How to Manage Manufacturing Process Emissions to Minimize H Uptake (process control)

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Emission Control Goals

The primary goal of emission control in manufacturing processes is to minimize the uptake of hydrogen (H) while maintaining operational efficiency and product quality. This objective is driven by both environmental concerns and the need to optimize resource utilization. Reducing H uptake is crucial for several reasons, including the prevention of material embrittlement, enhancement of product durability, and compliance with increasingly stringent environmental regulations.

To achieve these goals, a multi-faceted approach is necessary. First and foremost, manufacturers must focus on optimizing process parameters to minimize the generation of hydrogen-containing emissions at the source. This involves fine-tuning temperature, pressure, and chemical composition in various stages of the manufacturing process. By doing so, companies can significantly reduce the overall volume of emissions that require treatment or containment.

Another key objective is the implementation of advanced monitoring and control systems. Real-time monitoring of hydrogen levels in the manufacturing environment allows for immediate adjustments to process conditions, preventing sudden spikes in H concentration. This proactive approach not only helps in maintaining consistent product quality but also ensures that emission levels remain within acceptable limits throughout the production cycle.

Emission control goals also extend to the development and integration of cutting-edge filtration and capture technologies. These systems should be capable of efficiently trapping hydrogen-containing compounds before they can be released into the broader environment or absorbed by the manufactured products. The aim is to achieve a high capture efficiency while minimizing energy consumption and operational costs associated with emission control equipment.

Furthermore, the goals of emission control encompass the establishment of comprehensive waste management protocols. This includes the proper handling, storage, and disposal of hydrogen-rich byproducts and waste streams. By implementing closed-loop systems and recycling processes where possible, manufacturers can reduce the overall emission footprint and potentially recover valuable resources.

Lastly, a critical objective in managing manufacturing process emissions is to foster a culture of continuous improvement and innovation. This involves setting progressively ambitious targets for emission reduction, investing in research and development of novel emission control technologies, and actively participating in industry-wide initiatives to share best practices and advance collective knowledge in this field.

To achieve these goals, a multi-faceted approach is necessary. First and foremost, manufacturers must focus on optimizing process parameters to minimize the generation of hydrogen-containing emissions at the source. This involves fine-tuning temperature, pressure, and chemical composition in various stages of the manufacturing process. By doing so, companies can significantly reduce the overall volume of emissions that require treatment or containment.

Another key objective is the implementation of advanced monitoring and control systems. Real-time monitoring of hydrogen levels in the manufacturing environment allows for immediate adjustments to process conditions, preventing sudden spikes in H concentration. This proactive approach not only helps in maintaining consistent product quality but also ensures that emission levels remain within acceptable limits throughout the production cycle.

Emission control goals also extend to the development and integration of cutting-edge filtration and capture technologies. These systems should be capable of efficiently trapping hydrogen-containing compounds before they can be released into the broader environment or absorbed by the manufactured products. The aim is to achieve a high capture efficiency while minimizing energy consumption and operational costs associated with emission control equipment.

Furthermore, the goals of emission control encompass the establishment of comprehensive waste management protocols. This includes the proper handling, storage, and disposal of hydrogen-rich byproducts and waste streams. By implementing closed-loop systems and recycling processes where possible, manufacturers can reduce the overall emission footprint and potentially recover valuable resources.

Lastly, a critical objective in managing manufacturing process emissions is to foster a culture of continuous improvement and innovation. This involves setting progressively ambitious targets for emission reduction, investing in research and development of novel emission control technologies, and actively participating in industry-wide initiatives to share best practices and advance collective knowledge in this field.

Market Demand Analysis

The market demand for effective management of manufacturing process emissions to minimize hydrogen uptake is experiencing significant growth, driven by several key factors. Firstly, there is an increasing regulatory pressure on manufacturers to reduce their environmental impact and improve workplace safety. Stringent emission control regulations, particularly in developed countries, are forcing companies to invest in advanced process control technologies to comply with legal requirements and avoid potential fines or operational disruptions.

Secondly, the rising awareness of the detrimental effects of hydrogen uptake on material properties and product quality is fueling the demand for better emission management solutions. Industries such as steel manufacturing, semiconductor production, and chemical processing are particularly vulnerable to hydrogen embrittlement, which can lead to premature failure of components and increased maintenance costs. This has created a strong incentive for these sectors to adopt more sophisticated process control measures.

The automotive and aerospace industries are also significant drivers of market demand in this area. As these sectors increasingly utilize high-strength materials that are susceptible to hydrogen embrittlement, the need for effective emission management during manufacturing processes has become critical. This is especially true for the production of advanced alloys and composite materials used in lightweight vehicle structures and aircraft components.

Furthermore, the growing emphasis on sustainability and corporate social responsibility is pushing companies to seek innovative solutions for reducing their carbon footprint and improving overall process efficiency. Effective management of manufacturing emissions not only helps in minimizing hydrogen uptake but also contributes to energy conservation and waste reduction, aligning with broader sustainability goals.

The market for emission management solutions in manufacturing is also being influenced by the trend towards Industry 4.0 and smart manufacturing. There is an increasing demand for integrated process control systems that can monitor and manage emissions in real-time, utilizing advanced sensors, data analytics, and artificial intelligence to optimize manufacturing processes and prevent hydrogen uptake issues proactively.

Geographically, the demand is particularly strong in regions with a high concentration of manufacturing activities, such as East Asia, North America, and Western Europe. Emerging economies with rapidly growing industrial sectors are also showing increased interest in advanced emission management technologies as they seek to modernize their manufacturing capabilities and meet international standards.

In terms of market size, the global market for industrial emission control systems, which includes technologies for managing process emissions and minimizing hydrogen uptake, is projected to experience steady growth over the coming years. This growth is expected to be driven by a combination of regulatory compliance requirements, technological advancements, and the increasing recognition of the long-term economic benefits of effective emission management in manufacturing processes.

Secondly, the rising awareness of the detrimental effects of hydrogen uptake on material properties and product quality is fueling the demand for better emission management solutions. Industries such as steel manufacturing, semiconductor production, and chemical processing are particularly vulnerable to hydrogen embrittlement, which can lead to premature failure of components and increased maintenance costs. This has created a strong incentive for these sectors to adopt more sophisticated process control measures.

The automotive and aerospace industries are also significant drivers of market demand in this area. As these sectors increasingly utilize high-strength materials that are susceptible to hydrogen embrittlement, the need for effective emission management during manufacturing processes has become critical. This is especially true for the production of advanced alloys and composite materials used in lightweight vehicle structures and aircraft components.

Furthermore, the growing emphasis on sustainability and corporate social responsibility is pushing companies to seek innovative solutions for reducing their carbon footprint and improving overall process efficiency. Effective management of manufacturing emissions not only helps in minimizing hydrogen uptake but also contributes to energy conservation and waste reduction, aligning with broader sustainability goals.

The market for emission management solutions in manufacturing is also being influenced by the trend towards Industry 4.0 and smart manufacturing. There is an increasing demand for integrated process control systems that can monitor and manage emissions in real-time, utilizing advanced sensors, data analytics, and artificial intelligence to optimize manufacturing processes and prevent hydrogen uptake issues proactively.

Geographically, the demand is particularly strong in regions with a high concentration of manufacturing activities, such as East Asia, North America, and Western Europe. Emerging economies with rapidly growing industrial sectors are also showing increased interest in advanced emission management technologies as they seek to modernize their manufacturing capabilities and meet international standards.

In terms of market size, the global market for industrial emission control systems, which includes technologies for managing process emissions and minimizing hydrogen uptake, is projected to experience steady growth over the coming years. This growth is expected to be driven by a combination of regulatory compliance requirements, technological advancements, and the increasing recognition of the long-term economic benefits of effective emission management in manufacturing processes.

Current Challenges

Managing manufacturing process emissions to minimize hydrogen uptake presents several significant challenges in the current industrial landscape. One of the primary obstacles is the complexity of emission control systems in manufacturing processes. These systems often involve intricate networks of equipment, sensors, and control mechanisms, making it difficult to identify and isolate specific sources of hydrogen emissions.

The variability of manufacturing processes further complicates emission management. Different production lines, materials, and operating conditions can lead to fluctuations in hydrogen emissions, requiring adaptive control strategies that can respond to changing conditions in real-time. This variability also makes it challenging to establish standardized protocols for emission control across diverse manufacturing environments.

Another critical challenge is the limitations of existing monitoring technologies. While advancements have been made in emission detection and measurement, many current systems lack the sensitivity and specificity required to accurately quantify low-level hydrogen emissions. This gap in monitoring capabilities can lead to underestimation of hydrogen uptake and hinder the effectiveness of control measures.

The integration of emission control systems with existing manufacturing infrastructure poses additional challenges. Retrofitting older facilities with advanced emission management technologies can be costly and disruptive to ongoing operations. Moreover, ensuring compatibility between new control systems and legacy equipment often requires significant engineering efforts and may result in compromises in system performance.

Economic considerations also play a crucial role in the implementation of emission control strategies. The high costs associated with advanced emission management technologies can be prohibitive for many manufacturers, particularly small and medium-sized enterprises. Balancing the need for effective emission control with financial constraints remains a significant challenge for the industry.

Regulatory compliance adds another layer of complexity to emission management. Evolving environmental regulations and standards require manufacturers to continuously adapt their emission control strategies. The lack of harmonized global standards for hydrogen emissions in manufacturing processes further complicates compliance efforts for multinational corporations.

Lastly, the shortage of skilled personnel with expertise in both manufacturing processes and advanced emission control technologies presents a human resource challenge. Training and retaining qualified staff to operate and maintain sophisticated emission management systems is crucial for long-term success but remains difficult in many regions.

Addressing these challenges requires a multifaceted approach that combines technological innovation, process optimization, and strategic investments in emission control infrastructure. As the manufacturing industry continues to evolve, overcoming these obstacles will be essential for minimizing hydrogen uptake and improving overall environmental performance.

The variability of manufacturing processes further complicates emission management. Different production lines, materials, and operating conditions can lead to fluctuations in hydrogen emissions, requiring adaptive control strategies that can respond to changing conditions in real-time. This variability also makes it challenging to establish standardized protocols for emission control across diverse manufacturing environments.

Another critical challenge is the limitations of existing monitoring technologies. While advancements have been made in emission detection and measurement, many current systems lack the sensitivity and specificity required to accurately quantify low-level hydrogen emissions. This gap in monitoring capabilities can lead to underestimation of hydrogen uptake and hinder the effectiveness of control measures.

The integration of emission control systems with existing manufacturing infrastructure poses additional challenges. Retrofitting older facilities with advanced emission management technologies can be costly and disruptive to ongoing operations. Moreover, ensuring compatibility between new control systems and legacy equipment often requires significant engineering efforts and may result in compromises in system performance.

Economic considerations also play a crucial role in the implementation of emission control strategies. The high costs associated with advanced emission management technologies can be prohibitive for many manufacturers, particularly small and medium-sized enterprises. Balancing the need for effective emission control with financial constraints remains a significant challenge for the industry.

Regulatory compliance adds another layer of complexity to emission management. Evolving environmental regulations and standards require manufacturers to continuously adapt their emission control strategies. The lack of harmonized global standards for hydrogen emissions in manufacturing processes further complicates compliance efforts for multinational corporations.

Lastly, the shortage of skilled personnel with expertise in both manufacturing processes and advanced emission control technologies presents a human resource challenge. Training and retaining qualified staff to operate and maintain sophisticated emission management systems is crucial for long-term success but remains difficult in many regions.

Addressing these challenges requires a multifaceted approach that combines technological innovation, process optimization, and strategic investments in emission control infrastructure. As the manufacturing industry continues to evolve, overcoming these obstacles will be essential for minimizing hydrogen uptake and improving overall environmental performance.

Existing Control Methods

01 Hydrogen uptake in manufacturing processes

Various manufacturing processes involve the uptake of hydrogen, which can be used to reduce emissions or as a reactant. These processes may include metal production, chemical synthesis, or fuel cell applications. Optimizing hydrogen uptake can lead to more efficient and environmentally friendly manufacturing processes.- Hydrogen uptake in manufacturing processes: Various manufacturing processes involve the uptake of hydrogen, which can be used to reduce emissions or as a reactant. These processes may include metal production, chemical synthesis, or fuel cell applications. Optimizing hydrogen uptake can lead to more efficient and environmentally friendly manufacturing methods.

- Emission control systems in industrial processes: Industrial processes often require sophisticated emission control systems to manage and reduce harmful outputs. These systems may incorporate technologies such as scrubbers, filters, or catalytic converters to capture or convert emissions. Advancements in these systems aim to improve efficiency and minimize environmental impact.

- Innovative manufacturing techniques for reduced emissions: New manufacturing techniques are being developed to inherently reduce emissions during production processes. These may include novel reactor designs, process intensification methods, or the use of alternative raw materials. Such innovations aim to minimize the generation of pollutants at the source rather than relying solely on end-of-pipe treatments.

- Integration of hydrogen in sustainable manufacturing: Hydrogen is increasingly being integrated into manufacturing processes as a clean energy carrier or reactant. This integration can lead to reduced carbon emissions and improved energy efficiency. Applications may include using hydrogen in steel production, ammonia synthesis, or as a fuel in high-temperature industrial processes.

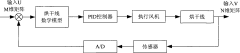

- Monitoring and optimization of emission uptake: Advanced monitoring systems and optimization techniques are being employed to enhance the uptake of emissions, including hydrogen, in manufacturing processes. These may involve real-time sensors, data analytics, and machine learning algorithms to fine-tune process parameters and maximize emission capture or utilization efficiency.

02 Emission reduction techniques in industrial processes

Manufacturing processes often generate emissions that need to be controlled or reduced. Techniques such as scrubbing, filtration, and catalytic conversion can be employed to minimize harmful emissions. These methods may involve the use of specialized equipment or chemical reactions to capture or transform pollutants.Expand Specific Solutions03 Hydrogen production and purification methods

Efficient production and purification of hydrogen are crucial for its use in manufacturing processes. Methods may include steam reforming, electrolysis, or biological processes. Purification techniques such as pressure swing adsorption or membrane separation can be used to obtain high-purity hydrogen for industrial applications.Expand Specific Solutions04 Integration of hydrogen in existing manufacturing systems

Incorporating hydrogen into existing manufacturing processes can help reduce emissions and improve efficiency. This may involve modifying equipment, developing new reaction pathways, or creating hybrid systems that combine conventional and hydrogen-based technologies. Careful integration is necessary to ensure compatibility and safety.Expand Specific Solutions05 Monitoring and control systems for hydrogen uptake

Advanced monitoring and control systems are essential for optimizing hydrogen uptake in manufacturing processes. These systems may include sensors, data analytics, and automated control mechanisms to ensure efficient hydrogen utilization, maintain safety, and minimize emissions. Real-time monitoring can help identify issues and optimize process parameters.Expand Specific Solutions

Key Industry Players

The management of manufacturing process emissions to minimize H uptake is a critical technological challenge in the advanced manufacturing sector. This field is currently in a growth phase, with increasing market demand driven by environmental regulations and sustainability initiatives. The global market for emission control technologies is expanding, with projections indicating significant growth in the coming years. Technologically, the field is moderately mature, with established players like Air Products & Chemicals, Dow Global Technologies, and Air Liquide leading innovation. However, there's room for advancement, particularly in process control optimization. Emerging companies like LanzaTech are introducing novel approaches, while industrial giants such as Toyota and Honeywell are integrating these technologies into their manufacturing processes, indicating a competitive and dynamic landscape.

Air Products & Chemicals, Inc.

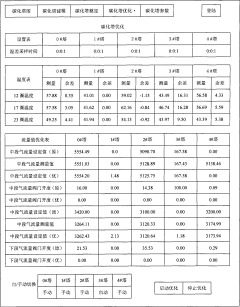

Technical Solution: Air Products & Chemicals has developed advanced process control systems for managing manufacturing process emissions to minimize H uptake. Their approach involves real-time monitoring and adjustment of process parameters using AI-driven algorithms. The system continuously analyzes data from multiple sensors throughout the manufacturing process, including temperature, pressure, and gas composition sensors. It then makes precise adjustments to optimize the process conditions, reducing the formation of hydrogen-containing byproducts and minimizing H uptake [1][3]. The company has also implemented a novel catalytic converter technology that can effectively remove hydrogen from exhaust gases, further reducing the risk of H uptake in downstream processes [2].

Strengths: Comprehensive real-time monitoring and control, AI-driven optimization, and effective hydrogen removal technology. Weaknesses: May require significant initial investment and ongoing maintenance of complex sensor networks.

Dow Global Technologies LLC

Technical Solution: Dow Global Technologies has developed a multi-faceted approach to manage manufacturing process emissions and minimize H uptake. Their strategy includes advanced materials selection, process intensification, and innovative emission control technologies. They have introduced a new class of hydrogen-resistant polymers for use in critical components, reducing the risk of H embrittlement [4]. Additionally, Dow has implemented a closed-loop recycling system that captures and purifies hydrogen-containing waste streams, allowing for the recovery and reuse of valuable materials while minimizing emissions [5]. The company has also developed a novel membrane technology that selectively removes hydrogen from process gases, significantly reducing the potential for H uptake in downstream operations [6].

Strengths: Comprehensive approach addressing materials, process design, and emission control; potential for material recovery and reuse. Weaknesses: May require significant changes to existing manufacturing processes and equipment.

Innovative Technologies

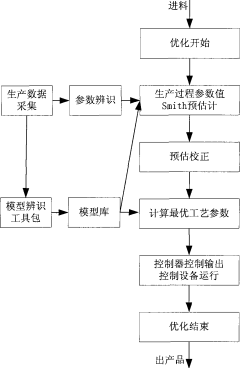

Energy-saving consumption reduction oriented process efficiency optimization control method and use thereof

PatentInactiveCN101477367A

Innovation

- By analyzing the production process mechanism of the process industry, we establish a mathematical model for energy saving and consumption reduction, collect production data in real time, use the model identification toolkit to perform energy efficiency optimization calculations, and control the production process through the controller output to achieve optimal energy efficiency. and product quality optimization.

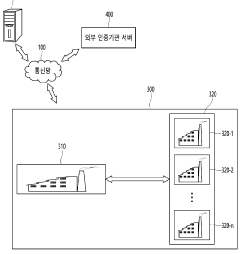

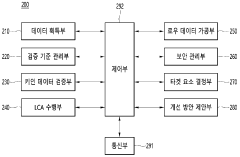

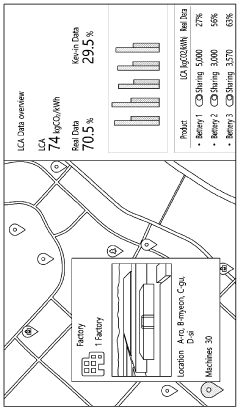

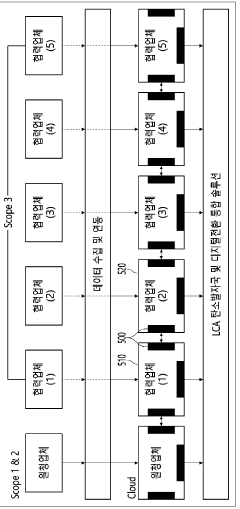

Method and system for managing manufacturing process to reduce carbon emissions

PatentWO2024123115A1

Innovation

- A system and method for establishing verification criteria for key-in data on carbon emissions, processing raw data to generate reliable LCA data, and blocking raw data from being shared outside a security scope, while allowing only LCA data to be shared, to facilitate smooth data collection and management across the manufacturing process.

Environmental Regulations

Environmental regulations play a crucial role in managing manufacturing process emissions to minimize hydrogen uptake. These regulations are designed to protect public health, environmental quality, and worker safety by setting limits on emissions and mandating control measures. In the context of hydrogen uptake, regulatory frameworks often focus on reducing the release of hydrogen-containing compounds and improving process control to prevent unintended hydrogen absorption.

Many countries have established comprehensive environmental regulations that address industrial emissions. In the United States, the Environmental Protection Agency (EPA) enforces the Clean Air Act, which sets National Ambient Air Quality Standards (NAAQS) for six criteria pollutants, including particulate matter and ozone. These standards indirectly impact hydrogen-related emissions by regulating precursor pollutants. The EPA also implements the New Source Performance Standards (NSPS) and National Emission Standards for Hazardous Air Pollutants (NESHAP), which may apply to processes involving hydrogen.

The European Union has implemented the Industrial Emissions Directive (IED), which requires industrial facilities to operate under an integrated permit based on Best Available Techniques (BAT). This directive encourages the adoption of advanced process control systems and emission reduction technologies, which can help minimize hydrogen uptake in manufacturing processes. Additionally, the EU's Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) regulation may impact the use and handling of hydrogen-containing substances in industrial processes.

In Asia, countries like China and Japan have also strengthened their environmental regulations. China's Air Pollution Prevention and Control Law and Japan's Air Pollution Control Act both set emission standards and require the implementation of pollution control measures in industrial facilities. These regulations often necessitate the use of advanced monitoring systems and process control technologies to ensure compliance.

Compliance with these regulations often requires manufacturers to implement robust emission monitoring and control systems. This may include continuous emission monitoring systems (CEMS), leak detection and repair (LDAR) programs, and advanced process control strategies. Such measures not only help in meeting regulatory requirements but also contribute to minimizing hydrogen uptake by improving overall process efficiency and reducing fugitive emissions.

Furthermore, many regulatory frameworks are evolving to incorporate more stringent standards and innovative approaches to emission control. This includes the development of performance-based standards, which focus on achieving specific environmental outcomes rather than prescribing particular technologies. Such approaches can encourage innovation in process control and emission reduction strategies, potentially leading to more effective methods for managing hydrogen uptake in manufacturing processes.

Many countries have established comprehensive environmental regulations that address industrial emissions. In the United States, the Environmental Protection Agency (EPA) enforces the Clean Air Act, which sets National Ambient Air Quality Standards (NAAQS) for six criteria pollutants, including particulate matter and ozone. These standards indirectly impact hydrogen-related emissions by regulating precursor pollutants. The EPA also implements the New Source Performance Standards (NSPS) and National Emission Standards for Hazardous Air Pollutants (NESHAP), which may apply to processes involving hydrogen.

The European Union has implemented the Industrial Emissions Directive (IED), which requires industrial facilities to operate under an integrated permit based on Best Available Techniques (BAT). This directive encourages the adoption of advanced process control systems and emission reduction technologies, which can help minimize hydrogen uptake in manufacturing processes. Additionally, the EU's Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) regulation may impact the use and handling of hydrogen-containing substances in industrial processes.

In Asia, countries like China and Japan have also strengthened their environmental regulations. China's Air Pollution Prevention and Control Law and Japan's Air Pollution Control Act both set emission standards and require the implementation of pollution control measures in industrial facilities. These regulations often necessitate the use of advanced monitoring systems and process control technologies to ensure compliance.

Compliance with these regulations often requires manufacturers to implement robust emission monitoring and control systems. This may include continuous emission monitoring systems (CEMS), leak detection and repair (LDAR) programs, and advanced process control strategies. Such measures not only help in meeting regulatory requirements but also contribute to minimizing hydrogen uptake by improving overall process efficiency and reducing fugitive emissions.

Furthermore, many regulatory frameworks are evolving to incorporate more stringent standards and innovative approaches to emission control. This includes the development of performance-based standards, which focus on achieving specific environmental outcomes rather than prescribing particular technologies. Such approaches can encourage innovation in process control and emission reduction strategies, potentially leading to more effective methods for managing hydrogen uptake in manufacturing processes.

Economic Impact Analysis

The economic impact of managing manufacturing process emissions to minimize H uptake extends far beyond the immediate production environment. Effective process control measures can lead to significant cost savings and improved operational efficiency for manufacturers. By reducing H uptake, companies can extend the lifespan of equipment and materials, thereby decreasing maintenance and replacement costs. This, in turn, can result in substantial long-term savings on capital expenditures.

Furthermore, minimizing emissions through advanced process control techniques can lead to reduced energy consumption and improved resource utilization. This not only lowers operational costs but also aligns with increasingly stringent environmental regulations, potentially avoiding hefty fines and penalties. The implementation of such control measures may require initial investments in technology and training, but the return on investment is often realized through enhanced productivity and reduced waste.

From a broader economic perspective, industries that successfully manage their emissions and minimize H uptake are likely to gain a competitive edge in the global market. This can translate into increased market share, higher revenues, and potentially job creation. Moreover, as consumers become more environmentally conscious, companies demonstrating responsible emission management may benefit from improved brand reputation and customer loyalty.

The ripple effects of effective emission management extend to related industries as well. Suppliers of emission control technologies and services may experience growth, fostering innovation and creating new economic opportunities. Additionally, the development and implementation of advanced process control systems can stimulate research and development activities, potentially leading to technological breakthroughs with wider applications across various sectors.

On a macroeconomic level, widespread adoption of efficient emission management practices can contribute to overall industrial sustainability and economic resilience. By reducing the environmental impact of manufacturing processes, industries can mitigate potential future costs associated with climate change and environmental degradation. This proactive approach can help safeguard long-term economic stability and growth, particularly in regions heavily dependent on manufacturing sectors.

Furthermore, minimizing emissions through advanced process control techniques can lead to reduced energy consumption and improved resource utilization. This not only lowers operational costs but also aligns with increasingly stringent environmental regulations, potentially avoiding hefty fines and penalties. The implementation of such control measures may require initial investments in technology and training, but the return on investment is often realized through enhanced productivity and reduced waste.

From a broader economic perspective, industries that successfully manage their emissions and minimize H uptake are likely to gain a competitive edge in the global market. This can translate into increased market share, higher revenues, and potentially job creation. Moreover, as consumers become more environmentally conscious, companies demonstrating responsible emission management may benefit from improved brand reputation and customer loyalty.

The ripple effects of effective emission management extend to related industries as well. Suppliers of emission control technologies and services may experience growth, fostering innovation and creating new economic opportunities. Additionally, the development and implementation of advanced process control systems can stimulate research and development activities, potentially leading to technological breakthroughs with wider applications across various sectors.

On a macroeconomic level, widespread adoption of efficient emission management practices can contribute to overall industrial sustainability and economic resilience. By reducing the environmental impact of manufacturing processes, industries can mitigate potential future costs associated with climate change and environmental degradation. This proactive approach can help safeguard long-term economic stability and growth, particularly in regions heavily dependent on manufacturing sectors.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!