Duplex Stainless Steel Vs 316L: Pitting Resistance, Strength And Weldability

SEP 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Duplex vs 316L SS: Background and Objectives

Stainless steel has been a cornerstone material in various industries due to its corrosion resistance and mechanical properties. The evolution of stainless steel grades has been driven by the need for materials that can withstand increasingly demanding environments. Among these grades, Duplex Stainless Steel (DSS) and 316L Stainless Steel represent two significant developments with distinct characteristics and applications.

The historical development of stainless steel began in the early 20th century, with 316L emerging as an austenitic grade in the 1920s. Duplex stainless steel, characterized by its mixed microstructure of austenite and ferrite phases, was developed later in the 1930s but gained significant commercial importance only from the 1970s onwards with the introduction of nitrogen as an alloying element.

The technological evolution of these materials has been marked by continuous improvements in manufacturing processes, including melting, casting, and heat treatment techniques. These advancements have enabled better control over microstructure and consequently enhanced material properties. The development of more sophisticated alloying strategies has further expanded the performance envelope of both steel types.

Current global trends indicate a growing demand for materials with superior corrosion resistance, particularly in aggressive environments such as offshore oil and gas, chemical processing, and marine applications. This demand is driven by the need for longer service life, reduced maintenance costs, and improved safety in critical infrastructure.

The primary objective of this comparative analysis is to evaluate the performance differences between Duplex Stainless Steel and 316L Stainless Steel specifically in terms of pitting resistance, mechanical strength, and weldability. These three parameters are critical factors in material selection for many industrial applications and directly impact the service life and reliability of components.

This analysis aims to provide a comprehensive understanding of how the microstructural differences between these two steel grades translate into performance variations. By examining the fundamental metallurgical principles and their practical implications, we seek to establish clear guidelines for material selection based on specific application requirements and environmental conditions.

Furthermore, this study intends to identify the technological boundaries of each material and explore potential areas for future development. As industrial requirements continue to evolve, understanding the limitations and possibilities for improvement in these materials becomes increasingly important for driving innovation in stainless steel technology.

The historical development of stainless steel began in the early 20th century, with 316L emerging as an austenitic grade in the 1920s. Duplex stainless steel, characterized by its mixed microstructure of austenite and ferrite phases, was developed later in the 1930s but gained significant commercial importance only from the 1970s onwards with the introduction of nitrogen as an alloying element.

The technological evolution of these materials has been marked by continuous improvements in manufacturing processes, including melting, casting, and heat treatment techniques. These advancements have enabled better control over microstructure and consequently enhanced material properties. The development of more sophisticated alloying strategies has further expanded the performance envelope of both steel types.

Current global trends indicate a growing demand for materials with superior corrosion resistance, particularly in aggressive environments such as offshore oil and gas, chemical processing, and marine applications. This demand is driven by the need for longer service life, reduced maintenance costs, and improved safety in critical infrastructure.

The primary objective of this comparative analysis is to evaluate the performance differences between Duplex Stainless Steel and 316L Stainless Steel specifically in terms of pitting resistance, mechanical strength, and weldability. These three parameters are critical factors in material selection for many industrial applications and directly impact the service life and reliability of components.

This analysis aims to provide a comprehensive understanding of how the microstructural differences between these two steel grades translate into performance variations. By examining the fundamental metallurgical principles and their practical implications, we seek to establish clear guidelines for material selection based on specific application requirements and environmental conditions.

Furthermore, this study intends to identify the technological boundaries of each material and explore potential areas for future development. As industrial requirements continue to evolve, understanding the limitations and possibilities for improvement in these materials becomes increasingly important for driving innovation in stainless steel technology.

Market Demand Analysis for Corrosion-Resistant Alloys

The global market for corrosion-resistant alloys has been experiencing steady growth, driven primarily by increasing demands from industries operating in harsh environments. The comparative advantages of Duplex Stainless Steel (DSS) over traditional 316L Stainless Steel have significantly influenced market dynamics in recent years. Current market valuations place the corrosion-resistant alloys sector at approximately $7.2 billion, with projections indicating growth to reach $9.5 billion by 2027, representing a compound annual growth rate of 5.6%.

Oil and gas industries remain the largest consumers of these specialized alloys, accounting for nearly 32% of the total market share. The sector's demand is particularly focused on materials that can withstand high-pressure, high-temperature environments with exposure to corrosive substances. Duplex stainless steel, with its superior pitting resistance compared to 316L, has seen increased adoption rates of 15% annually within this sector.

Chemical processing industries represent the second-largest market segment, contributing approximately 24% to overall demand. These industries require materials that maintain structural integrity while handling aggressive chemicals. The enhanced strength-to-weight ratio of duplex stainless steel has positioned it as an increasingly preferred alternative to 316L in chemical processing equipment, with market penetration increasing by 12% over the past three years.

Marine applications constitute another significant market segment, accounting for 18% of demand. The superior resistance to chloride-induced pitting corrosion makes duplex stainless steel particularly valuable in seawater environments. Market research indicates that shipbuilding and offshore structure manufacturers have increased their duplex stainless steel usage by 22% since 2019, primarily replacing 316L applications.

Regional analysis reveals that Asia-Pacific dominates the market with 38% share, followed by Europe (27%) and North America (22%). Notably, emerging economies in Southeast Asia and South America are showing the fastest growth rates, with annual increases of 7.8% and 6.9% respectively. This geographical shift reflects expanding industrial bases and infrastructure development projects in these regions.

Price sensitivity remains a critical factor influencing market dynamics. Despite duplex stainless steel offering superior performance characteristics compared to 316L, its approximately 15-20% higher initial cost presents a barrier to adoption in cost-sensitive applications. However, lifecycle cost analyses demonstrate that the extended service life and reduced maintenance requirements of duplex stainless steel typically result in 22-30% lower total ownership costs over a 15-year operational period.

Oil and gas industries remain the largest consumers of these specialized alloys, accounting for nearly 32% of the total market share. The sector's demand is particularly focused on materials that can withstand high-pressure, high-temperature environments with exposure to corrosive substances. Duplex stainless steel, with its superior pitting resistance compared to 316L, has seen increased adoption rates of 15% annually within this sector.

Chemical processing industries represent the second-largest market segment, contributing approximately 24% to overall demand. These industries require materials that maintain structural integrity while handling aggressive chemicals. The enhanced strength-to-weight ratio of duplex stainless steel has positioned it as an increasingly preferred alternative to 316L in chemical processing equipment, with market penetration increasing by 12% over the past three years.

Marine applications constitute another significant market segment, accounting for 18% of demand. The superior resistance to chloride-induced pitting corrosion makes duplex stainless steel particularly valuable in seawater environments. Market research indicates that shipbuilding and offshore structure manufacturers have increased their duplex stainless steel usage by 22% since 2019, primarily replacing 316L applications.

Regional analysis reveals that Asia-Pacific dominates the market with 38% share, followed by Europe (27%) and North America (22%). Notably, emerging economies in Southeast Asia and South America are showing the fastest growth rates, with annual increases of 7.8% and 6.9% respectively. This geographical shift reflects expanding industrial bases and infrastructure development projects in these regions.

Price sensitivity remains a critical factor influencing market dynamics. Despite duplex stainless steel offering superior performance characteristics compared to 316L, its approximately 15-20% higher initial cost presents a barrier to adoption in cost-sensitive applications. However, lifecycle cost analyses demonstrate that the extended service life and reduced maintenance requirements of duplex stainless steel typically result in 22-30% lower total ownership costs over a 15-year operational period.

Current Challenges in Stainless Steel Applications

The stainless steel industry faces several significant challenges in modern applications, particularly when comparing high-performance alloys like Duplex Stainless Steel and 316L Stainless Steel. One of the primary challenges is achieving optimal corrosion resistance in increasingly aggressive environments. While 316L offers good general corrosion resistance, it struggles with pitting in chloride-rich environments, creating a performance gap that engineers must address when designing critical components for marine, chemical, or offshore applications.

Material cost fluctuations represent another substantial challenge, with nickel price volatility significantly impacting 316L production costs. This economic pressure has accelerated the search for alternatives like Duplex grades, which contain less nickel while offering superior strength. However, this substitution introduces new challenges in manufacturing processes and material handling protocols that many facilities are not fully equipped to manage.

Fabrication difficulties present ongoing obstacles, particularly in welding applications. 316L exhibits excellent weldability but may suffer from sensitization in heat-affected zones. Duplex grades, while offering superior strength and corrosion resistance, require more precise heat input control and post-weld heat treatments to maintain their balanced microstructure, creating significant challenges for fabricators without specialized expertise.

The industry also struggles with standardization issues across global supply chains. Different regional standards for material composition, testing protocols, and quality assurance create inconsistencies that complicate material selection and validation processes. This is particularly problematic when comparing performance metrics between Duplex and 316L grades from different suppliers or regions.

Environmental sustainability presents another growing challenge, with increasing pressure to reduce the environmental footprint of stainless steel production. While both 316L and Duplex grades are fully recyclable, their production processes differ in energy consumption and emissions. The industry must balance performance requirements with sustainability goals, particularly as regulatory frameworks become more stringent.

Application-specific optimization remains difficult, especially in emerging sectors like renewable energy and biomedical implants. Engineers must carefully weigh the superior pitting resistance and strength of Duplex against the proven track record and fabrication advantages of 316L. This decision becomes increasingly complex as application environments become more specialized and demanding, requiring extensive testing and validation.

Material cost fluctuations represent another substantial challenge, with nickel price volatility significantly impacting 316L production costs. This economic pressure has accelerated the search for alternatives like Duplex grades, which contain less nickel while offering superior strength. However, this substitution introduces new challenges in manufacturing processes and material handling protocols that many facilities are not fully equipped to manage.

Fabrication difficulties present ongoing obstacles, particularly in welding applications. 316L exhibits excellent weldability but may suffer from sensitization in heat-affected zones. Duplex grades, while offering superior strength and corrosion resistance, require more precise heat input control and post-weld heat treatments to maintain their balanced microstructure, creating significant challenges for fabricators without specialized expertise.

The industry also struggles with standardization issues across global supply chains. Different regional standards for material composition, testing protocols, and quality assurance create inconsistencies that complicate material selection and validation processes. This is particularly problematic when comparing performance metrics between Duplex and 316L grades from different suppliers or regions.

Environmental sustainability presents another growing challenge, with increasing pressure to reduce the environmental footprint of stainless steel production. While both 316L and Duplex grades are fully recyclable, their production processes differ in energy consumption and emissions. The industry must balance performance requirements with sustainability goals, particularly as regulatory frameworks become more stringent.

Application-specific optimization remains difficult, especially in emerging sectors like renewable energy and biomedical implants. Engineers must carefully weigh the superior pitting resistance and strength of Duplex against the proven track record and fabrication advantages of 316L. This decision becomes increasingly complex as application environments become more specialized and demanding, requiring extensive testing and validation.

Comparative Technical Solutions Analysis

01 Pitting resistance comparison between duplex and 316L stainless steel

Duplex stainless steel generally exhibits superior pitting resistance compared to 316L stainless steel due to its higher chromium and molybdenum content. The dual-phase microstructure of ferrite and austenite in duplex stainless steel contributes to its enhanced resistance to localized corrosion. The pitting resistance equivalent number (PREN) for duplex stainless steel is typically higher than that of 316L, making it more suitable for aggressive environments containing chlorides.- Pitting resistance comparison between duplex and 316L stainless steel: Duplex stainless steel generally exhibits superior pitting resistance compared to 316L stainless steel due to its higher chromium and molybdenum content. The dual-phase microstructure of ferrite and austenite in duplex stainless steel contributes to its enhanced resistance to localized corrosion. The pitting resistance equivalent number (PREN) for duplex stainless steel is typically higher than that of 316L, making it more suitable for aggressive environments containing chlorides.

- Mechanical strength properties of duplex vs 316L stainless steel: Duplex stainless steel offers significantly higher yield and tensile strength compared to 316L stainless steel. The dual-phase microstructure provides a combination of strength and toughness that exceeds that of conventional austenitic grades. Typically, duplex grades have yield strengths approximately twice that of 316L, making them advantageous for applications requiring high strength-to-weight ratios and structural integrity under load. This strength difference allows for potential material thickness reduction in certain applications.

- Weldability characteristics and challenges: Welding duplex stainless steel requires more careful control of heat input and cooling rates compared to 316L stainless steel. The main challenge with duplex grades is maintaining the proper ferrite-austenite phase balance in the weld and heat-affected zone. Excessive ferrite content can lead to reduced corrosion resistance and toughness. 316L stainless steel is generally considered easier to weld with fewer precautions needed. For duplex grades, nitrogen-containing shielding gases and appropriate filler metals are often recommended to promote austenite formation during welding.

- Alloying elements and microstructure effects: The composition and microstructure of duplex and 316L stainless steels significantly influence their properties. Duplex grades contain higher levels of chromium (typically 22-25%) and nitrogen, with a balanced ferrite-austenite microstructure. 316L is an austenitic grade with lower chromium (16-18%) and contains molybdenum for improved corrosion resistance. The addition of specific alloying elements like nitrogen, molybdenum, and nickel can be optimized to enhance particular properties such as pitting resistance, strength, and phase stability during processing and welding.

- Application-specific performance comparison: The selection between duplex and 316L stainless steel depends on specific application requirements. Duplex grades excel in environments with high chloride content, stress corrosion cracking risks, and where high strength is needed, such as offshore structures, chemical processing equipment, and pressure vessels. 316L is preferred for applications requiring excellent formability, non-magnetic properties, and good general corrosion resistance in less aggressive environments. Cost considerations also play a role, as duplex grades typically command a premium price but may offer lifecycle cost advantages through extended service life and reduced maintenance.

02 Mechanical strength properties of duplex vs 316L stainless steel

Duplex stainless steel demonstrates significantly higher yield and tensile strength compared to 316L stainless steel. The dual-phase microstructure of duplex stainless steel, consisting of approximately equal amounts of ferrite and austenite, provides enhanced mechanical properties. Duplex grades typically have yield strengths about twice that of 316L austenitic stainless steel, making them advantageous for applications requiring high strength with reduced material thickness and weight.Expand Specific Solutions03 Weldability characteristics and challenges

Duplex stainless steel presents more welding challenges compared to 316L stainless steel due to its dual-phase microstructure. Welding of duplex stainless steel requires careful control of heat input and cooling rates to maintain the proper ferrite-austenite balance in the weld zone and heat-affected zone. 316L stainless steel generally offers better weldability with fewer precautions needed. For duplex grades, proper filler metal selection and post-weld heat treatment may be necessary to ensure optimal corrosion resistance and mechanical properties in welded joints.Expand Specific Solutions04 Alloying elements and their effects on properties

The composition differences between duplex and 316L stainless steels significantly impact their properties. Duplex stainless steel contains higher levels of chromium, molybdenum, and nitrogen, which enhance pitting resistance and strength. The addition of nitrogen particularly improves pitting resistance while stabilizing the austenite phase. In 316L, the lower carbon content (0.03% max) improves weldability by reducing susceptibility to sensitization. The balanced alloying in duplex grades creates the characteristic dual-phase microstructure that provides the combination of strength and corrosion resistance.Expand Specific Solutions05 Applications based on performance characteristics

The selection between duplex and 316L stainless steel depends on specific application requirements. Duplex stainless steel is preferred for environments requiring high strength combined with excellent corrosion resistance, such as offshore platforms, chemical processing equipment, and desalination plants. 316L stainless steel is more commonly used in less severe corrosive environments where moderate strength is sufficient, including food processing equipment, pharmaceutical applications, and architectural components. The cost-effectiveness of each material must be evaluated based on the specific performance requirements of the application.Expand Specific Solutions

Key Manufacturers and Industry Leaders

The duplex stainless steel market is experiencing robust growth in the mature stainless steel industry, driven by increasing demand for corrosion-resistant materials in harsh environments. The global market size for duplex stainless steel is expanding at a CAGR of approximately 4-5%, with applications spanning oil & gas, chemical processing, and marine sectors. Technologically, major players like POSCO Holdings, Outokumpu Oyj, and NIPPON STEEL Stainless Steel Corp. have achieved significant advancements in improving pitting resistance through optimized alloy compositions. Companies including JFE Steel, Alleima Tube, and Industeel France are focusing on enhancing weldability while maintaining superior mechanical properties compared to 316L stainless steel. Research institutions such as Central South University and Korea Institute of Materials Science are collaborating with manufacturers to develop next-generation duplex grades with improved strength-to-weight ratios and processing characteristics.

POSCO Holdings, Inc.

Technical Solution: POSCO has developed advanced duplex stainless steel grades including POSASD™ (POSCO Advanced Super Duplex) that demonstrate significantly higher pitting resistance than 316L, with PREN values exceeding 40 compared to 316L's 24-26. Their proprietary processing techniques create a precisely balanced microstructure of approximately 50% ferrite and 50% austenite, yielding yield strengths of 450-550 MPa versus 316L's typical 220-240 MPa. POSCO's research has shown their duplex grades maintain mechanical properties at elevated temperatures up to 280°C, whereas 316L experiences strength reduction above 260°C. For weldability, POSCO employs controlled cooling rates and specialized heat treatment protocols to prevent detrimental intermetallic phase formation in the heat-affected zone. Their duplex grades demonstrate superior resistance to chloride stress corrosion cracking, with testing showing no failures after 1000 hours in boiling 42% MgCl₂ solution, while 316L typically fails within 10-20 hours under identical conditions.

Strengths: Exceptional combination of high strength and corrosion resistance; superior performance in chloride-containing environments; excellent resistance to stress corrosion cracking; reduced material requirements due to higher strength allowing thinner sections. Weaknesses: More complex welding procedures requiring precise heat input control; higher initial material cost compared to 316L; more limited availability in certain product forms; potential for 475°C embrittlement in the ferrite phase during prolonged exposure at certain temperatures.

NIPPON STEEL CORP.

Technical Solution: Nippon Steel has developed proprietary duplex stainless steel grades including NSSC® 2120 (lean duplex) and NSSC® 2351 (standard duplex) that offer enhanced pitting resistance compared to 316L. Their research demonstrates critical pitting temperatures (CPT) of 35-45°C for their duplex grades versus 15-25°C for 316L in standardized testing. Nippon Steel's duplex grades achieve yield strengths of 450-550 MPa, approximately twice that of 316L (220-240 MPa), while maintaining good ductility with elongation values of 25-30%. Their metallurgical expertise has enabled precise control of nitrogen content (0.14-0.20%) to optimize both strength and corrosion resistance. For weldability, Nippon Steel has developed specialized welding consumables and procedures that maintain phase balance in the heat-affected zone, preventing excessive ferrite formation that could compromise mechanical properties. Their duplex grades demonstrate superior resistance to chloride stress corrosion cracking, with testing showing no failures after extended exposure to environments where 316L typically fails within hours.

Strengths: Excellent combination of high strength and corrosion resistance allowing reduced material thickness and weight savings; superior performance in chloride-containing environments; good formability for a duplex grade; comprehensive technical support and application expertise. Weaknesses: Higher initial material cost compared to 316L; more complex welding procedures requiring stricter parameter control; potential for embrittlement if improperly heat treated; more limited availability in certain product forms compared to 316L.

Critical Research on Pitting Resistance Mechanisms

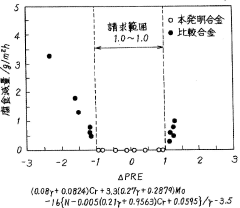

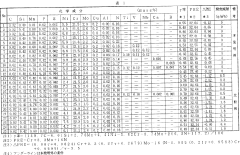

Duplex stainless steel having excellent pitting corrosion resistance

PatentInactiveJP2003293090A

Innovation

- Optimized chemical composition with specific ranges for C, Si, Mn, P, S, Ni, Cr, Mo, Cu, Al, and N to achieve excellent pitting corrosion resistance in duplex stainless steel.

- Controlled γ ratio (austenite-ferrite balance) of 0.3 to 0.7 to ensure optimal combination of strength and corrosion resistance properties.

- Specified PRE (Pitting Resistant Equivalent) ≥32.5 and ΔPRE of -1.0 to 1.0 to ensure uniform corrosion resistance throughout the material structure.

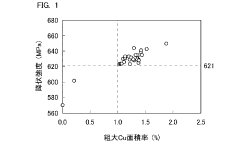

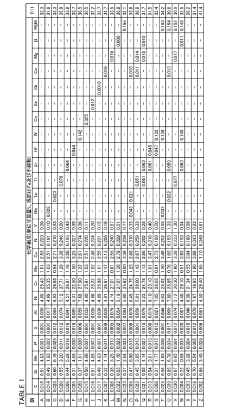

Duplex stainless steel

PatentActiveJP2021167446A

Innovation

- A duplex stainless steel material with a specific chemical composition and microstructure, including 30.0 to 70.0% ferrite and the balance austenite, along with controlled Cu precipitates, satisfies the formula Cr+3.3(Mo+0.5W)+16N≧30.0, ensuring a yield strength of 621 MPa or more and enhanced pitting corrosion resistance.

Lifecycle Cost Assessment

When evaluating the economic viability of Duplex Stainless Steel (DSS) versus 316L Stainless Steel, lifecycle cost assessment provides critical insights beyond initial material expenses. This comprehensive analysis encompasses acquisition, installation, maintenance, operational costs, and end-of-life considerations over the entire service period.

Initial acquisition costs typically favor 316L stainless steel, which commands a 15-25% lower price point than duplex grades. However, this initial advantage must be weighed against long-term performance factors. The superior corrosion resistance of DSS, particularly in chloride-rich environments, translates to significantly reduced maintenance requirements and extended service life—often 1.5 to 2 times longer than 316L installations.

Maintenance cost differentials become particularly evident in aggressive environments. Field data indicates that 316L systems may require maintenance interventions every 5-7 years, while comparable DSS installations often operate 10-15 years before similar attention is needed. This maintenance frequency reduction directly impacts both direct costs (materials, labor) and indirect costs (operational downtime, production losses).

The higher strength of DSS enables material thickness reductions of approximately 30-40% compared to 316L for equivalent performance specifications. This weight reduction cascades into savings across transportation, handling, and installation phases. Additionally, lighter structures may reduce ancillary support requirements and associated costs throughout the infrastructure lifecycle.

Energy consumption during manufacturing represents another significant cost factor. While DSS production typically requires 5-8% more energy than 316L, this is often offset by the reduced material volume needed. Furthermore, the extended service life of DSS installations amortizes this energy premium over a longer operational period, improving overall sustainability metrics.

End-of-life considerations also favor DSS in many applications. Both materials offer excellent recyclability, but the higher alloy content in DSS potentially commands premium recycling values. Current market data suggests DSS scrap typically recovers 10-15% more value than 316L, partially offsetting the initial cost differential when considering total lifecycle economics.

Risk assessment calculations further enhance DSS's economic proposition in critical applications where failure consequences are severe. When factoring potential downtime costs, product contamination risks, and safety implications, the enhanced reliability of DSS often justifies its premium, particularly in pharmaceutical, chemical processing, and offshore applications.

Initial acquisition costs typically favor 316L stainless steel, which commands a 15-25% lower price point than duplex grades. However, this initial advantage must be weighed against long-term performance factors. The superior corrosion resistance of DSS, particularly in chloride-rich environments, translates to significantly reduced maintenance requirements and extended service life—often 1.5 to 2 times longer than 316L installations.

Maintenance cost differentials become particularly evident in aggressive environments. Field data indicates that 316L systems may require maintenance interventions every 5-7 years, while comparable DSS installations often operate 10-15 years before similar attention is needed. This maintenance frequency reduction directly impacts both direct costs (materials, labor) and indirect costs (operational downtime, production losses).

The higher strength of DSS enables material thickness reductions of approximately 30-40% compared to 316L for equivalent performance specifications. This weight reduction cascades into savings across transportation, handling, and installation phases. Additionally, lighter structures may reduce ancillary support requirements and associated costs throughout the infrastructure lifecycle.

Energy consumption during manufacturing represents another significant cost factor. While DSS production typically requires 5-8% more energy than 316L, this is often offset by the reduced material volume needed. Furthermore, the extended service life of DSS installations amortizes this energy premium over a longer operational period, improving overall sustainability metrics.

End-of-life considerations also favor DSS in many applications. Both materials offer excellent recyclability, but the higher alloy content in DSS potentially commands premium recycling values. Current market data suggests DSS scrap typically recovers 10-15% more value than 316L, partially offsetting the initial cost differential when considering total lifecycle economics.

Risk assessment calculations further enhance DSS's economic proposition in critical applications where failure consequences are severe. When factoring potential downtime costs, product contamination risks, and safety implications, the enhanced reliability of DSS often justifies its premium, particularly in pharmaceutical, chemical processing, and offshore applications.

Environmental Impact and Sustainability Factors

The environmental impact and sustainability considerations of stainless steel selection have become increasingly important factors in engineering decisions. Duplex stainless steel demonstrates significant environmental advantages over 316L stainless steel, primarily due to its reduced material requirements. The higher strength of duplex grades allows for thinner wall designs in pressure vessels and structural components, resulting in up to 30% less material usage compared to austenitic counterparts like 316L.

This reduction in material consumption directly translates to lower energy requirements during production. The manufacturing process for duplex stainless steel typically consumes approximately 20-25% less energy than that required for equivalent 316L components, contributing to a smaller carbon footprint across the product lifecycle. Additionally, the mining impact is proportionally reduced due to decreased raw material extraction needs.

The superior corrosion resistance of duplex stainless steel, particularly in chloride environments, extends service life considerably beyond that of 316L in comparable applications. This longevity factor significantly enhances sustainability by reducing replacement frequency and associated environmental costs of manufacturing replacement components. Studies indicate that duplex grades can provide 1.5-2 times longer service life in aggressive environments.

Recycling characteristics represent another important sustainability consideration. Both duplex and 316L stainless steels are 100% recyclable with well-established recycling streams. However, the higher nickel content in 316L (10-14%) versus duplex (4-7%) creates different environmental implications. Nickel extraction and processing are associated with higher environmental impacts, giving duplex a slight advantage in this aspect.

From a life cycle assessment perspective, the reduced material requirements, lower energy consumption during production, and extended service life of duplex stainless steel generally result in a more favorable environmental profile compared to 316L. However, this advantage must be balanced against application-specific requirements and local availability of materials and processing capabilities.

The maintenance requirements also factor into sustainability considerations. Duplex stainless steel typically requires less frequent maintenance interventions in corrosive environments, reducing the environmental impact associated with maintenance activities, including chemical cleaning agents and energy consumption during maintenance procedures.

This reduction in material consumption directly translates to lower energy requirements during production. The manufacturing process for duplex stainless steel typically consumes approximately 20-25% less energy than that required for equivalent 316L components, contributing to a smaller carbon footprint across the product lifecycle. Additionally, the mining impact is proportionally reduced due to decreased raw material extraction needs.

The superior corrosion resistance of duplex stainless steel, particularly in chloride environments, extends service life considerably beyond that of 316L in comparable applications. This longevity factor significantly enhances sustainability by reducing replacement frequency and associated environmental costs of manufacturing replacement components. Studies indicate that duplex grades can provide 1.5-2 times longer service life in aggressive environments.

Recycling characteristics represent another important sustainability consideration. Both duplex and 316L stainless steels are 100% recyclable with well-established recycling streams. However, the higher nickel content in 316L (10-14%) versus duplex (4-7%) creates different environmental implications. Nickel extraction and processing are associated with higher environmental impacts, giving duplex a slight advantage in this aspect.

From a life cycle assessment perspective, the reduced material requirements, lower energy consumption during production, and extended service life of duplex stainless steel generally result in a more favorable environmental profile compared to 316L. However, this advantage must be balanced against application-specific requirements and local availability of materials and processing capabilities.

The maintenance requirements also factor into sustainability considerations. Duplex stainless steel typically requires less frequent maintenance interventions in corrosive environments, reducing the environmental impact associated with maintenance activities, including chemical cleaning agents and energy consumption during maintenance procedures.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!