How to Evaluate HE Susceptibility: Standard Slow-Strain Rate and Electrochemical Methods

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HE Susceptibility Background and Objectives

Hydrogen embrittlement (HE) susceptibility is a critical concern in materials science and engineering, particularly in industries where high-strength metals are exposed to hydrogen-rich environments. The evaluation of HE susceptibility has become increasingly important as materials are pushed to their limits in demanding applications such as aerospace, automotive, and energy sectors.

The background of HE susceptibility evaluation dates back to the early 20th century when researchers first observed the detrimental effects of hydrogen on metal properties. Since then, the field has evolved significantly, with advancements in understanding the mechanisms of hydrogen-induced damage and the development of various testing methodologies.

The primary objective of evaluating HE susceptibility is to assess the vulnerability of materials to hydrogen-induced degradation under specific environmental and loading conditions. This evaluation is crucial for predicting material performance, ensuring structural integrity, and preventing catastrophic failures in hydrogen-containing environments.

Standard slow-strain rate testing (SSRT) and electrochemical methods have emerged as two of the most widely used techniques for evaluating HE susceptibility. SSRT involves subjecting a material to a constant, slow strain rate while exposed to a hydrogen-rich environment, allowing for the observation of hydrogen effects on mechanical properties and fracture behavior. This method simulates real-world conditions where materials are subjected to both mechanical stress and hydrogen exposure simultaneously.

Electrochemical methods, on the other hand, focus on the interaction between the material and its environment at the atomic level. These techniques utilize electrochemical principles to control hydrogen uptake and measure the material's response to hydrogen charging. By manipulating factors such as applied potential, current density, and electrolyte composition, researchers can investigate the kinetics of hydrogen absorption and its impact on material properties.

The development of these evaluation methods has been driven by the need for more accurate and reliable assessments of HE susceptibility. As industries continue to push the boundaries of material performance, the importance of these evaluation techniques has grown. They not only help in material selection and design but also contribute to the development of mitigation strategies against hydrogen embrittlement.

The objectives of current research in HE susceptibility evaluation include improving the sensitivity and reproducibility of existing methods, developing new techniques for in-situ monitoring of hydrogen effects, and establishing standardized protocols for comparing results across different laboratories and material systems. Additionally, there is a growing emphasis on correlating laboratory test results with real-world performance to enhance the predictive capabilities of these evaluation methods.

The background of HE susceptibility evaluation dates back to the early 20th century when researchers first observed the detrimental effects of hydrogen on metal properties. Since then, the field has evolved significantly, with advancements in understanding the mechanisms of hydrogen-induced damage and the development of various testing methodologies.

The primary objective of evaluating HE susceptibility is to assess the vulnerability of materials to hydrogen-induced degradation under specific environmental and loading conditions. This evaluation is crucial for predicting material performance, ensuring structural integrity, and preventing catastrophic failures in hydrogen-containing environments.

Standard slow-strain rate testing (SSRT) and electrochemical methods have emerged as two of the most widely used techniques for evaluating HE susceptibility. SSRT involves subjecting a material to a constant, slow strain rate while exposed to a hydrogen-rich environment, allowing for the observation of hydrogen effects on mechanical properties and fracture behavior. This method simulates real-world conditions where materials are subjected to both mechanical stress and hydrogen exposure simultaneously.

Electrochemical methods, on the other hand, focus on the interaction between the material and its environment at the atomic level. These techniques utilize electrochemical principles to control hydrogen uptake and measure the material's response to hydrogen charging. By manipulating factors such as applied potential, current density, and electrolyte composition, researchers can investigate the kinetics of hydrogen absorption and its impact on material properties.

The development of these evaluation methods has been driven by the need for more accurate and reliable assessments of HE susceptibility. As industries continue to push the boundaries of material performance, the importance of these evaluation techniques has grown. They not only help in material selection and design but also contribute to the development of mitigation strategies against hydrogen embrittlement.

The objectives of current research in HE susceptibility evaluation include improving the sensitivity and reproducibility of existing methods, developing new techniques for in-situ monitoring of hydrogen effects, and establishing standardized protocols for comparing results across different laboratories and material systems. Additionally, there is a growing emphasis on correlating laboratory test results with real-world performance to enhance the predictive capabilities of these evaluation methods.

Market Demand for HE Testing

The market demand for hydrogen embrittlement (HE) testing has been steadily increasing due to the growing awareness of its critical impact on material integrity across various industries. As materials science advances and new alloys are developed, the need for accurate and reliable HE susceptibility evaluation methods becomes paramount. Industries such as aerospace, automotive, oil and gas, and nuclear power are particularly invested in HE testing to ensure the safety and longevity of their components and structures.

In the aerospace sector, the demand for HE testing is driven by the use of high-strength steels and titanium alloys in aircraft structures. These materials, while offering excellent strength-to-weight ratios, are susceptible to hydrogen embrittlement. The market for HE testing in this industry is expected to grow as manufacturers seek to optimize material selection and improve safety standards.

The automotive industry is another significant driver of HE testing demand. With the increasing adoption of advanced high-strength steels in vehicle manufacturing to meet fuel efficiency and safety requirements, the need for comprehensive HE susceptibility evaluation has intensified. Additionally, the emerging hydrogen fuel cell vehicle market has created a new segment requiring specialized HE testing for fuel storage and distribution components.

In the oil and gas sector, HE testing is crucial for ensuring the integrity of pipelines, offshore structures, and drilling equipment exposed to hydrogen-rich environments. The market demand in this sector is influenced by stringent safety regulations and the need to prevent catastrophic failures in harsh operating conditions.

The nuclear power industry also contributes to the growing demand for HE testing. Reactor components and fuel cladding materials must withstand extreme conditions without succumbing to hydrogen-induced degradation. As countries invest in nuclear energy as part of their clean energy strategies, the market for HE testing in this sector is expected to expand.

Furthermore, the global push towards a hydrogen-based economy has created new opportunities for HE testing. As hydrogen production, storage, and transportation infrastructure develops, there is an increased need for materials that can withstand hydrogen exposure. This trend is driving research into novel materials and coatings, which in turn fuels the demand for advanced HE testing methodologies.

The market for HE testing is also influenced by the development of international standards and regulations. As governing bodies and industry associations establish more comprehensive guidelines for material qualification and safety assurance, companies are compelled to invest in robust HE testing protocols. This regulatory landscape is expected to further stimulate market growth in the coming years.

In the aerospace sector, the demand for HE testing is driven by the use of high-strength steels and titanium alloys in aircraft structures. These materials, while offering excellent strength-to-weight ratios, are susceptible to hydrogen embrittlement. The market for HE testing in this industry is expected to grow as manufacturers seek to optimize material selection and improve safety standards.

The automotive industry is another significant driver of HE testing demand. With the increasing adoption of advanced high-strength steels in vehicle manufacturing to meet fuel efficiency and safety requirements, the need for comprehensive HE susceptibility evaluation has intensified. Additionally, the emerging hydrogen fuel cell vehicle market has created a new segment requiring specialized HE testing for fuel storage and distribution components.

In the oil and gas sector, HE testing is crucial for ensuring the integrity of pipelines, offshore structures, and drilling equipment exposed to hydrogen-rich environments. The market demand in this sector is influenced by stringent safety regulations and the need to prevent catastrophic failures in harsh operating conditions.

The nuclear power industry also contributes to the growing demand for HE testing. Reactor components and fuel cladding materials must withstand extreme conditions without succumbing to hydrogen-induced degradation. As countries invest in nuclear energy as part of their clean energy strategies, the market for HE testing in this sector is expected to expand.

Furthermore, the global push towards a hydrogen-based economy has created new opportunities for HE testing. As hydrogen production, storage, and transportation infrastructure develops, there is an increased need for materials that can withstand hydrogen exposure. This trend is driving research into novel materials and coatings, which in turn fuels the demand for advanced HE testing methodologies.

The market for HE testing is also influenced by the development of international standards and regulations. As governing bodies and industry associations establish more comprehensive guidelines for material qualification and safety assurance, companies are compelled to invest in robust HE testing protocols. This regulatory landscape is expected to further stimulate market growth in the coming years.

Current HE Evaluation Challenges

The evaluation of hydrogen embrittlement (HE) susceptibility faces several significant challenges in current research and industrial applications. One of the primary issues is the lack of standardization in testing methodologies, which leads to inconsistencies in results across different laboratories and studies. This variability makes it difficult to compare and validate findings, hindering the development of reliable predictive models for HE behavior.

Another challenge lies in the complexity of the HE phenomenon itself. The interaction between hydrogen and materials involves multiple mechanisms, including hydrogen diffusion, trapping, and localized plasticity. These processes are influenced by various factors such as material microstructure, environmental conditions, and applied stress states. As a result, developing comprehensive evaluation methods that account for all these variables remains a significant hurdle.

The time-dependent nature of HE poses additional difficulties in assessment. Traditional mechanical testing methods often fail to capture the long-term effects of hydrogen exposure, which can lead to underestimation of HE susceptibility. This limitation is particularly problematic for materials used in applications with extended service lives, such as infrastructure and energy systems.

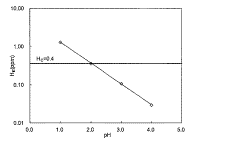

Furthermore, the sensitivity of HE to environmental factors presents challenges in replicating real-world conditions during laboratory testing. Factors such as temperature, pH, and electrochemical potential can significantly influence hydrogen uptake and embrittlement behavior. Accurately simulating these conditions in accelerated testing environments while maintaining relevance to actual service conditions is a complex task.

The development of in-situ monitoring techniques for HE evaluation is another area of ongoing challenge. Current methods often rely on post-mortem analysis, which limits the understanding of HE progression and the ability to detect early stages of embrittlement. Advanced techniques for real-time monitoring of hydrogen concentration, distribution, and material degradation are needed to enhance the accuracy and predictive power of HE susceptibility evaluations.

Lastly, the increasing use of advanced materials and manufacturing processes, such as additive manufacturing and high-entropy alloys, introduces new complexities in HE evaluation. These materials often exhibit unique microstructures and properties that may not be adequately assessed by conventional testing methods. Developing tailored evaluation techniques for these emerging materials is crucial for their safe implementation in hydrogen-rich environments.

Another challenge lies in the complexity of the HE phenomenon itself. The interaction between hydrogen and materials involves multiple mechanisms, including hydrogen diffusion, trapping, and localized plasticity. These processes are influenced by various factors such as material microstructure, environmental conditions, and applied stress states. As a result, developing comprehensive evaluation methods that account for all these variables remains a significant hurdle.

The time-dependent nature of HE poses additional difficulties in assessment. Traditional mechanical testing methods often fail to capture the long-term effects of hydrogen exposure, which can lead to underestimation of HE susceptibility. This limitation is particularly problematic for materials used in applications with extended service lives, such as infrastructure and energy systems.

Furthermore, the sensitivity of HE to environmental factors presents challenges in replicating real-world conditions during laboratory testing. Factors such as temperature, pH, and electrochemical potential can significantly influence hydrogen uptake and embrittlement behavior. Accurately simulating these conditions in accelerated testing environments while maintaining relevance to actual service conditions is a complex task.

The development of in-situ monitoring techniques for HE evaluation is another area of ongoing challenge. Current methods often rely on post-mortem analysis, which limits the understanding of HE progression and the ability to detect early stages of embrittlement. Advanced techniques for real-time monitoring of hydrogen concentration, distribution, and material degradation are needed to enhance the accuracy and predictive power of HE susceptibility evaluations.

Lastly, the increasing use of advanced materials and manufacturing processes, such as additive manufacturing and high-entropy alloys, introduces new complexities in HE evaluation. These materials often exhibit unique microstructures and properties that may not be adequately assessed by conventional testing methods. Developing tailored evaluation techniques for these emerging materials is crucial for their safe implementation in hydrogen-rich environments.

Standard Slow-Strain Rate Method

01 Methods for assessing HE susceptibility

Various techniques and systems have been developed to evaluate an individual's susceptibility to hepatic encephalopathy (HE). These methods may involve analyzing biomarkers, genetic factors, or neurological indicators to determine the likelihood of developing HE or its progression.- Methods for assessing HE susceptibility: Various techniques and systems have been developed to evaluate an individual's susceptibility to hepatic encephalopathy (HE). These methods may involve analyzing biomarkers, genetic factors, or neurological indicators to determine the likelihood of developing HE or its progression.

- Imaging techniques for HE diagnosis: Advanced imaging technologies are employed to detect and assess HE susceptibility. These may include magnetic resonance imaging (MRI), computed tomography (CT), or other specialized imaging methods to visualize brain changes associated with HE.

- Genetic markers for HE susceptibility: Research has identified specific genetic markers that may indicate a predisposition to HE. Genetic testing and analysis of these markers can help in early identification of individuals at higher risk for developing HE.

- Biomarker analysis for HE risk assessment: Certain biomarkers in blood or other bodily fluids can be indicative of HE susceptibility. Analytical methods and devices have been developed to detect and measure these biomarkers, aiding in the assessment of HE risk.

- Neurological testing for HE susceptibility: Specialized neurological tests and cognitive assessments have been designed to evaluate an individual's susceptibility to HE. These tests may measure factors such as reaction time, memory, and other cognitive functions that can be affected by HE.

02 Imaging techniques for HE susceptibility

Advanced imaging technologies are employed to detect and assess HE susceptibility. These may include magnetic resonance imaging (MRI), computed tomography (CT), or other specialized imaging methods to visualize brain changes associated with HE risk.Expand Specific Solutions03 Genetic markers for HE susceptibility

Research has identified specific genetic markers that may indicate an increased susceptibility to HE. Genetic testing and analysis of these markers can help in predicting an individual's risk of developing HE or experiencing more severe symptoms.Expand Specific Solutions04 Biomarker analysis for HE susceptibility

Various biomarkers in blood, urine, or other bodily fluids are being studied and utilized to assess HE susceptibility. These biomarkers may indicate liver function, ammonia levels, or other factors related to HE risk.Expand Specific Solutions05 Neurological testing for HE susceptibility

Specialized neurological tests and assessments have been developed to evaluate cognitive function and detect early signs of HE. These tests may involve measuring reaction times, memory function, or other neurological indicators associated with HE susceptibility.Expand Specific Solutions

Key Players in HE Testing Industry

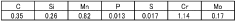

The evaluation of hydrogen embrittlement (HE) susceptibility using standard slow-strain rate and electrochemical methods is a critical area of research in materials science and engineering. The industry is in a mature stage, with established testing protocols and a growing market driven by the increasing use of high-strength materials in various sectors. Key players in this field include major steel manufacturers like NIPPON STEEL CORP., JFE Steel Corp., and POSCO Holdings, Inc., as well as research institutions such as Tianjin University and King Fahd University of Petroleum & Minerals. These organizations are actively involved in developing and refining testing methodologies, with a focus on improving the accuracy and reliability of HE susceptibility assessments for advanced materials used in critical applications.

NIPPON STEEL CORP.

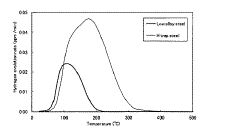

Technical Solution: NIPPON STEEL CORP. has developed advanced methods for evaluating Hydrogen Embrittlement (HE) susceptibility, focusing on both standard slow-strain rate and electrochemical techniques. Their approach combines traditional Slow Strain Rate Testing (SSRT) with in-situ hydrogen charging, allowing for real-time observation of material degradation under hydrogen influence[1]. They have also implemented Electrochemical Hydrogen Permeation tests to quantify hydrogen diffusion and trapping behavior in various steel grades[3]. Additionally, NIPPON STEEL has developed a novel technique using thermal desorption spectroscopy (TDS) coupled with SSRT to analyze hydrogen trapping sites and their impact on mechanical properties[5].

Strengths: Comprehensive evaluation combining mechanical and electrochemical methods, advanced in-situ monitoring capabilities. Weaknesses: Complex testing procedures may require specialized equipment and expertise, potentially limiting widespread adoption.

JFE Steel Corp.

Technical Solution: JFE Steel Corp. has implemented a multi-faceted approach to evaluate HE susceptibility, integrating both standard slow-strain rate and electrochemical methods. Their technique involves a modified SSRT procedure that incorporates controlled hydrogen charging conditions, allowing for precise measurement of ductility loss and fracture behavior[2]. JFE has also developed an advanced electrochemical impedance spectroscopy (EIS) method to assess hydrogen uptake and its effect on passive film stability in various environments[4]. Furthermore, they have pioneered the use of hydrogen microprint technique (HMT) in conjunction with SSRT to visualize hydrogen distribution and its correlation with crack initiation sites[6].

Strengths: High-resolution analysis of hydrogen effects, integration of multiple evaluation techniques. Weaknesses: Time-consuming testing procedures, may require significant sample preparation.

Electrochemical HE Testing Techniques

Evaluation method of hydrogen embrittlement resistance

PatentActiveJP2018159701A

Innovation

- A method involving immersing a test piece in an acid solution to charge hydrogen, measuring the critical diffusible hydrogen content, and determining the range of acid solution concentrations where penetrating hydrogen is lower than the critical diffusible hydrogen, using a test piece with specific dimensions and stress concentration factors, to evaluate hydrogen embrittlement resistance.

Regulatory Standards for HE Testing

Regulatory standards for hydrogen embrittlement (HE) testing play a crucial role in ensuring the safety and reliability of materials and components across various industries. These standards provide a framework for consistent and reliable evaluation of HE susceptibility, allowing for comparisons between different materials and testing conditions.

The American Society for Testing and Materials (ASTM) has developed several key standards for HE testing. ASTM F1940 is a widely recognized standard that outlines the process for evaluating the hydrogen embrittlement characteristics of metallic materials using the slow strain rate test method. This standard provides detailed guidelines for specimen preparation, test procedures, and data analysis.

Another important standard is ASTM F519, which focuses on mechanical hydrogen embrittlement evaluation of plating processes and service environments. This standard is particularly relevant for industries dealing with coated or plated components that may be exposed to hydrogen-rich environments.

The International Organization for Standardization (ISO) has also contributed to the standardization of HE testing methods. ISO 16573 provides guidelines for the evaluation of hydrogen embrittlement in metallic materials, emphasizing the importance of standardized testing procedures for accurate assessment of material susceptibility.

In the aerospace industry, the National Aerospace and Defense Contractors Accreditation Program (NADCAP) has established specific requirements for HE testing. These requirements are often more stringent than general industry standards and are tailored to the unique demands of aerospace applications.

For the automotive sector, the Society of Automotive Engineers (SAE) has developed standards such as SAE J2334, which addresses cyclic corrosion testing of materials used in automotive applications. While not specifically focused on HE, this standard includes considerations for hydrogen-induced damage in its testing protocols.

The European Committee for Standardization (CEN) has also contributed to the field with standards like EN ISO 15330, which covers preloading tests for the detection of hydrogen embrittlement in fasteners. This standard is particularly relevant for industries where high-strength fasteners are used in critical applications.

It is important to note that regulatory standards for HE testing are continually evolving as new research and testing methodologies emerge. Industry professionals must stay informed about updates to these standards and adapt their testing protocols accordingly to ensure compliance and maintain the highest levels of safety and reliability in their products and processes.

The American Society for Testing and Materials (ASTM) has developed several key standards for HE testing. ASTM F1940 is a widely recognized standard that outlines the process for evaluating the hydrogen embrittlement characteristics of metallic materials using the slow strain rate test method. This standard provides detailed guidelines for specimen preparation, test procedures, and data analysis.

Another important standard is ASTM F519, which focuses on mechanical hydrogen embrittlement evaluation of plating processes and service environments. This standard is particularly relevant for industries dealing with coated or plated components that may be exposed to hydrogen-rich environments.

The International Organization for Standardization (ISO) has also contributed to the standardization of HE testing methods. ISO 16573 provides guidelines for the evaluation of hydrogen embrittlement in metallic materials, emphasizing the importance of standardized testing procedures for accurate assessment of material susceptibility.

In the aerospace industry, the National Aerospace and Defense Contractors Accreditation Program (NADCAP) has established specific requirements for HE testing. These requirements are often more stringent than general industry standards and are tailored to the unique demands of aerospace applications.

For the automotive sector, the Society of Automotive Engineers (SAE) has developed standards such as SAE J2334, which addresses cyclic corrosion testing of materials used in automotive applications. While not specifically focused on HE, this standard includes considerations for hydrogen-induced damage in its testing protocols.

The European Committee for Standardization (CEN) has also contributed to the field with standards like EN ISO 15330, which covers preloading tests for the detection of hydrogen embrittlement in fasteners. This standard is particularly relevant for industries where high-strength fasteners are used in critical applications.

It is important to note that regulatory standards for HE testing are continually evolving as new research and testing methodologies emerge. Industry professionals must stay informed about updates to these standards and adapt their testing protocols accordingly to ensure compliance and maintain the highest levels of safety and reliability in their products and processes.

HE Testing Data Analysis and Interpretation

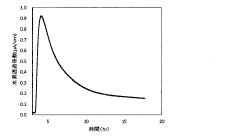

The analysis and interpretation of hydrogen embrittlement (HE) testing data are crucial steps in evaluating material susceptibility to HE. When examining slow-strain rate test results, key parameters such as time to failure, reduction in area, and elongation are compared between tests conducted in air and hydrogen-containing environments. A significant decrease in these parameters in the presence of hydrogen indicates HE susceptibility.

For electrochemical testing methods, the interpretation focuses on changes in polarization curves and electrochemical impedance spectra. Shifts in corrosion potential, increases in corrosion current density, and alterations in passive film behavior can all be indicators of hydrogen effects on the material. The presence of hydrogen often leads to a more negative corrosion potential and higher corrosion rates.

Statistical analysis plays a vital role in data interpretation. Techniques such as analysis of variance (ANOVA) and regression analysis are employed to determine the significance of observed differences and establish correlations between test parameters and HE susceptibility. These methods help in quantifying the reliability and reproducibility of the test results.

Fractography and microstructural analysis complement the mechanical and electrochemical data. Examination of fracture surfaces using scanning electron microscopy can reveal characteristic features of hydrogen-induced failure, such as intergranular fracture or quasi-cleavage patterns. These observations provide valuable insights into the mechanisms of hydrogen damage and support the interpretation of quantitative test data.

The integration of multiple testing methods is essential for a comprehensive evaluation of HE susceptibility. Correlations between slow-strain rate test results and electrochemical measurements can provide a more robust assessment of material behavior in hydrogen-containing environments. This multi-faceted approach helps in identifying potential discrepancies and ensures a more accurate interpretation of the material's susceptibility to HE.

Data visualization techniques, including stress-strain curves, Nyquist plots, and cumulative probability distributions, are invaluable tools for presenting and interpreting HE test results. These graphical representations facilitate the comparison of material performance across different test conditions and aid in identifying trends that may not be apparent from numerical data alone.

For electrochemical testing methods, the interpretation focuses on changes in polarization curves and electrochemical impedance spectra. Shifts in corrosion potential, increases in corrosion current density, and alterations in passive film behavior can all be indicators of hydrogen effects on the material. The presence of hydrogen often leads to a more negative corrosion potential and higher corrosion rates.

Statistical analysis plays a vital role in data interpretation. Techniques such as analysis of variance (ANOVA) and regression analysis are employed to determine the significance of observed differences and establish correlations between test parameters and HE susceptibility. These methods help in quantifying the reliability and reproducibility of the test results.

Fractography and microstructural analysis complement the mechanical and electrochemical data. Examination of fracture surfaces using scanning electron microscopy can reveal characteristic features of hydrogen-induced failure, such as intergranular fracture or quasi-cleavage patterns. These observations provide valuable insights into the mechanisms of hydrogen damage and support the interpretation of quantitative test data.

The integration of multiple testing methods is essential for a comprehensive evaluation of HE susceptibility. Correlations between slow-strain rate test results and electrochemical measurements can provide a more robust assessment of material behavior in hydrogen-containing environments. This multi-faceted approach helps in identifying potential discrepancies and ensures a more accurate interpretation of the material's susceptibility to HE.

Data visualization techniques, including stress-strain curves, Nyquist plots, and cumulative probability distributions, are invaluable tools for presenting and interpreting HE test results. These graphical representations facilitate the comparison of material performance across different test conditions and aid in identifying trends that may not be apparent from numerical data alone.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!