation methods for determining hydrogen concentrations, as well as guidelines for assessing measurement uncertainties. Standardized reporting formats ensure that all relevant information, such as sample history and measurement conditions, is consistently documented.

Interlaboratory comparison studies play a vital role in validating and refining standardized procedures. These studies involve multiple laboratories performing measurements on identical samples, allowing for the assessment of reproducibility and the identification of potential sources of variability. The results of these studies can be used to further refine measurement protocols and improve overall accuracy.

International standards organizations, such as ISO and ASTM, play a crucial role in developing and maintaining standardized hydrogen measurement procedures. These organizations bring together experts from various fields to create consensus-based standards that are widely accepted and implemented across industries. Regular reviews and updates of these standards ensure that they remain relevant and incorporate the latest technological advancements.

Training and certification programs for laboratory personnel are essential for ensuring the proper implementation of standardized procedures. These programs provide technicians with the necessary skills and knowledge to perform measurements accurately and consistently, further enhancing the reliability of results across different laboratories and organizations.

One key aspect of standardization is the development of precise protocols for sample collection and handling. This includes guidelines for extracting samples from specific locations within materials, as well as procedures for preserving the integrity of the samples during transportation and storage. Standardized sample preparation techniques, such as surface cleaning and degreasing, are also essential to minimize contamination and ensure accurate measurements.

Measurement techniques themselves must be standardized to allow for meaningful comparisons between different studies and laboratories. This involves specifying the exact equipment to be used, such as gas chromatographs or mass spectrometers, and detailing the operating parameters for these instruments. Calibration procedures using certified reference materials are also crucial to ensure the accuracy and traceability of measurements.

Data analysis and interpretation methods are another critical component of standardization. This includes establishing uniform calculation methods for determining hydrogen concentrations, as well as guidelines for assessing measurement uncertainties. Standardized reporting formats ensure that all relevant information, such as sample history and measurement conditions, is consistently documented.

Interlaboratory comparison studies play a vital role in validating and refining standardized procedures. These studies involve multiple laboratories performing measurements on identical samples, allowing for the assessment of reproducibility and the identification of potential sources of variability. The results of these studies can be used to further refine measurement protocols and improve overall accuracy.

International standards organizations, such as ISO and ASTM, play a crucial role in developing and maintaining standardized hydrogen measurement procedures. These organizations bring together experts from various fields to create consensus-based standards that are widely accepted and implemented across industries. Regular reviews and updates of these standards ensure that they remain relevant and incorporate the latest technological advancements.

Training and certification programs for laboratory personnel are essential for ensuring the proper implementation of standardized procedures. These programs provide technicians with the necessary skills and knowledge to perform measurements accurately and consistently, further enhancing the reliability of results across different laboratories and organizations.

Correlation of Hydrogen Levels with Material Failures

The correlation between hydrogen levels and material failures is a critical aspect of failure analysis in various industries, particularly in metallurgy and materials science. Hydrogen embrittlement, a phenomenon where hydrogen atoms diffuse into a metal's crystal structure, can significantly compromise the material's mechanical properties, leading to unexpected failures. This correlation is particularly pronounced in high-strength steels, aluminum alloys, and titanium alloys.

Research has shown that even small amounts of hydrogen, measured in parts per million (ppm), can have detrimental effects on material integrity. The relationship between hydrogen concentration and material failure is often non-linear, with a threshold level above which the risk of failure increases dramatically. This threshold varies depending on the material composition, microstructure, and applied stress.

In steels, for instance, hydrogen levels as low as 1-5 ppm can initiate cracking in high-strength grades. The susceptibility to hydrogen-induced cracking generally increases with the material's tensile strength. For aluminum alloys, the critical hydrogen concentration is typically higher, but the effects can be equally severe, particularly in aerospace applications where safety margins are crucial.

The correlation extends beyond immediate failures to long-term degradation of material properties. Hydrogen can accumulate over time, leading to a gradual decrease in ductility and toughness. This time-dependent behavior complicates the analysis, as failures may occur long after the initial hydrogen exposure.

Environmental factors play a significant role in this correlation. Acidic or cathodic environments can promote hydrogen uptake, exacerbating the risk of failure. Temperature also influences the hydrogen-material interaction, with elevated temperatures generally accelerating diffusion and increasing the likelihood of failure.

Understanding this correlation is essential for developing effective mitigation strategies. These may include surface treatments to reduce hydrogen uptake, heat treatments to remove trapped hydrogen, or the use of hydrogen trapping elements in alloy design. The interpretation of hydrogen level measurements must consider these factors to accurately assess the risk of material failure and implement appropriate preventive measures.

Research has shown that even small amounts of hydrogen, measured in parts per million (ppm), can have detrimental effects on material integrity. The relationship between hydrogen concentration and material failure is often non-linear, with a threshold level above which the risk of failure increases dramatically. This threshold varies depending on the material composition, microstructure, and applied stress.

In steels, for instance, hydrogen levels as low as 1-5 ppm can initiate cracking in high-strength grades. The susceptibility to hydrogen-induced cracking generally increases with the material's tensile strength. For aluminum alloys, the critical hydrogen concentration is typically higher, but the effects can be equally severe, particularly in aerospace applications where safety margins are crucial.

The correlation extends beyond immediate failures to long-term degradation of material properties. Hydrogen can accumulate over time, leading to a gradual decrease in ductility and toughness. This time-dependent behavior complicates the analysis, as failures may occur long after the initial hydrogen exposure.

Environmental factors play a significant role in this correlation. Acidic or cathodic environments can promote hydrogen uptake, exacerbating the risk of failure. Temperature also influences the hydrogen-material interaction, with elevated temperatures generally accelerating diffusion and increasing the likelihood of failure.

Understanding this correlation is essential for developing effective mitigation strategies. These may include surface treatments to reduce hydrogen uptake, heat treatments to remove trapped hydrogen, or the use of hydrogen trapping elements in alloy design. The interpretation of hydrogen level measurements must consider these factors to accurately assess the risk of material failure and implement appropriate preventive measures.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!