Duplex Stainless Steel Surface Treatments: Pickling, Passivation And Corrosion Performance

SEP 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DSS Surface Treatment Background and Objectives

Duplex stainless steels (DSS) have emerged as critical materials in various industrial applications due to their exceptional combination of mechanical properties and corrosion resistance. The evolution of DSS began in the early 1930s, with significant advancements occurring in the 1970s and 1980s when improved manufacturing techniques enabled better control of alloying elements and microstructure. This technological progression has led to the development of several generations of DSS, including super duplex and hyper duplex grades, expanding their application scope considerably.

Surface treatment processes for DSS, particularly pickling and passivation, have evolved alongside the material itself. Traditional methods developed for austenitic stainless steels proved inadequate for DSS due to their dual-phase microstructure consisting of approximately equal proportions of austenite and ferrite phases. This unique microstructure necessitates specialized surface treatment approaches to ensure optimal corrosion performance.

The global trend toward more aggressive operating environments in industries such as oil and gas, chemical processing, and marine applications has intensified the demand for enhanced DSS surface treatment technologies. Particularly challenging are environments involving high chloride concentrations, elevated temperatures, and varying pH conditions, where inadequate surface treatment can lead to premature failure through localized corrosion mechanisms.

Recent technological trends indicate a shift toward more environmentally sustainable pickling and passivation processes, reducing the use of hazardous chemicals such as nitric acid and hydrofluoric acid mixtures. Additionally, there is growing interest in developing more efficient processes that minimize treatment time while maximizing corrosion resistance, driven by economic considerations in industrial applications.

The primary objective of this technical research is to comprehensively evaluate current DSS surface treatment methodologies, specifically focusing on pickling and passivation processes and their direct impact on corrosion performance. This includes assessing the effectiveness of various chemical formulations, process parameters, and application techniques across different DSS grades.

Furthermore, this research aims to identify optimal surface treatment protocols that balance technical performance with environmental and economic considerations. By analyzing the relationship between surface treatment parameters and resulting corrosion resistance, we seek to establish evidence-based best practices for industry implementation.

An additional objective is to explore emerging technologies and innovative approaches in DSS surface treatment, including electrochemical techniques, advanced passivation formulations, and novel process control methodologies that may offer significant improvements over conventional practices. This forward-looking assessment will help position organizations to adopt next-generation surface treatment technologies as they mature.

Surface treatment processes for DSS, particularly pickling and passivation, have evolved alongside the material itself. Traditional methods developed for austenitic stainless steels proved inadequate for DSS due to their dual-phase microstructure consisting of approximately equal proportions of austenite and ferrite phases. This unique microstructure necessitates specialized surface treatment approaches to ensure optimal corrosion performance.

The global trend toward more aggressive operating environments in industries such as oil and gas, chemical processing, and marine applications has intensified the demand for enhanced DSS surface treatment technologies. Particularly challenging are environments involving high chloride concentrations, elevated temperatures, and varying pH conditions, where inadequate surface treatment can lead to premature failure through localized corrosion mechanisms.

Recent technological trends indicate a shift toward more environmentally sustainable pickling and passivation processes, reducing the use of hazardous chemicals such as nitric acid and hydrofluoric acid mixtures. Additionally, there is growing interest in developing more efficient processes that minimize treatment time while maximizing corrosion resistance, driven by economic considerations in industrial applications.

The primary objective of this technical research is to comprehensively evaluate current DSS surface treatment methodologies, specifically focusing on pickling and passivation processes and their direct impact on corrosion performance. This includes assessing the effectiveness of various chemical formulations, process parameters, and application techniques across different DSS grades.

Furthermore, this research aims to identify optimal surface treatment protocols that balance technical performance with environmental and economic considerations. By analyzing the relationship between surface treatment parameters and resulting corrosion resistance, we seek to establish evidence-based best practices for industry implementation.

An additional objective is to explore emerging technologies and innovative approaches in DSS surface treatment, including electrochemical techniques, advanced passivation formulations, and novel process control methodologies that may offer significant improvements over conventional practices. This forward-looking assessment will help position organizations to adopt next-generation surface treatment technologies as they mature.

Market Demand Analysis for Corrosion-Resistant DSS

The global market for corrosion-resistant Duplex Stainless Steel (DSS) has experienced significant growth in recent years, driven primarily by increasing demand from industries operating in harsh environments. The oil and gas sector remains the largest consumer of DSS, accounting for approximately 30% of total market consumption, particularly in offshore applications where resistance to seawater corrosion is critical.

Chemical processing industries represent the second-largest market segment, with growing adoption rates in equipment such as heat exchangers, pressure vessels, and piping systems. This growth is attributed to DSS's superior resistance to stress corrosion cracking in chloride-containing environments compared to traditional austenitic grades.

Market research indicates that the global DSS market was valued at 3.2 billion USD in 2022 and is projected to reach 4.5 billion USD by 2027, reflecting a compound annual growth rate of 7.1%. The Asia-Pacific region, particularly China and India, demonstrates the fastest growth trajectory due to rapid industrialization and infrastructure development projects.

The demand for properly treated DSS surfaces has intensified as end-users increasingly recognize the correlation between surface treatment quality and long-term performance. Industry surveys reveal that over 65% of premature DSS failures are directly linked to inadequate surface treatment processes, highlighting the critical importance of proper pickling and passivation procedures.

Environmental regulations have emerged as significant market drivers, with stricter emissions standards in Europe and North America pushing industries toward more corrosion-resistant materials to prevent leaks and extend equipment lifespans. This regulatory pressure has accelerated the adoption of DSS in traditional carbon steel applications.

The marine and desalination sectors show particularly promising growth potential, with projected market expansion of 9.3% annually through 2028. These industries require materials capable of withstanding continuous exposure to chloride-rich environments while maintaining structural integrity.

Customer requirements are evolving toward comprehensive surface treatment solutions rather than just material supply. This trend has prompted leading suppliers to develop integrated service offerings that include specialized pickling and passivation treatments tailored to specific application environments.

The market also shows increasing demand for standardized testing and certification of surface treatment quality, with customers willing to pay premium prices for guaranteed corrosion performance. This has created new market opportunities for specialized testing services and quality assurance programs focused on DSS surface treatments.

Chemical processing industries represent the second-largest market segment, with growing adoption rates in equipment such as heat exchangers, pressure vessels, and piping systems. This growth is attributed to DSS's superior resistance to stress corrosion cracking in chloride-containing environments compared to traditional austenitic grades.

Market research indicates that the global DSS market was valued at 3.2 billion USD in 2022 and is projected to reach 4.5 billion USD by 2027, reflecting a compound annual growth rate of 7.1%. The Asia-Pacific region, particularly China and India, demonstrates the fastest growth trajectory due to rapid industrialization and infrastructure development projects.

The demand for properly treated DSS surfaces has intensified as end-users increasingly recognize the correlation between surface treatment quality and long-term performance. Industry surveys reveal that over 65% of premature DSS failures are directly linked to inadequate surface treatment processes, highlighting the critical importance of proper pickling and passivation procedures.

Environmental regulations have emerged as significant market drivers, with stricter emissions standards in Europe and North America pushing industries toward more corrosion-resistant materials to prevent leaks and extend equipment lifespans. This regulatory pressure has accelerated the adoption of DSS in traditional carbon steel applications.

The marine and desalination sectors show particularly promising growth potential, with projected market expansion of 9.3% annually through 2028. These industries require materials capable of withstanding continuous exposure to chloride-rich environments while maintaining structural integrity.

Customer requirements are evolving toward comprehensive surface treatment solutions rather than just material supply. This trend has prompted leading suppliers to develop integrated service offerings that include specialized pickling and passivation treatments tailored to specific application environments.

The market also shows increasing demand for standardized testing and certification of surface treatment quality, with customers willing to pay premium prices for guaranteed corrosion performance. This has created new market opportunities for specialized testing services and quality assurance programs focused on DSS surface treatments.

Current Challenges in DSS Surface Treatment Technologies

Despite significant advancements in duplex stainless steel (DSS) surface treatment technologies, several critical challenges persist that impede optimal performance and reliability. The complex microstructure of DSS, characterized by approximately equal proportions of austenite and ferrite phases, creates unique difficulties during surface treatment processes. These distinct phases respond differently to chemical treatments, resulting in preferential attack of one phase over another during pickling operations, which can compromise surface integrity and corrosion resistance.

A primary challenge in DSS pickling is achieving uniform removal of heat tints and oxide scales without causing excessive material loss or surface degradation. Conventional pickling solutions containing nitric and hydrofluoric acids often result in uneven surface finishes due to the differential etching rates between austenite and ferrite phases. This selective etching can create micro-topographical features that become initiation sites for localized corrosion.

Temperature control during pickling presents another significant challenge. DSS requires precise temperature management during treatment, as excessive temperatures can lead to over-pickling of the more reactive phase, while insufficient temperatures may result in incomplete oxide removal. This narrow processing window makes industrial-scale implementation particularly demanding, especially for complex geometries and welded components.

The environmental and health concerns associated with traditional pickling chemicals constitute a growing challenge. Nitric acid contributes to NOx emissions, while hydrofluoric acid poses severe safety hazards. Regulatory pressures are increasingly restricting the use of these chemicals, necessitating the development of more environmentally friendly alternatives without compromising treatment effectiveness.

Passivation processes for DSS face their own set of challenges. The formation of a uniform, stable chromium-rich passive layer is complicated by the dual-phase nature of the material. Ensuring complete passivation of both phases simultaneously requires carefully optimized treatment parameters that are often difficult to establish across varying DSS grades and surface conditions.

Quality control and verification of surface treatment effectiveness represent ongoing challenges. Current non-destructive testing methods have limitations in accurately assessing the completeness of oxide removal or the quality of the passive layer, particularly in field applications or for complex component geometries.

For welded DSS components, the heat-affected zones present particular treatment difficulties. These areas exhibit altered microstructures and compositions that respond differently to standard pickling and passivation protocols, often requiring specialized approaches to ensure adequate corrosion protection.

A primary challenge in DSS pickling is achieving uniform removal of heat tints and oxide scales without causing excessive material loss or surface degradation. Conventional pickling solutions containing nitric and hydrofluoric acids often result in uneven surface finishes due to the differential etching rates between austenite and ferrite phases. This selective etching can create micro-topographical features that become initiation sites for localized corrosion.

Temperature control during pickling presents another significant challenge. DSS requires precise temperature management during treatment, as excessive temperatures can lead to over-pickling of the more reactive phase, while insufficient temperatures may result in incomplete oxide removal. This narrow processing window makes industrial-scale implementation particularly demanding, especially for complex geometries and welded components.

The environmental and health concerns associated with traditional pickling chemicals constitute a growing challenge. Nitric acid contributes to NOx emissions, while hydrofluoric acid poses severe safety hazards. Regulatory pressures are increasingly restricting the use of these chemicals, necessitating the development of more environmentally friendly alternatives without compromising treatment effectiveness.

Passivation processes for DSS face their own set of challenges. The formation of a uniform, stable chromium-rich passive layer is complicated by the dual-phase nature of the material. Ensuring complete passivation of both phases simultaneously requires carefully optimized treatment parameters that are often difficult to establish across varying DSS grades and surface conditions.

Quality control and verification of surface treatment effectiveness represent ongoing challenges. Current non-destructive testing methods have limitations in accurately assessing the completeness of oxide removal or the quality of the passive layer, particularly in field applications or for complex component geometries.

For welded DSS components, the heat-affected zones present particular treatment difficulties. These areas exhibit altered microstructures and compositions that respond differently to standard pickling and passivation protocols, often requiring specialized approaches to ensure adequate corrosion protection.

Current Pickling and Passivation Solutions for DSS

01 Chemical surface treatments for corrosion resistance

Various chemical treatments can be applied to duplex stainless steel surfaces to enhance corrosion resistance. These include passivation treatments, acid pickling, and chemical conversion coatings that form protective layers on the steel surface. These treatments remove contaminants and create a stable passive film that prevents corrosion initiation, particularly in aggressive environments. The chemical composition of these treatments is optimized to maintain the balanced microstructure of duplex stainless steel while improving its surface properties.- Chemical surface treatments for corrosion resistance: Various chemical treatments can be applied to duplex stainless steel surfaces to enhance corrosion resistance. These include passivation treatments, acid pickling, and chemical conversion coatings that form protective oxide layers. These treatments remove surface contaminants and create a uniform passive film that significantly improves the material's resistance to pitting and crevice corrosion in aggressive environments.

- Heat treatment effects on corrosion performance: Heat treatment processes significantly influence the corrosion performance of duplex stainless steels by affecting their microstructure and phase balance. Proper solution annealing and controlled cooling rates help maintain the optimal austenite-ferrite ratio, while preventing the formation of detrimental intermetallic phases and chromium carbides that can compromise corrosion resistance. Post-weld heat treatments are particularly important for restoring corrosion resistance in welded components.

- Mechanical surface finishing techniques: Mechanical surface finishing techniques such as grinding, polishing, shot peening, and burnishing can significantly improve the corrosion performance of duplex stainless steels. These processes remove surface defects, reduce roughness, and induce beneficial compressive stresses in the surface layer. A smooth surface with minimal irregularities provides fewer sites for corrosion initiation and enhances the effectiveness of the passive film.

- Surface modification with coatings and alloying elements: Surface modification techniques involving the application of protective coatings or the introduction of beneficial alloying elements can enhance the corrosion resistance of duplex stainless steels. These include nitriding, carburizing, PVD/CVD coatings, and surface alloying processes. Such treatments create barrier layers that protect the underlying metal from corrosive media or modify the surface composition to improve inherent corrosion resistance properties.

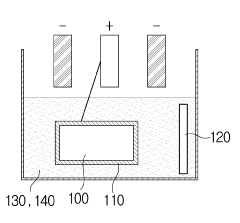

- Electrochemical surface treatments: Electrochemical surface treatments such as electropolishing, anodizing, and electrochemical passivation can significantly enhance the corrosion performance of duplex stainless steels. These processes selectively dissolve surface irregularities, enrich the surface with chromium, and form a more uniform and stable passive film. The resulting surfaces exhibit improved resistance to localized corrosion and extended service life in aggressive environments.

02 Heat treatment effects on corrosion performance

Heat treatment processes significantly impact the corrosion performance of duplex stainless steel. Controlled heating and cooling cycles can optimize the austenite-ferrite phase balance, which is crucial for corrosion resistance. Solution annealing followed by rapid cooling prevents the formation of detrimental intermetallic phases that would otherwise compromise corrosion resistance. Post-weld heat treatments are particularly important for maintaining corrosion performance in welded components by restoring the optimal microstructure in heat-affected zones.Expand Specific Solutions03 Mechanical surface treatments for improved corrosion resistance

Mechanical surface treatments such as shot peening, grinding, polishing, and burnishing can significantly enhance the corrosion resistance of duplex stainless steel. These processes induce compressive residual stresses in the surface layer, reduce surface roughness, and create a more homogeneous passive film. The improved surface finish reduces potential sites for corrosion initiation and increases resistance to pitting and crevice corrosion. Additionally, these treatments can improve the fatigue strength and wear resistance while maintaining excellent corrosion performance.Expand Specific Solutions04 Coating technologies for duplex stainless steel protection

Various coating technologies can be applied to duplex stainless steel to provide additional corrosion protection in extremely aggressive environments. These include PVD/CVD coatings, organic coatings, and composite multilayer systems. Specialized coatings can provide barrier protection against specific corrosive media while maintaining the mechanical properties of the base material. Advanced coating techniques ensure strong adhesion to the duplex stainless steel substrate and long-term durability under service conditions, extending the service life of components in corrosive environments.Expand Specific Solutions05 Electrochemical surface modifications for enhanced corrosion performance

Electrochemical surface treatments such as electropolishing, anodizing, and electrochemical passivation can significantly improve the corrosion resistance of duplex stainless steel. These processes selectively modify the surface composition and structure, creating a more uniform and stable passive film. Electrochemical treatments can remove surface defects and enrich the surface with chromium, enhancing resistance to localized corrosion. These methods are particularly effective for complex geometries and can be tailored to specific service environments to optimize corrosion performance.Expand Specific Solutions

Leading Manufacturers and Research Institutions in DSS Treatment

The duplex stainless steel surface treatment market is currently in a growth phase, driven by increasing demand for corrosion-resistant materials in harsh environments. The global market size is estimated to exceed $2 billion, with a projected CAGR of 5-7% through 2028. Technical maturity varies across treatment methods, with pickling and passivation being well-established processes while advanced surface modifications are still evolving. Key industry players demonstrate varying specialization levels: Outokumpu and POSCO lead in material production; Henkel and POLIGRAT excel in chemical treatment solutions; while companies like JFE Steel, Nippon Steel, and Kobe Steel focus on integrated processing technologies. Research collaboration between industrial players and institutions like Harbin Engineering University is accelerating innovation in environmentally friendly treatment methods with enhanced corrosion performance.

Henkel AG & Co. KGaA

Technical Solution: Henkel has developed environmentally-friendly pickling and passivation solutions specifically for duplex stainless steels under their Bonderite product line. Their technology replaces traditional nitric acid-based formulations with safer alternatives while maintaining effectiveness. Henkel's dual-action passivation treatments simultaneously remove free iron contamination and enhance the chromium oxide layer formation. Their research shows these treatments can improve the critical pitting temperature (CPT) of duplex stainless steel by 5-8°C compared to untreated surfaces. Henkel's latest innovation includes gel-based pickling formulations that allow for targeted application on welds and heat-affected zones without affecting surrounding areas. Their solutions are designed to work at lower temperatures (20-40°C) than conventional processes, reducing energy consumption while still achieving complete oxide scale removal within 30-60 minutes depending on steel grade and surface condition.

Strengths: Environmentally compliant formulations meeting global regulations; comprehensive product range addressing various application methods; strong technical support and customization capabilities. Weaknesses: Some solutions may require longer processing times than traditional acid mixtures; initial investment costs for switching to their systems can be higher than conventional treatments.

POLIGRAT GmbH

Technical Solution: POLIGRAT has developed specialized electrochemical surface treatment technologies for duplex stainless steels that combine pickling and passivation in a single process. Their POLINOX system utilizes controlled current density and proprietary electrolyte formulations to selectively dissolve the oxide layer while simultaneously enhancing the chromium content at the surface. This results in a passive layer with Cr/Fe ratios exceeding 3:1, significantly higher than conventional chemical treatments. Their process achieves complete removal of heat tints and welding discoloration within minutes rather than hours required by immersion methods. POLIGRAT's technology includes portable systems for on-site treatment of large structures and fixed installations. Testing has demonstrated that their electrochemical passivation improves the pitting resistance equivalent number (PREN) of the surface layer by approximately 20% compared to the base material, translating to superior performance in chloride-containing environments.

Strengths: Rapid processing times reducing production bottlenecks; precise control over treatment parameters allowing customization for specific alloys; minimal waste generation compared to bath immersion techniques. Weaknesses: Higher initial equipment investment compared to conventional chemical treatments; requires specialized training for operators; process optimization needed for each specific application.

Key Innovations in DSS Corrosion Performance Enhancement

Pickling or brightening/passivating solution and process for steel and stainless steel

PatentInactiveUS8192556B2

Innovation

- The use of complex fluoro acids of elements from groups 4, 13, or 14, such as SiF62−, TiF62−, and ZrF62−, in combination with strong acids and hydrogen peroxide, maintains the redox potential and prevents excessive decomposition, allowing for a single bleaching/passivating solution for all stainless steel grades without the risk of over-etching.

Passivation Surface Treatment of Stainless Steel

PatentActiveKR1020190083472A

Innovation

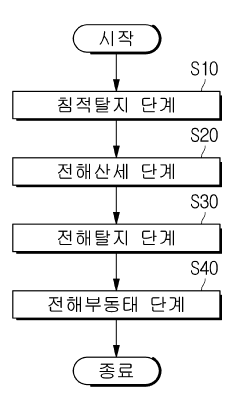

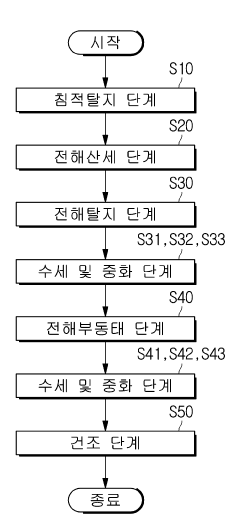

- A passivation treatment method involving electrolytic degreasing and passivation steps using specific solutions and voltage ranges, including electrolytic pickling with phosphoric and sulfuric acids, and electrolytic passivation with dichromic acid and chromium sulfate, to form a stable oxide film.

Environmental Impact of DSS Surface Treatment Processes

The surface treatment processes for Duplex Stainless Steel (DSS) present significant environmental considerations that must be addressed in modern industrial applications. Pickling and passivation treatments, while essential for optimal corrosion performance, utilize chemicals that pose potential environmental hazards when improperly managed. The primary environmental concerns stem from the acids used in these processes, particularly nitric, hydrofluoric, and sulfuric acids, which can contribute to air pollution, water contamination, and soil degradation if released untreated.

Traditional pickling processes generate acidic waste streams containing heavy metals, including chromium, nickel, and molybdenum leached from the DSS surface. These effluents require specialized treatment systems to neutralize acids and precipitate metals before discharge, adding considerable operational costs and environmental management responsibilities to manufacturers.

Recent environmental regulations worldwide have imposed stricter limits on emissions and waste disposal from metal finishing operations. The EU's REACH regulation and similar frameworks in North America and Asia have specifically targeted reduction of hexavalent chromium and other hazardous substances commonly associated with stainless steel processing. This regulatory landscape has driven significant innovation in more environmentally compatible treatment methods.

Emerging eco-friendly alternatives include low-acid or acid-free passivation techniques, electrolytic pickling processes that reduce chemical consumption, and closed-loop systems that enable recovery and reuse of treatment chemicals. These approaches not only minimize environmental impact but often deliver economic benefits through reduced waste management costs and improved resource efficiency.

Water consumption represents another critical environmental factor in DSS surface treatments. Conventional processes require substantial volumes for rinsing operations, creating large quantities of contaminated wastewater. Advanced water conservation technologies, including cascade rinsing systems and water recycling infrastructure, have demonstrated potential to reduce freshwater requirements by up to 80% in optimized facilities.

Energy consumption during heating and drying phases of surface treatments contributes to the carbon footprint of DSS processing. Implementation of heat recovery systems and process optimization can significantly reduce energy demands, aligning with global carbon reduction initiatives while lowering operational costs.

Life cycle assessment studies comparing traditional and modern DSS surface treatment methods indicate that environmentally optimized processes can reduce overall ecological impact by 30-50% when considering the complete production chain. These improvements become increasingly important as sustainability metrics gain prominence in material selection criteria across industries utilizing DSS components.

Traditional pickling processes generate acidic waste streams containing heavy metals, including chromium, nickel, and molybdenum leached from the DSS surface. These effluents require specialized treatment systems to neutralize acids and precipitate metals before discharge, adding considerable operational costs and environmental management responsibilities to manufacturers.

Recent environmental regulations worldwide have imposed stricter limits on emissions and waste disposal from metal finishing operations. The EU's REACH regulation and similar frameworks in North America and Asia have specifically targeted reduction of hexavalent chromium and other hazardous substances commonly associated with stainless steel processing. This regulatory landscape has driven significant innovation in more environmentally compatible treatment methods.

Emerging eco-friendly alternatives include low-acid or acid-free passivation techniques, electrolytic pickling processes that reduce chemical consumption, and closed-loop systems that enable recovery and reuse of treatment chemicals. These approaches not only minimize environmental impact but often deliver economic benefits through reduced waste management costs and improved resource efficiency.

Water consumption represents another critical environmental factor in DSS surface treatments. Conventional processes require substantial volumes for rinsing operations, creating large quantities of contaminated wastewater. Advanced water conservation technologies, including cascade rinsing systems and water recycling infrastructure, have demonstrated potential to reduce freshwater requirements by up to 80% in optimized facilities.

Energy consumption during heating and drying phases of surface treatments contributes to the carbon footprint of DSS processing. Implementation of heat recovery systems and process optimization can significantly reduce energy demands, aligning with global carbon reduction initiatives while lowering operational costs.

Life cycle assessment studies comparing traditional and modern DSS surface treatment methods indicate that environmentally optimized processes can reduce overall ecological impact by 30-50% when considering the complete production chain. These improvements become increasingly important as sustainability metrics gain prominence in material selection criteria across industries utilizing DSS components.

Quality Control Standards and Testing Methodologies

Quality control in duplex stainless steel surface treatments requires rigorous standards and testing methodologies to ensure optimal corrosion resistance and surface integrity. The industry has established several internationally recognized standards, including ASTM A967, ASTM A380, and ISO 17864, which provide comprehensive guidelines for pickling and passivation processes. These standards define acceptable parameters for surface finish, chromium-to-iron ratios, and minimum passivation times based on alloy composition.

Testing methodologies for duplex stainless steel treatments typically follow a multi-tiered approach. Non-destructive testing methods include visual inspection using magnification to detect surface irregularities, and colorimetric tests to verify complete removal of free iron contamination. The ferroxyl test (also known as the potassium ferricyanide test) remains a standard field method for detecting residual free iron, with blue spots indicating contamination areas requiring further treatment.

Electrochemical testing provides quantitative assessment of passivation quality. Electrochemical Impedance Spectroscopy (EIS) measures the passive film resistance, while Critical Pitting Temperature (CPT) testing evaluates pitting corrosion resistance. The Electrochemical Potentiokinetic Reactivation (EPR) test specifically assesses the degree of sensitization in duplex grades, critical for detecting chromium-depleted areas.

Salt spray testing according to ASTM B117 remains an industry standard for accelerated corrosion testing, typically requiring 1,000+ hours of exposure without visible corrosion for properly treated duplex stainless steel. More advanced cyclic corrosion tests that alternate between salt spray, humidity, and drying cycles provide better correlation with real-world performance.

Surface analysis techniques including X-ray Photoelectron Spectroscopy (XPS) and Auger Electron Spectroscopy (AES) enable precise characterization of the passive layer composition and thickness. These methods can determine the chromium enrichment factor, which should typically exceed 1.5 for properly passivated duplex stainless steel surfaces.

Quality control documentation systems have evolved to include digital tracking of treatment parameters, test results, and material traceability. Modern facilities implement statistical process control (SPC) to monitor treatment bath chemistry, temperature, and immersion times, establishing control limits that ensure consistent results across production batches.

Acceptance criteria typically specify maximum allowable surface roughness values (Ra), minimum chromium-to-iron ratios in the passive layer, and zero tolerance for visible rust after accelerated corrosion testing. For critical applications in chemical processing and offshore environments, supplementary hydrogen embrittlement testing may be required to ensure treatment processes haven't compromised the material's mechanical integrity.

Testing methodologies for duplex stainless steel treatments typically follow a multi-tiered approach. Non-destructive testing methods include visual inspection using magnification to detect surface irregularities, and colorimetric tests to verify complete removal of free iron contamination. The ferroxyl test (also known as the potassium ferricyanide test) remains a standard field method for detecting residual free iron, with blue spots indicating contamination areas requiring further treatment.

Electrochemical testing provides quantitative assessment of passivation quality. Electrochemical Impedance Spectroscopy (EIS) measures the passive film resistance, while Critical Pitting Temperature (CPT) testing evaluates pitting corrosion resistance. The Electrochemical Potentiokinetic Reactivation (EPR) test specifically assesses the degree of sensitization in duplex grades, critical for detecting chromium-depleted areas.

Salt spray testing according to ASTM B117 remains an industry standard for accelerated corrosion testing, typically requiring 1,000+ hours of exposure without visible corrosion for properly treated duplex stainless steel. More advanced cyclic corrosion tests that alternate between salt spray, humidity, and drying cycles provide better correlation with real-world performance.

Surface analysis techniques including X-ray Photoelectron Spectroscopy (XPS) and Auger Electron Spectroscopy (AES) enable precise characterization of the passive layer composition and thickness. These methods can determine the chromium enrichment factor, which should typically exceed 1.5 for properly passivated duplex stainless steel surfaces.

Quality control documentation systems have evolved to include digital tracking of treatment parameters, test results, and material traceability. Modern facilities implement statistical process control (SPC) to monitor treatment bath chemistry, temperature, and immersion times, establishing control limits that ensure consistent results across production batches.

Acceptance criteria typically specify maximum allowable surface roughness values (Ra), minimum chromium-to-iron ratios in the passive layer, and zero tolerance for visible rust after accelerated corrosion testing. For critical applications in chemical processing and offshore environments, supplementary hydrogen embrittlement testing may be required to ensure treatment processes haven't compromised the material's mechanical integrity.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!