Column Chromatography Safety and Solvent Disposal Best Practices for Scale-up Operations

AUG 21, 202511 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Chromatography Safety Evolution and Objectives

Column chromatography has evolved significantly over the past several decades, transforming from a purely analytical technique to a critical industrial separation process. The earliest applications in the 1950s and 1960s focused primarily on small-scale laboratory separations with minimal safety protocols. As industrial adoption increased in the 1970s and 1980s, incidents involving solvent fires, chemical exposures, and equipment failures highlighted the need for comprehensive safety frameworks.

The 1990s marked a turning point with the introduction of the first standardized safety guidelines for large-scale chromatographic operations, including proper ventilation requirements, solvent handling protocols, and emergency response procedures. These early standards, however, primarily addressed immediate physical hazards rather than long-term environmental impacts or operator health concerns.

The 2000s witnessed significant advancements in safety engineering for chromatography systems, including the development of closed-loop solvent recovery systems, automated pressure relief mechanisms, and improved column design to prevent catastrophic failures during scale-up operations. This period also saw the emergence of regulatory frameworks specifically addressing chromatography operations in pharmaceutical and biotechnology manufacturing environments.

Recent technological developments have focused on inherently safer design principles, with innovations such as solvent-free chromatography methods, green chemistry approaches to mobile phase selection, and advanced monitoring systems that can detect potential hazards before they escalate. The integration of digital technologies has enabled real-time safety monitoring and predictive maintenance, significantly reducing operational risks.

The primary objective of modern chromatography safety protocols is to establish a comprehensive framework that addresses all aspects of risk throughout the scale-up process. This includes not only preventing acute incidents but also minimizing chronic exposures, environmental impacts, and ensuring regulatory compliance across global operations.

Key technical goals include the development of standardized risk assessment methodologies specific to chromatography scale-up, engineering controls that effectively mitigate identified hazards, and training protocols that ensure operator competency regardless of facility location or experience level. Additionally, there is growing emphasis on designing systems that facilitate proper solvent disposal and recovery, reducing both environmental impact and operational costs.

The evolution trajectory points toward increasingly automated systems with enhanced safety features, reduced solvent consumption, and improved waste management capabilities. Future objectives will likely focus on the development of universal safety standards that can be applied across different industries and regulatory environments, ensuring consistent protection for operators, communities, and ecosystems affected by large-scale chromatographic operations.

The 1990s marked a turning point with the introduction of the first standardized safety guidelines for large-scale chromatographic operations, including proper ventilation requirements, solvent handling protocols, and emergency response procedures. These early standards, however, primarily addressed immediate physical hazards rather than long-term environmental impacts or operator health concerns.

The 2000s witnessed significant advancements in safety engineering for chromatography systems, including the development of closed-loop solvent recovery systems, automated pressure relief mechanisms, and improved column design to prevent catastrophic failures during scale-up operations. This period also saw the emergence of regulatory frameworks specifically addressing chromatography operations in pharmaceutical and biotechnology manufacturing environments.

Recent technological developments have focused on inherently safer design principles, with innovations such as solvent-free chromatography methods, green chemistry approaches to mobile phase selection, and advanced monitoring systems that can detect potential hazards before they escalate. The integration of digital technologies has enabled real-time safety monitoring and predictive maintenance, significantly reducing operational risks.

The primary objective of modern chromatography safety protocols is to establish a comprehensive framework that addresses all aspects of risk throughout the scale-up process. This includes not only preventing acute incidents but also minimizing chronic exposures, environmental impacts, and ensuring regulatory compliance across global operations.

Key technical goals include the development of standardized risk assessment methodologies specific to chromatography scale-up, engineering controls that effectively mitigate identified hazards, and training protocols that ensure operator competency regardless of facility location or experience level. Additionally, there is growing emphasis on designing systems that facilitate proper solvent disposal and recovery, reducing both environmental impact and operational costs.

The evolution trajectory points toward increasingly automated systems with enhanced safety features, reduced solvent consumption, and improved waste management capabilities. Future objectives will likely focus on the development of universal safety standards that can be applied across different industries and regulatory environments, ensuring consistent protection for operators, communities, and ecosystems affected by large-scale chromatographic operations.

Industrial Demand for Safe Scale-up Chromatography

The pharmaceutical and biotechnology industries are experiencing unprecedented growth in the development of complex biologics, monoclonal antibodies, and specialized small molecule therapeutics. This expansion has directly increased the demand for efficient, safe, and environmentally responsible chromatography processes at industrial scale. Market research indicates that the global chromatography market is projected to reach $15 billion by 2025, with industrial-scale applications accounting for approximately 40% of this value.

Safety considerations have become paramount as organizations scale up chromatography operations from laboratory to production levels. A survey of pharmaceutical manufacturers revealed that 78% consider safety protocols for large-scale chromatography as "critically important" to their operations, particularly when handling flammable, toxic, or environmentally hazardous solvents. This heightened awareness stems from several high-profile incidents involving solvent fires and chemical exposures in manufacturing facilities over the past decade.

Regulatory pressures are also driving demand for safer chromatography practices. The implementation of stricter environmental regulations in North America, Europe, and increasingly in Asia has compelled companies to invest in improved solvent handling systems and disposal methods. The European Chemicals Agency's REACH regulations and similar frameworks worldwide have established more stringent requirements for chemical management, with non-compliance resulting in substantial financial penalties and operational disruptions.

Cost considerations further amplify industry interest in optimized chromatography safety protocols. Solvent procurement, storage, and disposal represent significant operational expenses in large-scale purification processes. Companies report that solvent-related costs can constitute up to 30% of total chromatography operational expenses. Implementing efficient solvent recovery systems and safer handling protocols has demonstrated potential cost reductions of 15-25% while simultaneously improving worker safety and environmental compliance.

The biopharmaceutical sector specifically shows the strongest demand for advanced safety solutions in chromatography operations. With biologics manufacturing requiring larger volumes of solvents and buffers compared to traditional pharmaceutical processes, these facilities face unique challenges in scaling chromatography safely. Industry reports indicate that biopharmaceutical companies are investing 40% more in chromatography safety infrastructure compared to traditional pharmaceutical manufacturers.

Contract manufacturing organizations (CMOs) represent another significant market segment driving demand for safer chromatography practices. As these organizations handle diverse projects with varying solvent requirements, they require flexible yet comprehensive safety systems that can adapt to different chromatographic methods while maintaining consistent safety standards across operations.

Safety considerations have become paramount as organizations scale up chromatography operations from laboratory to production levels. A survey of pharmaceutical manufacturers revealed that 78% consider safety protocols for large-scale chromatography as "critically important" to their operations, particularly when handling flammable, toxic, or environmentally hazardous solvents. This heightened awareness stems from several high-profile incidents involving solvent fires and chemical exposures in manufacturing facilities over the past decade.

Regulatory pressures are also driving demand for safer chromatography practices. The implementation of stricter environmental regulations in North America, Europe, and increasingly in Asia has compelled companies to invest in improved solvent handling systems and disposal methods. The European Chemicals Agency's REACH regulations and similar frameworks worldwide have established more stringent requirements for chemical management, with non-compliance resulting in substantial financial penalties and operational disruptions.

Cost considerations further amplify industry interest in optimized chromatography safety protocols. Solvent procurement, storage, and disposal represent significant operational expenses in large-scale purification processes. Companies report that solvent-related costs can constitute up to 30% of total chromatography operational expenses. Implementing efficient solvent recovery systems and safer handling protocols has demonstrated potential cost reductions of 15-25% while simultaneously improving worker safety and environmental compliance.

The biopharmaceutical sector specifically shows the strongest demand for advanced safety solutions in chromatography operations. With biologics manufacturing requiring larger volumes of solvents and buffers compared to traditional pharmaceutical processes, these facilities face unique challenges in scaling chromatography safely. Industry reports indicate that biopharmaceutical companies are investing 40% more in chromatography safety infrastructure compared to traditional pharmaceutical manufacturers.

Contract manufacturing organizations (CMOs) represent another significant market segment driving demand for safer chromatography practices. As these organizations handle diverse projects with varying solvent requirements, they require flexible yet comprehensive safety systems that can adapt to different chromatographic methods while maintaining consistent safety standards across operations.

Current Safety Challenges in Large-Scale Column Operations

As column chromatography operations scale up from laboratory to industrial levels, several critical safety challenges emerge that require systematic attention. The handling of large volumes of potentially hazardous solvents presents significant risks to personnel and facilities. Flammability concerns become paramount, as industrial-scale operations may involve hundreds of liters of highly flammable organic solvents such as hexane, acetone, and methanol. The increased quantities amplify explosion and fire hazards, necessitating robust ventilation systems, specialized electrical equipment, and comprehensive fire suppression infrastructure.

Toxicity management becomes increasingly complex at scale. Chronic exposure to solvents like dichloromethane, chloroform, and toluene poses serious health risks including liver damage, neurological effects, and carcinogenic potential. The challenge lies in maintaining effective exposure controls when processing volumes that generate substantially more vapors and potential for spills than laboratory-scale operations.

Pressure-related hazards represent another significant concern. Large columns can develop dangerous pressure differentials, particularly during packing procedures or if flow becomes restricted. Without proper pressure relief systems and monitoring protocols, column ruptures can occur, resulting in catastrophic solvent releases and potential injuries from projectile materials.

Ergonomic and mechanical risks increase substantially with scale-up. Handling multi-kilogram quantities of stationary phases and large glass or metal columns introduces risks of musculoskeletal injuries and crushing hazards. The physical manipulation of heavy equipment often requires specialized lifting devices and training that may be overlooked during scale-up planning.

Waste management presents perhaps the most persistent challenge. Industrial chromatography generates substantial volumes of contaminated solvents that cannot be disposed of through conventional laboratory waste streams. The environmental impact and regulatory compliance requirements become significantly more complex, with facilities often lacking adequate infrastructure for proper segregation, temporary storage, and disposal of these waste streams.

Cross-contamination risks also increase with scale. In pharmaceutical and food applications, inadequate cleaning between production runs can lead to product contamination with potentially serious consequences for consumer safety. The validation of cleaning procedures becomes more challenging as equipment size increases and access to internal surfaces becomes more difficult.

Emergency response capabilities frequently fail to scale proportionally with operations. Spill containment systems designed for laboratory incidents may be wholly inadequate for industrial-scale releases. Similarly, evacuation procedures and personnel training often do not account for the increased hazard potential of large-scale operations.

Human Engineering | Technology Research Institute

AI: The scale-up of column chromatography operations from laboratory to industrial levels introduces significant safety challenges that require comprehensive management strategies. When handling large volumes of solvents, flammability risks become exponentially greater, as industrial operations may involve hundreds of liters of highly flammable organic solvents such as hexane, acetone, and methanol. These increased quantities necessitate sophisticated fire detection systems, explosion-proof electrical equipment, and specialized ventilation infrastructure that may not be required at laboratory scale.

Toxicity management becomes considerably more complex in scaled-up operations. Workers face potential exposure to significantly larger volumes of harmful solvents including dichloromethane, chloroform, and toluene, which can cause serious health effects ranging from acute respiratory irritation to long-term organ damage and carcinogenic effects. The challenge of maintaining effective exposure controls increases dramatically when processing volumes that generate substantially more vapors and present greater potential for catastrophic spills.

Pressure-related hazards represent a critical safety concern in large-scale column operations. Industrial chromatography columns can develop dangerous pressure differentials, particularly during packing procedures or if flow becomes restricted due to particulate buildup. Without properly engineered pressure relief systems and continuous monitoring protocols, column ruptures can occur with devastating consequences, including explosive solvent releases and injuries from projectile materials.

Physical handling risks increase substantially with scale-up. The manipulation of multi-kilogram quantities of stationary phases and large columns introduces significant ergonomic challenges and potential for crushing injuries. These risks often require specialized material handling equipment and training that may be overlooked during the transition from laboratory to industrial scale.

Waste management presents persistent challenges in scaled-up operations. The volume of contaminated solvents increases dramatically, often overwhelming existing waste handling systems designed for laboratory operations. Regulatory compliance becomes more complex, with facilities facing stricter reporting requirements and potential environmental liabilities associated with larger waste volumes.

Emergency response capabilities frequently fail to scale appropriately with operations. Spill containment systems designed for laboratory incidents may be wholly inadequate for industrial-scale releases. Similarly, evacuation procedures and personnel training often do not account for the increased hazard potential when working with large volumes of hazardous materials.

Cross-contamination risks also increase with scale, particularly in pharmaceutical and food applications where product purity is critical. The validation of cleaning procedures becomes significantly more challenging as equipment size increases and access to internal surfaces becomes more restricted.

Toxicity management becomes increasingly complex at scale. Chronic exposure to solvents like dichloromethane, chloroform, and toluene poses serious health risks including liver damage, neurological effects, and carcinogenic potential. The challenge lies in maintaining effective exposure controls when processing volumes that generate substantially more vapors and potential for spills than laboratory-scale operations.

Pressure-related hazards represent another significant concern. Large columns can develop dangerous pressure differentials, particularly during packing procedures or if flow becomes restricted. Without proper pressure relief systems and monitoring protocols, column ruptures can occur, resulting in catastrophic solvent releases and potential injuries from projectile materials.

Ergonomic and mechanical risks increase substantially with scale-up. Handling multi-kilogram quantities of stationary phases and large glass or metal columns introduces risks of musculoskeletal injuries and crushing hazards. The physical manipulation of heavy equipment often requires specialized lifting devices and training that may be overlooked during scale-up planning.

Waste management presents perhaps the most persistent challenge. Industrial chromatography generates substantial volumes of contaminated solvents that cannot be disposed of through conventional laboratory waste streams. The environmental impact and regulatory compliance requirements become significantly more complex, with facilities often lacking adequate infrastructure for proper segregation, temporary storage, and disposal of these waste streams.

Cross-contamination risks also increase with scale. In pharmaceutical and food applications, inadequate cleaning between production runs can lead to product contamination with potentially serious consequences for consumer safety. The validation of cleaning procedures becomes more challenging as equipment size increases and access to internal surfaces becomes more difficult.

Emergency response capabilities frequently fail to scale proportionally with operations. Spill containment systems designed for laboratory incidents may be wholly inadequate for industrial-scale releases. Similarly, evacuation procedures and personnel training often do not account for the increased hazard potential of large-scale operations.

Human Engineering | Technology Research Institute

AI: The scale-up of column chromatography operations from laboratory to industrial levels introduces significant safety challenges that require comprehensive management strategies. When handling large volumes of solvents, flammability risks become exponentially greater, as industrial operations may involve hundreds of liters of highly flammable organic solvents such as hexane, acetone, and methanol. These increased quantities necessitate sophisticated fire detection systems, explosion-proof electrical equipment, and specialized ventilation infrastructure that may not be required at laboratory scale.

Toxicity management becomes considerably more complex in scaled-up operations. Workers face potential exposure to significantly larger volumes of harmful solvents including dichloromethane, chloroform, and toluene, which can cause serious health effects ranging from acute respiratory irritation to long-term organ damage and carcinogenic effects. The challenge of maintaining effective exposure controls increases dramatically when processing volumes that generate substantially more vapors and present greater potential for catastrophic spills.

Pressure-related hazards represent a critical safety concern in large-scale column operations. Industrial chromatography columns can develop dangerous pressure differentials, particularly during packing procedures or if flow becomes restricted due to particulate buildup. Without properly engineered pressure relief systems and continuous monitoring protocols, column ruptures can occur with devastating consequences, including explosive solvent releases and injuries from projectile materials.

Physical handling risks increase substantially with scale-up. The manipulation of multi-kilogram quantities of stationary phases and large columns introduces significant ergonomic challenges and potential for crushing injuries. These risks often require specialized material handling equipment and training that may be overlooked during the transition from laboratory to industrial scale.

Waste management presents persistent challenges in scaled-up operations. The volume of contaminated solvents increases dramatically, often overwhelming existing waste handling systems designed for laboratory operations. Regulatory compliance becomes more complex, with facilities facing stricter reporting requirements and potential environmental liabilities associated with larger waste volumes.

Emergency response capabilities frequently fail to scale appropriately with operations. Spill containment systems designed for laboratory incidents may be wholly inadequate for industrial-scale releases. Similarly, evacuation procedures and personnel training often do not account for the increased hazard potential when working with large volumes of hazardous materials.

Cross-contamination risks also increase with scale, particularly in pharmaceutical and food applications where product purity is critical. The validation of cleaning procedures becomes significantly more challenging as equipment size increases and access to internal surfaces becomes more restricted.

Established Solvent Handling and Disposal Methodologies

01 Safe handling and containment systems for chromatography solvents

Safety systems for handling volatile and hazardous solvents used in column chromatography, including specialized containment vessels, ventilation systems, and protective equipment. These systems help minimize exposure to toxic vapors, prevent spills, and reduce fire hazards associated with flammable solvents during chromatographic procedures.- Safe handling and disposal of chromatography solvents: Column chromatography involves the use of various solvents that may be hazardous. Proper handling and disposal methods are essential to ensure laboratory safety and environmental protection. This includes collecting waste solvents in designated containers, implementing solvent recovery systems, and following regulatory guidelines for hazardous waste disposal. Proper ventilation systems should be in place to minimize exposure to solvent vapors during chromatography procedures.

- Solvent recovery and recycling systems: Specialized systems for recovering and recycling solvents used in column chromatography can significantly reduce waste and environmental impact. These systems typically involve distillation or filtration processes to purify used solvents for reuse. Implementing solvent recovery technology not only reduces disposal costs but also minimizes the environmental footprint of laboratory operations while maintaining analytical quality and efficiency.

- Safety equipment and protective measures: Proper safety equipment and protective measures are crucial when performing column chromatography. This includes the use of fume hoods, personal protective equipment such as gloves and safety glasses, spill containment systems, and emergency response protocols. Specialized chromatography workstations with integrated safety features can help minimize exposure to hazardous solvents and reduce the risk of accidents during the chromatographic process.

- Environmentally friendly chromatography methods: Development of green chromatography techniques focuses on reducing environmental impact through the use of less toxic solvents, miniaturization of systems, and implementation of more efficient separation methods. These approaches include using water-based mobile phases, biodegradable solvents, or supercritical fluids instead of traditional organic solvents. Such methods maintain analytical performance while significantly reducing hazardous waste generation and improving laboratory safety profiles.

- Automated waste management systems: Automated systems for managing chromatography waste improve safety and efficiency in laboratories. These systems can include integrated waste collection, automated solvent classification, and programmable disposal protocols that minimize human contact with hazardous materials. Some advanced systems incorporate sensors to monitor waste composition and volume, ensuring compliance with disposal regulations and providing documentation for regulatory reporting requirements.

02 Environmentally friendly solvent disposal methods

Methods for proper disposal of used chromatography solvents that minimize environmental impact, including solvent recovery systems, waste treatment processes, and recycling techniques. These approaches help reduce the volume of hazardous waste generated and ensure compliance with environmental regulations while maintaining laboratory efficiency.Expand Specific Solutions03 Automated solvent handling and waste collection systems

Automated systems designed to handle solvents and collect waste during chromatography procedures, reducing manual handling and exposure risks. These systems incorporate sensors, controlled dispensing mechanisms, and integrated waste collection containers that enhance safety while improving process efficiency and reproducibility.Expand Specific Solutions04 Alternative green solvents for column chromatography

Development and implementation of environmentally benign solvents as alternatives to traditional toxic or hazardous solvents in column chromatography. These green solvents reduce safety risks, minimize environmental impact, and simplify disposal procedures while maintaining separation efficiency and analytical performance.Expand Specific Solutions05 Solvent recovery and purification systems

Systems and methods for recovering and purifying used chromatography solvents, allowing for their reuse in subsequent procedures. These technologies include distillation units, filtration systems, and adsorption techniques that reduce waste generation, lower operational costs, and minimize the environmental footprint of chromatographic analyses.Expand Specific Solutions

Leading Organizations in Chromatography Safety Standards

Column chromatography safety and solvent disposal for scale-up operations is evolving in a maturing market with increasing regulatory scrutiny. The global chromatography market, valued at approximately $10 billion, is growing steadily at 6-8% annually, driven by pharmaceutical and biotechnology applications. Leading companies like Agilent Technologies, Waters Technology, and Cytiva Sweden AB have developed comprehensive safety systems integrating automated solvent handling and disposal. Biotage AB and Novasep Process SAS focus on green chemistry approaches with reduced solvent usage, while Sartorius Stedim Biotech and Asahi Kasei Bioprocess offer closed-system technologies minimizing exposure risks. SACHEM and Sinopec are advancing solvent recycling technologies, reflecting the industry's shift toward sustainable practices and enhanced safety protocols for large-scale operations.

Cytiva Sweden AB

Technical Solution: Cytiva's ChromSafe technology platform addresses scale-up chromatography safety through a holistic approach combining hardware innovations and process optimization. Their system features modular containment units that can be configured to match production scale requirements, with specialized ventilation systems that maintain negative pressure in solvent handling areas[1]. For waste management, Cytiva has developed a three-tier solvent classification system that categorizes waste streams based on toxicity, flammability, and recoverability, with corresponding automated handling protocols for each category[2]. The platform incorporates continuous monitoring of oxygen levels and solvent vapor concentrations with automatic shutdown protocols if safety thresholds are exceeded. Their solvent recovery technology employs membrane-based separation techniques that can process up to 500 liters of mixed solvent waste daily, recovering approximately 80% of acetonitrile and other high-value solvents[3]. The system also includes comprehensive training modules and visual workflow guidance to ensure consistent adherence to safety protocols across different operator skill levels.

Strengths: Excellent scalability from laboratory to production environments, strong focus on operator training, and effective integration with existing GMP documentation systems. Weaknesses: Higher operational complexity requiring dedicated technical staff and more extensive maintenance requirements than simpler systems.

Waters Technology Corp.

Technical Solution: Waters has developed the SolventSafe platform specifically for scale-up chromatography operations, focusing on both safety and environmental sustainability. Their system employs closed-loop solvent handling that minimizes operator exposure through vapor-tight connections and automated solvent transfers[1]. The platform incorporates intelligent waste segregation technology that automatically directs waste streams to appropriate collection vessels based on solvent composition analysis performed in real-time[2]. For scale-up operations, Waters' solution includes predictive maintenance algorithms that identify potential leaks or equipment failures before they occur, reducing the risk of accidents during large-volume processing. Their solvent recovery system achieves efficiency rates of 85-95% for common HPLC solvents like acetonitrile and methanol, with integrated distillation technology that maintains solvent purity for potential reuse[3]. The platform also features comprehensive digital tracking of solvent lifecycles from receipt through disposal, ensuring complete chain-of-custody documentation for regulatory compliance.

Strengths: Exceptional solvent recovery rates, sophisticated predictive maintenance capabilities, and comprehensive digital tracking system. Weaknesses: Complex implementation process requiring significant laboratory modifications and ongoing technical support for optimal performance.

Critical Safety Technologies for Scale-up Chromatography

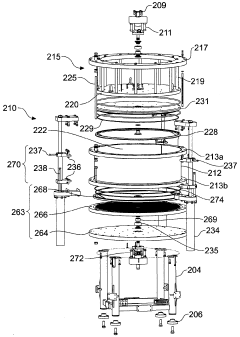

Chromatography columns

PatentInactiveEP3583990A1

Innovation

- Embedding an electrically conductive material, such as carbon-based particles, into the polymeric material of the chromatography columns to reduce or eliminate electrostatic discharge, while maintaining mechanical strength to withstand pressures common in FLASH chromatography.

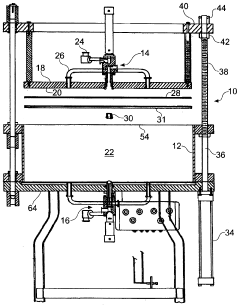

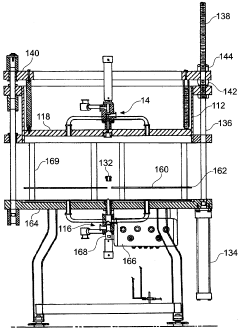

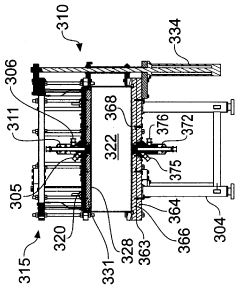

Chromatography column and maintenance method

PatentInactiveIN4198DELNP2010A

Innovation

- The chromatography column design eliminates the need for hoists or cranes during disassembly, significantly improving operational safety by reducing suspended load hazards.

- The column features improved interior access and a specialized handling device for component removal and replacement, streamlining maintenance operations.

- The design incorporates safety-focused engineering that protects operators from working beneath suspended loads within the column structure.

Regulatory Compliance Framework for Chemical Waste Management

The regulatory landscape governing chemical waste management in column chromatography operations is complex and multifaceted, requiring careful navigation to ensure compliance across different jurisdictional levels. At the federal level, the Resource Conservation and Recovery Act (RCRA) establishes the framework for hazardous waste management, with specific provisions for laboratory and industrial chemical waste. The Environmental Protection Agency (EPA) enforces these regulations through permits, inspections, and potential penalties for non-compliance.

State and local regulations often impose additional requirements beyond federal standards, creating a layered compliance framework that varies geographically. Organizations conducting scale-up chromatography operations must maintain comprehensive awareness of these regional variations to ensure full compliance across all operational sites.

International frameworks such as the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and their Disposal become relevant for multinational operations or when shipping waste across borders. These agreements establish protocols for waste classification, documentation, and transfer procedures that must be integrated into organizational compliance systems.

Industry-specific guidelines from organizations like the American Chemical Society (ACS) and the International Conference on Harmonisation (ICH) provide technical standards that complement regulatory requirements. These guidelines often address specialized aspects of chromatography waste management not explicitly covered in broader regulations, such as specific solvent mixtures and column packing materials disposal.

Documentation and reporting constitute critical components of regulatory compliance. Organizations must maintain detailed waste manifests, training records, and disposal documentation. Electronic waste tracking systems have become increasingly important for demonstrating compliance during regulatory audits and inspections.

Waste characterization represents a fundamental compliance requirement, with chromatography operations needing to properly identify, classify, and label all waste streams. This includes determining whether solvents are listed hazardous wastes, exhibit hazardous characteristics, or qualify for specific exemptions under applicable regulations.

Permit requirements vary based on waste volumes and types, with larger scale operations typically facing more stringent permitting processes. Treatment, storage, and disposal facility (TSDF) selection must align with regulatory authorizations for specific waste streams generated during chromatography processes.

Employee training programs must address both general hazardous waste management principles and specific protocols for chromatography solvents and materials. Regular compliance audits and continuous monitoring of regulatory changes complete the framework necessary for maintaining ongoing compliance in scale-up chromatography operations.

State and local regulations often impose additional requirements beyond federal standards, creating a layered compliance framework that varies geographically. Organizations conducting scale-up chromatography operations must maintain comprehensive awareness of these regional variations to ensure full compliance across all operational sites.

International frameworks such as the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and their Disposal become relevant for multinational operations or when shipping waste across borders. These agreements establish protocols for waste classification, documentation, and transfer procedures that must be integrated into organizational compliance systems.

Industry-specific guidelines from organizations like the American Chemical Society (ACS) and the International Conference on Harmonisation (ICH) provide technical standards that complement regulatory requirements. These guidelines often address specialized aspects of chromatography waste management not explicitly covered in broader regulations, such as specific solvent mixtures and column packing materials disposal.

Documentation and reporting constitute critical components of regulatory compliance. Organizations must maintain detailed waste manifests, training records, and disposal documentation. Electronic waste tracking systems have become increasingly important for demonstrating compliance during regulatory audits and inspections.

Waste characterization represents a fundamental compliance requirement, with chromatography operations needing to properly identify, classify, and label all waste streams. This includes determining whether solvents are listed hazardous wastes, exhibit hazardous characteristics, or qualify for specific exemptions under applicable regulations.

Permit requirements vary based on waste volumes and types, with larger scale operations typically facing more stringent permitting processes. Treatment, storage, and disposal facility (TSDF) selection must align with regulatory authorizations for specific waste streams generated during chromatography processes.

Employee training programs must address both general hazardous waste management principles and specific protocols for chromatography solvents and materials. Regular compliance audits and continuous monitoring of regulatory changes complete the framework necessary for maintaining ongoing compliance in scale-up chromatography operations.

Risk Assessment Strategies for Scale-up Operations

Risk assessment in column chromatography scale-up operations requires a systematic approach to identify, evaluate, and mitigate potential hazards. The transition from laboratory to industrial scale introduces new dimensions of risk that must be carefully managed to ensure personnel safety and environmental protection.

A comprehensive risk assessment framework begins with hazard identification specific to large-scale chromatography operations. This includes chemical hazards from solvents (flammability, toxicity, reactivity), physical hazards (high pressure systems, mechanical failures), and process-specific risks (exothermic reactions, uncontrolled releases). The assessment should catalog all materials used, their quantities, and potential interaction effects that may be amplified at scale.

Quantitative risk evaluation methodologies become essential when scaling up operations. Techniques such as Failure Mode and Effects Analysis (FMEA), Hazard and Operability Study (HAZOP), and Layer of Protection Analysis (LOPA) provide structured approaches to evaluate the likelihood and severity of potential incidents. These methodologies help prioritize risks based on their potential impact and probability, enabling resource-efficient mitigation strategies.

Exposure assessment constitutes a critical component of the overall risk framework. At industrial scale, worker exposure to solvents through inhalation, dermal contact, or accidental ingestion presents significant concerns. Implementing occupational exposure limits (OELs) and regular monitoring protocols helps ensure compliance with safety standards. Advanced modeling techniques can predict exposure scenarios under various operating conditions, informing the design of engineering controls.

Engineering controls represent the primary line of defense in risk mitigation. These include closed systems for solvent handling, automated sampling systems, pressure relief devices, ventilation systems, and containment strategies. The hierarchy of controls (elimination, substitution, engineering controls, administrative controls, personal protective equipment) should guide implementation decisions, with preference given to higher-order controls whenever feasible.

Administrative controls complement engineering measures through procedural safeguards. These include standard operating procedures (SOPs) for normal operations and emergency scenarios, training programs tailored to scale-up operations, permit-to-work systems for maintenance activities, and regular safety audits. Documentation and communication systems ensure that risk information flows effectively throughout the organization.

Continuous risk monitoring and review processes are essential as operations evolve. This includes regular reassessment of existing controls, incident investigation protocols, management of change procedures for process modifications, and performance indicators to track safety metrics. The feedback loop ensures that risk assessment remains dynamic and responsive to operational realities.

A comprehensive risk assessment framework begins with hazard identification specific to large-scale chromatography operations. This includes chemical hazards from solvents (flammability, toxicity, reactivity), physical hazards (high pressure systems, mechanical failures), and process-specific risks (exothermic reactions, uncontrolled releases). The assessment should catalog all materials used, their quantities, and potential interaction effects that may be amplified at scale.

Quantitative risk evaluation methodologies become essential when scaling up operations. Techniques such as Failure Mode and Effects Analysis (FMEA), Hazard and Operability Study (HAZOP), and Layer of Protection Analysis (LOPA) provide structured approaches to evaluate the likelihood and severity of potential incidents. These methodologies help prioritize risks based on their potential impact and probability, enabling resource-efficient mitigation strategies.

Exposure assessment constitutes a critical component of the overall risk framework. At industrial scale, worker exposure to solvents through inhalation, dermal contact, or accidental ingestion presents significant concerns. Implementing occupational exposure limits (OELs) and regular monitoring protocols helps ensure compliance with safety standards. Advanced modeling techniques can predict exposure scenarios under various operating conditions, informing the design of engineering controls.

Engineering controls represent the primary line of defense in risk mitigation. These include closed systems for solvent handling, automated sampling systems, pressure relief devices, ventilation systems, and containment strategies. The hierarchy of controls (elimination, substitution, engineering controls, administrative controls, personal protective equipment) should guide implementation decisions, with preference given to higher-order controls whenever feasible.

Administrative controls complement engineering measures through procedural safeguards. These include standard operating procedures (SOPs) for normal operations and emergency scenarios, training programs tailored to scale-up operations, permit-to-work systems for maintenance activities, and regular safety audits. Documentation and communication systems ensure that risk information flows effectively throughout the organization.

Continuous risk monitoring and review processes are essential as operations evolve. This includes regular reassessment of existing controls, incident investigation protocols, management of change procedures for process modifications, and performance indicators to track safety metrics. The feedback loop ensures that risk assessment remains dynamic and responsive to operational realities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!