Column Chromatography Method Development: Stationary Phase, Mobile Phase and Gradient Optimization

AUG 21, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Chromatography Evolution and Development Objectives

Column chromatography has evolved significantly since its inception in the early 20th century. Initially developed as a simple separation technique using glass columns packed with adsorbent materials, it has transformed into a sophisticated analytical and preparative methodology essential across multiple industries. The evolution began with the pioneering work of Mikhail Tsvet in 1903, who first demonstrated the separation of plant pigments using calcium carbonate columns. This fundamental discovery laid the groundwork for modern chromatographic techniques.

The 1940s and 1950s marked significant advancements with the development of paper chromatography and thin-layer chromatography (TLC), which provided more accessible platforms for separation science. The true revolution came in the 1960s with the introduction of high-performance liquid chromatography (HPLC), dramatically enhancing separation efficiency and detection sensitivity through pressurized systems and improved column technologies.

Recent decades have witnessed exponential growth in chromatographic capabilities, particularly in stationary phase chemistry. The development of silica-based materials with controlled pore sizes, bonded phases with various functionalities, and monolithic columns has expanded the application spectrum. Concurrently, mobile phase optimization has progressed from simple isocratic systems to complex gradient methodologies, enabling the separation of increasingly challenging analyte mixtures.

The primary objective of modern column chromatography method development is to establish robust, efficient, and reproducible separation protocols. This involves systematic optimization of stationary phases, mobile phase compositions, and gradient profiles to achieve desired resolution while minimizing analysis time and solvent consumption. The ultimate goal is to create methods that balance analytical performance with practical considerations such as cost-effectiveness and environmental impact.

Current development efforts focus on enhancing selectivity through novel stationary phase chemistries, improving efficiency through particle size reduction and core-shell technologies, and increasing throughput via ultra-high-pressure systems. Additionally, there is growing emphasis on developing "green" chromatography methods that reduce organic solvent usage and environmental footprint.

The technological trajectory points toward increased automation in method development, with algorithm-driven optimization processes becoming standard practice. Machine learning approaches are beginning to transform how chromatographic methods are developed, allowing for more efficient exploration of the vast parameter space that influences separation performance.

Looking forward, the field aims to achieve greater integration with complementary analytical techniques, particularly mass spectrometry, to enhance detection capabilities and information content. The development objectives also include miniaturization for point-of-use applications and the creation of more universal methods capable of addressing diverse analytical challenges across pharmaceutical, environmental, food safety, and clinical diagnostics domains.

The 1940s and 1950s marked significant advancements with the development of paper chromatography and thin-layer chromatography (TLC), which provided more accessible platforms for separation science. The true revolution came in the 1960s with the introduction of high-performance liquid chromatography (HPLC), dramatically enhancing separation efficiency and detection sensitivity through pressurized systems and improved column technologies.

Recent decades have witnessed exponential growth in chromatographic capabilities, particularly in stationary phase chemistry. The development of silica-based materials with controlled pore sizes, bonded phases with various functionalities, and monolithic columns has expanded the application spectrum. Concurrently, mobile phase optimization has progressed from simple isocratic systems to complex gradient methodologies, enabling the separation of increasingly challenging analyte mixtures.

The primary objective of modern column chromatography method development is to establish robust, efficient, and reproducible separation protocols. This involves systematic optimization of stationary phases, mobile phase compositions, and gradient profiles to achieve desired resolution while minimizing analysis time and solvent consumption. The ultimate goal is to create methods that balance analytical performance with practical considerations such as cost-effectiveness and environmental impact.

Current development efforts focus on enhancing selectivity through novel stationary phase chemistries, improving efficiency through particle size reduction and core-shell technologies, and increasing throughput via ultra-high-pressure systems. Additionally, there is growing emphasis on developing "green" chromatography methods that reduce organic solvent usage and environmental footprint.

The technological trajectory points toward increased automation in method development, with algorithm-driven optimization processes becoming standard practice. Machine learning approaches are beginning to transform how chromatographic methods are developed, allowing for more efficient exploration of the vast parameter space that influences separation performance.

Looking forward, the field aims to achieve greater integration with complementary analytical techniques, particularly mass spectrometry, to enhance detection capabilities and information content. The development objectives also include miniaturization for point-of-use applications and the creation of more universal methods capable of addressing diverse analytical challenges across pharmaceutical, environmental, food safety, and clinical diagnostics domains.

Market Applications and Analytical Demands

Column chromatography has established itself as an indispensable analytical technique across diverse market sectors, with demand continuously evolving to meet increasingly complex analytical challenges. The pharmaceutical industry represents the largest market segment, where chromatographic methods are critical for drug discovery, development, and quality control processes. Regulatory requirements from agencies like FDA and EMA drive the need for highly specific, sensitive, and reproducible chromatographic methods capable of detecting impurities at increasingly lower levels.

The biopharmaceutical sector presents unique analytical demands, particularly for the characterization of large biomolecules such as monoclonal antibodies, requiring specialized chromatographic approaches including size exclusion, ion exchange, and affinity chromatography. Method development in this space must address challenges related to protein stability, post-translational modifications, and aggregation behavior.

Environmental analysis constitutes another significant market application, where chromatographic methods are employed to detect and quantify pollutants, pesticides, and emerging contaminants in various matrices. This sector demands methods with high throughput capabilities and multi-residue analysis potential, often requiring complex gradient optimization to separate structurally similar compounds.

The food and beverage industry relies heavily on chromatographic techniques for quality control, authenticity verification, and safety testing. Method development in this sector must overcome challenges related to complex matrices and the need to detect contaminants at trace levels while maintaining high sample throughput.

Clinical diagnostics represents a rapidly growing application area, where chromatographic methods are increasingly utilized for biomarker discovery and therapeutic drug monitoring. These applications demand methods with exceptional sensitivity, specificity, and robustness, often requiring specialized stationary phases and carefully optimized mobile phase compositions.

Across all these sectors, several common analytical demands are driving innovation in column chromatography method development. These include requirements for faster analysis times without compromising resolution, increased method robustness across different laboratories and instrument platforms, and enhanced sensitivity for trace analysis. Additionally, there is growing demand for "green" chromatography methods that reduce solvent consumption and utilize environmentally friendly mobile phases.

The trend toward miniaturization and automation is reshaping analytical demands, with increasing interest in micro-scale separations and fully automated method development platforms. These technologies promise to reduce sample and solvent requirements while accelerating the optimization process through intelligent algorithms and design of experiments approaches.

The biopharmaceutical sector presents unique analytical demands, particularly for the characterization of large biomolecules such as monoclonal antibodies, requiring specialized chromatographic approaches including size exclusion, ion exchange, and affinity chromatography. Method development in this space must address challenges related to protein stability, post-translational modifications, and aggregation behavior.

Environmental analysis constitutes another significant market application, where chromatographic methods are employed to detect and quantify pollutants, pesticides, and emerging contaminants in various matrices. This sector demands methods with high throughput capabilities and multi-residue analysis potential, often requiring complex gradient optimization to separate structurally similar compounds.

The food and beverage industry relies heavily on chromatographic techniques for quality control, authenticity verification, and safety testing. Method development in this sector must overcome challenges related to complex matrices and the need to detect contaminants at trace levels while maintaining high sample throughput.

Clinical diagnostics represents a rapidly growing application area, where chromatographic methods are increasingly utilized for biomarker discovery and therapeutic drug monitoring. These applications demand methods with exceptional sensitivity, specificity, and robustness, often requiring specialized stationary phases and carefully optimized mobile phase compositions.

Across all these sectors, several common analytical demands are driving innovation in column chromatography method development. These include requirements for faster analysis times without compromising resolution, increased method robustness across different laboratories and instrument platforms, and enhanced sensitivity for trace analysis. Additionally, there is growing demand for "green" chromatography methods that reduce solvent consumption and utilize environmentally friendly mobile phases.

The trend toward miniaturization and automation is reshaping analytical demands, with increasing interest in micro-scale separations and fully automated method development platforms. These technologies promise to reduce sample and solvent requirements while accelerating the optimization process through intelligent algorithms and design of experiments approaches.

Current Challenges in Column Chromatography Methods

Despite significant advancements in column chromatography techniques, several persistent challenges continue to impede optimal method development. The selection of appropriate stationary phases remains problematic due to the vast array of commercially available options with subtle differences in selectivity and retention mechanisms. Researchers often resort to trial-and-error approaches rather than systematic selection methodologies, resulting in inefficient development processes and suboptimal separations.

Mobile phase optimization presents another significant hurdle, particularly for complex samples containing compounds with diverse physicochemical properties. The intricate interplay between pH, buffer concentration, organic modifier type and percentage creates a multidimensional parameter space that is difficult to navigate efficiently. Traditional one-factor-at-a-time optimization approaches frequently fail to identify true optima due to parameter interdependencies.

Gradient development continues to challenge chromatographers, especially when dealing with samples containing components spanning wide polarity ranges. Determining optimal starting conditions, gradient slopes, and hold times requires extensive experimentation. Current predictive models often fall short when applied to novel compound classes or complex matrices, necessitating substantial manual optimization.

Method robustness and transferability represent persistent issues in chromatographic method development. Minor variations in instrument configurations, column batches, or reagent quality can significantly impact separation performance. This challenge is particularly pronounced when methods need to be transferred between different laboratories or scaled from analytical to preparative applications.

The increasing complexity of sample matrices in pharmaceutical, environmental, and biological applications demands more sophisticated separation strategies. Co-eluting compounds, matrix effects, and trace-level analytes in complex backgrounds push conventional chromatographic methods to their limits. Current approaches often struggle to achieve adequate resolution without excessive analysis times.

Automation and high-throughput screening tools, while increasingly available, still present integration challenges with existing workflows. Many laboratories lack seamless systems that can efficiently explore the vast experimental space of chromatographic parameters while minimizing solvent consumption and analyst time.

Emerging regulatory requirements for green chemistry and sustainable analytical methods create additional constraints on method development. Traditional approaches often rely on environmentally problematic solvents and generate significant waste. Developing equally effective methods using greener alternatives requires rethinking established paradigms in chromatographic separations.

Mobile phase optimization presents another significant hurdle, particularly for complex samples containing compounds with diverse physicochemical properties. The intricate interplay between pH, buffer concentration, organic modifier type and percentage creates a multidimensional parameter space that is difficult to navigate efficiently. Traditional one-factor-at-a-time optimization approaches frequently fail to identify true optima due to parameter interdependencies.

Gradient development continues to challenge chromatographers, especially when dealing with samples containing components spanning wide polarity ranges. Determining optimal starting conditions, gradient slopes, and hold times requires extensive experimentation. Current predictive models often fall short when applied to novel compound classes or complex matrices, necessitating substantial manual optimization.

Method robustness and transferability represent persistent issues in chromatographic method development. Minor variations in instrument configurations, column batches, or reagent quality can significantly impact separation performance. This challenge is particularly pronounced when methods need to be transferred between different laboratories or scaled from analytical to preparative applications.

The increasing complexity of sample matrices in pharmaceutical, environmental, and biological applications demands more sophisticated separation strategies. Co-eluting compounds, matrix effects, and trace-level analytes in complex backgrounds push conventional chromatographic methods to their limits. Current approaches often struggle to achieve adequate resolution without excessive analysis times.

Automation and high-throughput screening tools, while increasingly available, still present integration challenges with existing workflows. Many laboratories lack seamless systems that can efficiently explore the vast experimental space of chromatographic parameters while minimizing solvent consumption and analyst time.

Emerging regulatory requirements for green chemistry and sustainable analytical methods create additional constraints on method development. Traditional approaches often rely on environmentally problematic solvents and generate significant waste. Developing equally effective methods using greener alternatives requires rethinking established paradigms in chromatographic separations.

Contemporary Stationary and Mobile Phase Solutions

01 Mobile phase optimization for column chromatography

Optimization of the mobile phase composition is crucial for effective column chromatography separation. This includes selecting appropriate solvents, adjusting pH levels, and modifying ionic strength to enhance separation efficiency. The mobile phase can be optimized to improve resolution, reduce analysis time, and increase sensitivity for specific analytes. Various techniques such as gradient elution and isocratic separation can be employed based on the complexity of the sample mixture.- Mobile phase optimization techniques: Optimization of the mobile phase composition is crucial for effective column chromatography. This includes selecting appropriate solvents, adjusting pH levels, and modifying buffer concentrations to enhance separation efficiency. Gradient elution techniques can be employed to improve resolution for complex mixtures. The proper selection of mobile phase components significantly impacts retention time, peak shape, and overall chromatographic performance.

- Stationary phase selection and modification: The choice and modification of stationary phases play a vital role in column chromatography optimization. Different stationary phases offer varying selectivity for target analytes. Surface modifications, such as bonding specific functional groups to silica supports, can enhance separation specificity. Particle size, pore diameter, and surface area are critical parameters that affect resolution and column efficiency. Novel stationary phase materials can provide improved performance for specific applications.

- Column design and hardware improvements: Innovations in column design and hardware components significantly enhance chromatographic performance. This includes developments in column dimensions, packing techniques, and connection systems. Temperature control mechanisms improve reproducibility and efficiency. Advanced column technologies, such as monolithic columns and core-shell particles, offer improved mass transfer and reduced back pressure. Hardware modifications can minimize dead volume and improve peak resolution.

- Detection and analytical method development: Optimization of detection methods and analytical procedures is essential for accurate quantification and identification of separated compounds. This includes selection of appropriate detectors based on analyte properties, optimization of detector settings, and development of calibration methods. Advanced data processing algorithms enhance signal-to-noise ratios and peak integration. Method validation protocols ensure reliability and reproducibility of chromatographic analyses.

- Automated and high-throughput optimization systems: Automated systems for column chromatography optimization improve efficiency and reproducibility. These include robotic sample preparation, automated method development platforms, and software for experimental design. Machine learning algorithms can predict optimal conditions based on compound properties. High-throughput screening approaches allow rapid evaluation of multiple parameters simultaneously. These systems reduce manual intervention and accelerate the optimization process for complex separations.

02 Stationary phase selection and modification

The selection and modification of stationary phases significantly impact chromatographic performance. Different stationary phases offer varying selectivity for different analytes. Modifications can include surface functionalization, particle size optimization, and pore structure engineering to enhance separation efficiency. Specialized stationary phases can be developed for specific applications, such as chiral separations or size-exclusion chromatography, to improve resolution and selectivity.Expand Specific Solutions03 Column design and hardware optimization

The physical design of chromatography columns significantly affects separation performance. Optimization includes column dimensions (length and diameter), packing methods, and hardware components such as frits and connectors. Advanced column designs can incorporate temperature control systems, pressure-resistant materials, and improved flow distribution mechanisms. These optimizations help minimize band broadening, reduce back pressure, and enhance overall chromatographic efficiency.Expand Specific Solutions04 Automated and intelligent chromatography systems

Modern column chromatography optimization increasingly relies on automated systems and intelligent software. These systems can perform method development through systematic variation of parameters, real-time monitoring of separations, and data analysis. Machine learning algorithms can predict optimal conditions based on molecular structures and previous separation data. Automated systems also enable high-throughput screening of conditions, reducing development time and improving reproducibility.Expand Specific Solutions05 Sample preparation and injection techniques

Effective sample preparation and injection techniques are essential for optimal chromatographic performance. This includes methods for sample concentration, clean-up procedures to remove interfering compounds, and appropriate dissolution techniques. The injection volume, concentration, and solvent compatibility with the mobile phase significantly impact peak shape and resolution. Advanced techniques such as online sample preparation and automated injection systems can improve reproducibility and throughput in column chromatography.Expand Specific Solutions

Leading Manufacturers and Research Institutions

Column chromatography method development is currently in a mature phase, with significant advancements in stationary phase materials, mobile phase compositions, and gradient optimization techniques. The global chromatography market exceeds $10 billion, growing steadily at 6-8% annually, driven by pharmaceutical, biotechnology, and environmental applications. Leading players include Agilent Technologies, Waters Technology, and Daicel Corp., who have developed proprietary stationary phases with enhanced selectivity and efficiency. Biotage AB and Shimazu KK focus on automated systems for gradient optimization, while academic institutions like Vrije Universiteit Brussel and CNRS contribute fundamental research. Pharmaceutical companies such as Merck and Biogen leverage these technologies for drug development, indicating the technology's critical role across multiple industries.

Agilent Technologies, Inc.

Technical Solution: Agilent has developed the InfinityLab LC Method Development Solution, which integrates hardware and software for comprehensive column chromatography optimization. Their approach utilizes multiple column/solvent combinations in parallel with automated method scouting capabilities. The system incorporates Intelligent System Emulation Technology (ISET) that allows methods to be transferred between different LC instruments while maintaining chromatographic results. Agilent's OpenLab CDS software features built-in method development tools that can automatically analyze results from multiple method conditions and rank them based on critical quality attributes like resolution, peak capacity, and analysis time[1]. Their 2D-LC technology enables comprehensive analysis of complex samples by combining orthogonal separation mechanisms, significantly improving peak capacity and resolution for challenging separations[2]. Agilent has also pioneered superficially porous particle (SPP) technology in their Poroshell columns, offering faster analysis with lower backpressure compared to traditional fully porous particles.

Strengths: Comprehensive integrated solution combining hardware and software; automated method scouting reduces development time; advanced software algorithms for intelligent method ranking; wide range of column chemistries available in consistent formats. Weaknesses: Higher initial investment cost compared to manual approaches; complex software may require significant training; proprietary nature of some technologies may limit flexibility with non-Agilent components.

Waters Technology Corp.

Technical Solution: Waters has developed the ACQUITY UPLC Method Development System, which incorporates their patented Ultra Performance Liquid Chromatography (UPLC) technology for superior resolution and speed. Their approach focuses on sub-2-micron particle technology combined with optimized system design to handle higher pressures (up to 15,000 psi), enabling faster separations without sacrificing performance[3]. Waters' Auto•Blend Plus technology automatically creates mobile phase compositions of precise pH and ionic strength, eliminating manual preparation errors and ensuring reproducibility. Their Fusion QbD Method Development Software employs Quality by Design principles with advanced modeling algorithms to predict chromatographic behavior across multiple method parameters simultaneously[4]. The software can generate 3D resolution maps that visualize the "design space" where acceptable separation occurs. Waters has also pioneered charged surface hybrid (CSH) technology in their columns, which provides improved peak shape for basic compounds while maintaining compatibility with a wide pH range (1-11), allowing method developers greater flexibility in mobile phase selection.

Strengths: Industry-leading UPLC technology provides superior resolution and speed; comprehensive QbD-based software for systematic method development; advanced column technologies with unique selectivities; excellent technical support and method transfer capabilities. Weaknesses: Higher system pressure requirements may necessitate newer instrumentation; proprietary column technologies may create vendor lock-in; premium pricing compared to standard HPLC approaches.

Breakthrough Innovations in Phase Chemistry

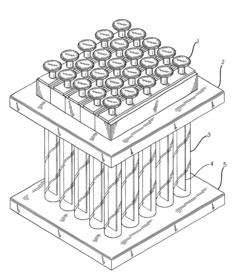

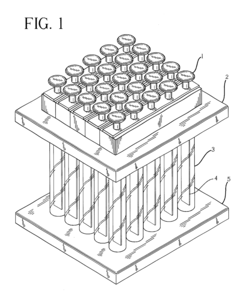

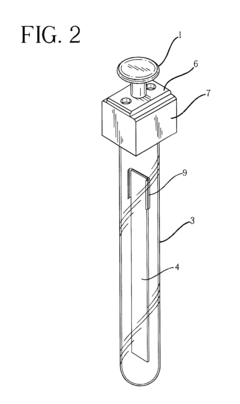

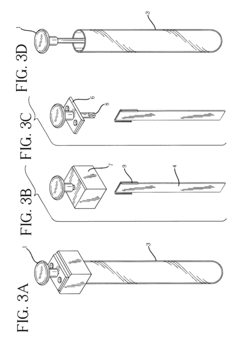

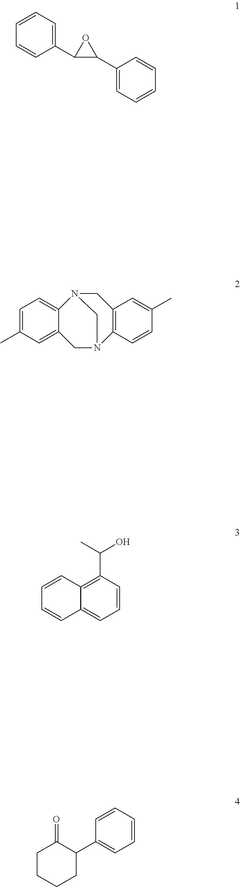

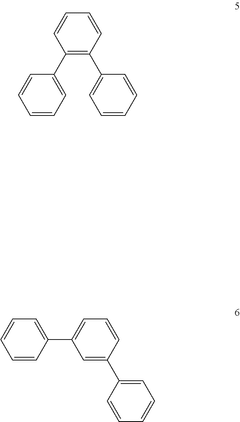

Method and apparatus for developing thin layer chromatography plates for maximizing mobile phase conditions in column chromatography

PatentInactiveUS6264893B1

Innovation

- An apparatus and method utilizing a grid of multiple TLC developing chambers to conduct simultaneous tests with varying solvents and concentrations, optimizing mobile phase conditions for the smallest spot sizes and greatest Rf differences, allowing for the translation of these conditions to achieve the narrowest bands and greatest distance between bands in column chromatography.

Method for producing stationary phase for column chromatography

PatentPendingUS20240382933A1

Innovation

- A method involving radical copolymerization of a base material with radically polymerizable functional groups and a monomer in a heterogeneous system, where the monomer is not completely dissolved in the solvent, to produce a stationary phase with high immobilization and performance.

Validation and Quality Control Strategies

Validation and quality control strategies are essential components of robust column chromatography method development. The establishment of comprehensive validation protocols ensures that methods for stationary phase selection, mobile phase composition, and gradient optimization deliver consistent, reliable, and accurate results. These strategies typically follow regulatory guidelines such as ICH Q2(R1), USP <621>, and FDA guidance documents, which provide frameworks for method validation parameters including specificity, linearity, accuracy, precision, detection limit, quantitation limit, range, robustness, and system suitability.

System suitability testing (SST) serves as a critical quality control measure performed before analytical runs to verify that the chromatographic system operates within acceptable parameters. Key SST metrics include retention factor, resolution, tailing factor, theoretical plate count, and relative standard deviation of replicate injections. These parameters must meet predetermined acceptance criteria to ensure the system's performance is suitable for the intended analysis.

Method transfer protocols are equally important when implementing optimized chromatographic methods across different laboratories or manufacturing sites. These protocols typically involve comparative testing between sending and receiving laboratories, with predefined acceptance criteria for critical method parameters. Successful method transfer ensures consistent performance regardless of location or instrumentation variations.

Continuous method monitoring through control charts and trend analysis provides ongoing verification of method performance. Statistical process control techniques help identify shifts or drifts in chromatographic parameters before they impact data quality. Implementation of quality by design (QbD) principles further enhances method robustness by establishing a design space within which method parameters can vary without significantly affecting results.

Lifecycle management of chromatographic methods involves periodic reviews and revalidation when necessary. Changes in raw materials, equipment, or manufacturing processes may necessitate method adjustments and subsequent revalidation. Modern approaches incorporate analytical quality by design (AQbD) principles, defining method operable design regions (MODR) that establish boundaries within which method parameters can vary while maintaining acceptable performance.

Risk assessment tools such as failure mode and effects analysis (FMEA) help identify critical method parameters that require stringent control. This risk-based approach focuses validation efforts on parameters with the greatest potential impact on method performance, ensuring efficient use of resources while maintaining high-quality results. The integration of automated compliance systems further enhances quality control by providing real-time monitoring and documentation of method performance parameters.

System suitability testing (SST) serves as a critical quality control measure performed before analytical runs to verify that the chromatographic system operates within acceptable parameters. Key SST metrics include retention factor, resolution, tailing factor, theoretical plate count, and relative standard deviation of replicate injections. These parameters must meet predetermined acceptance criteria to ensure the system's performance is suitable for the intended analysis.

Method transfer protocols are equally important when implementing optimized chromatographic methods across different laboratories or manufacturing sites. These protocols typically involve comparative testing between sending and receiving laboratories, with predefined acceptance criteria for critical method parameters. Successful method transfer ensures consistent performance regardless of location or instrumentation variations.

Continuous method monitoring through control charts and trend analysis provides ongoing verification of method performance. Statistical process control techniques help identify shifts or drifts in chromatographic parameters before they impact data quality. Implementation of quality by design (QbD) principles further enhances method robustness by establishing a design space within which method parameters can vary without significantly affecting results.

Lifecycle management of chromatographic methods involves periodic reviews and revalidation when necessary. Changes in raw materials, equipment, or manufacturing processes may necessitate method adjustments and subsequent revalidation. Modern approaches incorporate analytical quality by design (AQbD) principles, defining method operable design regions (MODR) that establish boundaries within which method parameters can vary while maintaining acceptable performance.

Risk assessment tools such as failure mode and effects analysis (FMEA) help identify critical method parameters that require stringent control. This risk-based approach focuses validation efforts on parameters with the greatest potential impact on method performance, ensuring efficient use of resources while maintaining high-quality results. The integration of automated compliance systems further enhances quality control by providing real-time monitoring and documentation of method performance parameters.

Sustainability in Chromatographic Methods

Sustainability in chromatographic methods has become a critical consideration in modern analytical chemistry, driven by increasing environmental awareness and regulatory pressures. Traditional chromatographic techniques often rely on large volumes of organic solvents and generate significant waste, contradicting the principles of green chemistry. The environmental impact of column chromatography extends beyond solvent consumption to energy usage, carbon footprint, and resource depletion.

Recent advances in sustainable chromatography focus on minimizing solvent consumption through miniaturization and optimization of separation processes. Reduced column dimensions, such as those used in micro-bore and capillary columns, significantly decrease mobile phase requirements while maintaining separation efficiency. These approaches align with the "less is more" principle in green analytical chemistry, offering comparable analytical performance with substantially reduced environmental impact.

Mobile phase selection represents another crucial aspect of sustainable chromatography. Water-based mobile phases and the replacement of toxic organic solvents with greener alternatives like ethanol, acetone, or supercritical CO2 have gained traction. The implementation of solvent recycling systems further reduces waste generation and operational costs, creating a more sustainable analytical workflow.

Gradient optimization techniques contribute significantly to sustainability efforts by reducing analysis time and solvent consumption. Computer-assisted method development tools enable the creation of optimized gradients that achieve target separations with minimal resource utilization. These software solutions incorporate sustainability metrics into their algorithms, balancing separation quality with environmental considerations.

The development of room-temperature ionic liquids (RTILs) as alternative stationary phases represents an innovative approach to sustainable chromatography. These designer solvents offer unique selectivity while eliminating the need for traditional organic modifiers in many applications. Similarly, the emergence of solid-phase microextraction (SPME) and stir-bar sorptive extraction (SBSE) techniques has revolutionized sample preparation, dramatically reducing solvent requirements in the pre-chromatographic stage.

Quality-by-Design (QbD) approaches to method development inherently support sustainability by establishing robust methods that minimize failed analyses and subsequent waste generation. By understanding the critical method parameters and their acceptable ranges, analysts can develop methods that remain reliable across varying conditions, reducing the environmental burden associated with repeated analyses and troubleshooting.

The economic benefits of sustainable chromatographic methods often align with environmental advantages. Reduced solvent consumption translates to lower purchase and disposal costs, while energy-efficient instruments decrease operational expenses. These financial incentives, coupled with regulatory compliance and corporate sustainability goals, continue to drive innovation in green chromatography technologies and methodologies.

Recent advances in sustainable chromatography focus on minimizing solvent consumption through miniaturization and optimization of separation processes. Reduced column dimensions, such as those used in micro-bore and capillary columns, significantly decrease mobile phase requirements while maintaining separation efficiency. These approaches align with the "less is more" principle in green analytical chemistry, offering comparable analytical performance with substantially reduced environmental impact.

Mobile phase selection represents another crucial aspect of sustainable chromatography. Water-based mobile phases and the replacement of toxic organic solvents with greener alternatives like ethanol, acetone, or supercritical CO2 have gained traction. The implementation of solvent recycling systems further reduces waste generation and operational costs, creating a more sustainable analytical workflow.

Gradient optimization techniques contribute significantly to sustainability efforts by reducing analysis time and solvent consumption. Computer-assisted method development tools enable the creation of optimized gradients that achieve target separations with minimal resource utilization. These software solutions incorporate sustainability metrics into their algorithms, balancing separation quality with environmental considerations.

The development of room-temperature ionic liquids (RTILs) as alternative stationary phases represents an innovative approach to sustainable chromatography. These designer solvents offer unique selectivity while eliminating the need for traditional organic modifiers in many applications. Similarly, the emergence of solid-phase microextraction (SPME) and stir-bar sorptive extraction (SBSE) techniques has revolutionized sample preparation, dramatically reducing solvent requirements in the pre-chromatographic stage.

Quality-by-Design (QbD) approaches to method development inherently support sustainability by establishing robust methods that minimize failed analyses and subsequent waste generation. By understanding the critical method parameters and their acceptable ranges, analysts can develop methods that remain reliable across varying conditions, reducing the environmental burden associated with repeated analyses and troubleshooting.

The economic benefits of sustainable chromatographic methods often align with environmental advantages. Reduced solvent consumption translates to lower purchase and disposal costs, while energy-efficient instruments decrease operational expenses. These financial incentives, coupled with regulatory compliance and corporate sustainability goals, continue to drive innovation in green chromatography technologies and methodologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!