How to Rehabilitate HE-affected Components: Repair Methods, Re-qualification and Testing

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HE Rehabilitation Background and Objectives

Hydrogen embrittlement (HE) has been a persistent challenge in the materials science and engineering field for decades. This phenomenon, characterized by the degradation of mechanical properties in metals due to hydrogen absorption, has significant implications for various industries, including aerospace, automotive, and energy sectors. The evolution of HE research has been driven by the increasing demand for high-strength materials in critical applications and the growing awareness of its detrimental effects on structural integrity.

The primary objective of HE rehabilitation is to restore the mechanical properties and structural integrity of affected components, ensuring their safe and reliable operation. This goal encompasses not only the development of effective repair methods but also the establishment of rigorous re-qualification and testing protocols. The rehabilitation process aims to address both the immediate concerns of compromised components and the long-term prevention of future HE-related failures.

Recent technological advancements have expanded the scope of HE rehabilitation, introducing innovative repair techniques and more sophisticated testing methodologies. These developments are particularly crucial in industries where component failure can lead to catastrophic consequences, such as in nuclear power plants or offshore oil and gas platforms. The integration of advanced materials science, non-destructive testing techniques, and computational modeling has significantly enhanced our ability to detect, assess, and mitigate HE-related issues.

The objectives of HE rehabilitation extend beyond mere repair to include a comprehensive understanding of the underlying mechanisms of hydrogen embrittlement. This knowledge is essential for developing more effective prevention strategies and designing materials with enhanced resistance to HE. Furthermore, the rehabilitation process aims to establish standardized procedures for assessing the extent of hydrogen damage, selecting appropriate repair methods, and validating the effectiveness of rehabilitation efforts.

As industries continue to push the boundaries of material performance, the importance of HE rehabilitation grows. The field is evolving to address new challenges posed by emerging materials and extreme operating conditions. This includes the development of rehabilitation techniques for advanced alloys, composite materials, and components subjected to complex loading scenarios. The ultimate goal is to create a comprehensive framework for HE rehabilitation that can be adapted to diverse industrial applications, ensuring the longevity and reliability of critical components in demanding environments.

The primary objective of HE rehabilitation is to restore the mechanical properties and structural integrity of affected components, ensuring their safe and reliable operation. This goal encompasses not only the development of effective repair methods but also the establishment of rigorous re-qualification and testing protocols. The rehabilitation process aims to address both the immediate concerns of compromised components and the long-term prevention of future HE-related failures.

Recent technological advancements have expanded the scope of HE rehabilitation, introducing innovative repair techniques and more sophisticated testing methodologies. These developments are particularly crucial in industries where component failure can lead to catastrophic consequences, such as in nuclear power plants or offshore oil and gas platforms. The integration of advanced materials science, non-destructive testing techniques, and computational modeling has significantly enhanced our ability to detect, assess, and mitigate HE-related issues.

The objectives of HE rehabilitation extend beyond mere repair to include a comprehensive understanding of the underlying mechanisms of hydrogen embrittlement. This knowledge is essential for developing more effective prevention strategies and designing materials with enhanced resistance to HE. Furthermore, the rehabilitation process aims to establish standardized procedures for assessing the extent of hydrogen damage, selecting appropriate repair methods, and validating the effectiveness of rehabilitation efforts.

As industries continue to push the boundaries of material performance, the importance of HE rehabilitation grows. The field is evolving to address new challenges posed by emerging materials and extreme operating conditions. This includes the development of rehabilitation techniques for advanced alloys, composite materials, and components subjected to complex loading scenarios. The ultimate goal is to create a comprehensive framework for HE rehabilitation that can be adapted to diverse industrial applications, ensuring the longevity and reliability of critical components in demanding environments.

Market Demand for HE Rehabilitation Solutions

The market demand for hydrogen embrittlement (HE) rehabilitation solutions has been steadily increasing across various industries, particularly in sectors where high-strength materials are extensively used under harsh environmental conditions. Oil and gas, aerospace, automotive, and nuclear power industries are at the forefront of this demand, as they face significant challenges related to HE-affected components.

In the oil and gas sector, the growing exploration and production activities in deep-sea and high-pressure environments have intensified the need for effective HE rehabilitation methods. The industry requires solutions that can extend the lifespan of critical components exposed to hydrogen-rich environments, such as pipelines, valves, and pressure vessels. This demand is further amplified by the increasing focus on safety and reliability in offshore operations.

The aerospace industry, with its stringent safety requirements and the need for lightweight, high-strength materials, has become a key driver in the HE rehabilitation market. As aircraft manufacturers push the boundaries of material performance, the risk of hydrogen embrittlement in critical components like landing gear, fasteners, and turbine parts has become a major concern. This has led to a surge in demand for advanced repair and re-qualification techniques that can ensure the long-term integrity of these components.

In the automotive sector, the shift towards hydrogen fuel cell vehicles has created a new dimension of HE-related challenges. The industry is actively seeking rehabilitation solutions for components exposed to high-pressure hydrogen storage and distribution systems. This includes tanks, valves, and fuel lines that require regular inspection and potential repair to maintain their structural integrity and safety.

The nuclear power industry, with its aging infrastructure and the need for extended plant life, has also contributed significantly to the market demand for HE rehabilitation solutions. Reactor components, pressure vessels, and piping systems in nuclear facilities are subject to harsh environments that can lead to hydrogen embrittlement. The industry requires sophisticated repair methods and testing protocols to ensure the continued safe operation of these critical components.

The market for HE rehabilitation solutions is not limited to these sectors alone. Other industries such as chemical processing, renewable energy, and manufacturing are also recognizing the importance of addressing hydrogen embrittlement issues in their operations. This broad-based demand is driving innovation in repair technologies, non-destructive testing methods, and re-qualification procedures.

As environmental regulations become more stringent and the focus on sustainability intensifies, there is a growing emphasis on developing eco-friendly and cost-effective rehabilitation solutions. This trend is expected to further shape the market demand, with a preference for methods that minimize waste, reduce energy consumption, and extend the service life of components without compromising on safety or performance.

In the oil and gas sector, the growing exploration and production activities in deep-sea and high-pressure environments have intensified the need for effective HE rehabilitation methods. The industry requires solutions that can extend the lifespan of critical components exposed to hydrogen-rich environments, such as pipelines, valves, and pressure vessels. This demand is further amplified by the increasing focus on safety and reliability in offshore operations.

The aerospace industry, with its stringent safety requirements and the need for lightweight, high-strength materials, has become a key driver in the HE rehabilitation market. As aircraft manufacturers push the boundaries of material performance, the risk of hydrogen embrittlement in critical components like landing gear, fasteners, and turbine parts has become a major concern. This has led to a surge in demand for advanced repair and re-qualification techniques that can ensure the long-term integrity of these components.

In the automotive sector, the shift towards hydrogen fuel cell vehicles has created a new dimension of HE-related challenges. The industry is actively seeking rehabilitation solutions for components exposed to high-pressure hydrogen storage and distribution systems. This includes tanks, valves, and fuel lines that require regular inspection and potential repair to maintain their structural integrity and safety.

The nuclear power industry, with its aging infrastructure and the need for extended plant life, has also contributed significantly to the market demand for HE rehabilitation solutions. Reactor components, pressure vessels, and piping systems in nuclear facilities are subject to harsh environments that can lead to hydrogen embrittlement. The industry requires sophisticated repair methods and testing protocols to ensure the continued safe operation of these critical components.

The market for HE rehabilitation solutions is not limited to these sectors alone. Other industries such as chemical processing, renewable energy, and manufacturing are also recognizing the importance of addressing hydrogen embrittlement issues in their operations. This broad-based demand is driving innovation in repair technologies, non-destructive testing methods, and re-qualification procedures.

As environmental regulations become more stringent and the focus on sustainability intensifies, there is a growing emphasis on developing eco-friendly and cost-effective rehabilitation solutions. This trend is expected to further shape the market demand, with a preference for methods that minimize waste, reduce energy consumption, and extend the service life of components without compromising on safety or performance.

Current Challenges in HE-affected Component Repair

The rehabilitation of HE-affected components presents several significant challenges in the current technological landscape. One of the primary obstacles is the accurate detection and characterization of hydrogen embrittlement (HE) damage. Traditional non-destructive testing methods often struggle to identify microscopic cracks and material degradation caused by hydrogen ingress, leading to potential oversight of critical damage.

Another major challenge lies in the development of effective repair methodologies that can fully restore the mechanical properties and structural integrity of HE-affected components. Conventional repair techniques, such as heat treatment or surface treatments, may not always be sufficient to completely reverse the effects of hydrogen embrittlement, especially in cases of severe damage or in components with complex geometries.

The re-qualification process for repaired components poses its own set of challenges. Establishing standardized protocols and acceptance criteria for repaired HE-affected components is crucial, yet often lacking in many industries. This absence of clear guidelines can lead to inconsistencies in the evaluation of repaired parts and potential safety risks if inadequately repaired components are returned to service.

Furthermore, the time-sensitive nature of HE damage repair adds another layer of complexity. Hydrogen can continue to diffuse and cause further embrittlement even after a component is removed from service, necessitating rapid assessment and repair procedures. However, rushed repairs without proper evaluation and testing can lead to inadequate restoration of material properties.

The testing of repaired components also presents challenges, particularly in replicating service conditions and long-term performance. Accelerated testing methods may not always accurately predict the behavior of repaired components under actual operating conditions, especially considering the potential for residual hydrogen or microstructural changes introduced during the repair process.

Lastly, the cost-effectiveness of repair versus replacement remains a significant consideration. Developing economically viable repair solutions that can compete with the option of component replacement, especially for high-value or critical components, is an ongoing challenge in the field of HE-affected component rehabilitation.

Another major challenge lies in the development of effective repair methodologies that can fully restore the mechanical properties and structural integrity of HE-affected components. Conventional repair techniques, such as heat treatment or surface treatments, may not always be sufficient to completely reverse the effects of hydrogen embrittlement, especially in cases of severe damage or in components with complex geometries.

The re-qualification process for repaired components poses its own set of challenges. Establishing standardized protocols and acceptance criteria for repaired HE-affected components is crucial, yet often lacking in many industries. This absence of clear guidelines can lead to inconsistencies in the evaluation of repaired parts and potential safety risks if inadequately repaired components are returned to service.

Furthermore, the time-sensitive nature of HE damage repair adds another layer of complexity. Hydrogen can continue to diffuse and cause further embrittlement even after a component is removed from service, necessitating rapid assessment and repair procedures. However, rushed repairs without proper evaluation and testing can lead to inadequate restoration of material properties.

The testing of repaired components also presents challenges, particularly in replicating service conditions and long-term performance. Accelerated testing methods may not always accurately predict the behavior of repaired components under actual operating conditions, especially considering the potential for residual hydrogen or microstructural changes introduced during the repair process.

Lastly, the cost-effectiveness of repair versus replacement remains a significant consideration. Developing economically viable repair solutions that can compete with the option of component replacement, especially for high-value or critical components, is an ongoing challenge in the field of HE-affected component rehabilitation.

Existing HE Component Repair Methods

01 Rehabilitation methods for HE-affected components

Various rehabilitation methods are developed for components affected by hydrogen embrittlement (HE). These methods may include heat treatments, surface modifications, or specialized coating applications to restore the mechanical properties and integrity of the affected parts. The rehabilitation process aims to reverse or mitigate the effects of hydrogen embrittlement, improving the component's durability and performance.- Rehabilitation methods for HE-affected components: Various rehabilitation methods are developed for components affected by hydrogen embrittlement (HE). These methods may include heat treatments, surface modifications, or specialized coating applications to restore the mechanical properties and integrity of the affected parts. The rehabilitation process aims to reverse or mitigate the effects of hydrogen embrittlement, improving the component's durability and performance.

- Detection and analysis of HE-affected components: Advanced techniques are employed to detect and analyze components affected by hydrogen embrittlement. These may include non-destructive testing methods, microscopic analysis, and specialized sensors to identify the extent of hydrogen damage. Early detection allows for timely intervention and more effective rehabilitation strategies.

- Preventive measures against hydrogen embrittlement: Preventive measures are developed to protect components from hydrogen embrittlement. These may include the use of hydrogen-resistant materials, protective coatings, or environmental control strategies to minimize hydrogen exposure. Implementing these measures can significantly reduce the need for rehabilitation and extend component lifespan.

- Innovative materials for HE resistance: Research focuses on developing new materials or modifying existing ones to enhance resistance to hydrogen embrittlement. This includes the creation of novel alloys, composites, or surface treatments that can withstand hydrogen exposure without significant degradation, reducing the need for frequent rehabilitation.

- Monitoring and maintenance strategies for HE-prone components: Comprehensive monitoring and maintenance strategies are implemented for components prone to hydrogen embrittlement. These strategies may involve regular inspections, predictive maintenance techniques, and real-time monitoring systems to track the condition of critical components and schedule timely rehabilitation or replacement.

02 Detection and analysis of HE-affected components

Advanced techniques are employed to detect and analyze components affected by hydrogen embrittlement. These may include non-destructive testing methods, microscopic analysis, and specialized sensors to identify the extent of hydrogen damage. Early detection allows for timely intervention and more effective rehabilitation strategies.Expand Specific Solutions03 Preventive measures against hydrogen embrittlement

Preventive measures are developed to protect components from hydrogen embrittlement. These may include the use of hydrogen-resistant materials, protective coatings, or environmental control strategies to minimize hydrogen exposure. Implementing these measures can significantly reduce the need for rehabilitation and extend component lifespan.Expand Specific Solutions04 Innovative materials for HE resistance

Research focuses on developing new materials or modifying existing ones to enhance resistance to hydrogen embrittlement. This includes the creation of novel alloys, composites, or surface treatments that can withstand hydrogen exposure without significant degradation, reducing the need for frequent rehabilitation.Expand Specific Solutions05 Monitoring and maintenance strategies for HE-prone components

Comprehensive monitoring and maintenance strategies are implemented for components prone to hydrogen embrittlement. These may involve regular inspections, predictive maintenance techniques, and real-time monitoring systems to track the condition of critical components. Such strategies enable proactive rehabilitation and prevent catastrophic failures due to HE.Expand Specific Solutions

Key Players in HE Rehabilitation Industry

The competitive landscape for rehabilitating HE-affected components is in a mature stage, with a well-established market and significant industry players. The global market size for this technology is substantial, driven by the increasing need for maintenance and repair in various sectors, including aerospace, energy, and manufacturing. Technologically, the field is advanced, with companies like Rolls-Royce, Safran Aircraft Engines, and General Electric leading in innovation. These firms have developed sophisticated repair methods, re-qualification processes, and testing procedures. Other key players such as Mitsubishi Heavy Industries, Siemens Energy, and IHI Corp. also contribute significantly to the sector's technological maturity, offering diverse solutions for component rehabilitation across different industries.

Safran Aircraft Engines SAS

Technical Solution: Safran has developed specialized repair techniques for HE-affected components in aircraft engines. Their approach focuses on precision repairs using adaptive machining and advanced welding technologies. Safran employs robotic TIG welding systems with real-time monitoring for high-precision repairs of turbine blades and combustor components[7]. They have also implemented innovative cold spray technology for restoring dimensional accuracy of engine casings and frames affected by HE[8]. For re-qualification, Safran utilizes advanced non-destructive testing methods, including computed tomography (CT) scanning and phased array ultrasonic testing (PAUT). Their testing procedures involve extensive rig testing and flight testing to ensure component performance and safety under real-world conditions[9].

Strengths: Expertise in aerospace-specific repairs, advanced NDT capabilities, and rigorous flight testing protocols. Weaknesses: Limited application outside of aerospace and potentially higher costs due to stringent aviation regulations.

General Electric Company

Technical Solution: GE has developed advanced repair methods for HE-affected components in gas turbines. Their approach includes a combination of welding techniques, thermal spray coatings, and advanced heat treatments. GE utilizes automated laser welding systems for precise repairs of turbine blades and vanes[1]. They have also implemented advanced thermal barrier coatings (TBCs) to enhance component resilience against high-temperature oxidation and corrosion[2]. For re-qualification, GE employs non-destructive testing (NDT) methods such as ultrasonic and eddy current inspections to ensure structural integrity. Their testing procedures involve simulated operating conditions in specialized test rigs to validate component performance and durability[3].

Strengths: Comprehensive repair solutions, advanced automation in repair processes, and extensive testing capabilities. Weaknesses: High costs associated with specialized equipment and potential longer downtime for complex repairs.

Innovative HE Rehabilitation Technologies

Method for evaluating hydrogen embrittlement characteristics

PatentWO2019186898A1

Innovation

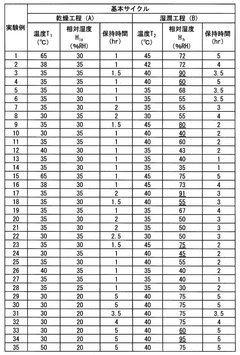

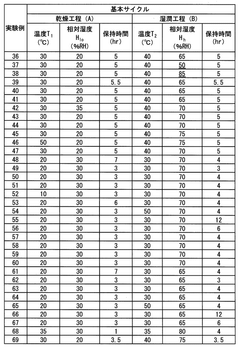

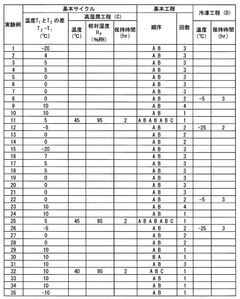

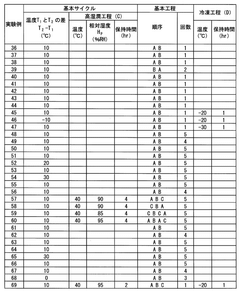

- A method involving a salt adhesion step followed by controlled humidity and temperature cycles, including a wetting step at relative humidity levels close to the deliquescent humidity of the metal salt, a drying step at low temperatures, and a high humidity step, to simulate the corrosion and hydrogen penetration conditions found in real environments, ensuring accurate reproduction of hydrogen embrittlement.

Hydrogen embrittlement evaluation method and evaluation device

PatentWO2024135188A1

Innovation

- A method and device that apply stress to steel specimens with preselected stress triaxiality values between 0.30 and 0.80, simulating actual part stress states by controlling the width-to-thickness ratio and using stress application techniques like bending and ball head extension, while determining the critical hydrogen content using Zn-plated test pieces.

Regulatory Framework for HE Component Re-qualification

The regulatory framework for re-qualifying hydrogen embrittlement (HE) affected components is a critical aspect of ensuring the safety and reliability of repaired or rehabilitated parts. This framework typically involves a combination of industry standards, government regulations, and company-specific procedures.

International standards such as ASTM F1940 and ISO 15156 provide guidelines for testing and evaluating materials susceptible to hydrogen embrittlement. These standards outline specific test methods and acceptance criteria for various materials and applications. Compliance with these standards is often mandatory for industries dealing with high-pressure hydrogen systems or environments prone to HE.

Government agencies, such as the Occupational Safety and Health Administration (OSHA) in the United States, set regulations for workplace safety that include requirements for handling and maintaining equipment exposed to hydrogen. These regulations may specify inspection intervals, documentation requirements, and personnel qualifications for those involved in the re-qualification process.

Industry-specific bodies also play a crucial role in establishing re-qualification protocols. For instance, in the oil and gas sector, organizations like the American Petroleum Institute (API) provide recommended practices and specifications for equipment used in hydrogen-rich environments. These guidelines often become de facto standards for the industry.

The re-qualification process typically involves a series of steps, including non-destructive testing (NDT), mechanical property verification, and in some cases, accelerated life testing. The exact procedures and acceptance criteria may vary depending on the component's criticality, operating conditions, and material properties.

Documentation is a key element of the regulatory framework. Detailed records of the original component specifications, service history, repair procedures, and re-qualification test results must be maintained. This documentation serves as evidence of compliance and provides traceability in case of future issues.

Third-party certification is often required as part of the re-qualification process. Independent laboratories or certification bodies may be engaged to verify test results and ensure compliance with relevant standards and regulations. This adds an extra layer of assurance and credibility to the re-qualification process.

It's important to note that the regulatory framework for HE component re-qualification is not static. As new research emerges and industry practices evolve, standards and regulations are periodically updated. Companies must stay informed about these changes and adapt their re-qualification procedures accordingly to maintain compliance and ensure the ongoing safety and reliability of their equipment.

International standards such as ASTM F1940 and ISO 15156 provide guidelines for testing and evaluating materials susceptible to hydrogen embrittlement. These standards outline specific test methods and acceptance criteria for various materials and applications. Compliance with these standards is often mandatory for industries dealing with high-pressure hydrogen systems or environments prone to HE.

Government agencies, such as the Occupational Safety and Health Administration (OSHA) in the United States, set regulations for workplace safety that include requirements for handling and maintaining equipment exposed to hydrogen. These regulations may specify inspection intervals, documentation requirements, and personnel qualifications for those involved in the re-qualification process.

Industry-specific bodies also play a crucial role in establishing re-qualification protocols. For instance, in the oil and gas sector, organizations like the American Petroleum Institute (API) provide recommended practices and specifications for equipment used in hydrogen-rich environments. These guidelines often become de facto standards for the industry.

The re-qualification process typically involves a series of steps, including non-destructive testing (NDT), mechanical property verification, and in some cases, accelerated life testing. The exact procedures and acceptance criteria may vary depending on the component's criticality, operating conditions, and material properties.

Documentation is a key element of the regulatory framework. Detailed records of the original component specifications, service history, repair procedures, and re-qualification test results must be maintained. This documentation serves as evidence of compliance and provides traceability in case of future issues.

Third-party certification is often required as part of the re-qualification process. Independent laboratories or certification bodies may be engaged to verify test results and ensure compliance with relevant standards and regulations. This adds an extra layer of assurance and credibility to the re-qualification process.

It's important to note that the regulatory framework for HE component re-qualification is not static. As new research emerges and industry practices evolve, standards and regulations are periodically updated. Companies must stay informed about these changes and adapt their re-qualification procedures accordingly to maintain compliance and ensure the ongoing safety and reliability of their equipment.

Economic Impact of HE Rehabilitation Strategies

The economic impact of hydrogen embrittlement (HE) rehabilitation strategies is a critical consideration for industries dealing with high-pressure hydrogen environments. These strategies can significantly influence operational costs, asset longevity, and overall business performance. The implementation of effective repair methods, re-qualification processes, and testing procedures for HE-affected components can lead to substantial cost savings in the long term.

Repair methods for HE-affected components often involve specialized techniques such as heat treatment, surface modification, or material replacement. While these processes incur immediate costs, they can extend the service life of critical components, reducing the frequency of replacements and associated downtime. The economic benefits of such repairs are particularly evident in industries where equipment failure can result in significant production losses or safety hazards.

Re-qualification of repaired components is an essential step that ensures the restored parts meet the required performance standards. This process, although potentially time-consuming and resource-intensive, is crucial for maintaining operational integrity and regulatory compliance. The economic impact of re-qualification is twofold: it mitigates the risk of premature failure, which could lead to costly unplanned shutdowns, and it provides documentation that supports asset management and lifecycle planning.

Testing procedures for HE rehabilitation are integral to validating the effectiveness of repair methods and ensuring the long-term reliability of treated components. Advanced testing techniques, such as hydrogen permeation measurements or mechanical property assessments, may require substantial initial investments in equipment and expertise. However, these investments can yield significant returns by preventing catastrophic failures and extending the operational lifespan of critical infrastructure.

The economic impact of HE rehabilitation strategies extends beyond direct repair and testing costs. Improved component reliability can lead to reduced insurance premiums, enhanced operational efficiency, and increased customer confidence. Moreover, effective rehabilitation programs can defer or eliminate the need for complete system replacements, resulting in considerable capital expenditure savings.

In assessing the economic viability of HE rehabilitation strategies, organizations must consider the balance between upfront costs and long-term benefits. Factors such as the criticality of the component, the potential consequences of failure, and the expected service life post-rehabilitation all play crucial roles in determining the overall economic impact. Additionally, the development of in-house expertise in HE rehabilitation can position companies as industry leaders, potentially opening new revenue streams through consulting or specialized services.

Repair methods for HE-affected components often involve specialized techniques such as heat treatment, surface modification, or material replacement. While these processes incur immediate costs, they can extend the service life of critical components, reducing the frequency of replacements and associated downtime. The economic benefits of such repairs are particularly evident in industries where equipment failure can result in significant production losses or safety hazards.

Re-qualification of repaired components is an essential step that ensures the restored parts meet the required performance standards. This process, although potentially time-consuming and resource-intensive, is crucial for maintaining operational integrity and regulatory compliance. The economic impact of re-qualification is twofold: it mitigates the risk of premature failure, which could lead to costly unplanned shutdowns, and it provides documentation that supports asset management and lifecycle planning.

Testing procedures for HE rehabilitation are integral to validating the effectiveness of repair methods and ensuring the long-term reliability of treated components. Advanced testing techniques, such as hydrogen permeation measurements or mechanical property assessments, may require substantial initial investments in equipment and expertise. However, these investments can yield significant returns by preventing catastrophic failures and extending the operational lifespan of critical infrastructure.

The economic impact of HE rehabilitation strategies extends beyond direct repair and testing costs. Improved component reliability can lead to reduced insurance premiums, enhanced operational efficiency, and increased customer confidence. Moreover, effective rehabilitation programs can defer or eliminate the need for complete system replacements, resulting in considerable capital expenditure savings.

In assessing the economic viability of HE rehabilitation strategies, organizations must consider the balance between upfront costs and long-term benefits. Factors such as the criticality of the component, the potential consequences of failure, and the expected service life post-rehabilitation all play crucial roles in determining the overall economic impact. Additionally, the development of in-house expertise in HE rehabilitation can position companies as industry leaders, potentially opening new revenue streams through consulting or specialized services.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!