Field Case Studies: HE Failures and Lessons for Design & Maintenance Practices

AUG 21, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HE Failure Background

Heat exchanger (HE) failures have been a persistent challenge in various industries, particularly in oil and gas, chemical processing, and power generation sectors. These failures can lead to significant operational disruptions, safety hazards, and economic losses. The background of HE failures is multifaceted, encompassing a range of factors that contribute to their occurrence and severity.

Historically, heat exchangers have been critical components in industrial processes since the early 20th century. As industrial processes became more complex and demanding, the design and operation of heat exchangers evolved to meet these challenges. However, this evolution has also brought about new failure modes and mechanisms that were not initially anticipated.

One of the primary factors contributing to HE failures is the harsh operating environments in which these devices are often employed. Extreme temperatures, high pressures, and corrosive fluids can all take a toll on heat exchanger materials and components over time. These conditions can lead to various forms of degradation, including corrosion, erosion, and thermal fatigue, which ultimately result in failure if not properly managed.

Material selection plays a crucial role in the longevity and reliability of heat exchangers. Inadequate material choices, often driven by cost considerations or lack of understanding of the operating environment, can lead to premature failures. For instance, using carbon steel in environments with high chloride content can result in rapid corrosion and subsequent failure.

Design flaws are another significant contributor to HE failures. Improper sizing, inadequate flow distribution, and poor thermal expansion management can all lead to operational issues and eventual failure. These design-related problems often stem from insufficient understanding of the process conditions or oversimplification of complex fluid dynamics and heat transfer phenomena.

Operational factors also play a significant role in HE failures. Improper startup and shutdown procedures, inadequate monitoring of process parameters, and failure to adhere to recommended maintenance schedules can all contribute to premature failure. Additionally, changes in process conditions over time, which may not be accounted for in the original design, can lead to unexpected stresses on the heat exchanger.

The impact of HE failures extends beyond immediate operational disruptions. They can result in significant safety risks, including the release of hazardous materials or the potential for fires and explosions. Environmental concerns are also paramount, as failures can lead to uncontrolled emissions or spills. Furthermore, the economic implications of HE failures are substantial, encompassing not only the direct costs of repair or replacement but also the indirect costs associated with production losses and potential regulatory penalties.

Understanding the background of HE failures is crucial for developing effective strategies for their prevention and mitigation. This knowledge forms the foundation for improved design practices, more robust maintenance protocols, and the development of advanced monitoring and predictive maintenance technologies. As industries continue to push the boundaries of process efficiency and intensity, the importance of addressing and mitigating HE failures becomes increasingly critical for sustainable and safe operations.

Historically, heat exchangers have been critical components in industrial processes since the early 20th century. As industrial processes became more complex and demanding, the design and operation of heat exchangers evolved to meet these challenges. However, this evolution has also brought about new failure modes and mechanisms that were not initially anticipated.

One of the primary factors contributing to HE failures is the harsh operating environments in which these devices are often employed. Extreme temperatures, high pressures, and corrosive fluids can all take a toll on heat exchanger materials and components over time. These conditions can lead to various forms of degradation, including corrosion, erosion, and thermal fatigue, which ultimately result in failure if not properly managed.

Material selection plays a crucial role in the longevity and reliability of heat exchangers. Inadequate material choices, often driven by cost considerations or lack of understanding of the operating environment, can lead to premature failures. For instance, using carbon steel in environments with high chloride content can result in rapid corrosion and subsequent failure.

Design flaws are another significant contributor to HE failures. Improper sizing, inadequate flow distribution, and poor thermal expansion management can all lead to operational issues and eventual failure. These design-related problems often stem from insufficient understanding of the process conditions or oversimplification of complex fluid dynamics and heat transfer phenomena.

Operational factors also play a significant role in HE failures. Improper startup and shutdown procedures, inadequate monitoring of process parameters, and failure to adhere to recommended maintenance schedules can all contribute to premature failure. Additionally, changes in process conditions over time, which may not be accounted for in the original design, can lead to unexpected stresses on the heat exchanger.

The impact of HE failures extends beyond immediate operational disruptions. They can result in significant safety risks, including the release of hazardous materials or the potential for fires and explosions. Environmental concerns are also paramount, as failures can lead to uncontrolled emissions or spills. Furthermore, the economic implications of HE failures are substantial, encompassing not only the direct costs of repair or replacement but also the indirect costs associated with production losses and potential regulatory penalties.

Understanding the background of HE failures is crucial for developing effective strategies for their prevention and mitigation. This knowledge forms the foundation for improved design practices, more robust maintenance protocols, and the development of advanced monitoring and predictive maintenance technologies. As industries continue to push the boundaries of process efficiency and intensity, the importance of addressing and mitigating HE failures becomes increasingly critical for sustainable and safe operations.

Market Demand Analysis

The market demand for field case studies on heat exchanger (HE) failures and lessons for design and maintenance practices has been steadily increasing in recent years. This growth is primarily driven by the critical role heat exchangers play in various industries, including oil and gas, chemical processing, power generation, and HVAC systems. As these industries continue to expand and face more stringent efficiency and safety requirements, the need for comprehensive case studies and practical insights becomes paramount.

The global heat exchanger market is projected to reach significant growth in the coming years, with a compound annual growth rate (CAGR) expected to be substantial. This growth is attributed to increasing industrialization, particularly in emerging economies, and the rising demand for energy-efficient heating and cooling solutions. As the market expands, so does the demand for knowledge and expertise in preventing and addressing heat exchanger failures.

Industries are increasingly recognizing the importance of learning from past failures to improve design and maintenance practices. This has led to a surge in demand for field case studies that provide detailed analyses of heat exchanger failures, their root causes, and the lessons learned. These case studies serve as valuable resources for engineers, designers, and maintenance professionals seeking to enhance the reliability and performance of heat exchange systems.

The oil and gas sector, in particular, has shown a strong interest in such case studies due to the critical nature of heat exchangers in their operations. Failures in these systems can lead to significant downtime, production losses, and safety hazards. As a result, companies are investing heavily in research and training programs that incorporate real-world case studies to prevent costly incidents and improve overall operational efficiency.

Furthermore, the growing emphasis on sustainability and environmental regulations has intensified the focus on optimizing heat exchanger performance. Industries are seeking ways to reduce energy consumption and minimize environmental impact, driving the demand for case studies that highlight best practices in design and maintenance for improved efficiency and longevity of heat exchange systems.

The market for field case studies also extends to educational institutions and training organizations. Universities and technical schools are incorporating practical case studies into their curricula to better prepare future engineers for real-world challenges. Professional development programs and industry conferences are increasingly featuring sessions dedicated to analyzing heat exchanger failures and sharing lessons learned.

As digital transformation sweeps across industries, there is a rising demand for case studies that incorporate data analytics and predictive maintenance strategies. Companies are looking for insights on how to leverage advanced technologies to prevent failures and optimize heat exchanger performance, further driving the market for comprehensive field case studies.

The global heat exchanger market is projected to reach significant growth in the coming years, with a compound annual growth rate (CAGR) expected to be substantial. This growth is attributed to increasing industrialization, particularly in emerging economies, and the rising demand for energy-efficient heating and cooling solutions. As the market expands, so does the demand for knowledge and expertise in preventing and addressing heat exchanger failures.

Industries are increasingly recognizing the importance of learning from past failures to improve design and maintenance practices. This has led to a surge in demand for field case studies that provide detailed analyses of heat exchanger failures, their root causes, and the lessons learned. These case studies serve as valuable resources for engineers, designers, and maintenance professionals seeking to enhance the reliability and performance of heat exchange systems.

The oil and gas sector, in particular, has shown a strong interest in such case studies due to the critical nature of heat exchangers in their operations. Failures in these systems can lead to significant downtime, production losses, and safety hazards. As a result, companies are investing heavily in research and training programs that incorporate real-world case studies to prevent costly incidents and improve overall operational efficiency.

Furthermore, the growing emphasis on sustainability and environmental regulations has intensified the focus on optimizing heat exchanger performance. Industries are seeking ways to reduce energy consumption and minimize environmental impact, driving the demand for case studies that highlight best practices in design and maintenance for improved efficiency and longevity of heat exchange systems.

The market for field case studies also extends to educational institutions and training organizations. Universities and technical schools are incorporating practical case studies into their curricula to better prepare future engineers for real-world challenges. Professional development programs and industry conferences are increasingly featuring sessions dedicated to analyzing heat exchanger failures and sharing lessons learned.

As digital transformation sweeps across industries, there is a rising demand for case studies that incorporate data analytics and predictive maintenance strategies. Companies are looking for insights on how to leverage advanced technologies to prevent failures and optimize heat exchanger performance, further driving the market for comprehensive field case studies.

Current Challenges

Heat exchanger (HE) failures continue to pose significant challenges in various industries, particularly in oil and gas, chemical processing, and power generation sectors. These failures not only lead to substantial economic losses but also raise safety concerns and environmental risks. One of the primary challenges is the complexity of failure mechanisms, which often involve a combination of factors such as corrosion, erosion, fouling, and thermal fatigue.

Corrosion remains a persistent issue, with different types of corrosion affecting heat exchangers depending on the operating environment and materials used. Stress corrosion cracking, pitting corrosion, and galvanic corrosion are particularly problematic, often leading to premature failure of critical components. The difficulty in predicting and mitigating these corrosion mechanisms in diverse operational conditions presents a significant challenge for designers and maintenance teams.

Fouling is another major concern that affects heat exchanger performance and longevity. The accumulation of deposits on heat transfer surfaces reduces thermal efficiency and increases pressure drop, leading to higher energy consumption and potential equipment damage. Despite advancements in anti-fouling technologies, finding cost-effective and universally applicable solutions remains challenging, especially in industries dealing with complex fluid compositions.

Thermal fatigue poses a significant challenge, particularly in applications involving frequent temperature fluctuations or thermal cycling. The repeated expansion and contraction of materials can lead to crack initiation and propagation, ultimately resulting in leaks or catastrophic failures. Designing heat exchangers that can withstand these thermal stresses while maintaining optimal performance is an ongoing challenge for engineers.

The increasing demand for higher efficiency and compact designs adds another layer of complexity. As industries push for more efficient heat transfer and smaller footprints, the margin for error in design and operation becomes narrower. This trend often leads to more severe operating conditions, pushing materials and designs to their limits and increasing the risk of failure.

Maintenance practices face challenges in balancing the need for regular inspections and preventive maintenance with the pressure to minimize downtime and operational costs. Non-destructive testing methods, while improving, still have limitations in detecting early-stage defects, especially in complex geometries or hard-to-reach areas of heat exchangers.

Furthermore, the integration of new materials and advanced manufacturing techniques, such as additive manufacturing, introduces new variables in heat exchanger design and maintenance. While these innovations offer potential solutions to some existing problems, they also bring new challenges in terms of long-term reliability, standardization, and quality control.

Lastly, the growing emphasis on sustainability and environmental regulations adds another dimension to heat exchanger design and maintenance challenges. Engineers must now consider not only performance and reliability but also the environmental impact of materials, manufacturing processes, and end-of-life disposal or recycling options.

Corrosion remains a persistent issue, with different types of corrosion affecting heat exchangers depending on the operating environment and materials used. Stress corrosion cracking, pitting corrosion, and galvanic corrosion are particularly problematic, often leading to premature failure of critical components. The difficulty in predicting and mitigating these corrosion mechanisms in diverse operational conditions presents a significant challenge for designers and maintenance teams.

Fouling is another major concern that affects heat exchanger performance and longevity. The accumulation of deposits on heat transfer surfaces reduces thermal efficiency and increases pressure drop, leading to higher energy consumption and potential equipment damage. Despite advancements in anti-fouling technologies, finding cost-effective and universally applicable solutions remains challenging, especially in industries dealing with complex fluid compositions.

Thermal fatigue poses a significant challenge, particularly in applications involving frequent temperature fluctuations or thermal cycling. The repeated expansion and contraction of materials can lead to crack initiation and propagation, ultimately resulting in leaks or catastrophic failures. Designing heat exchangers that can withstand these thermal stresses while maintaining optimal performance is an ongoing challenge for engineers.

The increasing demand for higher efficiency and compact designs adds another layer of complexity. As industries push for more efficient heat transfer and smaller footprints, the margin for error in design and operation becomes narrower. This trend often leads to more severe operating conditions, pushing materials and designs to their limits and increasing the risk of failure.

Maintenance practices face challenges in balancing the need for regular inspections and preventive maintenance with the pressure to minimize downtime and operational costs. Non-destructive testing methods, while improving, still have limitations in detecting early-stage defects, especially in complex geometries or hard-to-reach areas of heat exchangers.

Furthermore, the integration of new materials and advanced manufacturing techniques, such as additive manufacturing, introduces new variables in heat exchanger design and maintenance. While these innovations offer potential solutions to some existing problems, they also bring new challenges in terms of long-term reliability, standardization, and quality control.

Lastly, the growing emphasis on sustainability and environmental regulations adds another dimension to heat exchanger design and maintenance challenges. Engineers must now consider not only performance and reliability but also the environmental impact of materials, manufacturing processes, and end-of-life disposal or recycling options.

Existing HE Solutions

01 Corrosion and fouling prevention

Heat exchanger failures often result from corrosion and fouling. Implementing preventive measures such as using corrosion-resistant materials, applying protective coatings, and incorporating fouling mitigation techniques can significantly extend the lifespan of heat exchangers and reduce failure rates.- Corrosion and fouling prevention: Heat exchanger failures often result from corrosion and fouling. Implementing corrosion-resistant materials and coatings, as well as designing for easy cleaning and maintenance, can help prevent these issues. Regular monitoring and cleaning schedules are essential to maintain efficiency and prevent premature failure.

- Thermal stress management: Thermal stress caused by temperature fluctuations and uneven heat distribution can lead to cracking and leakage in heat exchangers. Proper design considerations, such as expansion joints and flexible mounting, can help mitigate these issues. Additionally, implementing advanced control systems for temperature regulation can reduce thermal stress and extend equipment life.

- Vibration and fatigue reduction: Excessive vibration can cause fatigue failures in heat exchangers, particularly in tube-to-tubesheet joints. Implementing vibration dampening techniques, such as baffle design optimization and proper tube support, can help reduce these issues. Regular monitoring of vibration levels and addressing root causes can prevent premature failures.

- Improved flow distribution: Uneven flow distribution can lead to localized overheating, reduced efficiency, and premature failure of heat exchangers. Optimizing inlet and outlet designs, implementing flow distributors, and using computational fluid dynamics (CFD) analysis during the design phase can help ensure proper flow distribution and prevent related failures.

- Advanced monitoring and predictive maintenance: Implementing advanced monitoring systems and predictive maintenance techniques can help detect potential failures before they occur. This includes using sensors for real-time performance monitoring, data analytics for trend analysis, and machine learning algorithms for predicting maintenance needs. These approaches can significantly reduce downtime and extend the operational life of heat exchangers.

02 Thermal stress management

Thermal stress caused by temperature fluctuations and uneven heat distribution can lead to heat exchanger failures. Designing heat exchangers with proper expansion joints, flexible connections, and optimized flow patterns can help manage thermal stress and prevent structural damage.Expand Specific Solutions03 Leak detection and prevention

Leaks in heat exchangers can result in reduced efficiency and potential system failures. Implementing advanced leak detection systems, improving sealing technologies, and enhancing maintenance procedures can help identify and prevent leaks before they cause significant damage.Expand Specific Solutions04 Vibration and fatigue mitigation

Excessive vibration and fatigue can lead to mechanical failures in heat exchangers. Implementing vibration dampening techniques, optimizing flow distribution, and using advanced materials can help reduce the impact of vibration and extend the operational life of heat exchangers.Expand Specific Solutions05 Performance monitoring and predictive maintenance

Implementing advanced monitoring systems and predictive maintenance strategies can help identify potential issues before they lead to failures. This includes using sensors, data analytics, and machine learning algorithms to assess heat exchanger performance and schedule maintenance activities proactively.Expand Specific Solutions

Key Industry Players

The field of high-entropy (HE) alloy failures and design practices is in a rapidly evolving stage, with a growing market size and increasing technological maturity. The competitive landscape is characterized by a mix of established industry leaders and innovative research institutions. Companies like State Grid Corp. of China, Boeing, and Halliburton Energy Services are leveraging their extensive resources and expertise to advance HE alloy applications in their respective sectors. Meanwhile, research institutes associated with Guangdong Power Grid Co. and Shandong Electric Power Corp. are contributing to the knowledge base through focused studies on failure mechanisms and improved design methodologies. As the technology matures, collaboration between industry and academia is becoming crucial for addressing challenges in HE alloy implementation across various applications.

State Grid Corp. of China

Technical Solution: State Grid Corp. of China has developed a comprehensive approach to address HE (High Energy) failures in power systems. Their strategy includes advanced condition monitoring systems that utilize AI and machine learning algorithms to predict potential failures[1]. They have implemented a multi-layered defense system, combining real-time data analysis with historical failure patterns to identify high-risk components. The company has also developed specialized insulation materials and designs that can withstand extreme electrical and environmental stresses, significantly reducing the occurrence of HE failures[2]. Additionally, they have implemented a grid-wide asset management system that prioritizes maintenance and replacement based on risk assessment and criticality analysis[3].

Strengths: Comprehensive approach combining predictive analytics, advanced materials, and systematic asset management. Weaknesses: High implementation costs and potential over-reliance on technology for decision-making.

Guangdong Power Grid Co., Ltd. Electric Power Research Institute

Technical Solution: Guangdong Power Grid Co., Ltd. Electric Power Research Institute has developed an innovative approach to mitigate HE failures through their "Smart Grid Resilience Enhancement Program". This program integrates advanced sensor technologies with big data analytics to create a real-time monitoring system for critical grid components[1]. They have implemented a novel fault location algorithm that can pinpoint HE failure sites with high accuracy, reducing response times significantly[2]. The institute has also developed a unique thermal imaging system for early detection of potential failure points in transmission lines and substations[3]. Furthermore, they have pioneered the use of composite materials in insulator design, which have shown superior performance in high-voltage environments, reducing the likelihood of HE failures[4].

Strengths: Cutting-edge technology integration and innovative material science applications. Weaknesses: May require significant infrastructure upgrades and specialized training for maintenance personnel.

Core HE Technologies

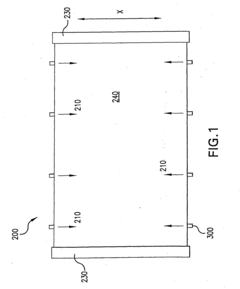

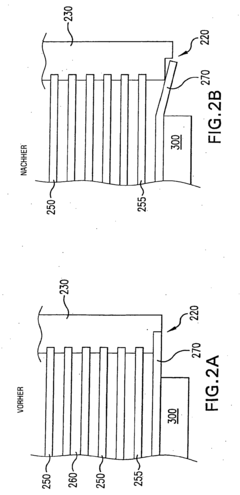

Header arrangement for holding side plates and maintaining constant pressing of outer fins

PatentActiveEP1754946A2

Innovation

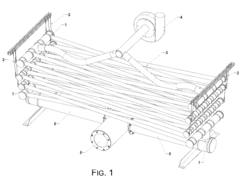

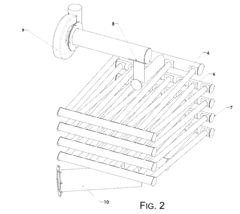

- A heat exchanger design with a header having projections to securely hold end members and allow condensate drainage, minimizing displacement and compression losses, and preventing corrosion by providing a gap for fluid flow between the header and end members.

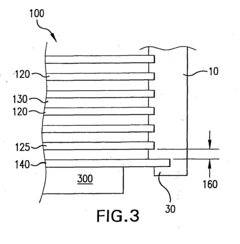

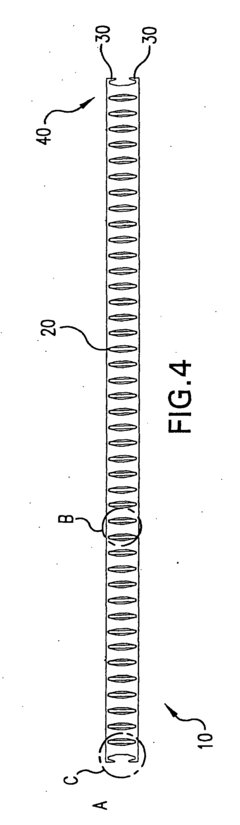

Heat exchanger and related methods

PatentInactiveUS20120305229A1

Innovation

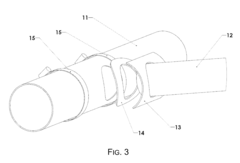

- The implementation of moveable or flexible joints between tubular members allows for thermal expansion and contraction, while maintaining a negative internal pressure to prevent flue gas escape, and includes refractory-lining for corrosion protection, enabling cost-effective and flexible heat exchanger design.

Regulatory Framework

The regulatory framework surrounding heat exchanger (HE) design, operation, and maintenance is a critical aspect of ensuring safety and reliability in industrial processes. Various international and national standards govern the design, fabrication, and inspection of heat exchangers, with organizations such as the American Society of Mechanical Engineers (ASME) and the European Pressure Equipment Directive (PED) playing key roles in setting these standards.

ASME's Boiler and Pressure Vessel Code (BPVC) is widely recognized and adopted globally. Section VIII of the BPVC specifically addresses the design and construction of pressure vessels, including heat exchangers. This section provides detailed guidelines on material selection, design calculations, fabrication techniques, and quality control measures. Compliance with these standards is often mandatory in many jurisdictions and is crucial for ensuring the structural integrity and safe operation of heat exchangers.

In Europe, the Pressure Equipment Directive (2014/68/EU) sets out the essential safety requirements for pressure equipment, including heat exchangers. This directive is harmonized across the European Union and requires manufacturers to perform risk assessments, implement appropriate design and manufacturing processes, and obtain CE marking for their products.

Regulatory bodies also mandate regular inspections and maintenance of heat exchangers. For instance, the Occupational Safety and Health Administration (OSHA) in the United States requires employers to maintain and inspect pressure vessels, including heat exchangers, to ensure workplace safety. Similarly, the Health and Safety Executive (HSE) in the United Kingdom provides guidance on the safe operation and maintenance of pressure systems.

Environmental regulations also play a significant role in heat exchanger design and operation. Agencies such as the Environmental Protection Agency (EPA) in the US and the European Environment Agency (EEA) set standards for emissions and energy efficiency, which directly impact heat exchanger design and operational practices.

The regulatory landscape is not static; it evolves in response to technological advancements, lessons learned from incidents, and changing environmental and safety priorities. For instance, the increasing focus on reducing greenhouse gas emissions has led to more stringent regulations on energy efficiency, prompting innovations in heat exchanger design to improve thermal performance and reduce energy consumption.

Understanding and adhering to this complex regulatory framework is essential for engineers and operators involved in heat exchanger design, maintenance, and operation. It not only ensures compliance with legal requirements but also promotes best practices that enhance safety, reliability, and efficiency in industrial processes.

ASME's Boiler and Pressure Vessel Code (BPVC) is widely recognized and adopted globally. Section VIII of the BPVC specifically addresses the design and construction of pressure vessels, including heat exchangers. This section provides detailed guidelines on material selection, design calculations, fabrication techniques, and quality control measures. Compliance with these standards is often mandatory in many jurisdictions and is crucial for ensuring the structural integrity and safe operation of heat exchangers.

In Europe, the Pressure Equipment Directive (2014/68/EU) sets out the essential safety requirements for pressure equipment, including heat exchangers. This directive is harmonized across the European Union and requires manufacturers to perform risk assessments, implement appropriate design and manufacturing processes, and obtain CE marking for their products.

Regulatory bodies also mandate regular inspections and maintenance of heat exchangers. For instance, the Occupational Safety and Health Administration (OSHA) in the United States requires employers to maintain and inspect pressure vessels, including heat exchangers, to ensure workplace safety. Similarly, the Health and Safety Executive (HSE) in the United Kingdom provides guidance on the safe operation and maintenance of pressure systems.

Environmental regulations also play a significant role in heat exchanger design and operation. Agencies such as the Environmental Protection Agency (EPA) in the US and the European Environment Agency (EEA) set standards for emissions and energy efficiency, which directly impact heat exchanger design and operational practices.

The regulatory landscape is not static; it evolves in response to technological advancements, lessons learned from incidents, and changing environmental and safety priorities. For instance, the increasing focus on reducing greenhouse gas emissions has led to more stringent regulations on energy efficiency, prompting innovations in heat exchanger design to improve thermal performance and reduce energy consumption.

Understanding and adhering to this complex regulatory framework is essential for engineers and operators involved in heat exchanger design, maintenance, and operation. It not only ensures compliance with legal requirements but also promotes best practices that enhance safety, reliability, and efficiency in industrial processes.

Economic Impact

The economic impact of heat exchanger (HE) failures in industrial settings can be substantial, affecting both operational efficiency and financial performance. These failures often lead to unplanned downtime, reduced production capacity, and increased maintenance costs, which collectively contribute to significant economic losses for businesses across various sectors.

In the oil and gas industry, for instance, HE failures can result in production interruptions that cost millions of dollars per day. A single day of downtime in a large refinery can lead to revenue losses exceeding $1 million, not including the additional expenses associated with emergency repairs and potential safety incidents. Similarly, in the power generation sector, HE failures in steam turbines or cooling systems can force entire plants offline, causing widespread power outages and substantial economic repercussions.

The chemical processing industry also faces severe economic consequences from HE failures. These incidents can disrupt production schedules, compromise product quality, and necessitate costly cleanup operations. In some cases, the financial impact extends beyond immediate operational losses to include regulatory fines, legal liabilities, and damage to company reputation.

Maintenance practices play a crucial role in mitigating these economic risks. Proactive maintenance strategies, such as condition-based monitoring and predictive maintenance, can significantly reduce the likelihood of catastrophic failures and extend the operational life of heat exchangers. While these approaches require initial investments in technology and training, they often result in substantial long-term cost savings by preventing unexpected shutdowns and optimizing maintenance schedules.

The economic benefits of improved design practices are equally significant. Advanced materials and innovative designs that enhance heat transfer efficiency and resistance to corrosion and fouling can dramatically reduce lifecycle costs. For example, the implementation of self-cleaning heat exchangers in certain applications has been shown to decrease maintenance requirements by up to 50%, resulting in considerable operational savings.

Furthermore, the economic impact of HE failures extends to the supply chain and associated industries. Suppliers of replacement parts and maintenance services may experience increased demand during periods of frequent failures, while industries dependent on the affected processes may face production delays and increased costs. This ripple effect underscores the far-reaching economic implications of HE reliability and the importance of robust design and maintenance practices in ensuring industrial stability and profitability.

In the oil and gas industry, for instance, HE failures can result in production interruptions that cost millions of dollars per day. A single day of downtime in a large refinery can lead to revenue losses exceeding $1 million, not including the additional expenses associated with emergency repairs and potential safety incidents. Similarly, in the power generation sector, HE failures in steam turbines or cooling systems can force entire plants offline, causing widespread power outages and substantial economic repercussions.

The chemical processing industry also faces severe economic consequences from HE failures. These incidents can disrupt production schedules, compromise product quality, and necessitate costly cleanup operations. In some cases, the financial impact extends beyond immediate operational losses to include regulatory fines, legal liabilities, and damage to company reputation.

Maintenance practices play a crucial role in mitigating these economic risks. Proactive maintenance strategies, such as condition-based monitoring and predictive maintenance, can significantly reduce the likelihood of catastrophic failures and extend the operational life of heat exchangers. While these approaches require initial investments in technology and training, they often result in substantial long-term cost savings by preventing unexpected shutdowns and optimizing maintenance schedules.

The economic benefits of improved design practices are equally significant. Advanced materials and innovative designs that enhance heat transfer efficiency and resistance to corrosion and fouling can dramatically reduce lifecycle costs. For example, the implementation of self-cleaning heat exchangers in certain applications has been shown to decrease maintenance requirements by up to 50%, resulting in considerable operational savings.

Furthermore, the economic impact of HE failures extends to the supply chain and associated industries. Suppliers of replacement parts and maintenance services may experience increased demand during periods of frequent failures, while industries dependent on the affected processes may face production delays and increased costs. This ripple effect underscores the far-reaching economic implications of HE reliability and the importance of robust design and maintenance practices in ensuring industrial stability and profitability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!