How Duplex Stainless Steel Ensures Phase Balance In Complex Welded Assemblies?

SEP 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Duplex Steel Phase Balance Background and Objectives

Duplex stainless steels emerged in the early 1930s, with significant commercial development occurring in the 1970s and 1980s. These alloys are characterized by their balanced microstructure of approximately 50% austenite and 50% ferrite phases, which provides an exceptional combination of mechanical properties and corrosion resistance. The evolution of duplex stainless steels has been driven by the need for materials that can withstand increasingly demanding environments in industries such as oil and gas, chemical processing, and marine applications.

The technological trajectory of duplex stainless steels has seen continuous refinement in alloy composition and processing techniques. First-generation duplex steels contained relatively high carbon content, which limited their weldability. Second-generation alloys introduced nitrogen as a key alloying element, significantly improving phase stability during welding operations. The most recent developments have focused on lean duplex grades that optimize cost while maintaining performance, and super duplex grades that offer enhanced resistance to pitting and crevice corrosion in aggressive environments.

The primary technical objective in duplex stainless steel welding is maintaining the critical phase balance between austenite and ferrite in the weld metal and heat-affected zone (HAZ). This balance is essential because excessive ferrite content can lead to reduced toughness and increased susceptibility to hydrogen embrittlement, while excessive austenite may compromise stress corrosion cracking resistance. The challenge intensifies in complex welded assemblies where multiple weld passes, varying section thicknesses, and different cooling rates can significantly alter the microstructure.

Current research aims to develop comprehensive understanding of phase transformation kinetics during the welding thermal cycle. This includes quantifying the effects of heat input, cooling rate, and filler metal composition on the resulting microstructure. Advanced computational models are being developed to predict phase balance based on welding parameters, enabling more precise control of the welding process.

Another key objective is establishing standardized methodologies for assessing phase balance in welded joints, particularly for complex geometries where traditional metallographic techniques may be insufficient. This includes the development of non-destructive testing methods that can verify phase balance in-situ during fabrication or in service.

The ultimate goal is to establish robust welding procedures that ensure consistent phase balance across all regions of complex welded assemblies, thereby maintaining the intended mechanical properties and corrosion resistance throughout the structure. This requires integrating metallurgical knowledge with advanced welding technologies and quality control systems to create reliable, high-performance welded components for critical applications.

The technological trajectory of duplex stainless steels has seen continuous refinement in alloy composition and processing techniques. First-generation duplex steels contained relatively high carbon content, which limited their weldability. Second-generation alloys introduced nitrogen as a key alloying element, significantly improving phase stability during welding operations. The most recent developments have focused on lean duplex grades that optimize cost while maintaining performance, and super duplex grades that offer enhanced resistance to pitting and crevice corrosion in aggressive environments.

The primary technical objective in duplex stainless steel welding is maintaining the critical phase balance between austenite and ferrite in the weld metal and heat-affected zone (HAZ). This balance is essential because excessive ferrite content can lead to reduced toughness and increased susceptibility to hydrogen embrittlement, while excessive austenite may compromise stress corrosion cracking resistance. The challenge intensifies in complex welded assemblies where multiple weld passes, varying section thicknesses, and different cooling rates can significantly alter the microstructure.

Current research aims to develop comprehensive understanding of phase transformation kinetics during the welding thermal cycle. This includes quantifying the effects of heat input, cooling rate, and filler metal composition on the resulting microstructure. Advanced computational models are being developed to predict phase balance based on welding parameters, enabling more precise control of the welding process.

Another key objective is establishing standardized methodologies for assessing phase balance in welded joints, particularly for complex geometries where traditional metallographic techniques may be insufficient. This includes the development of non-destructive testing methods that can verify phase balance in-situ during fabrication or in service.

The ultimate goal is to establish robust welding procedures that ensure consistent phase balance across all regions of complex welded assemblies, thereby maintaining the intended mechanical properties and corrosion resistance throughout the structure. This requires integrating metallurgical knowledge with advanced welding technologies and quality control systems to create reliable, high-performance welded components for critical applications.

Market Demand Analysis for Balanced Duplex Steel Assemblies

The global market for duplex stainless steel in complex welded assemblies has experienced significant growth, driven by increasing demand across multiple industries requiring materials with superior corrosion resistance and mechanical properties. The oil and gas sector remains the largest consumer, accounting for approximately 30% of the market share, particularly for offshore platforms, pipelines, and processing equipment operating in highly corrosive environments.

Chemical processing industries represent the second-largest market segment, where balanced duplex steel assemblies are essential for reactors, heat exchangers, and storage tanks handling aggressive chemicals. The power generation sector, especially nuclear and desalination plants, has also shown increased adoption rates due to the material's excellent resistance to stress corrosion cracking in high-temperature applications.

Market analysis indicates that regions with extensive maritime and offshore activities, such as Northern Europe, North America, and parts of Asia, particularly China and South Korea, demonstrate the highest demand growth rates. The Middle East market has expanded considerably due to substantial investments in oil and gas infrastructure and desalination facilities.

A notable market trend is the increasing specification of duplex stainless steel in architectural applications for coastal structures and bridges, where the combination of strength and corrosion resistance offers significant lifecycle cost advantages despite higher initial investment. This shift represents a growing recognition of total cost of ownership rather than upfront material costs alone.

Supply chain dynamics reveal that while raw material costs for duplex stainless steel fluctuate with nickel and molybdenum prices, manufacturers are increasingly willing to absorb premium costs due to the demonstrable performance benefits in welded assemblies. Market research indicates that properly balanced duplex steel assemblies can reduce maintenance costs by up to 40% compared to conventional materials in corrosive environments.

Industry forecasts project a compound annual growth rate of 5.8% for balanced duplex steel assemblies through 2028, with particularly strong growth in emerging economies developing infrastructure in challenging environments. The marine sector represents the fastest-growing application segment, with increasing adoption in shipbuilding, offshore wind foundations, and port infrastructure.

Customer demand patterns show growing sophistication, with end-users increasingly specifying not just the material grade but also the welding procedures and post-weld treatments necessary to maintain phase balance. This trend has created market opportunities for specialized welding service providers and inspection companies focused on duplex stainless steel applications.

Chemical processing industries represent the second-largest market segment, where balanced duplex steel assemblies are essential for reactors, heat exchangers, and storage tanks handling aggressive chemicals. The power generation sector, especially nuclear and desalination plants, has also shown increased adoption rates due to the material's excellent resistance to stress corrosion cracking in high-temperature applications.

Market analysis indicates that regions with extensive maritime and offshore activities, such as Northern Europe, North America, and parts of Asia, particularly China and South Korea, demonstrate the highest demand growth rates. The Middle East market has expanded considerably due to substantial investments in oil and gas infrastructure and desalination facilities.

A notable market trend is the increasing specification of duplex stainless steel in architectural applications for coastal structures and bridges, where the combination of strength and corrosion resistance offers significant lifecycle cost advantages despite higher initial investment. This shift represents a growing recognition of total cost of ownership rather than upfront material costs alone.

Supply chain dynamics reveal that while raw material costs for duplex stainless steel fluctuate with nickel and molybdenum prices, manufacturers are increasingly willing to absorb premium costs due to the demonstrable performance benefits in welded assemblies. Market research indicates that properly balanced duplex steel assemblies can reduce maintenance costs by up to 40% compared to conventional materials in corrosive environments.

Industry forecasts project a compound annual growth rate of 5.8% for balanced duplex steel assemblies through 2028, with particularly strong growth in emerging economies developing infrastructure in challenging environments. The marine sector represents the fastest-growing application segment, with increasing adoption in shipbuilding, offshore wind foundations, and port infrastructure.

Customer demand patterns show growing sophistication, with end-users increasingly specifying not just the material grade but also the welding procedures and post-weld treatments necessary to maintain phase balance. This trend has created market opportunities for specialized welding service providers and inspection companies focused on duplex stainless steel applications.

Current Challenges in Duplex Steel Welding Technology

Despite significant advancements in duplex stainless steel (DSS) welding technology, several critical challenges persist that impact phase balance maintenance in complex welded assemblies. The fundamental difficulty lies in the precise control of ferrite-austenite ratio during the welding thermal cycle. Unlike base metal manufacturing where processing parameters can be tightly controlled, welding introduces rapid heating and cooling cycles that significantly alter microstructural evolution dynamics.

Heat input management represents a primary challenge, as both insufficient and excessive heat input can disrupt phase balance. Low heat input results in accelerated cooling rates that favor excessive ferrite formation (>70%), compromising corrosion resistance and toughness. Conversely, excessive heat input promotes intermetallic precipitation and chromium nitride formation, particularly in heat-affected zones (HAZ), leading to embrittlement and reduced corrosion performance.

Filler metal selection and composition optimization remain problematic, especially for complex multi-pass welds. Current filler metals often contain elevated nickel and nitrogen content to promote austenite formation, but achieving consistent chemical distribution throughout the weld becomes increasingly difficult in complex geometries with varying section thicknesses. This challenge is magnified when joining DSS to dissimilar metals, where diffusion of alloying elements across the fusion boundary creates localized compositional gradients.

Post-weld heat treatment (PWHT) effectiveness is limited by geometric constraints in complex assemblies. Uneven heating and cooling rates across different sections create varying microstructural responses, making uniform phase balance restoration extremely difficult. Additionally, many field applications prohibit PWHT due to practical limitations, forcing reliance solely on controlled welding parameters.

Nitrogen loss during welding presents another significant challenge. As a potent austenite stabilizer in DSS, nitrogen depletion in the weld pool can dramatically shift phase balance toward ferrite. Current shielding gas technologies struggle to fully compensate for this loss in complex joint configurations with limited accessibility, particularly in orbital and position welding scenarios.

Non-destructive testing limitations further complicate quality assurance. While ferrite measurement tools exist, they typically provide surface or near-surface readings only. Internal phase balance verification in complex assemblies often requires destructive testing, which is impractical for production components. Advanced techniques like phased array ultrasonics show promise but remain limited in resolution and interpretation reliability for phase balance quantification.

Heat input management represents a primary challenge, as both insufficient and excessive heat input can disrupt phase balance. Low heat input results in accelerated cooling rates that favor excessive ferrite formation (>70%), compromising corrosion resistance and toughness. Conversely, excessive heat input promotes intermetallic precipitation and chromium nitride formation, particularly in heat-affected zones (HAZ), leading to embrittlement and reduced corrosion performance.

Filler metal selection and composition optimization remain problematic, especially for complex multi-pass welds. Current filler metals often contain elevated nickel and nitrogen content to promote austenite formation, but achieving consistent chemical distribution throughout the weld becomes increasingly difficult in complex geometries with varying section thicknesses. This challenge is magnified when joining DSS to dissimilar metals, where diffusion of alloying elements across the fusion boundary creates localized compositional gradients.

Post-weld heat treatment (PWHT) effectiveness is limited by geometric constraints in complex assemblies. Uneven heating and cooling rates across different sections create varying microstructural responses, making uniform phase balance restoration extremely difficult. Additionally, many field applications prohibit PWHT due to practical limitations, forcing reliance solely on controlled welding parameters.

Nitrogen loss during welding presents another significant challenge. As a potent austenite stabilizer in DSS, nitrogen depletion in the weld pool can dramatically shift phase balance toward ferrite. Current shielding gas technologies struggle to fully compensate for this loss in complex joint configurations with limited accessibility, particularly in orbital and position welding scenarios.

Non-destructive testing limitations further complicate quality assurance. While ferrite measurement tools exist, they typically provide surface or near-surface readings only. Internal phase balance verification in complex assemblies often requires destructive testing, which is impractical for production components. Advanced techniques like phased array ultrasonics show promise but remain limited in resolution and interpretation reliability for phase balance quantification.

Current Phase Balance Maintenance Solutions in Welding

01 Composition control for phase balance in duplex stainless steel

Controlling the chemical composition of duplex stainless steel is crucial for achieving optimal phase balance between austenite and ferrite phases. Specific elements like nickel, nitrogen, manganese, and chromium can be adjusted to promote either austenite or ferrite formation. The proper balance of these elements ensures the desired microstructure and mechanical properties while maintaining corrosion resistance. Heat treatment parameters must be carefully controlled alongside composition to achieve the target phase ratio.- Composition control for phase balance: Controlling the chemical composition of duplex stainless steel is crucial for achieving optimal phase balance between austenite and ferrite. Specific elements like nickel, nitrogen, manganese, and chromium can be adjusted to promote either austenite or ferrite formation. The proper balance of these alloying elements ensures the desired microstructure and mechanical properties while maintaining corrosion resistance. Precise control of these elements during manufacturing helps achieve the ideal 50:50 phase ratio that provides the best combination of strength and ductility.

- Heat treatment processes for phase balance optimization: Various heat treatment processes are employed to optimize the phase balance in duplex stainless steels. Solution annealing at specific temperatures followed by controlled cooling rates can significantly influence the austenite-ferrite ratio. Annealing temperatures typically range between 1020-1100°C to dissolve unwanted precipitates and achieve the desired microstructure. Post-weld heat treatments are particularly important to restore phase balance in welded regions where thermal cycles can disrupt the optimal microstructure. Proper heat treatment schedules prevent the formation of detrimental phases that could compromise mechanical properties and corrosion resistance.

- Microstructural analysis and testing methods: Advanced testing and analysis methods are essential for evaluating phase balance in duplex stainless steels. Techniques include optical microscopy, electron backscatter diffraction (EBSD), X-ray diffraction, and magnetic measurements to quantify the ferrite-austenite ratio. Image analysis software can be used to determine phase percentages from metallographic samples. Ferrite content is often measured using magnetic methods since ferrite is ferromagnetic while austenite is not. These testing methods ensure that the desired phase balance is achieved during production and maintained after processing steps like welding or forming.

- Processing parameters for welding and forming: Specific processing parameters during welding and forming operations are critical for maintaining phase balance in duplex stainless steels. Controlled cooling rates after welding prevent excessive ferrite formation or precipitation of detrimental phases. Heat input during welding must be carefully managed to avoid thermal imbalances that could alter the microstructure. For hot forming operations, temperature ranges must be strictly controlled to maintain the desired austenite-ferrite ratio. Post-processing heat treatments may be necessary to restore phase balance after manufacturing operations that disrupt the microstructure.

- Novel alloy designs for improved phase stability: Innovative alloy designs focus on improving phase stability in duplex stainless steels across various service conditions. These designs incorporate precise balances of austenite and ferrite stabilizers to maintain optimal phase ratios during thermal cycling. Some approaches include lean duplex compositions with reduced nickel content compensated by increased nitrogen and manganese. Other innovations involve micro-alloying additions that enhance phase stability during welding or high-temperature service. These novel alloys aim to provide better corrosion resistance, mechanical properties, and phase balance stability in challenging environments while potentially reducing material costs.

02 Heat treatment processes for phase balance optimization

Heat treatment processes significantly impact the phase balance in duplex stainless steel. Solution annealing, quenching, and controlled cooling rates are employed to achieve the desired austenite-ferrite ratio. The temperature and duration of heat treatments must be precisely controlled to prevent the formation of detrimental phases. Post-weld heat treatments are particularly important for restoring phase balance in welded components, as the heat-affected zone often experiences phase imbalance during welding operations.Expand Specific Solutions03 Microstructural analysis and testing methods for phase balance

Various testing and analysis methods are employed to evaluate and verify the phase balance in duplex stainless steel. These include optical microscopy, electron microscopy, X-ray diffraction, and magnetic measurement techniques. Quantitative metallography is used to determine the volume fractions of austenite and ferrite phases. Corrosion testing and mechanical property evaluations are conducted to confirm that the achieved phase balance provides the expected performance characteristics. These methods are essential for quality control in production environments.Expand Specific Solutions04 Processing techniques for maintaining phase balance during manufacturing

Manufacturing processes must be carefully controlled to maintain proper phase balance in duplex stainless steel products. Hot and cold working operations, including rolling, forging, and drawing, can alter the phase balance if not properly executed. Intermediate annealing steps may be required to restore the optimal microstructure. The cooling rate after hot working is particularly critical, as it influences the transformation kinetics between austenite and ferrite. Special processing routes have been developed for different product forms to ensure consistent phase balance throughout the material.Expand Specific Solutions05 Alloying strategies for enhanced phase stability in aggressive environments

Advanced alloying strategies are employed to enhance phase stability in duplex stainless steels exposed to aggressive environments. The addition of elements like molybdenum, tungsten, and copper improves corrosion resistance while maintaining phase balance. Nitrogen is particularly effective at stabilizing austenite and improving mechanical properties. Micro-alloying with elements such as cerium or titanium can refine grain structure and prevent the formation of detrimental intermetallic phases. These alloying approaches enable duplex stainless steels to maintain their balanced microstructure even under extreme service conditions.Expand Specific Solutions

Key Industry Players in Duplex Stainless Steel Manufacturing

The duplex stainless steel market is currently in a growth phase, driven by increasing demand for corrosion-resistant materials in complex welded assemblies across marine, chemical, and energy sectors. The global market size is estimated at $3.5 billion, with projected annual growth of 4-6% through 2028. Leading players like NIPPON STEEL, JFE Steel, and Sandvik Intellectual Property have achieved significant technological maturity in phase balance control through advanced alloying techniques and heat treatment processes. Companies such as POSCO Holdings and Alleima Tube are pioneering innovations in welding consumables specifically designed to maintain ferrite-austenite ratios during multi-pass welding. Carpenter Technology and Shanxi Taigang are focusing on post-weld heat treatments to restore optimal microstructure in heat-affected zones.

NIPPON STEEL CORP.

Technical Solution: Nippon Steel has developed advanced duplex stainless steel welding technologies that ensure phase balance through precise control of nitrogen content in the weld metal. Their approach involves carefully calibrated shielding gas mixtures containing nitrogen to compensate for nitrogen loss during welding. The company employs a proprietary heat input control system that maintains optimal ferrite-austenite ratios (typically 50:50) throughout the heat-affected zone (HAZ). Their solution includes specialized filler metals with enhanced nitrogen and nickel content specifically designed for different duplex grades. Nippon Steel's process also incorporates post-weld heat treatment protocols optimized through computational modeling to predict and control phase transformations. Their technology enables consistent mechanical properties across welded joints in complex assemblies, with corrosion resistance equivalent to the base metal.

Strengths: Superior nitrogen control methodology provides excellent phase balance consistency across various welding conditions. Their integrated computational modeling approach allows for predictive quality control. Weaknesses: The specialized filler materials and shielding gas requirements increase production costs, and the process demands highly skilled welders with specific training in duplex welding techniques.

JFE Steel Corp.

Technical Solution: JFE Steel has developed an innovative approach to duplex stainless steel welding that centers on their "Balanced Phase Welding" (BPW) technology. This system utilizes precisely controlled heat input parameters combined with specialized cooling strategies to maintain optimal ferrite-austenite ratios throughout welded assemblies. JFE's solution incorporates advanced filler metals with tailored nitrogen and nickel content that compensate for elemental losses during welding. Their process features a proprietary pulsed welding technique that creates micro-cooling cycles within the weld pool, promoting balanced phase transformation. JFE has also implemented an automated monitoring system that analyzes real-time thermal profiles during welding to ensure consistent microstructural development. Their technology includes post-weld treatment protocols specifically designed to homogenize phase distribution in complex geometries where thermal gradients vary significantly.

Strengths: The pulsed welding approach provides excellent control over solidification patterns and phase transformation, resulting in consistent properties across varying joint configurations. Their automated monitoring enables quality assurance in production environments. Weaknesses: The system requires complex equipment calibration and is sensitive to variations in base material composition, potentially limiting its effectiveness across different duplex grades.

Critical Patents and Research on Duplex Steel Microstructure

Duplex stainless steel product and production method thereof

PatentWO2017047262A1

Innovation

- A compositionally modulated structure is formed in the grain boundary region of duplex stainless steel using spinodal decomposition and a controlled magnetic field during heat treatment, creating a layered structure that suppresses the diffusion and growth of the σ phase by maintaining a low temperature and applying a magnetic field between 0.1 T and 10 T, thereby inhibiting σ-phase formation.

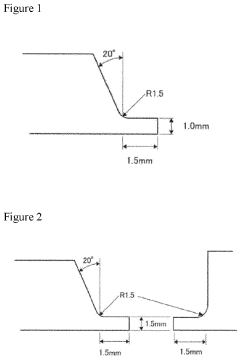

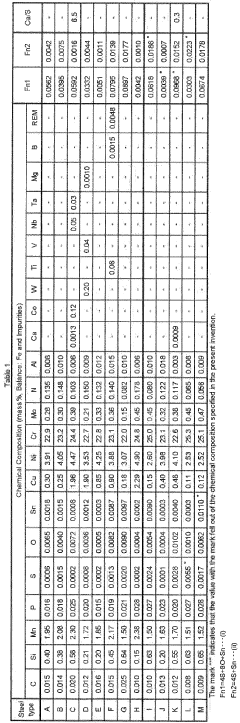

Two-phase stainless steel pipe and welded fitting

PatentPendingEP4174205A1

Innovation

- A duplex stainless steel tube with a specific chemical composition and surface roughness, including controlled levels of elements like S, Sn, O, and Ca, and a Ca/S ratio, to stabilize the formation of internal weld beads and enhance the toughness of the weld heat-affected zone, ensuring a stable and effective welding process.

Metallurgical Testing and Quality Assurance Protocols

Maintaining phase balance in duplex stainless steel welded assemblies requires comprehensive metallurgical testing and quality assurance protocols. These protocols must be systematically implemented throughout the manufacturing process to ensure optimal microstructural properties and mechanical performance.

X-ray diffraction (XRD) analysis serves as a primary quantitative method for determining ferrite-austenite phase ratios in duplex stainless steel welds. This technique provides precise measurements of phase percentages, allowing manufacturers to verify compliance with the ideal 50:50 balance or acceptable tolerance ranges (typically 40-60% ferrite). Complementary to XRD, magnetic ferrite testing offers rapid on-site assessment of ferrite content, enabling real-time adjustments during production.

Optical microscopy and scanning electron microscopy (SEM) with energy-dispersive X-ray spectroscopy (EDS) capabilities form the cornerstone of microstructural evaluation. These techniques reveal not only phase distribution patterns but also identify detrimental intermetallic precipitates that may form during improper thermal cycles. Standard metallographic preparation involving etching with solutions such as Beraha's reagent or modified Murakami's reagent enhances phase contrast for accurate visual assessment.

Mechanical property verification through tensile testing, impact testing, and hardness measurements provides functional validation of proper phase balance. Particularly, Charpy V-notch impact testing at various temperatures helps assess toughness retention, which directly correlates with optimal austenite-ferrite ratios. Hardness mapping across heat-affected zones can identify localized phase imbalances that might compromise structural integrity.

Corrosion resistance testing protocols, including ASTM G48 (pitting resistance), ASTM A923 (detrimental phase detection), and electrochemical critical pitting temperature tests, evaluate the practical consequences of phase balance deviations. These tests are crucial as improper phase ratios significantly impact corrosion performance, especially in chloride-containing environments.

In-process quality assurance requires strict thermal monitoring during welding operations. Temperature control systems with data logging capabilities ensure that peak temperatures and cooling rates remain within parameters that preserve phase balance. Heat input calculations must be documented for each weld pass, with verification that values remain within qualified ranges.

Post-weld heat treatment (PWHT) protocols, when applicable, must include precise temperature control and uniform heating verification. Infrared thermography during PWHT helps identify potential cold or hot spots that could lead to localized phase imbalances. Final certification typically requires comprehensive documentation of all testing results, ensuring traceability throughout the manufacturing process.

X-ray diffraction (XRD) analysis serves as a primary quantitative method for determining ferrite-austenite phase ratios in duplex stainless steel welds. This technique provides precise measurements of phase percentages, allowing manufacturers to verify compliance with the ideal 50:50 balance or acceptable tolerance ranges (typically 40-60% ferrite). Complementary to XRD, magnetic ferrite testing offers rapid on-site assessment of ferrite content, enabling real-time adjustments during production.

Optical microscopy and scanning electron microscopy (SEM) with energy-dispersive X-ray spectroscopy (EDS) capabilities form the cornerstone of microstructural evaluation. These techniques reveal not only phase distribution patterns but also identify detrimental intermetallic precipitates that may form during improper thermal cycles. Standard metallographic preparation involving etching with solutions such as Beraha's reagent or modified Murakami's reagent enhances phase contrast for accurate visual assessment.

Mechanical property verification through tensile testing, impact testing, and hardness measurements provides functional validation of proper phase balance. Particularly, Charpy V-notch impact testing at various temperatures helps assess toughness retention, which directly correlates with optimal austenite-ferrite ratios. Hardness mapping across heat-affected zones can identify localized phase imbalances that might compromise structural integrity.

Corrosion resistance testing protocols, including ASTM G48 (pitting resistance), ASTM A923 (detrimental phase detection), and electrochemical critical pitting temperature tests, evaluate the practical consequences of phase balance deviations. These tests are crucial as improper phase ratios significantly impact corrosion performance, especially in chloride-containing environments.

In-process quality assurance requires strict thermal monitoring during welding operations. Temperature control systems with data logging capabilities ensure that peak temperatures and cooling rates remain within parameters that preserve phase balance. Heat input calculations must be documented for each weld pass, with verification that values remain within qualified ranges.

Post-weld heat treatment (PWHT) protocols, when applicable, must include precise temperature control and uniform heating verification. Infrared thermography during PWHT helps identify potential cold or hot spots that could lead to localized phase imbalances. Final certification typically requires comprehensive documentation of all testing results, ensuring traceability throughout the manufacturing process.

Corrosion Resistance Optimization in Welded Assemblies

Corrosion resistance in welded duplex stainless steel (DSS) assemblies represents a critical performance parameter that directly impacts structural integrity and service life. The optimization of corrosion resistance requires careful consideration of phase balance maintenance during and after welding processes, as this balance fundamentally determines the material's electrochemical properties.

The welding thermal cycle significantly alters the carefully engineered 50:50 austenite-ferrite phase ratio that gives DSS its superior corrosion resistance. Heat-affected zones (HAZ) typically experience ferrite enrichment, creating localized areas with diminished corrosion resistance compared to the base metal. This imbalance creates electrochemical potential differences that can accelerate localized corrosion mechanisms, particularly in chloride-containing environments.

Research indicates that optimizing nitrogen content in shielding gases during welding can promote austenite reformation in the weld metal and HAZ. Studies have demonstrated that nitrogen additions of 1-2% in argon-based shielding gases significantly improve pitting corrosion resistance by facilitating austenite nucleation and growth during cooling. This approach helps maintain the critical phase balance necessary for optimal corrosion performance.

Post-weld heat treatment (PWHT) protocols have been developed specifically for complex DSS assemblies to restore phase balance. Controlled heating to 1050-1100°C followed by rapid cooling has proven effective in redistributing alloying elements and regenerating appropriate austenite content. However, this approach presents challenges in large or geometrically complex assemblies where uniform heating cannot be easily achieved.

Filler metal selection represents another crucial factor in corrosion resistance optimization. Over-alloyed fillers containing elevated nickel and nitrogen content compared to the base metal compensate for preferential element loss during welding. These specialized consumables promote austenite formation during solidification and cooling, helping maintain phase balance and consequently preserving corrosion resistance properties.

Advanced surface treatments such as laser surface melting and plasma nitriding have emerged as promising techniques for enhancing the corrosion resistance of welded zones. These processes modify the surface microstructure and composition, creating a more homogeneous passive layer that improves resistance to pitting and crevice corrosion without affecting the bulk material properties.

Electrochemical potential mapping techniques now enable precise identification of susceptible areas in welded assemblies, allowing for targeted corrosion mitigation strategies. This approach has proven particularly valuable in complex multi-pass welds where microstructural variations can be difficult to predict using conventional methods.

The welding thermal cycle significantly alters the carefully engineered 50:50 austenite-ferrite phase ratio that gives DSS its superior corrosion resistance. Heat-affected zones (HAZ) typically experience ferrite enrichment, creating localized areas with diminished corrosion resistance compared to the base metal. This imbalance creates electrochemical potential differences that can accelerate localized corrosion mechanisms, particularly in chloride-containing environments.

Research indicates that optimizing nitrogen content in shielding gases during welding can promote austenite reformation in the weld metal and HAZ. Studies have demonstrated that nitrogen additions of 1-2% in argon-based shielding gases significantly improve pitting corrosion resistance by facilitating austenite nucleation and growth during cooling. This approach helps maintain the critical phase balance necessary for optimal corrosion performance.

Post-weld heat treatment (PWHT) protocols have been developed specifically for complex DSS assemblies to restore phase balance. Controlled heating to 1050-1100°C followed by rapid cooling has proven effective in redistributing alloying elements and regenerating appropriate austenite content. However, this approach presents challenges in large or geometrically complex assemblies where uniform heating cannot be easily achieved.

Filler metal selection represents another crucial factor in corrosion resistance optimization. Over-alloyed fillers containing elevated nickel and nitrogen content compared to the base metal compensate for preferential element loss during welding. These specialized consumables promote austenite formation during solidification and cooling, helping maintain phase balance and consequently preserving corrosion resistance properties.

Advanced surface treatments such as laser surface melting and plasma nitriding have emerged as promising techniques for enhancing the corrosion resistance of welded zones. These processes modify the surface microstructure and composition, creating a more homogeneous passive layer that improves resistance to pitting and crevice corrosion without affecting the bulk material properties.

Electrochemical potential mapping techniques now enable precise identification of susceptible areas in welded assemblies, allowing for targeted corrosion mitigation strategies. This approach has proven particularly valuable in complex multi-pass welds where microstructural variations can be difficult to predict using conventional methods.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!