Hydrogen Embrittlement in Welds: Preheat/Postheat, Filler Selection and Inspection Protocols

AUG 21, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogen Embrittlement Background and Objectives

Hydrogen embrittlement (HE) has been a significant concern in the welding industry for decades, posing substantial challenges to the integrity and longevity of welded structures. This phenomenon occurs when atomic hydrogen diffuses into metal, causing a reduction in ductility and load-bearing capacity, ultimately leading to premature failure. The issue is particularly critical in high-strength steels and other susceptible materials widely used in various industrial applications.

The evolution of welding technologies and materials has brought about new challenges in managing hydrogen embrittlement. As industries push for stronger, lighter, and more durable materials, the risk of hydrogen-induced cracking has become more pronounced. This has necessitated a comprehensive approach to understanding and mitigating the effects of hydrogen embrittlement in welds.

The primary objective of this research is to investigate and develop advanced strategies for preventing and managing hydrogen embrittlement in welded joints. Specifically, the study aims to explore the effectiveness of preheat and postheat treatments, optimize filler material selection, and establish robust inspection protocols to ensure weld integrity and longevity.

Preheat and postheat treatments have long been recognized as crucial steps in controlling hydrogen content in welds. However, the optimal parameters for these treatments vary significantly depending on the base material, welding process, and environmental conditions. This research seeks to refine and standardize these heat treatment processes across a range of materials and welding scenarios.

The selection of appropriate filler materials plays a vital role in mitigating hydrogen embrittlement. The study aims to evaluate various filler metal compositions and their impact on hydrogen uptake and diffusion in the weld zone. By identifying optimal filler materials for different base metals and welding conditions, the research intends to provide practical guidelines for welding engineers and technicians.

Inspection protocols form the final line of defense against hydrogen-induced failures. The research objectives include developing and validating advanced non-destructive testing methods capable of detecting hydrogen-related defects at early stages. This encompasses the exploration of novel techniques such as acoustic emission testing, advanced ultrasonic methods, and electrochemical hydrogen detection systems.

By addressing these key aspects of hydrogen embrittlement in welds, the research aims to contribute significantly to the body of knowledge in welding metallurgy and to provide practical solutions for industry applications. The outcomes of this study are expected to enhance the reliability and safety of welded structures across various sectors, including aerospace, automotive, and energy industries.

The evolution of welding technologies and materials has brought about new challenges in managing hydrogen embrittlement. As industries push for stronger, lighter, and more durable materials, the risk of hydrogen-induced cracking has become more pronounced. This has necessitated a comprehensive approach to understanding and mitigating the effects of hydrogen embrittlement in welds.

The primary objective of this research is to investigate and develop advanced strategies for preventing and managing hydrogen embrittlement in welded joints. Specifically, the study aims to explore the effectiveness of preheat and postheat treatments, optimize filler material selection, and establish robust inspection protocols to ensure weld integrity and longevity.

Preheat and postheat treatments have long been recognized as crucial steps in controlling hydrogen content in welds. However, the optimal parameters for these treatments vary significantly depending on the base material, welding process, and environmental conditions. This research seeks to refine and standardize these heat treatment processes across a range of materials and welding scenarios.

The selection of appropriate filler materials plays a vital role in mitigating hydrogen embrittlement. The study aims to evaluate various filler metal compositions and their impact on hydrogen uptake and diffusion in the weld zone. By identifying optimal filler materials for different base metals and welding conditions, the research intends to provide practical guidelines for welding engineers and technicians.

Inspection protocols form the final line of defense against hydrogen-induced failures. The research objectives include developing and validating advanced non-destructive testing methods capable of detecting hydrogen-related defects at early stages. This encompasses the exploration of novel techniques such as acoustic emission testing, advanced ultrasonic methods, and electrochemical hydrogen detection systems.

By addressing these key aspects of hydrogen embrittlement in welds, the research aims to contribute significantly to the body of knowledge in welding metallurgy and to provide practical solutions for industry applications. The outcomes of this study are expected to enhance the reliability and safety of welded structures across various sectors, including aerospace, automotive, and energy industries.

Market Demand for Improved Weld Integrity

The market demand for improved weld integrity, particularly in relation to hydrogen embrittlement, has been steadily increasing across various industries. This growth is primarily driven by the expanding use of high-strength steels in critical applications, where weld failures can lead to catastrophic consequences. Industries such as oil and gas, aerospace, automotive, and construction are particularly concerned with the risks associated with hydrogen embrittlement in welds.

In the oil and gas sector, the push for deeper offshore drilling and exploration in harsh environments has intensified the need for welds that can withstand extreme pressures and corrosive conditions. The integrity of pipelines, pressure vessels, and offshore structures heavily relies on the quality of welds, making hydrogen embrittlement a critical concern. The market for advanced welding technologies and inspection protocols in this sector is expected to grow significantly in the coming years.

The aerospace industry, with its stringent safety requirements, is another major driver of demand for improved weld integrity. As aircraft manufacturers continue to incorporate advanced materials to reduce weight and improve fuel efficiency, the complexity of welding processes increases. This has led to a growing market for specialized welding techniques and filler materials that can mitigate the risk of hydrogen embrittlement in critical components.

In the automotive sector, the shift towards lightweight materials and electric vehicles has created new challenges in welding. The use of high-strength steels and aluminum alloys in vehicle structures requires advanced welding techniques to ensure structural integrity while minimizing the risk of hydrogen embrittlement. This trend is expected to drive significant investment in research and development of new welding technologies and inspection methods.

The construction industry, particularly in the development of high-rise buildings and large-scale infrastructure projects, is also contributing to the demand for improved weld integrity. As structures become taller and more complex, the consequences of weld failures become more severe. This has led to increased focus on welding quality control and the adoption of advanced inspection protocols to detect potential hydrogen embrittlement issues.

The market for preheat and postheat treatments in welding processes is experiencing growth as industries recognize their importance in reducing the risk of hydrogen embrittlement. Similarly, there is a rising demand for advanced filler materials designed to minimize hydrogen uptake during welding. These trends are driving innovation in welding consumables and equipment manufacturing sectors.

The development of more sophisticated non-destructive testing (NDT) methods for weld inspection is another area of significant market growth. Advanced techniques such as phased array ultrasonic testing and digital radiography are gaining traction as industries seek more reliable ways to detect potential hydrogen embrittlement issues in welds.

Overall, the market demand for improved weld integrity, particularly in addressing hydrogen embrittlement, is expected to continue its upward trajectory. This growth is fueled by the increasing complexity of materials and structures across industries, coupled with a heightened awareness of the potential risks associated with weld failures. As a result, there is a substantial opportunity for companies that can provide innovative solutions to enhance weld integrity and mitigate the effects of hydrogen embrittlement.

In the oil and gas sector, the push for deeper offshore drilling and exploration in harsh environments has intensified the need for welds that can withstand extreme pressures and corrosive conditions. The integrity of pipelines, pressure vessels, and offshore structures heavily relies on the quality of welds, making hydrogen embrittlement a critical concern. The market for advanced welding technologies and inspection protocols in this sector is expected to grow significantly in the coming years.

The aerospace industry, with its stringent safety requirements, is another major driver of demand for improved weld integrity. As aircraft manufacturers continue to incorporate advanced materials to reduce weight and improve fuel efficiency, the complexity of welding processes increases. This has led to a growing market for specialized welding techniques and filler materials that can mitigate the risk of hydrogen embrittlement in critical components.

In the automotive sector, the shift towards lightweight materials and electric vehicles has created new challenges in welding. The use of high-strength steels and aluminum alloys in vehicle structures requires advanced welding techniques to ensure structural integrity while minimizing the risk of hydrogen embrittlement. This trend is expected to drive significant investment in research and development of new welding technologies and inspection methods.

The construction industry, particularly in the development of high-rise buildings and large-scale infrastructure projects, is also contributing to the demand for improved weld integrity. As structures become taller and more complex, the consequences of weld failures become more severe. This has led to increased focus on welding quality control and the adoption of advanced inspection protocols to detect potential hydrogen embrittlement issues.

The market for preheat and postheat treatments in welding processes is experiencing growth as industries recognize their importance in reducing the risk of hydrogen embrittlement. Similarly, there is a rising demand for advanced filler materials designed to minimize hydrogen uptake during welding. These trends are driving innovation in welding consumables and equipment manufacturing sectors.

The development of more sophisticated non-destructive testing (NDT) methods for weld inspection is another area of significant market growth. Advanced techniques such as phased array ultrasonic testing and digital radiography are gaining traction as industries seek more reliable ways to detect potential hydrogen embrittlement issues in welds.

Overall, the market demand for improved weld integrity, particularly in addressing hydrogen embrittlement, is expected to continue its upward trajectory. This growth is fueled by the increasing complexity of materials and structures across industries, coupled with a heightened awareness of the potential risks associated with weld failures. As a result, there is a substantial opportunity for companies that can provide innovative solutions to enhance weld integrity and mitigate the effects of hydrogen embrittlement.

Current Challenges in Hydrogen Embrittlement Prevention

Hydrogen embrittlement in welds remains a significant challenge in the field of materials science and engineering. Despite decades of research and advancements in welding technologies, the prevention and mitigation of hydrogen-induced cracking continue to pose substantial difficulties for manufacturers and engineers across various industries.

One of the primary challenges lies in the complex interplay between hydrogen, microstructure, and stress in welded joints. The presence of hydrogen, even in small quantities, can lead to catastrophic failures in high-strength steels and other susceptible materials. The difficulty in accurately predicting and controlling hydrogen uptake during welding processes further complicates prevention efforts.

The optimization of preheat and postheat treatments presents another significant challenge. While these thermal treatments are known to be effective in reducing hydrogen content and mitigating embrittlement risks, determining the optimal temperature and duration for specific materials and welding conditions remains a complex task. Balancing the need for hydrogen removal with the potential for undesirable microstructural changes adds to the complexity of this challenge.

Filler material selection also poses ongoing difficulties in hydrogen embrittlement prevention. The development of low-hydrogen consumables has made significant progress, but ensuring compatibility with base materials while maintaining desired mechanical properties and corrosion resistance is an ongoing challenge. Additionally, the behavior of these fillers under various welding conditions and their long-term performance in service environments require further investigation.

Inspection protocols for hydrogen embrittlement detection present another set of challenges. Current non-destructive testing methods often lack the sensitivity to detect early-stage hydrogen damage or to accurately predict the risk of future embrittlement. The development of more reliable and efficient inspection techniques, particularly for in-service components, remains a critical area of research.

The increasing use of high-strength materials in various applications, driven by the demand for lightweight and high-performance structures, further exacerbates the challenges of hydrogen embrittlement prevention. These materials often exhibit greater susceptibility to hydrogen-induced damage, necessitating more stringent control measures and innovative prevention strategies.

Lastly, the lack of standardized testing methods and acceptance criteria for hydrogen embrittlement resistance across different industries and applications poses a significant challenge. This absence of uniformity hampers the development of universally applicable prevention strategies and complicates the comparison of different materials and welding techniques.

One of the primary challenges lies in the complex interplay between hydrogen, microstructure, and stress in welded joints. The presence of hydrogen, even in small quantities, can lead to catastrophic failures in high-strength steels and other susceptible materials. The difficulty in accurately predicting and controlling hydrogen uptake during welding processes further complicates prevention efforts.

The optimization of preheat and postheat treatments presents another significant challenge. While these thermal treatments are known to be effective in reducing hydrogen content and mitigating embrittlement risks, determining the optimal temperature and duration for specific materials and welding conditions remains a complex task. Balancing the need for hydrogen removal with the potential for undesirable microstructural changes adds to the complexity of this challenge.

Filler material selection also poses ongoing difficulties in hydrogen embrittlement prevention. The development of low-hydrogen consumables has made significant progress, but ensuring compatibility with base materials while maintaining desired mechanical properties and corrosion resistance is an ongoing challenge. Additionally, the behavior of these fillers under various welding conditions and their long-term performance in service environments require further investigation.

Inspection protocols for hydrogen embrittlement detection present another set of challenges. Current non-destructive testing methods often lack the sensitivity to detect early-stage hydrogen damage or to accurately predict the risk of future embrittlement. The development of more reliable and efficient inspection techniques, particularly for in-service components, remains a critical area of research.

The increasing use of high-strength materials in various applications, driven by the demand for lightweight and high-performance structures, further exacerbates the challenges of hydrogen embrittlement prevention. These materials often exhibit greater susceptibility to hydrogen-induced damage, necessitating more stringent control measures and innovative prevention strategies.

Lastly, the lack of standardized testing methods and acceptance criteria for hydrogen embrittlement resistance across different industries and applications poses a significant challenge. This absence of uniformity hampers the development of universally applicable prevention strategies and complicates the comparison of different materials and welding techniques.

Existing Solutions for Hydrogen Embrittlement Mitigation

01 Welding techniques to reduce hydrogen embrittlement

Various welding techniques can be employed to minimize hydrogen embrittlement in welds. These include using low-hydrogen electrodes, controlling heat input, and implementing proper pre-heating and post-weld heat treatment procedures. Such techniques help reduce hydrogen absorption and diffusion in the weld metal and heat-affected zone, thereby decreasing the risk of embrittlement.- Welding techniques to reduce hydrogen embrittlement: Various welding techniques can be employed to minimize hydrogen embrittlement in welds. These include using low-hydrogen electrodes, controlling heat input, and implementing proper pre-heating and post-weld heat treatment procedures. Such techniques help reduce hydrogen absorption and diffusion in the weld metal and heat-affected zone, thereby decreasing the risk of embrittlement.

- Material selection for hydrogen embrittlement resistance: Choosing appropriate materials with inherent resistance to hydrogen embrittlement is crucial for welding applications in hydrogen-rich environments. This includes selecting specific alloy compositions, such as austenitic stainless steels or nickel-based alloys, which are less susceptible to hydrogen-induced cracking. The proper material selection can significantly enhance the overall resistance of the welded structure to hydrogen embrittlement.

- Surface treatments to mitigate hydrogen embrittlement: Various surface treatments can be applied to welded joints to reduce the risk of hydrogen embrittlement. These treatments may include shot peening, laser peening, or the application of protective coatings. Such methods can create compressive stresses on the surface, modify the microstructure, or provide a barrier against hydrogen ingress, thereby enhancing the resistance to hydrogen-induced cracking.

- Monitoring and detection of hydrogen embrittlement in welds: Advanced monitoring and detection techniques are essential for identifying and preventing hydrogen embrittlement in welded structures. These may include non-destructive testing methods, such as ultrasonic testing or acoustic emission monitoring, as well as the use of hydrogen sensors. Early detection of hydrogen-induced defects can help prevent catastrophic failures and guide maintenance strategies.

- Post-weld treatments for hydrogen removal: Various post-weld treatments can be employed to remove hydrogen from the weld and surrounding areas, reducing the risk of embrittlement. These treatments may include baking at elevated temperatures, vacuum degassing, or the application of electrolytic hydrogen removal techniques. Such methods aim to extract hydrogen from the material before it can cause damage, thereby improving the long-term integrity of the welded structure.

02 Material selection for hydrogen embrittlement resistance

Choosing appropriate materials with inherent resistance to hydrogen embrittlement is crucial for welding applications in hydrogen-rich environments. This includes selecting specific alloy compositions, such as austenitic stainless steels or nickel-based alloys, which are less susceptible to hydrogen-induced cracking. The proper material selection can significantly enhance the overall resistance of the welded structure to hydrogen embrittlement.Expand Specific Solutions03 Surface treatments to mitigate hydrogen embrittlement

Various surface treatments can be applied to welded joints to reduce the risk of hydrogen embrittlement. These treatments may include shot peening, laser peening, or the application of protective coatings. Such methods can create compressive stresses on the surface, modify the microstructure, or provide a barrier against hydrogen ingress, thereby enhancing the resistance to hydrogen-induced cracking in welded components.Expand Specific Solutions04 Monitoring and detection of hydrogen embrittlement in welds

Advanced monitoring and detection techniques are essential for identifying and preventing hydrogen embrittlement in welded structures. These may include non-destructive testing methods, such as ultrasonic testing or acoustic emission monitoring, as well as in-situ hydrogen sensing technologies. Early detection of hydrogen-induced defects can help prevent catastrophic failures and guide maintenance strategies for welded components in hydrogen-rich environments.Expand Specific Solutions05 Post-weld treatments for hydrogen removal

Various post-weld treatments can be employed to remove hydrogen from the weld metal and heat-affected zone, reducing the risk of embrittlement. These treatments may include baking at elevated temperatures, vacuum degassing, or electrolytic hydrogen removal. By effectively removing hydrogen from the welded joint, these methods can significantly improve the mechanical properties and long-term reliability of the welded structure in hydrogen-rich environments.Expand Specific Solutions

Key Players in Welding Industry and Research

The research on hydrogen embrittlement in welds is currently in a mature development stage, with significant market potential due to its critical importance in various industries, particularly in oil and gas, aerospace, and automotive sectors. The global market for welding technologies and materials is substantial, with key players like Illinois Tool Works Inc., NIPPON STEEL CORP., and Lincoln Global, Inc. leading innovation efforts. These companies, along with others such as Kobe Steel, Ltd. and ArcelorMittal SA, are investing heavily in R&D to address challenges related to hydrogen embrittlement. The technology's maturity is evident in the advanced solutions offered by industry leaders, focusing on optimizing preheat/postheat treatments, filler material selection, and developing sophisticated inspection protocols to mitigate hydrogen-induced cracking risks in welded structures.

NIPPON STEEL CORP.

Technical Solution: NIPPON STEEL CORP. has developed advanced techniques for mitigating hydrogen embrittlement in welds. Their approach includes optimized preheat and postheat treatments, tailored to specific steel grades and welding processes. They have introduced a novel filler material with controlled diffusible hydrogen content, reducing the risk of embrittlement[1]. Their inspection protocols involve advanced non-destructive testing methods, including phased array ultrasonic testing and hydrogen detection sensors, to ensure weld integrity[2]. The company has also implemented machine learning algorithms to predict and prevent hydrogen-induced cracking based on welding parameters and environmental conditions[3].

Strengths: Comprehensive approach addressing multiple aspects of hydrogen embrittlement; advanced inspection technologies. Weaknesses: Potentially higher costs due to specialized materials and processes; may require additional training for welders and inspectors.

Lincoln Global, Inc.

Technical Solution: Lincoln Global, Inc. has developed a multi-faceted approach to combat hydrogen embrittlement in welds. Their strategy includes the use of low-hydrogen electrodes and flux-cored wires specifically designed to minimize hydrogen introduction during welding[4]. They have also implemented advanced preheat and postheat protocols that are tailored to the specific alloy composition and welding process. Their proprietary "HydroCure" postheat treatment has shown to reduce diffusible hydrogen content by up to 80% in high-strength steels[5]. Lincoln's inspection protocols incorporate both traditional methods and innovative techniques such as real-time hydrogen monitoring during welding and post-weld hydrogen analysis using gas chromatography[6].

Strengths: Comprehensive solution covering filler material, heat treatments, and inspection; proven effectiveness in reducing hydrogen content. Weaknesses: May require significant changes to existing welding procedures; potential for increased production time due to additional treatments.

Core Innovations in Preheat/Postheat Techniques

Flux binder system

PatentInactiveEP1468778A2

Innovation

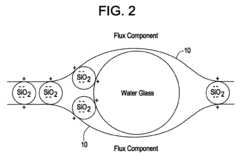

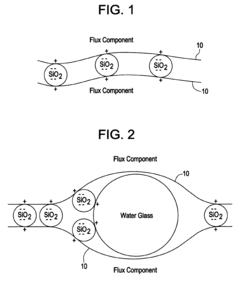

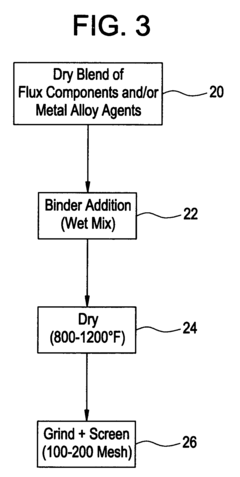

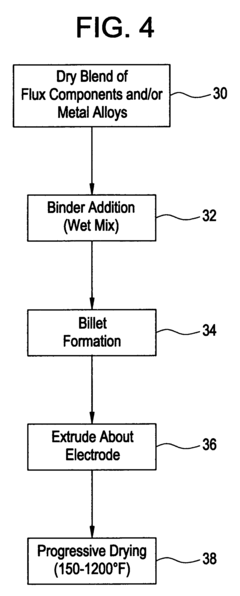

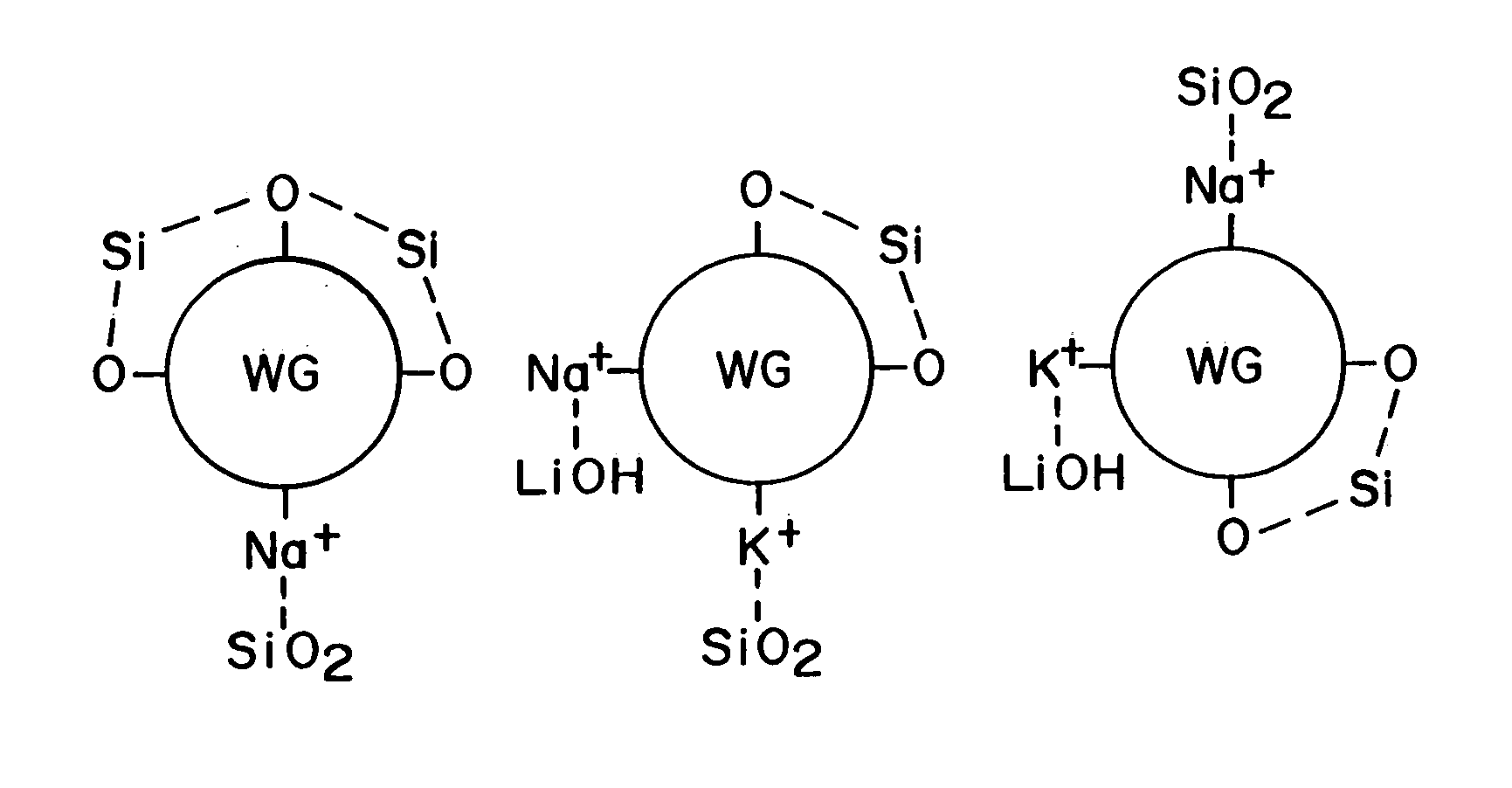

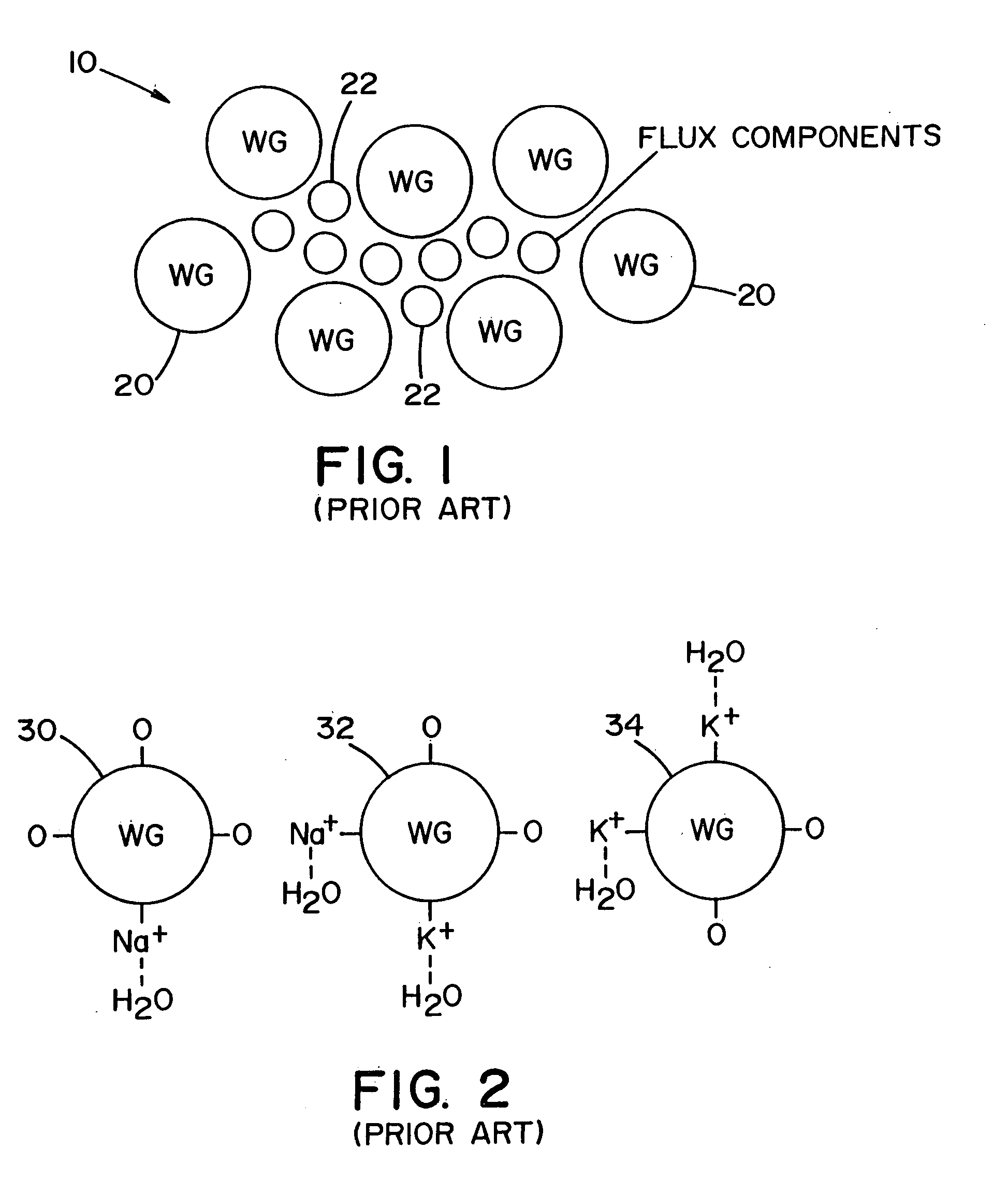

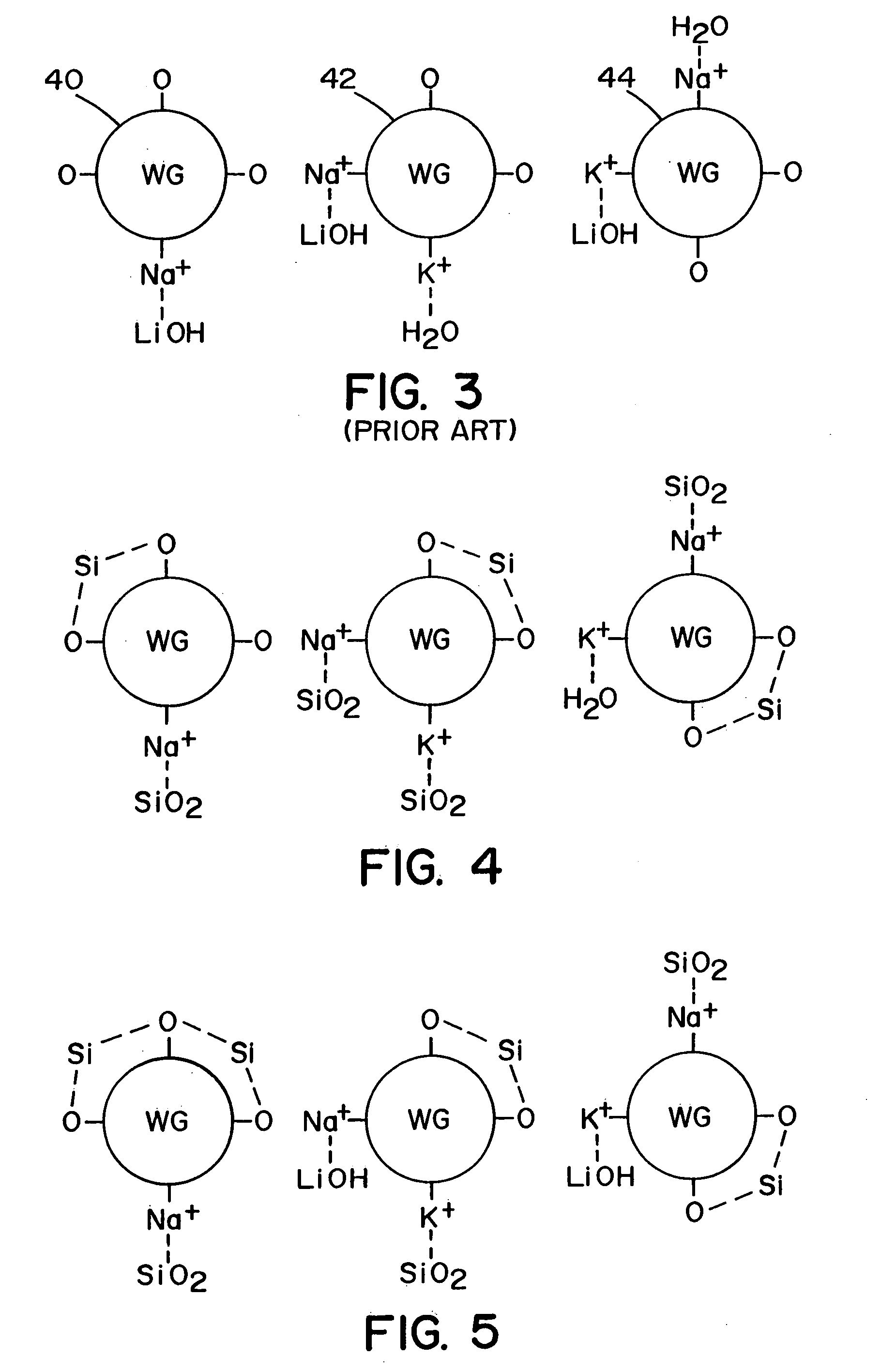

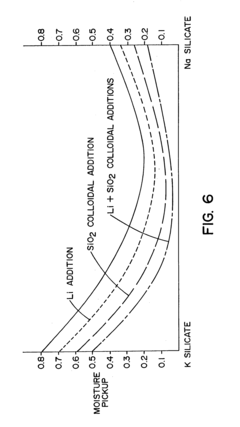

- A colloidal binder system utilizing metal oxides, primarily silicon dioxide, that sets at lower temperatures, reducing moisture content and preventing hydrogen introduction, allowing for expanded use of flux components and improved arc stability without the need for high-temperature drying.

Colloidal silica binder system

PatentInactiveUS20050121110A1

Innovation

- A novel welding flux binder system combining silicates with colloidal materials, such as colloidal silica, and optionally lithium compounds, to reduce hygroscopicity, allowing for a higher silicate content and lower moisture retention, suitable for various welding processes including submerged arc, shielded metal arc, and flux-cored welding, with the ability to be dried at lower temperatures without additional costly processes.

Regulatory Framework for Welding Standards

The regulatory framework for welding standards plays a crucial role in ensuring the safety, quality, and reliability of welded structures, particularly in the context of hydrogen embrittlement prevention. This framework encompasses a wide range of national and international standards, codes, and regulations that govern welding practices, materials selection, and inspection protocols.

At the international level, organizations such as the International Organization for Standardization (ISO) and the International Institute of Welding (IIW) develop and maintain comprehensive welding standards. These standards provide guidelines for welding processes, qualification of welders, and quality assurance measures. Specifically, ISO 3834 series addresses quality requirements for fusion welding of metallic materials, while ISO 15614 series covers the qualification of welding procedures for metallic materials.

In the United States, the American Welding Society (AWS) and the American Society of Mechanical Engineers (ASME) are key players in establishing welding standards. The AWS D1.1 Structural Welding Code - Steel is widely recognized and adopted, providing detailed requirements for welding structural steel. ASME Boiler and Pressure Vessel Code Section IX focuses on welding and brazing qualifications, which are particularly relevant for industries dealing with high-pressure systems where hydrogen embrittlement is a significant concern.

European standards, such as those developed by the European Committee for Standardization (CEN), also contribute significantly to the global regulatory framework. EN 1011 series provides recommendations for welding of metallic materials, addressing various aspects including hydrogen-induced cracking.

Regulatory bodies in different countries often incorporate these standards into their national regulations. For instance, the U.S. Department of Transportation's Pipeline and Hazardous Materials Safety Administration (PHMSA) enforces regulations that reference specific welding standards for pipeline construction and maintenance, where hydrogen embrittlement is a critical consideration.

Industry-specific regulations also play a vital role. In the aerospace industry, for example, NASA has developed its own set of welding standards, such as NASA-STD-5006, which includes provisions for mitigating hydrogen embrittlement in critical components. Similarly, the nuclear industry has stringent welding regulations outlined in documents like the ASME Boiler and Pressure Vessel Code Section III.

These regulatory frameworks typically address key aspects related to hydrogen embrittlement prevention, including requirements for preheat and postheat treatments, filler material selection, and inspection protocols. They often specify minimum preheat temperatures, holding times, and cooling rates to control hydrogen diffusion. Guidelines for selecting appropriate filler materials with low hydrogen content are also commonly included. Additionally, these standards outline inspection requirements, including non-destructive testing methods and acceptance criteria, to ensure the integrity of welds potentially susceptible to hydrogen embrittlement.

At the international level, organizations such as the International Organization for Standardization (ISO) and the International Institute of Welding (IIW) develop and maintain comprehensive welding standards. These standards provide guidelines for welding processes, qualification of welders, and quality assurance measures. Specifically, ISO 3834 series addresses quality requirements for fusion welding of metallic materials, while ISO 15614 series covers the qualification of welding procedures for metallic materials.

In the United States, the American Welding Society (AWS) and the American Society of Mechanical Engineers (ASME) are key players in establishing welding standards. The AWS D1.1 Structural Welding Code - Steel is widely recognized and adopted, providing detailed requirements for welding structural steel. ASME Boiler and Pressure Vessel Code Section IX focuses on welding and brazing qualifications, which are particularly relevant for industries dealing with high-pressure systems where hydrogen embrittlement is a significant concern.

European standards, such as those developed by the European Committee for Standardization (CEN), also contribute significantly to the global regulatory framework. EN 1011 series provides recommendations for welding of metallic materials, addressing various aspects including hydrogen-induced cracking.

Regulatory bodies in different countries often incorporate these standards into their national regulations. For instance, the U.S. Department of Transportation's Pipeline and Hazardous Materials Safety Administration (PHMSA) enforces regulations that reference specific welding standards for pipeline construction and maintenance, where hydrogen embrittlement is a critical consideration.

Industry-specific regulations also play a vital role. In the aerospace industry, for example, NASA has developed its own set of welding standards, such as NASA-STD-5006, which includes provisions for mitigating hydrogen embrittlement in critical components. Similarly, the nuclear industry has stringent welding regulations outlined in documents like the ASME Boiler and Pressure Vessel Code Section III.

These regulatory frameworks typically address key aspects related to hydrogen embrittlement prevention, including requirements for preheat and postheat treatments, filler material selection, and inspection protocols. They often specify minimum preheat temperatures, holding times, and cooling rates to control hydrogen diffusion. Guidelines for selecting appropriate filler materials with low hydrogen content are also commonly included. Additionally, these standards outline inspection requirements, including non-destructive testing methods and acceptance criteria, to ensure the integrity of welds potentially susceptible to hydrogen embrittlement.

Economic Impact of Hydrogen Embrittlement Prevention

The economic impact of hydrogen embrittlement prevention in welds is significant and multifaceted, affecting various industries and sectors. Implementing effective prevention measures can lead to substantial cost savings and improved operational efficiency.

One of the primary economic benefits of preventing hydrogen embrittlement is the reduction in maintenance and repair costs. By implementing proper preheat and postheat treatments, selecting appropriate filler materials, and following rigorous inspection protocols, companies can significantly extend the lifespan of welded structures and components. This results in fewer instances of unexpected failures, reduced downtime, and lower replacement costs.

In safety-critical industries such as aerospace, automotive, and oil and gas, the prevention of hydrogen embrittlement is crucial for avoiding catastrophic failures. The economic consequences of such failures can be enormous, including potential loss of life, environmental damage, and severe reputational harm. By investing in prevention measures, companies can mitigate these risks and avoid the associated financial and legal repercussions.

The implementation of hydrogen embrittlement prevention techniques can also lead to improved product quality and reliability. This, in turn, can enhance a company's competitive position in the market, potentially leading to increased market share and customer loyalty. The ability to produce high-quality, durable welded components can be a significant differentiator in industries where reliability is paramount.

From a supply chain perspective, effective hydrogen embrittlement prevention can reduce the need for frequent material replacements and minimize production delays. This can lead to more streamlined operations, reduced inventory costs, and improved overall supply chain efficiency. Additionally, companies that demonstrate consistent quality and reliability in their welded products may be able to command premium prices, further enhancing their economic position.

The investment in research and development of advanced hydrogen embrittlement prevention techniques can also drive innovation and create new business opportunities. Companies that develop proprietary methods or technologies for preventing hydrogen embrittlement may be able to license these solutions to others, creating additional revenue streams.

However, it is important to note that the implementation of hydrogen embrittlement prevention measures does come with associated costs. These may include investments in specialized equipment, training for personnel, and potentially longer production times due to additional processing steps. Companies must carefully balance these costs against the long-term economic benefits of improved reliability and reduced failure rates.

In conclusion, the economic impact of hydrogen embrittlement prevention in welds is substantial and far-reaching. While there are upfront costs associated with implementing prevention measures, the long-term benefits in terms of reduced maintenance costs, improved safety, enhanced product quality, and potential market advantages make it a worthwhile investment for many industries.

One of the primary economic benefits of preventing hydrogen embrittlement is the reduction in maintenance and repair costs. By implementing proper preheat and postheat treatments, selecting appropriate filler materials, and following rigorous inspection protocols, companies can significantly extend the lifespan of welded structures and components. This results in fewer instances of unexpected failures, reduced downtime, and lower replacement costs.

In safety-critical industries such as aerospace, automotive, and oil and gas, the prevention of hydrogen embrittlement is crucial for avoiding catastrophic failures. The economic consequences of such failures can be enormous, including potential loss of life, environmental damage, and severe reputational harm. By investing in prevention measures, companies can mitigate these risks and avoid the associated financial and legal repercussions.

The implementation of hydrogen embrittlement prevention techniques can also lead to improved product quality and reliability. This, in turn, can enhance a company's competitive position in the market, potentially leading to increased market share and customer loyalty. The ability to produce high-quality, durable welded components can be a significant differentiator in industries where reliability is paramount.

From a supply chain perspective, effective hydrogen embrittlement prevention can reduce the need for frequent material replacements and minimize production delays. This can lead to more streamlined operations, reduced inventory costs, and improved overall supply chain efficiency. Additionally, companies that demonstrate consistent quality and reliability in their welded products may be able to command premium prices, further enhancing their economic position.

The investment in research and development of advanced hydrogen embrittlement prevention techniques can also drive innovation and create new business opportunities. Companies that develop proprietary methods or technologies for preventing hydrogen embrittlement may be able to license these solutions to others, creating additional revenue streams.

However, it is important to note that the implementation of hydrogen embrittlement prevention measures does come with associated costs. These may include investments in specialized equipment, training for personnel, and potentially longer production times due to additional processing steps. Companies must carefully balance these costs against the long-term economic benefits of improved reliability and reduced failure rates.

In conclusion, the economic impact of hydrogen embrittlement prevention in welds is substantial and far-reaching. While there are upfront costs associated with implementing prevention measures, the long-term benefits in terms of reduced maintenance costs, improved safety, enhanced product quality, and potential market advantages make it a worthwhile investment for many industries.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!