How Duplex Stainless Steel Prevents Sigma Phase Formation In Thick-Section Fabrication?

SEP 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DSS Sigma Phase Formation Background and Objectives

Duplex Stainless Steel (DSS) has emerged as a critical material in modern industrial applications, particularly in environments requiring high corrosion resistance and mechanical strength. The evolution of DSS technology spans several decades, with significant advancements in metallurgical understanding and processing techniques. This technical evolution has been driven by the increasing demands of industries such as oil and gas, chemical processing, and marine engineering, where material failure can lead to catastrophic consequences.

The sigma phase formation in DSS represents one of the most challenging metallurgical phenomena that can severely compromise the material's intended properties. This intermetallic phase, typically forming between 650°C and 950°C, causes embrittlement and reduces corrosion resistance, particularly problematic in thick-section fabrications where thermal cycles are more complex and prolonged.

Historical data indicates that early DSS implementations in the 1970s and 1980s frequently encountered sigma phase issues, leading to premature failures in critical applications. The financial implications of these failures prompted intensive research efforts across both academic institutions and industrial R&D centers, resulting in a more sophisticated understanding of phase transformation kinetics in these alloys.

The technical trajectory has shown a clear shift from reactive problem-solving to proactive prevention strategies. Initial approaches focused primarily on post-fabrication treatments, while contemporary methodologies emphasize preventive measures integrated into the manufacturing process itself. This evolution reflects the growing sophistication of metallurgical science and the increasing precision of thermal management technologies.

Current technical objectives in this domain center on developing robust fabrication protocols that inherently minimize sigma phase formation risk in thick sections without compromising production efficiency or increasing costs prohibitively. Specifically, the industry aims to establish precise thermal cycle parameters that maintain the optimal ferrite-austenite balance throughout the material volume, even in sections exceeding 50mm thickness.

Additionally, there is significant interest in advancing real-time monitoring technologies capable of detecting early-stage sigma phase formation during fabrication processes. Such capabilities would enable adaptive manufacturing approaches that could adjust parameters dynamically to prevent detrimental microstructural changes.

The ultimate technical goal remains the development of a comprehensive, scientifically-grounded framework that enables predictable and consistent fabrication of thick-section DSS components with minimal sigma phase presence across diverse industrial applications. This framework must balance theoretical metallurgical principles with practical manufacturing constraints to deliver implementable solutions for industry stakeholders.

The sigma phase formation in DSS represents one of the most challenging metallurgical phenomena that can severely compromise the material's intended properties. This intermetallic phase, typically forming between 650°C and 950°C, causes embrittlement and reduces corrosion resistance, particularly problematic in thick-section fabrications where thermal cycles are more complex and prolonged.

Historical data indicates that early DSS implementations in the 1970s and 1980s frequently encountered sigma phase issues, leading to premature failures in critical applications. The financial implications of these failures prompted intensive research efforts across both academic institutions and industrial R&D centers, resulting in a more sophisticated understanding of phase transformation kinetics in these alloys.

The technical trajectory has shown a clear shift from reactive problem-solving to proactive prevention strategies. Initial approaches focused primarily on post-fabrication treatments, while contemporary methodologies emphasize preventive measures integrated into the manufacturing process itself. This evolution reflects the growing sophistication of metallurgical science and the increasing precision of thermal management technologies.

Current technical objectives in this domain center on developing robust fabrication protocols that inherently minimize sigma phase formation risk in thick sections without compromising production efficiency or increasing costs prohibitively. Specifically, the industry aims to establish precise thermal cycle parameters that maintain the optimal ferrite-austenite balance throughout the material volume, even in sections exceeding 50mm thickness.

Additionally, there is significant interest in advancing real-time monitoring technologies capable of detecting early-stage sigma phase formation during fabrication processes. Such capabilities would enable adaptive manufacturing approaches that could adjust parameters dynamically to prevent detrimental microstructural changes.

The ultimate technical goal remains the development of a comprehensive, scientifically-grounded framework that enables predictable and consistent fabrication of thick-section DSS components with minimal sigma phase presence across diverse industrial applications. This framework must balance theoretical metallurgical principles with practical manufacturing constraints to deliver implementable solutions for industry stakeholders.

Market Demand for Thick-Section DSS Applications

The global market for thick-section Duplex Stainless Steel (DSS) applications has experienced substantial growth over the past decade, driven primarily by increasing demands in critical infrastructure sectors. The oil and gas industry remains the largest consumer of thick-section DSS components, particularly for subsea equipment, pressure vessels, and pipelines operating in highly corrosive environments. Recent market analyses indicate that offshore oil and gas exploration in deeper waters has significantly boosted the demand for thick-section DSS that can withstand extreme conditions while maintaining structural integrity.

Chemical processing industries represent another major market segment, where thick-section DSS components are essential for reactors, heat exchangers, and storage tanks handling aggressive chemicals. The superior corrosion resistance combined with high mechanical strength makes DSS particularly valuable in these applications, where failure could result in catastrophic consequences both economically and environmentally.

Desalination plants worldwide have increasingly adopted thick-section DSS for critical components due to its exceptional resistance to chloride-induced stress corrosion cracking. As water scarcity becomes a global concern, the expansion of desalination infrastructure continues to drive demand for reliable materials that can handle prolonged exposure to seawater while maintaining operational efficiency.

The power generation sector, particularly nuclear and conventional thermal plants, constitutes another significant market for thick-section DSS applications. Components such as heat exchangers, pressure vessels, and piping systems benefit from the material's combination of strength and corrosion resistance in high-temperature environments where sigma phase formation becomes a critical concern.

Market trends indicate growing adoption in emerging economies, particularly in Asia-Pacific and Middle East regions, where rapid industrialization and infrastructure development projects require materials capable of withstanding harsh operating conditions while offering extended service life. The reduced maintenance requirements and longer lifecycle of DSS components provide compelling economic advantages despite higher initial investment costs.

End-users increasingly demand thick-section DSS components with guaranteed microstructural stability throughout their service life, placing emphasis on sigma phase prevention. This market requirement has intensified research efforts and manufacturing process improvements aimed at controlling phase transformations during fabrication of thick sections. Fabricators capable of delivering sigma-free thick-section components command premium pricing in the market, reflecting the critical importance of this technical challenge.

Chemical processing industries represent another major market segment, where thick-section DSS components are essential for reactors, heat exchangers, and storage tanks handling aggressive chemicals. The superior corrosion resistance combined with high mechanical strength makes DSS particularly valuable in these applications, where failure could result in catastrophic consequences both economically and environmentally.

Desalination plants worldwide have increasingly adopted thick-section DSS for critical components due to its exceptional resistance to chloride-induced stress corrosion cracking. As water scarcity becomes a global concern, the expansion of desalination infrastructure continues to drive demand for reliable materials that can handle prolonged exposure to seawater while maintaining operational efficiency.

The power generation sector, particularly nuclear and conventional thermal plants, constitutes another significant market for thick-section DSS applications. Components such as heat exchangers, pressure vessels, and piping systems benefit from the material's combination of strength and corrosion resistance in high-temperature environments where sigma phase formation becomes a critical concern.

Market trends indicate growing adoption in emerging economies, particularly in Asia-Pacific and Middle East regions, where rapid industrialization and infrastructure development projects require materials capable of withstanding harsh operating conditions while offering extended service life. The reduced maintenance requirements and longer lifecycle of DSS components provide compelling economic advantages despite higher initial investment costs.

End-users increasingly demand thick-section DSS components with guaranteed microstructural stability throughout their service life, placing emphasis on sigma phase prevention. This market requirement has intensified research efforts and manufacturing process improvements aimed at controlling phase transformations during fabrication of thick sections. Fabricators capable of delivering sigma-free thick-section components command premium pricing in the market, reflecting the critical importance of this technical challenge.

Technical Challenges in Preventing Sigma Phase Formation

The prevention of sigma phase formation in duplex stainless steel (DSS) during thick-section fabrication presents significant technical challenges due to the complex metallurgical behavior of these alloys. The primary difficulty lies in the inherent susceptibility of DSS to form intermetallic phases when exposed to elevated temperatures for extended periods, which is unavoidable during the welding and heat treatment of thick sections.

Thermal management represents one of the most critical challenges. Thick sections create substantial heat gradients and slower cooling rates, particularly in the heat-affected zone (HAZ). This prolonged exposure to temperatures between 650°C and 950°C—the critical range for sigma phase precipitation—significantly increases the risk of formation. Traditional cooling techniques that work effectively for thinner sections become inadequate as thickness increases beyond 25mm.

Compositional control presents another major hurdle. While modern DSS grades are designed with balanced chemistries to minimize sigma phase formation, maintaining this balance throughout thick sections is problematic. Elements like chromium, molybdenum, and silicon tend to segregate during solidification of large castings or forgings, creating localized regions with higher susceptibility to sigma phase precipitation.

Welding parameters optimization becomes exponentially more complex with increasing section thickness. The conventional wisdom of limiting heat input conflicts with the need to achieve full penetration in thick sections, creating a technical paradox. Multi-pass welding, often necessary for thick sections, compounds the problem by subjecting previously deposited material to multiple thermal cycles, each potentially contributing to sigma phase nucleation and growth.

Post-weld heat treatment (PWHT) protocols that work effectively for thin sections often prove inadequate for thick components. The challenge lies in achieving uniform temperature distribution throughout the entire cross-section while avoiding the critical temperature range for sigma formation. This becomes particularly problematic for components with varying thicknesses or complex geometries.

Non-destructive testing (NDT) limitations further complicate the situation. Current NDT methods struggle to reliably detect early-stage sigma phase formation deep within thick sections. The detection threshold typically requires approximately 4-5% volume fraction of sigma phase—a level at which mechanical properties may already be compromised.

Manufacturing process constraints add another layer of complexity. Rapid cooling techniques that effectively prevent sigma phase in laboratory settings often cannot be practically implemented in industrial fabrication of large, thick-section components due to equipment limitations, physical constraints, or economic considerations.

Thermal management represents one of the most critical challenges. Thick sections create substantial heat gradients and slower cooling rates, particularly in the heat-affected zone (HAZ). This prolonged exposure to temperatures between 650°C and 950°C—the critical range for sigma phase precipitation—significantly increases the risk of formation. Traditional cooling techniques that work effectively for thinner sections become inadequate as thickness increases beyond 25mm.

Compositional control presents another major hurdle. While modern DSS grades are designed with balanced chemistries to minimize sigma phase formation, maintaining this balance throughout thick sections is problematic. Elements like chromium, molybdenum, and silicon tend to segregate during solidification of large castings or forgings, creating localized regions with higher susceptibility to sigma phase precipitation.

Welding parameters optimization becomes exponentially more complex with increasing section thickness. The conventional wisdom of limiting heat input conflicts with the need to achieve full penetration in thick sections, creating a technical paradox. Multi-pass welding, often necessary for thick sections, compounds the problem by subjecting previously deposited material to multiple thermal cycles, each potentially contributing to sigma phase nucleation and growth.

Post-weld heat treatment (PWHT) protocols that work effectively for thin sections often prove inadequate for thick components. The challenge lies in achieving uniform temperature distribution throughout the entire cross-section while avoiding the critical temperature range for sigma formation. This becomes particularly problematic for components with varying thicknesses or complex geometries.

Non-destructive testing (NDT) limitations further complicate the situation. Current NDT methods struggle to reliably detect early-stage sigma phase formation deep within thick sections. The detection threshold typically requires approximately 4-5% volume fraction of sigma phase—a level at which mechanical properties may already be compromised.

Manufacturing process constraints add another layer of complexity. Rapid cooling techniques that effectively prevent sigma phase in laboratory settings often cannot be practically implemented in industrial fabrication of large, thick-section components due to equipment limitations, physical constraints, or economic considerations.

Current Methodologies for Sigma Phase Prevention

01 Composition control to prevent sigma phase formation

Controlling the chemical composition of duplex stainless steel is crucial for preventing sigma phase formation. Specific ratios of ferrite-forming elements (Cr, Mo, Si) to austenite-forming elements (Ni, N, C) can minimize sigma phase precipitation. Optimizing elements like chromium, molybdenum, and nitrogen within specific ranges helps maintain phase balance and reduces susceptibility to sigma phase formation during processing and service.- Factors affecting sigma phase formation in duplex stainless steel: Various factors influence the formation of sigma phase in duplex stainless steel, including chemical composition, temperature, and cooling rate. High chromium and molybdenum content promotes sigma phase formation. The temperature range of 600-1000°C is particularly critical for sigma phase precipitation. Rapid cooling can help prevent sigma phase formation, while slow cooling or prolonged exposure to critical temperatures increases the risk of sigma phase precipitation.

- Heat treatment methods to control sigma phase: Specific heat treatment protocols can be employed to control or eliminate sigma phase in duplex stainless steel. Solution annealing at temperatures above 1050°C followed by rapid quenching can dissolve existing sigma phase and prevent its reformation. Controlled cooling rates and intermediate heat treatments can be used to manage microstructure development. Post-weld heat treatments are particularly important for preventing sigma phase formation in welded duplex stainless steel components.

- Alloying elements and their impact on sigma phase formation: The addition or modification of specific alloying elements can significantly influence sigma phase formation in duplex stainless steel. Elements like chromium, molybdenum, and silicon promote sigma phase formation, while nitrogen and nickel can inhibit it. Balanced ferrite-austenite microstructure achieved through proper alloying can reduce susceptibility to sigma phase precipitation. Micro-alloying with elements like titanium, niobium, or rare earth metals can also help control sigma phase formation.

- Detection and measurement of sigma phase: Various techniques can be employed to detect and quantify sigma phase in duplex stainless steel. Non-destructive testing methods include ultrasonic testing, eddy current analysis, and magnetic measurements that can identify sigma phase presence. Microstructural examination using optical microscopy, scanning electron microscopy (SEM), and electron backscatter diffraction (EBSD) allows for detailed characterization. Electrochemical testing can also reveal the presence of sigma phase through changes in corrosion resistance.

- Manufacturing processes to minimize sigma phase: Specific manufacturing processes can be implemented to minimize sigma phase formation in duplex stainless steel products. Controlled hot working parameters including temperature, strain rate, and deformation degree can reduce sigma phase precipitation. Optimized welding procedures with proper heat input and interpass temperature control help prevent sigma phase formation in weld zones. Specialized thermomechanical processing routes can be designed to achieve desired microstructure while avoiding sigma phase formation.

02 Heat treatment processes to control sigma phase

Specific heat treatment protocols can be implemented to control or eliminate sigma phase in duplex stainless steels. Solution annealing at temperatures above 1000°C followed by rapid cooling can dissolve existing sigma phase. Controlled cooling rates through critical temperature ranges (700-950°C) where sigma phase forms most rapidly is essential. Post-weld heat treatments are particularly important as welding thermal cycles can promote sigma phase precipitation in the heat-affected zone.Expand Specific Solutions03 Microstructural analysis and detection methods

Various analytical techniques are employed to detect and quantify sigma phase formation in duplex stainless steels. These include optical microscopy with specialized etching techniques, scanning electron microscopy (SEM), electron backscatter diffraction (EBSD), and X-ray diffraction (XRD). Non-destructive testing methods such as ultrasonic testing and magnetic permeability measurements can be used for in-service inspection. Early detection of sigma phase is critical as even small amounts can significantly impact mechanical properties and corrosion resistance.Expand Specific Solutions04 Processing parameters to minimize sigma phase

Manufacturing and processing parameters significantly influence sigma phase formation in duplex stainless steels. Controlled hot working and forging within specific temperature ranges can minimize sigma phase precipitation. Optimized cooling rates during casting, rolling, and other forming operations are essential. Proper control of welding parameters including heat input, interpass temperature, and filler metal selection helps maintain phase balance and reduce sigma phase formation in welded components.Expand Specific Solutions05 Alloying strategies for sigma phase resistance

Novel alloying approaches can enhance resistance to sigma phase formation in duplex stainless steels. Addition of elements like tungsten, copper, or controlled amounts of nitrogen can stabilize the austenite phase and reduce sigma phase precipitation kinetics. Micro-alloying with elements that segregate to grain boundaries can inhibit sigma phase nucleation. Development of lean duplex grades with reduced molybdenum and chromium content offers improved resistance to sigma phase while maintaining adequate corrosion resistance for many applications.Expand Specific Solutions

Key Industry Players in DSS Manufacturing

The duplex stainless steel market is currently in a growth phase, driven by increasing demand in thick-section fabrications where sigma phase formation presents significant challenges. The global market size for duplex stainless steel is expanding, particularly in oil and gas, chemical processing, and marine applications, with an estimated value exceeding $3 billion. Leading companies like NIPPON STEEL, Outokumpu Oyj, and Sandvik Intellectual Property AB have developed advanced metallurgical solutions to prevent sigma phase formation through optimized chemical compositions, controlled cooling rates, and heat treatment processes. Other key players including JFE Steel, POSCO Holdings, and Alleima Tube AB are investing in R&D to enhance duplex grades with improved sigma phase resistance for thick-section applications, while academic institutions like University of Science & Technology Beijing contribute fundamental research to advance understanding of phase transformation mechanisms.

NIPPON STEEL CORP.

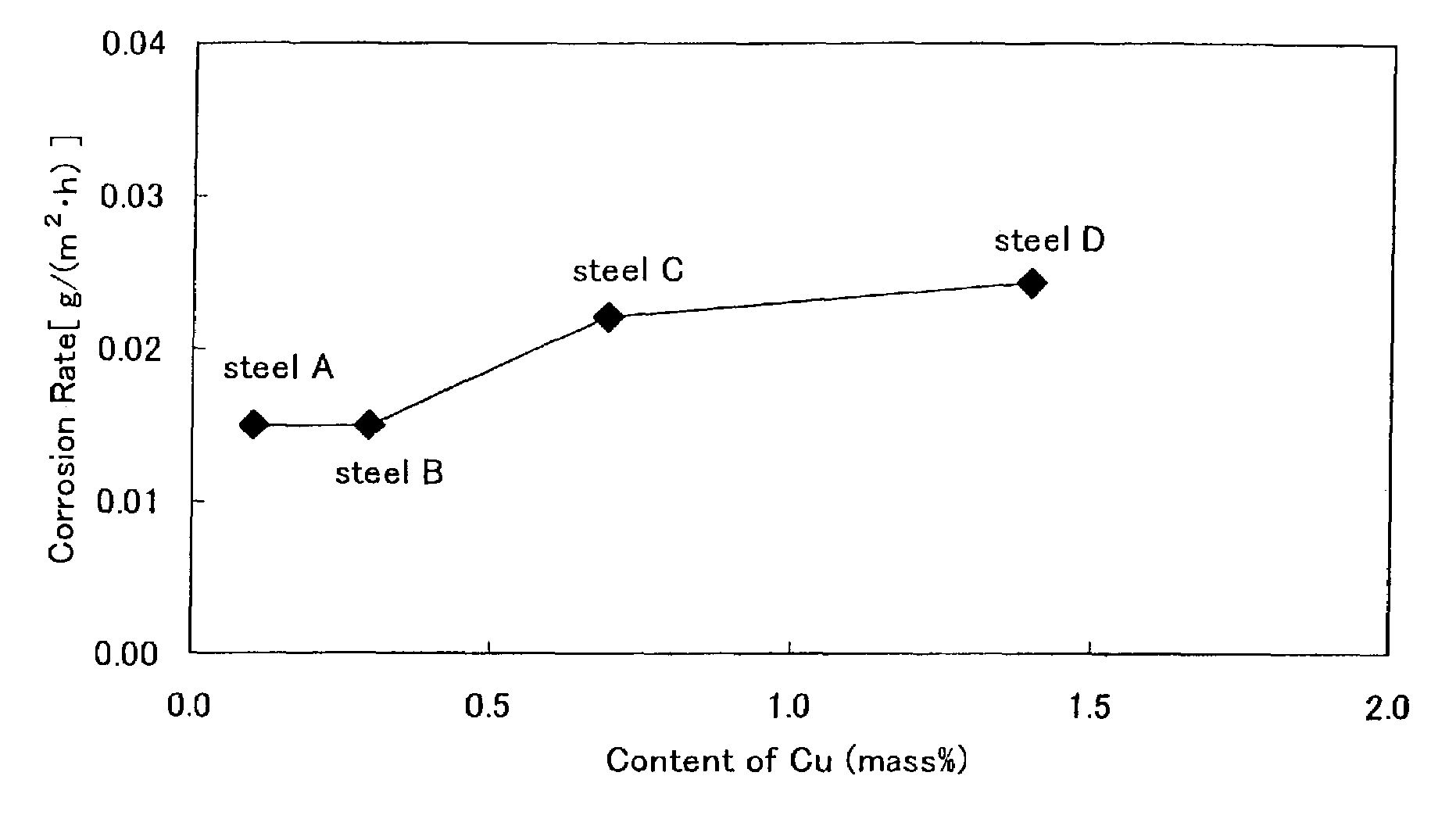

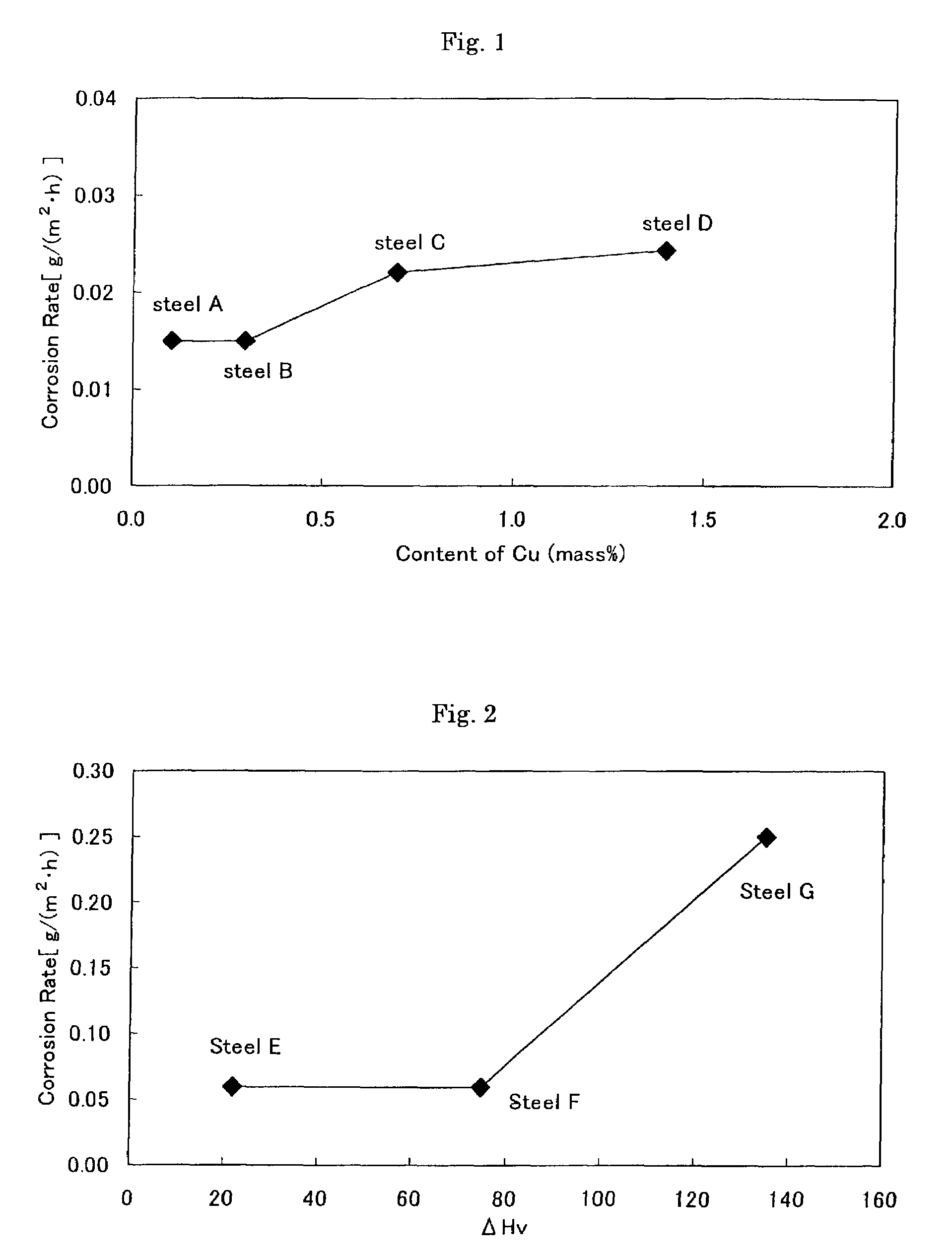

Technical Solution: NIPPON STEEL has developed a multi-faceted approach to prevent sigma phase formation in thick-section duplex stainless steel fabrication. Their technology centers on their proprietary "Controlled Diffusion Heat Treatment" (CDHT) process, which carefully manages the time-temperature profile during cooling to minimize chromium and molybdenum diffusion that leads to sigma phase nucleation. For thick sections exceeding 100mm, they implement a specialized step-cooling protocol that maintains the material above 950°C for a calculated duration based on section thickness, followed by accelerated cooling through the critical 650-900°C range where sigma phase forms most rapidly. NIPPON STEEL has also engineered specific alloy modifications for thick section applications, incorporating precise additions of manganese (0.8-1.2%) and copper (0.5-0.8%) that have been shown to retard sigma phase kinetics without compromising corrosion resistance. Their manufacturing process includes proprietary welding procedures with controlled heat input and interpass temperature management specifically designed for thick section joining, complemented by post-weld heat treatment protocols that ensure microstructural homogeneity throughout the heat-affected zones.

Strengths: NIPPON STEEL's comprehensive approach addresses both metallurgical and processing aspects of sigma phase prevention, resulting in highly reliable thick section components. Their CDHT process has been validated through extensive field testing in severe service environments. Weaknesses: The specialized heat treatment protocols require precise temperature control capabilities that may not be available in all fabrication facilities, potentially limiting widespread adoption of their techniques.

JFE Steel Corp.

Technical Solution: JFE Steel has developed an innovative approach to preventing sigma phase formation in thick-section duplex stainless steel through their "Microstructure Control Technology" (MCT). This comprehensive solution combines metallurgical design with advanced processing techniques. JFE's approach begins with precise control of ferrite-promoting elements (Cr, Mo, Si) and austenite-promoting elements (Ni, N, Mn) to achieve an optimal phase balance that inherently resists sigma transformation. For thick sections, they've developed a proprietary two-stage heat treatment process: first applying a high-temperature homogenization treatment (1150-1200°C) followed by a controlled cooling rate of approximately 10°C/min to 1050°C, then implementing water quenching with specialized fixtures designed to ensure uniform cooling even in sections exceeding 100mm. JFE has also pioneered the use of micro-alloying additions of copper (0.3-0.7%) and tungsten (0.2-0.5%) that occupy substitutional sites in the crystal structure, effectively blocking diffusion pathways that facilitate sigma phase formation without compromising mechanical properties or corrosion resistance.

Strengths: JFE's MCT approach provides exceptional resistance to sigma phase formation even during extended service at elevated temperatures (up to 300°C), making it ideal for demanding applications in chemical processing and offshore oil & gas. Their micro-alloying strategy offers inherent protection against sigma phase without requiring perfect cooling control. Weaknesses: The specialized alloy compositions may have higher initial material costs, and the two-stage heat treatment process increases production time compared to conventional methods.

Critical Metallurgical Innovations Analysis

Duplex stainless steel for urea manufacturing plants

PatentInactiveUS7347903B2

Innovation

- A duplex stainless steel composition with specific element limits, including Cr: 26-28%, Ni: 6-10%, Mo: 0.2-1.7%, W: 2-3%, N: 0.3-0.4%, and minimal Cu, along with optional Ca, Ce, and B additions, to prevent sigma phase formation and maintain high corrosion resistance, while adjusting Cr and W content to optimize ferrite stabilization and hot workability.

Super duplex stainless steel having excellent yield strength and impact toughness and manufacturing method therefor

PatentWO2016105094A1

Innovation

- Controlled reduction rate and heat treatment temperature during annealing to induce precipitation of CrN phase and secondary austenite phase within the ferrite phase, dissolving the sigma phase into solid solution, while maintaining a temperature increase rate of 0.11 to 0.17°C/s and annealing at 1020 to 1060°C for 20 to 60 minutes, to refine the microstructure and enhance mechanical properties.

Heat Treatment Optimization Strategies

Heat treatment optimization represents a critical strategy in preventing sigma phase formation in duplex stainless steel (DSS) thick-section fabrications. The time-temperature-transformation (TTT) behavior of DSS must be carefully managed through precisely controlled heating and cooling cycles to maintain the optimal austenite-ferrite balance while avoiding deleterious phase precipitation.

Solution annealing treatments at temperatures between 1050°C and 1100°C have proven effective in dissolving existing sigma phase and establishing the proper microstructure. This temperature range ensures complete dissolution of intermetallic phases while preventing excessive ferrite formation. The holding time at these temperatures must be calibrated according to section thickness, with thicker sections requiring longer times to achieve uniform temperature distribution throughout the material.

Rapid cooling following solution annealing is essential, particularly for sections exceeding 25mm in thickness. Water quenching provides the necessary cooling rates to bypass the sigma phase formation temperature range (approximately 650-950°C). For complex geometries where thermal gradients during quenching might induce residual stresses, controlled cooling rates of at least 15°C/min have been demonstrated to effectively prevent sigma precipitation while minimizing distortion.

Post-weld heat treatment (PWHT) protocols require special consideration for thick sections. Step-cooling approaches have emerged as an innovative solution, where the material is first held at approximately 1080°C for homogenization, followed by controlled cooling to intermediate temperatures (around 950°C) before final quenching. This approach helps manage the different thermal masses present in varied section thicknesses.

Advanced heat treatment monitoring technologies, including in-situ thermocouple arrays and thermal imaging systems, enable real-time temperature profile mapping across thick sections. This data-driven approach allows for dynamic adjustment of heating and cooling parameters to ensure uniform microstructural development throughout the component.

Computational modeling of heat treatment processes has become increasingly valuable for thick-section DSS fabrications. Finite element analysis (FEA) simulations can predict temperature gradients and phase transformation kinetics, enabling optimization of furnace loading arrangements and quenching methodologies before physical implementation. These models incorporate section thickness variations to develop customized heat treatment schedules that minimize sigma phase risk while maintaining production efficiency.

Industry best practices now include verification protocols such as ferritoscope measurements and targeted metallographic examination of representative thick sections to validate heat treatment effectiveness. This quality assurance approach ensures that optimized heat treatment strategies consistently deliver sigma-free microstructures in production environments.

Solution annealing treatments at temperatures between 1050°C and 1100°C have proven effective in dissolving existing sigma phase and establishing the proper microstructure. This temperature range ensures complete dissolution of intermetallic phases while preventing excessive ferrite formation. The holding time at these temperatures must be calibrated according to section thickness, with thicker sections requiring longer times to achieve uniform temperature distribution throughout the material.

Rapid cooling following solution annealing is essential, particularly for sections exceeding 25mm in thickness. Water quenching provides the necessary cooling rates to bypass the sigma phase formation temperature range (approximately 650-950°C). For complex geometries where thermal gradients during quenching might induce residual stresses, controlled cooling rates of at least 15°C/min have been demonstrated to effectively prevent sigma precipitation while minimizing distortion.

Post-weld heat treatment (PWHT) protocols require special consideration for thick sections. Step-cooling approaches have emerged as an innovative solution, where the material is first held at approximately 1080°C for homogenization, followed by controlled cooling to intermediate temperatures (around 950°C) before final quenching. This approach helps manage the different thermal masses present in varied section thicknesses.

Advanced heat treatment monitoring technologies, including in-situ thermocouple arrays and thermal imaging systems, enable real-time temperature profile mapping across thick sections. This data-driven approach allows for dynamic adjustment of heating and cooling parameters to ensure uniform microstructural development throughout the component.

Computational modeling of heat treatment processes has become increasingly valuable for thick-section DSS fabrications. Finite element analysis (FEA) simulations can predict temperature gradients and phase transformation kinetics, enabling optimization of furnace loading arrangements and quenching methodologies before physical implementation. These models incorporate section thickness variations to develop customized heat treatment schedules that minimize sigma phase risk while maintaining production efficiency.

Industry best practices now include verification protocols such as ferritoscope measurements and targeted metallographic examination of representative thick sections to validate heat treatment effectiveness. This quality assurance approach ensures that optimized heat treatment strategies consistently deliver sigma-free microstructures in production environments.

Corrosion Performance Impact Assessment

The formation of sigma phase in duplex stainless steel significantly impacts its corrosion resistance properties, particularly in thick-section fabrications where thermal cycles can promote precipitation. When sigma phase forms, it depletes chromium and molybdenum from the surrounding matrix, creating chromium-depleted zones that become susceptible to localized corrosion.

In chloride-containing environments, sigma phase presence can reduce pitting corrosion resistance by up to 30-40% compared to properly heat-treated duplex stainless steel. This reduction is quantified through critical pitting temperature (CPT) measurements, which typically show a decrease of 10-15°C in sigma-affected materials. The pitting resistance equivalent number (PREN) effectively decreases in areas adjacent to sigma precipitates, creating weak points for corrosion initiation.

Intergranular corrosion susceptibility increases dramatically with sigma phase formation, as the chromium-depleted boundaries surrounding sigma particles become preferential paths for corrosive attack. Testing per ASTM A262 practices demonstrates that samples with as little as 1-2% sigma phase can show significant intergranular corrosion rates compared to sigma-free specimens.

Stress corrosion cracking (SCC) resistance is also compromised by sigma phase presence. Research indicates that the time-to-failure in NACE TM0177 testing can decrease by 50-70% in specimens containing sigma phase compared to properly solution-annealed materials. This is particularly problematic in sour service applications where hydrogen embrittlement mechanisms may be enhanced by microstructural discontinuities.

Crevice corrosion performance, critical for components with flanges, gaskets, or overlapping sections, deteriorates with sigma phase formation. Studies show that the critical crevice temperature (CCT) can decrease by 8-12°C when sigma phase exceeds 3% volume fraction, significantly limiting the operational temperature range in seawater applications.

General corrosion rates typically increase by 2-3 times in acid environments when sigma phase is present in significant quantities. This is attributed to galvanic coupling between the noble sigma phase and the chromium-depleted matrix, accelerating dissolution of the latter. Electrochemical impedance spectroscopy (EIS) measurements confirm reduced polarization resistance in sigma-containing samples, indicating diminished passive film stability.

For thick-section fabrications in critical applications such as chemical processing equipment, offshore structures, or desalination plants, this corrosion performance degradation can lead to premature failure, increased maintenance costs, and potential safety hazards. Proper control of sigma phase is therefore essential to maintain the superior corrosion resistance that makes duplex stainless steel advantageous for these demanding applications.

In chloride-containing environments, sigma phase presence can reduce pitting corrosion resistance by up to 30-40% compared to properly heat-treated duplex stainless steel. This reduction is quantified through critical pitting temperature (CPT) measurements, which typically show a decrease of 10-15°C in sigma-affected materials. The pitting resistance equivalent number (PREN) effectively decreases in areas adjacent to sigma precipitates, creating weak points for corrosion initiation.

Intergranular corrosion susceptibility increases dramatically with sigma phase formation, as the chromium-depleted boundaries surrounding sigma particles become preferential paths for corrosive attack. Testing per ASTM A262 practices demonstrates that samples with as little as 1-2% sigma phase can show significant intergranular corrosion rates compared to sigma-free specimens.

Stress corrosion cracking (SCC) resistance is also compromised by sigma phase presence. Research indicates that the time-to-failure in NACE TM0177 testing can decrease by 50-70% in specimens containing sigma phase compared to properly solution-annealed materials. This is particularly problematic in sour service applications where hydrogen embrittlement mechanisms may be enhanced by microstructural discontinuities.

Crevice corrosion performance, critical for components with flanges, gaskets, or overlapping sections, deteriorates with sigma phase formation. Studies show that the critical crevice temperature (CCT) can decrease by 8-12°C when sigma phase exceeds 3% volume fraction, significantly limiting the operational temperature range in seawater applications.

General corrosion rates typically increase by 2-3 times in acid environments when sigma phase is present in significant quantities. This is attributed to galvanic coupling between the noble sigma phase and the chromium-depleted matrix, accelerating dissolution of the latter. Electrochemical impedance spectroscopy (EIS) measurements confirm reduced polarization resistance in sigma-containing samples, indicating diminished passive film stability.

For thick-section fabrications in critical applications such as chemical processing equipment, offshore structures, or desalination plants, this corrosion performance degradation can lead to premature failure, increased maintenance costs, and potential safety hazards. Proper control of sigma phase is therefore essential to maintain the superior corrosion resistance that makes duplex stainless steel advantageous for these demanding applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!