HE Risk Assessment Framework for Plant Engineers — Checklist and KPIs

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HE Risk Assessment Background and Objectives

The HE Risk Assessment Framework for Plant Engineers — Checklist and KPIs is a critical tool in the field of industrial safety and risk management. This framework has evolved over decades of industrial experience and regulatory development, aiming to address the complex challenges posed by hazardous energy (HE) in plant environments. The primary objective of this framework is to provide plant engineers with a structured approach to identify, assess, and mitigate risks associated with hazardous energy sources.

Historically, the need for such a framework arose from numerous industrial accidents and near-misses related to unexpected releases of hazardous energy. These incidents highlighted the importance of systematic risk assessment and management in industrial settings. The framework's development has been influenced by various factors, including advancements in safety engineering, lessons learned from past incidents, and evolving regulatory requirements across different industries and regions.

The HE Risk Assessment Framework aims to standardize the process of identifying potential hazards, evaluating their likelihood and potential impact, and implementing appropriate control measures. By providing a comprehensive checklist and key performance indicators (KPIs), it enables plant engineers to conduct thorough assessments of their facilities and processes. This standardization not only enhances safety but also promotes consistency in risk management practices across different plants and industries.

One of the key technological trends driving the evolution of this framework is the integration of digital tools and data analytics. Modern HE risk assessment frameworks increasingly incorporate real-time data collection, advanced modeling techniques, and predictive analytics to enhance the accuracy and efficiency of risk evaluations. This digital transformation allows for more dynamic and responsive risk management strategies, adapting to changing conditions in real-time.

The framework's objectives extend beyond mere compliance with safety regulations. It aims to foster a culture of proactive risk management, encouraging continuous improvement in safety practices. By providing a structured approach to risk assessment, it empowers plant engineers to make informed decisions about equipment design, maintenance schedules, and operational procedures. This, in turn, contributes to improved operational efficiency, reduced downtime, and enhanced overall plant reliability.

Furthermore, the HE Risk Assessment Framework serves as a valuable communication tool, facilitating dialogue between different stakeholders in industrial settings. It provides a common language and set of metrics for discussing safety concerns, prioritizing resources, and tracking progress in risk reduction efforts. This aspect of the framework is particularly crucial in complex industrial environments where multiple teams and departments must collaborate to ensure overall safety and operational excellence.

Historically, the need for such a framework arose from numerous industrial accidents and near-misses related to unexpected releases of hazardous energy. These incidents highlighted the importance of systematic risk assessment and management in industrial settings. The framework's development has been influenced by various factors, including advancements in safety engineering, lessons learned from past incidents, and evolving regulatory requirements across different industries and regions.

The HE Risk Assessment Framework aims to standardize the process of identifying potential hazards, evaluating their likelihood and potential impact, and implementing appropriate control measures. By providing a comprehensive checklist and key performance indicators (KPIs), it enables plant engineers to conduct thorough assessments of their facilities and processes. This standardization not only enhances safety but also promotes consistency in risk management practices across different plants and industries.

One of the key technological trends driving the evolution of this framework is the integration of digital tools and data analytics. Modern HE risk assessment frameworks increasingly incorporate real-time data collection, advanced modeling techniques, and predictive analytics to enhance the accuracy and efficiency of risk evaluations. This digital transformation allows for more dynamic and responsive risk management strategies, adapting to changing conditions in real-time.

The framework's objectives extend beyond mere compliance with safety regulations. It aims to foster a culture of proactive risk management, encouraging continuous improvement in safety practices. By providing a structured approach to risk assessment, it empowers plant engineers to make informed decisions about equipment design, maintenance schedules, and operational procedures. This, in turn, contributes to improved operational efficiency, reduced downtime, and enhanced overall plant reliability.

Furthermore, the HE Risk Assessment Framework serves as a valuable communication tool, facilitating dialogue between different stakeholders in industrial settings. It provides a common language and set of metrics for discussing safety concerns, prioritizing resources, and tracking progress in risk reduction efforts. This aspect of the framework is particularly crucial in complex industrial environments where multiple teams and departments must collaborate to ensure overall safety and operational excellence.

Market Demand for HE Risk Assessment Tools

The market demand for Heat Exchanger (HE) Risk Assessment Tools has been steadily growing in recent years, driven by the increasing complexity of industrial processes and the heightened focus on safety and efficiency in plant operations. Plant engineers and managers are recognizing the critical importance of proactive risk management in heat exchanger systems, which are integral components in various industries including oil and gas, chemical processing, power generation, and manufacturing.

The primary drivers for this demand include regulatory pressures, cost reduction initiatives, and the need for improved operational reliability. Regulatory bodies worldwide are imposing stricter safety standards and compliance requirements, compelling companies to adopt more sophisticated risk assessment methodologies. This has created a significant market for tools that can help plant engineers systematically identify, evaluate, and mitigate potential hazards associated with heat exchangers.

Cost reduction is another key factor fueling the demand for HE risk assessment tools. By implementing comprehensive risk assessment frameworks, companies can prevent costly equipment failures, reduce downtime, and optimize maintenance schedules. This proactive approach translates into substantial savings in repair costs, production losses, and potential legal liabilities.

The market is also being shaped by the increasing complexity of heat exchanger designs and the integration of advanced materials and technologies. As heat exchangers become more sophisticated, the need for specialized risk assessment tools that can handle these complexities grows. Plant engineers require tools that can account for various factors such as material degradation, process variations, and operational conditions specific to modern heat exchanger systems.

There is a notable trend towards digitalization and the adoption of Industry 4.0 principles in plant operations. This has created a demand for risk assessment tools that can integrate with existing digital systems, leveraging real-time data and advanced analytics to provide more accurate and dynamic risk evaluations. The market is seeing a shift from traditional, static checklists to more dynamic, data-driven assessment frameworks.

The global nature of industrial operations has also contributed to the expanding market for HE risk assessment tools. Multinational corporations are seeking standardized risk assessment methodologies that can be applied across their global operations, ensuring consistency in safety practices and compliance with diverse regional regulations.

In terms of market size, while specific figures for HE risk assessment tools are not readily available, the broader industrial risk assessment software market is projected to grow significantly. This growth is indicative of the increasing importance placed on specialized risk management tools across various industrial sectors, including those focused on heat exchanger systems.

The primary drivers for this demand include regulatory pressures, cost reduction initiatives, and the need for improved operational reliability. Regulatory bodies worldwide are imposing stricter safety standards and compliance requirements, compelling companies to adopt more sophisticated risk assessment methodologies. This has created a significant market for tools that can help plant engineers systematically identify, evaluate, and mitigate potential hazards associated with heat exchangers.

Cost reduction is another key factor fueling the demand for HE risk assessment tools. By implementing comprehensive risk assessment frameworks, companies can prevent costly equipment failures, reduce downtime, and optimize maintenance schedules. This proactive approach translates into substantial savings in repair costs, production losses, and potential legal liabilities.

The market is also being shaped by the increasing complexity of heat exchanger designs and the integration of advanced materials and technologies. As heat exchangers become more sophisticated, the need for specialized risk assessment tools that can handle these complexities grows. Plant engineers require tools that can account for various factors such as material degradation, process variations, and operational conditions specific to modern heat exchanger systems.

There is a notable trend towards digitalization and the adoption of Industry 4.0 principles in plant operations. This has created a demand for risk assessment tools that can integrate with existing digital systems, leveraging real-time data and advanced analytics to provide more accurate and dynamic risk evaluations. The market is seeing a shift from traditional, static checklists to more dynamic, data-driven assessment frameworks.

The global nature of industrial operations has also contributed to the expanding market for HE risk assessment tools. Multinational corporations are seeking standardized risk assessment methodologies that can be applied across their global operations, ensuring consistency in safety practices and compliance with diverse regional regulations.

In terms of market size, while specific figures for HE risk assessment tools are not readily available, the broader industrial risk assessment software market is projected to grow significantly. This growth is indicative of the increasing importance placed on specialized risk management tools across various industrial sectors, including those focused on heat exchanger systems.

Current Challenges in HE Risk Assessment

Heat exchanger (HE) risk assessment in industrial plants faces several significant challenges that hinder effective implementation and accurate evaluation. One primary issue is the complexity of heat exchanger systems, which often involve intricate designs and multiple components. This complexity makes it difficult for plant engineers to comprehensively identify all potential hazards and failure modes.

Another challenge is the dynamic nature of heat exchanger operations. Process conditions, such as temperature, pressure, and flow rates, can fluctuate rapidly, making it challenging to assess risks in real-time. This variability also complicates the development of standardized risk assessment protocols that can be universally applied across different heat exchanger types and operating conditions.

The lack of comprehensive historical data on heat exchanger failures and incidents poses another significant obstacle. Without a robust database of past events, it becomes challenging to accurately predict future risks and prioritize mitigation strategies. This data gap often leads to reliance on subjective expert judgment, which can introduce inconsistencies in risk assessments across different facilities or organizations.

Furthermore, the interdependencies between heat exchangers and other plant systems create additional complexities in risk assessment. Failures or operational issues in connected systems can have cascading effects on heat exchanger performance and safety, making it essential to consider these interactions in the risk assessment process.

The rapidly evolving regulatory landscape also presents challenges for HE risk assessment. Plant engineers must stay updated with changing safety standards and compliance requirements, which can vary across different regions and industries. This regulatory complexity often leads to confusion and inconsistencies in risk assessment methodologies.

Additionally, the integration of new technologies, such as advanced materials or smart monitoring systems, into heat exchanger designs introduces new risk factors that may not be fully understood or accounted for in traditional assessment frameworks. This technological evolution requires continuous adaptation of risk assessment methodologies to keep pace with industry advancements.

Lastly, there is often a gap between theoretical risk models and practical, on-the-ground realities in plant operations. Risk assessment frameworks that are too abstract or complex may be challenging for plant engineers to implement effectively in their daily routines, leading to potential oversights or misinterpretations of risk factors.

Another challenge is the dynamic nature of heat exchanger operations. Process conditions, such as temperature, pressure, and flow rates, can fluctuate rapidly, making it challenging to assess risks in real-time. This variability also complicates the development of standardized risk assessment protocols that can be universally applied across different heat exchanger types and operating conditions.

The lack of comprehensive historical data on heat exchanger failures and incidents poses another significant obstacle. Without a robust database of past events, it becomes challenging to accurately predict future risks and prioritize mitigation strategies. This data gap often leads to reliance on subjective expert judgment, which can introduce inconsistencies in risk assessments across different facilities or organizations.

Furthermore, the interdependencies between heat exchangers and other plant systems create additional complexities in risk assessment. Failures or operational issues in connected systems can have cascading effects on heat exchanger performance and safety, making it essential to consider these interactions in the risk assessment process.

The rapidly evolving regulatory landscape also presents challenges for HE risk assessment. Plant engineers must stay updated with changing safety standards and compliance requirements, which can vary across different regions and industries. This regulatory complexity often leads to confusion and inconsistencies in risk assessment methodologies.

Additionally, the integration of new technologies, such as advanced materials or smart monitoring systems, into heat exchanger designs introduces new risk factors that may not be fully understood or accounted for in traditional assessment frameworks. This technological evolution requires continuous adaptation of risk assessment methodologies to keep pace with industry advancements.

Lastly, there is often a gap between theoretical risk models and practical, on-the-ground realities in plant operations. Risk assessment frameworks that are too abstract or complex may be challenging for plant engineers to implement effectively in their daily routines, leading to potential oversights or misinterpretations of risk factors.

Existing HE Risk Assessment Frameworks

01 Risk assessment framework components

A comprehensive risk assessment framework for higher education (HE) institutions typically includes key components such as risk identification, analysis, evaluation, and treatment. The framework should cover various aspects of institutional operations, including academic, financial, operational, and reputational risks. It often involves a systematic approach to identifying potential threats and opportunities, assessing their likelihood and impact, and developing strategies to mitigate or capitalize on them.- Risk assessment framework components: A comprehensive risk assessment framework for higher education (HE) institutions typically includes key components such as risk identification, analysis, evaluation, and treatment. The framework should cover various risk categories like financial, operational, reputational, and compliance risks. It often involves a structured approach to assess and prioritize risks, enabling institutions to allocate resources effectively for risk mitigation.

- Key Performance Indicators (KPIs) for HE risk assessment: KPIs play a crucial role in measuring the effectiveness of risk management strategies in higher education. These indicators may include metrics related to student enrollment, retention rates, financial stability, research output, and compliance with regulatory requirements. KPIs help institutions track progress, identify areas of improvement, and make data-driven decisions in managing risks.

- Technology-enabled risk assessment tools: Advanced technological solutions are being developed to enhance risk assessment processes in higher education. These tools often incorporate artificial intelligence and machine learning algorithms to analyze large datasets, identify patterns, and predict potential risks. Such systems can automate risk monitoring, provide real-time insights, and facilitate more efficient decision-making in risk management.

- Compliance and regulatory risk management: Higher education institutions face various compliance and regulatory risks. A robust risk assessment framework should include mechanisms to identify, monitor, and address these risks. This may involve regular audits, policy reviews, and training programs to ensure adherence to legal and regulatory requirements specific to the education sector.

- Stakeholder engagement in risk assessment: Effective risk assessment in higher education requires active involvement of various stakeholders, including administrators, faculty, students, and external partners. The framework should incorporate methods for gathering input from these diverse groups, ensuring a comprehensive understanding of potential risks and their impacts. This collaborative approach can lead to more effective risk mitigation strategies and improved institutional resilience.

02 Key Performance Indicators (KPIs) for HE risk assessment

KPIs play a crucial role in measuring and monitoring the effectiveness of risk management strategies in higher education. These indicators may include metrics related to student enrollment, retention rates, research output, financial sustainability, and compliance with regulatory requirements. Effective KPIs should be specific, measurable, achievable, relevant, and time-bound (SMART) to provide meaningful insights into the institution's risk profile and performance.Expand Specific Solutions03 Technology-enabled risk assessment tools

Advanced technological solutions are increasingly being employed to enhance the efficiency and accuracy of risk assessment processes in higher education. These tools may include data analytics platforms, artificial intelligence-driven predictive models, and automated reporting systems. Such technologies can help institutions gather and analyze large volumes of data, identify emerging risks, and facilitate real-time decision-making in risk management.Expand Specific Solutions04 Compliance and regulatory considerations

Higher education institutions must navigate a complex landscape of regulatory requirements and compliance standards. A robust risk assessment framework should incorporate mechanisms to ensure adherence to relevant laws, accreditation standards, and industry best practices. This may include regular audits, compliance checklists, and ongoing training programs for staff and faculty to maintain awareness of regulatory obligations and institutional policies.Expand Specific Solutions05 Stakeholder engagement in risk assessment

Effective risk assessment in higher education requires active involvement from various stakeholders, including administrators, faculty, students, and external partners. Engaging diverse perspectives helps ensure a comprehensive understanding of potential risks and opportunities. Institutions may implement strategies such as regular surveys, focus groups, and collaborative workshops to gather input and foster a culture of risk awareness across the organization.Expand Specific Solutions

Key Players in HE Risk Assessment Industry

The HE Risk Assessment Framework for Plant Engineers is in a developing stage, with the market still emerging and technology maturing. Key players like Saudi Aramco, Sinopec, and PetroChina are driving innovation in this field, leveraging their extensive industry experience. Research institutions such as Suzhou Nuclear Power Research Institute and Zhejiang University of Technology are contributing to technological advancements. The market size is growing as more industries recognize the importance of health and environmental risk assessment. While the framework is not yet fully standardized, collaborations between industry leaders and academic institutions are accelerating its development and adoption across various sectors.

Saudi Arabian Oil Co.

Technical Solution: Saudi Aramco has developed a comprehensive HE Risk Assessment Framework specifically tailored for plant engineers. The framework incorporates a detailed checklist and Key Performance Indicators (KPIs) to systematically evaluate and mitigate hazardous energy risks in industrial facilities. The checklist covers various aspects of energy sources, including electrical, mechanical, chemical, and thermal hazards. It guides engineers through a step-by-step process to identify potential risks, assess their severity, and implement appropriate control measures[1]. The KPIs are designed to measure the effectiveness of risk mitigation strategies and track improvements over time. These metrics include incident rates, near-miss reports, and compliance with safety procedures[3]. The framework also integrates advanced digital technologies, such as IoT sensors and real-time monitoring systems, to enhance data collection and analysis for more accurate risk assessments[5].

Strengths: Comprehensive coverage of various energy hazards, integration of digital technologies for real-time monitoring, and tailored approach for the oil and gas industry. Weaknesses: May require significant resources for implementation and maintenance, potential complexity for smaller operations.

China Petroleum & Chemical Corp.

Technical Solution: Sinopec has implemented an advanced HE Risk Assessment Framework that combines traditional safety methodologies with cutting-edge digital technologies. The framework utilizes a multi-layered approach, starting with a detailed checklist that covers all potential hazardous energy sources in petrochemical plants. This checklist is integrated into a digital platform, allowing for real-time updates and easy access for plant engineers[2]. The KPIs are designed to measure both leading and lagging indicators, providing a comprehensive view of safety performance. These include metrics such as risk assessment completion rates, hazard identification efficiency, and incident prevention effectiveness[4]. Sinopec's framework also incorporates machine learning algorithms to analyze historical data and predict potential risks, enabling proactive risk management[6]. The system is linked to the company's overall safety management system, ensuring that risk assessments are not isolated activities but part of a holistic safety approach.

Strengths: Integration of advanced digital technologies, predictive risk analysis capabilities, and alignment with overall safety management systems. Weaknesses: High initial implementation costs, potential over-reliance on technology, and need for continuous training to keep up with system updates.

Core Innovations in HE Risk Assessment

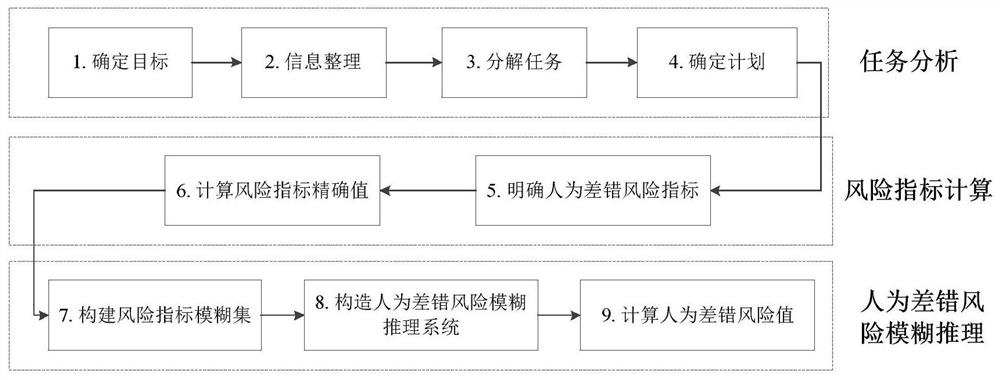

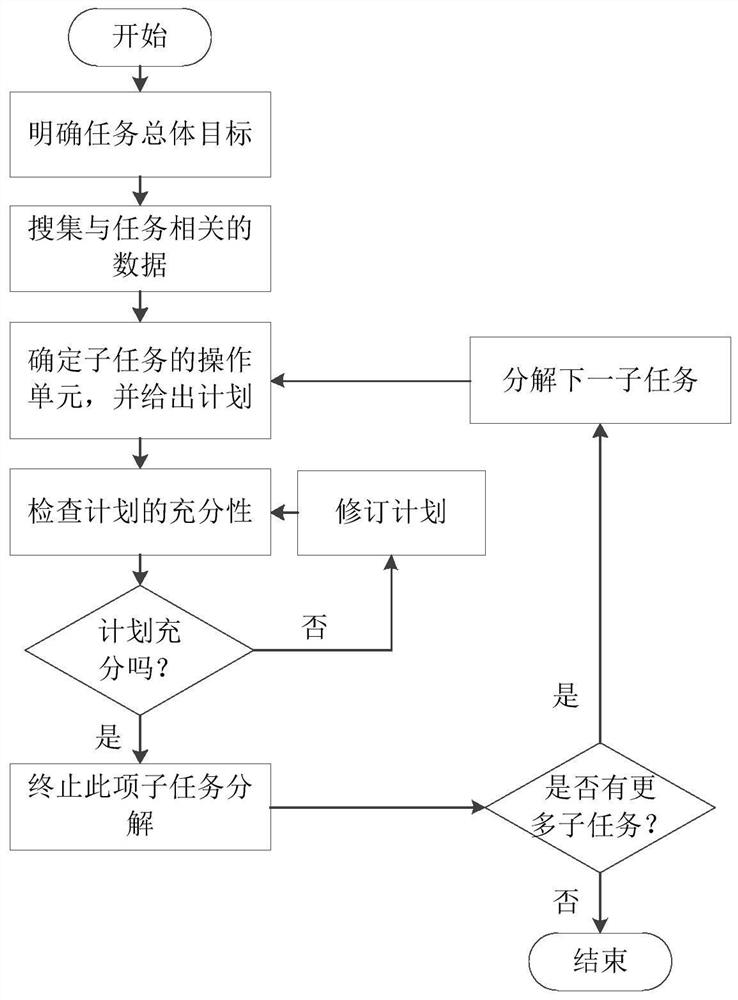

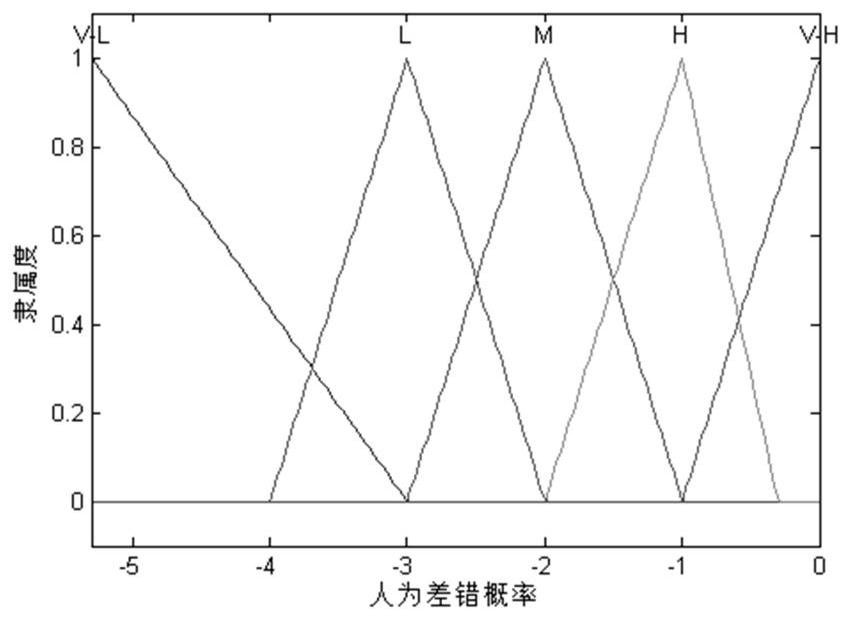

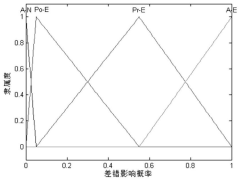

Task-oriented aircraft driving man-made error risk assessment method

PatentActiveCN111881623A

Innovation

- Using a task-oriented aircraft pilot human error risk assessment method, by determining the mission goal, decomposing the task, calculating the error probability and consequence severity during the human-computer interaction process, and combining the CREAM and FMECA methods, a human error risk fuzzy inference system was constructed using MATLAB Fuzzy Logic Toolbox performs fuzzy inference to obtain accurate risk assessment.

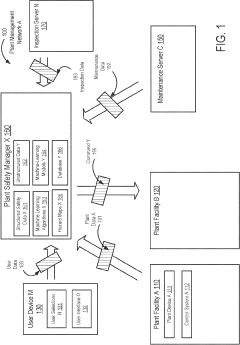

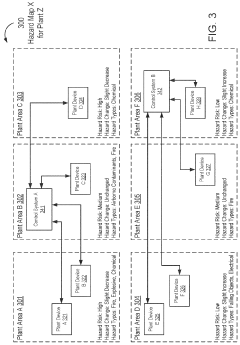

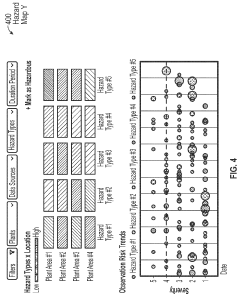

Method and system for managing plant safety using machine learning

PatentPendingUS20230115475A1

Innovation

- A method utilizing machine-learning models, including natural language processing, to classify and predict plant hazards by combining structured and unstructured data, generating hazard maps, and automatically determining mitigation operations based on hazard rates.

Regulatory Landscape for HE Risk Assessment

The regulatory landscape for HE (Hazardous Energy) Risk Assessment is complex and multifaceted, encompassing various international, national, and industry-specific standards and regulations. At the forefront of these regulations is the Occupational Safety and Health Administration (OSHA) in the United States, which mandates the implementation of energy control procedures, commonly known as Lockout/Tagout (LOTO), under 29 CFR 1910.147. This standard requires employers to establish and implement procedures to disable machinery or equipment during servicing and maintenance to prevent unexpected energization or start-up.

In the European Union, the Machinery Directive 2006/42/EC sets out essential health and safety requirements for machinery, including provisions for energy isolation and control. This directive is complemented by harmonized standards such as EN ISO 14118:2018, which specifically addresses the prevention of unexpected start-up in machinery. The International Organization for Standardization (ISO) has also developed ISO 45001:2018, an international standard for occupational health and safety management systems, which includes requirements for hazard identification and risk assessment.

For the process industry, the IEC 61511 standard on Functional Safety - Safety Instrumented Systems for the Process Industry Sector provides guidelines for the specification, design, installation, operation, and maintenance of safety instrumented functions. This standard is particularly relevant for HE risk assessment in plant environments where automated control systems are prevalent.

In addition to these overarching regulations, specific industries have developed their own standards and best practices. For instance, the American Petroleum Institute (API) has published API RP 754, which provides process safety performance indicators for the refining and petrochemical industries. This recommended practice includes metrics related to energy control and isolation procedures.

The regulatory landscape also extends to environmental considerations, with many countries implementing regulations that require risk assessments for potential environmental impacts of industrial processes. For example, the Environmental Protection Agency (EPA) in the United States enforces the Risk Management Program Rule (40 CFR Part 68), which requires facilities that use certain hazardous substances to develop and implement risk management programs.

As technology advances, regulatory bodies are also addressing emerging risks associated with new forms of energy and automation. The increasing use of robotics and artificial intelligence in industrial settings has led to the development of standards such as ISO/TS 15066:2016 for collaborative robots, which includes risk assessment methodologies for human-robot interactions.

In the European Union, the Machinery Directive 2006/42/EC sets out essential health and safety requirements for machinery, including provisions for energy isolation and control. This directive is complemented by harmonized standards such as EN ISO 14118:2018, which specifically addresses the prevention of unexpected start-up in machinery. The International Organization for Standardization (ISO) has also developed ISO 45001:2018, an international standard for occupational health and safety management systems, which includes requirements for hazard identification and risk assessment.

For the process industry, the IEC 61511 standard on Functional Safety - Safety Instrumented Systems for the Process Industry Sector provides guidelines for the specification, design, installation, operation, and maintenance of safety instrumented functions. This standard is particularly relevant for HE risk assessment in plant environments where automated control systems are prevalent.

In addition to these overarching regulations, specific industries have developed their own standards and best practices. For instance, the American Petroleum Institute (API) has published API RP 754, which provides process safety performance indicators for the refining and petrochemical industries. This recommended practice includes metrics related to energy control and isolation procedures.

The regulatory landscape also extends to environmental considerations, with many countries implementing regulations that require risk assessments for potential environmental impacts of industrial processes. For example, the Environmental Protection Agency (EPA) in the United States enforces the Risk Management Program Rule (40 CFR Part 68), which requires facilities that use certain hazardous substances to develop and implement risk management programs.

As technology advances, regulatory bodies are also addressing emerging risks associated with new forms of energy and automation. The increasing use of robotics and artificial intelligence in industrial settings has led to the development of standards such as ISO/TS 15066:2016 for collaborative robots, which includes risk assessment methodologies for human-robot interactions.

Economic Impact of HE Risk Management

The economic impact of HE (Heat Exchanger) risk management is significant and multifaceted, affecting various aspects of plant operations and financial performance. Effective risk management in heat exchanger systems can lead to substantial cost savings and improved operational efficiency.

One of the primary economic benefits of implementing a robust HE risk management framework is the reduction in unplanned downtime. Heat exchanger failures can result in costly production interruptions, which can amount to millions of dollars in lost revenue for large industrial plants. By identifying and mitigating potential risks early, companies can minimize these disruptions and maintain consistent production levels.

Maintenance costs are another area where effective risk management can yield significant economic benefits. Proactive maintenance strategies, guided by risk assessment frameworks, can extend the lifespan of heat exchangers and reduce the frequency of major repairs or replacements. This approach not only lowers direct maintenance expenses but also optimizes resource allocation, allowing maintenance teams to focus on critical issues rather than reactive problem-solving.

Energy efficiency is a crucial factor in the economic impact of HE risk management. Well-maintained heat exchangers operate at higher efficiency levels, reducing energy consumption and associated costs. In energy-intensive industries, even small improvements in heat transfer efficiency can translate to substantial savings over time.

Insurance premiums and compliance costs are also influenced by the effectiveness of risk management practices. Companies that demonstrate robust risk assessment and mitigation strategies may qualify for lower insurance rates, reflecting their reduced likelihood of major incidents. Additionally, adherence to regulatory standards through comprehensive risk management can help avoid costly fines and legal issues.

The implementation of advanced monitoring and predictive maintenance technologies, often part of modern HE risk management frameworks, can lead to long-term economic benefits. These systems allow for more accurate forecasting of maintenance needs and equipment lifespan, enabling better financial planning and capital expenditure optimization.

Furthermore, effective risk management contributes to improved product quality and consistency. By ensuring that heat exchangers operate within optimal parameters, companies can maintain product specifications more reliably, potentially leading to increased customer satisfaction and market share.

Lastly, the economic impact extends to the realm of corporate reputation and stakeholder confidence. Companies known for their strong risk management practices often enjoy better relationships with investors, regulators, and customers, which can translate into tangible financial benefits through improved access to capital and market opportunities.

One of the primary economic benefits of implementing a robust HE risk management framework is the reduction in unplanned downtime. Heat exchanger failures can result in costly production interruptions, which can amount to millions of dollars in lost revenue for large industrial plants. By identifying and mitigating potential risks early, companies can minimize these disruptions and maintain consistent production levels.

Maintenance costs are another area where effective risk management can yield significant economic benefits. Proactive maintenance strategies, guided by risk assessment frameworks, can extend the lifespan of heat exchangers and reduce the frequency of major repairs or replacements. This approach not only lowers direct maintenance expenses but also optimizes resource allocation, allowing maintenance teams to focus on critical issues rather than reactive problem-solving.

Energy efficiency is a crucial factor in the economic impact of HE risk management. Well-maintained heat exchangers operate at higher efficiency levels, reducing energy consumption and associated costs. In energy-intensive industries, even small improvements in heat transfer efficiency can translate to substantial savings over time.

Insurance premiums and compliance costs are also influenced by the effectiveness of risk management practices. Companies that demonstrate robust risk assessment and mitigation strategies may qualify for lower insurance rates, reflecting their reduced likelihood of major incidents. Additionally, adherence to regulatory standards through comprehensive risk management can help avoid costly fines and legal issues.

The implementation of advanced monitoring and predictive maintenance technologies, often part of modern HE risk management frameworks, can lead to long-term economic benefits. These systems allow for more accurate forecasting of maintenance needs and equipment lifespan, enabling better financial planning and capital expenditure optimization.

Furthermore, effective risk management contributes to improved product quality and consistency. By ensuring that heat exchangers operate within optimal parameters, companies can maintain product specifications more reliably, potentially leading to increased customer satisfaction and market share.

Lastly, the economic impact extends to the realm of corporate reputation and stakeholder confidence. Companies known for their strong risk management practices often enjoy better relationships with investors, regulators, and customers, which can translate into tangible financial benefits through improved access to capital and market opportunities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!