How Duplex Stainless Steel Maintains Corrosion Resistance After Thermal Rework And Repair?

SEP 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Duplex Stainless Steel Corrosion Resistance Background and Objectives

Duplex stainless steels (DSS) have emerged as a revolutionary material class since their development in the 1930s, with significant commercial adoption beginning in the 1970s. These alloys combine the beneficial properties of both austenitic and ferritic stainless steels, offering superior corrosion resistance alongside enhanced mechanical properties. The microstructural balance between austenite and ferrite phases, typically maintained at approximately 50:50 ratio, is fundamental to their exceptional performance in aggressive environments.

The evolution of DSS technology has progressed through several generations, from the first-generation alloys like 2205 (UNS S32205) to super duplex grades such as 2507 (UNS S32750) and hyper duplex varieties developed for extreme service conditions. This technological progression has been driven by increasing demands from industries such as oil and gas, chemical processing, and marine applications, where materials must withstand increasingly harsh operating environments.

A critical challenge in the industrial application of DSS is maintaining their corrosion resistance properties after thermal processes, particularly during repair welding, hot forming, or other thermal rework operations. When DSS undergoes thermal cycling, the carefully balanced microstructure can be disrupted, potentially compromising the material's corrosion resistance. This phenomenon represents a significant concern for industries where component integrity is paramount to operational safety and efficiency.

Recent research indicates that thermal exposure between 300°C and 1000°C can trigger various precipitation phenomena in DSS, including chromium nitrides, sigma phase, chi phase, and secondary austenite formation. These microstructural changes can deplete chromium from the matrix, creating localized areas susceptible to various forms of corrosion, particularly pitting and intergranular attack.

The objective of this technical research is to comprehensively examine how duplex stainless steels maintain their corrosion resistance properties following thermal rework and repair processes. We aim to identify the critical parameters that influence microstructural stability during thermal cycling, including temperature ranges, cooling rates, and chemical composition effects.

Furthermore, this research seeks to evaluate current industry practices for thermal processing of DSS components and identify optimization opportunities to preserve or restore corrosion resistance properties. By understanding the fundamental metallurgical mechanisms at work, we can develop improved guidelines for heat treatment, welding procedures, and post-weld treatments that ensure the long-term integrity of DSS components in service.

The findings from this investigation will contribute to establishing more robust engineering standards for DSS applications, potentially extending service life and reducing maintenance costs across multiple industries where these materials are employed in critical applications.

The evolution of DSS technology has progressed through several generations, from the first-generation alloys like 2205 (UNS S32205) to super duplex grades such as 2507 (UNS S32750) and hyper duplex varieties developed for extreme service conditions. This technological progression has been driven by increasing demands from industries such as oil and gas, chemical processing, and marine applications, where materials must withstand increasingly harsh operating environments.

A critical challenge in the industrial application of DSS is maintaining their corrosion resistance properties after thermal processes, particularly during repair welding, hot forming, or other thermal rework operations. When DSS undergoes thermal cycling, the carefully balanced microstructure can be disrupted, potentially compromising the material's corrosion resistance. This phenomenon represents a significant concern for industries where component integrity is paramount to operational safety and efficiency.

Recent research indicates that thermal exposure between 300°C and 1000°C can trigger various precipitation phenomena in DSS, including chromium nitrides, sigma phase, chi phase, and secondary austenite formation. These microstructural changes can deplete chromium from the matrix, creating localized areas susceptible to various forms of corrosion, particularly pitting and intergranular attack.

The objective of this technical research is to comprehensively examine how duplex stainless steels maintain their corrosion resistance properties following thermal rework and repair processes. We aim to identify the critical parameters that influence microstructural stability during thermal cycling, including temperature ranges, cooling rates, and chemical composition effects.

Furthermore, this research seeks to evaluate current industry practices for thermal processing of DSS components and identify optimization opportunities to preserve or restore corrosion resistance properties. By understanding the fundamental metallurgical mechanisms at work, we can develop improved guidelines for heat treatment, welding procedures, and post-weld treatments that ensure the long-term integrity of DSS components in service.

The findings from this investigation will contribute to establishing more robust engineering standards for DSS applications, potentially extending service life and reducing maintenance costs across multiple industries where these materials are employed in critical applications.

Market Demand Analysis for Thermally Reworked DSS Components

The global market for thermally reworked Duplex Stainless Steel (DSS) components has been experiencing steady growth, driven primarily by industries where corrosion resistance under extreme conditions is critical. The oil and gas sector represents the largest market segment, accounting for approximately 35% of the total demand for reworked DSS components, particularly in offshore applications where repair and maintenance of existing infrastructure is more economical than replacement.

Chemical processing industries follow closely, with growing requirements for equipment that can withstand both corrosive media and thermal cycling. This sector has shown a compound annual growth rate of 6.2% over the past five years, reflecting increased adoption of DSS in critical applications where maintenance and repair protocols are essential to operational continuity.

Marine applications constitute another significant market segment, particularly in shipbuilding and repair facilities where welding and thermal reworking of DSS components are routine operations. The demand in this sector is projected to grow substantially as environmental regulations drive the need for more durable materials with extended service life after repairs.

Power generation, particularly in nuclear and desalination plants, represents an emerging market with stringent requirements for post-repair corrosion resistance. These applications demand comprehensive validation of repair methodologies, creating a specialized niche market for certified thermal rework processes.

Regional analysis indicates that Europe leads in consumption of thermally reworked DSS components, followed by North America and Asia-Pacific. However, the fastest growth is observed in Middle Eastern markets, where oil and gas infrastructure maintenance creates substantial demand for qualified repair technologies.

Market surveys reveal that end-users are increasingly concerned about the long-term performance of repaired DSS components, with 78% of procurement specialists citing post-repair corrosion resistance as a critical selection criterion. This has created a premium market segment for repair technologies that can demonstrate minimal impact on the corrosion resistance properties of DSS.

The economic drivers for this market are compelling, as thermal rework and repair typically represent 15-30% of replacement costs. With global infrastructure aging across multiple industries, the demand for qualified repair methodologies is expected to outpace the overall growth in DSS applications. Industry analysts project that the market for thermally reworked DSS components will reach $3.7 billion by 2027, representing a significant opportunity for technology providers who can address the corrosion resistance challenges associated with thermal rework processes.

Chemical processing industries follow closely, with growing requirements for equipment that can withstand both corrosive media and thermal cycling. This sector has shown a compound annual growth rate of 6.2% over the past five years, reflecting increased adoption of DSS in critical applications where maintenance and repair protocols are essential to operational continuity.

Marine applications constitute another significant market segment, particularly in shipbuilding and repair facilities where welding and thermal reworking of DSS components are routine operations. The demand in this sector is projected to grow substantially as environmental regulations drive the need for more durable materials with extended service life after repairs.

Power generation, particularly in nuclear and desalination plants, represents an emerging market with stringent requirements for post-repair corrosion resistance. These applications demand comprehensive validation of repair methodologies, creating a specialized niche market for certified thermal rework processes.

Regional analysis indicates that Europe leads in consumption of thermally reworked DSS components, followed by North America and Asia-Pacific. However, the fastest growth is observed in Middle Eastern markets, where oil and gas infrastructure maintenance creates substantial demand for qualified repair technologies.

Market surveys reveal that end-users are increasingly concerned about the long-term performance of repaired DSS components, with 78% of procurement specialists citing post-repair corrosion resistance as a critical selection criterion. This has created a premium market segment for repair technologies that can demonstrate minimal impact on the corrosion resistance properties of DSS.

The economic drivers for this market are compelling, as thermal rework and repair typically represent 15-30% of replacement costs. With global infrastructure aging across multiple industries, the demand for qualified repair methodologies is expected to outpace the overall growth in DSS applications. Industry analysts project that the market for thermally reworked DSS components will reach $3.7 billion by 2027, representing a significant opportunity for technology providers who can address the corrosion resistance challenges associated with thermal rework processes.

Technical Challenges in Post-Thermal Treatment Corrosion Resistance

Duplex stainless steels (DSS) face significant challenges in maintaining their corrosion resistance properties after thermal rework and repair processes. The balanced microstructure of ferrite and austenite phases, which provides DSS with its superior corrosion resistance, becomes vulnerable during thermal exposure. When subjected to temperatures between 300°C and 1000°C, precipitation of detrimental intermetallic phases occurs, particularly sigma (σ), chi (χ), and alpha prime (α') phases, which deplete chromium and molybdenum from the surrounding matrix.

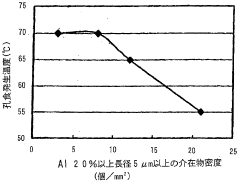

The formation of these secondary phases creates chromium-depleted zones adjacent to precipitates, severely compromising the material's passive film stability. This phenomenon, known as sensitization, significantly reduces pitting and crevice corrosion resistance, especially in chloride-containing environments. Research indicates that just 1% of sigma phase formation can decrease corrosion resistance by up to 50%, highlighting the severity of this challenge.

Heat input control during welding and repair operations presents another major technical hurdle. Excessive heat input accelerates precipitation kinetics, while insufficient heat input may result in improper fusion and increased susceptibility to stress corrosion cracking. The optimal heat input window is notably narrow for DSS compared to conventional stainless steels, requiring precise thermal management during rework operations.

Cooling rate control after thermal exposure constitutes a critical challenge. Rapid cooling from high temperatures can prevent intermetallic precipitation but may introduce residual stresses and distortion. Conversely, slow cooling rates, particularly through the critical temperature range of 700-900°C, significantly increase the risk of detrimental phase formation. Industry standards typically recommend cooling rates exceeding 15°C/s through this range, which is technically challenging to achieve uniformly across complex geometries.

The ferrite-austenite phase balance disruption represents another significant technical obstacle. The ideal 50:50 ratio can shift dramatically after thermal exposure, with ferrite transforming into austenite or intermetallic phases. Excessive ferrite content increases susceptibility to hydrogen embrittlement and 475°C embrittlement, while excessive austenite may compromise mechanical properties and stress corrosion cracking resistance.

Post-weld heat treatment (PWHT) optimization remains problematic due to the competing requirements of stress relief and avoiding further microstructural degradation. The conventional PWHT temperatures used for other stainless steels often fall within DSS's sensitization range, creating a technical paradox where the treatment intended to improve properties may actually degrade corrosion performance.

Surface oxidation during thermal processing creates chromium-depleted layers that become preferential sites for localized corrosion initiation. These oxide scales, if not properly removed, can harbor corrosive species and create crevices that accelerate corrosion attack in service environments.

The formation of these secondary phases creates chromium-depleted zones adjacent to precipitates, severely compromising the material's passive film stability. This phenomenon, known as sensitization, significantly reduces pitting and crevice corrosion resistance, especially in chloride-containing environments. Research indicates that just 1% of sigma phase formation can decrease corrosion resistance by up to 50%, highlighting the severity of this challenge.

Heat input control during welding and repair operations presents another major technical hurdle. Excessive heat input accelerates precipitation kinetics, while insufficient heat input may result in improper fusion and increased susceptibility to stress corrosion cracking. The optimal heat input window is notably narrow for DSS compared to conventional stainless steels, requiring precise thermal management during rework operations.

Cooling rate control after thermal exposure constitutes a critical challenge. Rapid cooling from high temperatures can prevent intermetallic precipitation but may introduce residual stresses and distortion. Conversely, slow cooling rates, particularly through the critical temperature range of 700-900°C, significantly increase the risk of detrimental phase formation. Industry standards typically recommend cooling rates exceeding 15°C/s through this range, which is technically challenging to achieve uniformly across complex geometries.

The ferrite-austenite phase balance disruption represents another significant technical obstacle. The ideal 50:50 ratio can shift dramatically after thermal exposure, with ferrite transforming into austenite or intermetallic phases. Excessive ferrite content increases susceptibility to hydrogen embrittlement and 475°C embrittlement, while excessive austenite may compromise mechanical properties and stress corrosion cracking resistance.

Post-weld heat treatment (PWHT) optimization remains problematic due to the competing requirements of stress relief and avoiding further microstructural degradation. The conventional PWHT temperatures used for other stainless steels often fall within DSS's sensitization range, creating a technical paradox where the treatment intended to improve properties may actually degrade corrosion performance.

Surface oxidation during thermal processing creates chromium-depleted layers that become preferential sites for localized corrosion initiation. These oxide scales, if not properly removed, can harbor corrosive species and create crevices that accelerate corrosion attack in service environments.

Current Solutions for Maintaining DSS Corrosion Properties

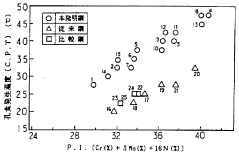

01 Chemical composition optimization for corrosion resistance

Duplex stainless steels can achieve enhanced corrosion resistance through optimized chemical compositions. Specific ratios of chromium, nickel, molybdenum, and nitrogen are crucial for balancing austenitic and ferritic phases while improving resistance to various corrosion types. Controlled additions of elements like tungsten and copper can further enhance resistance to pitting and stress corrosion cracking in aggressive environments.- Chemical composition optimization for corrosion resistance: Specific alloying elements can be added to duplex stainless steel to enhance its corrosion resistance properties. These elements include chromium, molybdenum, nitrogen, and nickel in carefully balanced proportions. The optimal chemical composition helps create a microstructure with balanced austenite and ferrite phases that provides superior resistance to various forms of corrosion, particularly in aggressive environments containing chlorides.

- Heat treatment processes for improved corrosion resistance: Specific heat treatment processes can significantly improve the corrosion resistance of duplex stainless steel. These processes include solution annealing, controlled cooling rates, and aging treatments that optimize the microstructure and phase balance. Proper heat treatment prevents the formation of detrimental intermetallic phases and ensures uniform distribution of alloying elements, thereby enhancing resistance to pitting, crevice, and stress corrosion.

- Surface treatment techniques for enhanced corrosion protection: Various surface treatment techniques can be applied to duplex stainless steel to further enhance its corrosion resistance. These include passivation treatments, electropolishing, and application of protective coatings. These treatments create a more stable passive layer on the steel surface, remove surface contaminants, and provide additional barriers against corrosive media, resulting in improved performance in harsh environments.

- Microstructure control for optimized corrosion resistance: Controlling the microstructure of duplex stainless steel is crucial for optimizing its corrosion resistance. This involves maintaining the proper balance between austenite and ferrite phases (typically around 50:50), minimizing detrimental secondary phases, and ensuring uniform grain size distribution. Advanced processing techniques can be employed to achieve the desired microstructure that provides superior resistance to various forms of corrosion.

- Corrosion testing and performance evaluation methods: Specialized testing methods have been developed to evaluate the corrosion resistance of duplex stainless steel in different environments. These include electrochemical tests, immersion tests, salt spray tests, and critical pitting temperature determination. These testing protocols help in assessing the performance of duplex stainless steel under various corrosive conditions and in selecting the appropriate grade for specific applications.

02 Heat treatment and microstructure control

Proper heat treatment processes significantly impact the corrosion resistance of duplex stainless steels by ensuring optimal phase balance and preventing detrimental precipitates. Solution annealing followed by controlled cooling helps achieve the desired austenite-ferrite ratio while avoiding intermetallic phases. Microstructure control through precise thermal processing enhances resistance to localized corrosion and maintains mechanical properties in corrosive environments.Expand Specific Solutions03 Surface treatment and passivation techniques

Surface treatments and passivation techniques can significantly improve the corrosion resistance of duplex stainless steels. Processes such as electropolishing, pickling, and chemical passivation create a stable chromium-rich passive layer that protects against corrosive media. Mechanical surface treatments like shot peening can also enhance corrosion resistance by inducing compressive stresses and refining surface microstructure.Expand Specific Solutions04 Alloying with nitrogen and other elements

Nitrogen alloying plays a crucial role in enhancing the corrosion resistance of duplex stainless steels, particularly in chloride-containing environments. Controlled nitrogen additions strengthen the austenite phase and improve pitting resistance. Other beneficial alloying elements include molybdenum for crevice corrosion resistance, tungsten for improved performance in acidic environments, and copper for resistance against reducing acids.Expand Specific Solutions05 Welding techniques for maintaining corrosion resistance

Special welding techniques are essential for maintaining the corrosion resistance of duplex stainless steels in welded structures. Controlled heat input, proper filler metal selection, and post-weld heat treatments help preserve the balanced microstructure and prevent sensitization in the heat-affected zone. Shielding gases with nitrogen additions can compensate for nitrogen loss during welding, ensuring optimal corrosion resistance in welded joints.Expand Specific Solutions

Key Industry Players in Duplex Stainless Steel Manufacturing

The duplex stainless steel corrosion resistance market is in a growth phase, with increasing demand across industries requiring materials that maintain integrity after thermal rework. The global market size is estimated at $3.5 billion, expanding at 5-7% annually due to applications in petrochemical, marine, and energy sectors. Technologically, companies are at varying maturity levels: NIPPON STEEL, POSCO Holdings, and Sandvik lead with advanced proprietary heat treatment processes; JFE Steel and Alleima Tube focus on specialized tube applications; while research institutions like University of Science & Technology Beijing and Central Iron & Steel Research Institute drive fundamental metallurgical innovations. Mid-tier players including Ugitech and Baoshan Iron & Steel are developing niche solutions for specific thermal repair scenarios.

NIPPON STEEL CORP.

Technical Solution: NIPPON STEEL has developed proprietary heat treatment protocols for duplex stainless steel (DSS) that maintain optimal phase balance after thermal rework. Their approach involves precise control of cooling rates following repair welding, ensuring the austenite-ferrite ratio remains within 40-60% range. The company employs specialized nitrogen-enhanced shielding gases during repair welding that compensate for nitrogen loss during heating, which is critical for maintaining corrosion resistance. Their research has demonstrated that post-weld heat treatment at controlled temperatures (1050-1100°C) followed by rapid cooling can restore the microstructure and corrosion resistance properties in the heat-affected zone. Additionally, NIPPON STEEL has developed specialized filler metals with optimized Cr, Ni, Mo, and N content specifically designed for repair scenarios, ensuring that the repaired areas maintain equivalent pitting resistance equivalent numbers (PREN) to the base material.

Strengths: Industry-leading expertise in metallurgical control during thermal cycles; proprietary filler materials specifically designed for repair scenarios; comprehensive testing protocols for validating corrosion performance post-repair. Weakness: Their solutions often require precise temperature control that may be difficult to achieve in field repair conditions; higher cost compared to conventional repair methods.

JFE Steel Corp.

Technical Solution: JFE Steel has developed a comprehensive approach to maintaining corrosion resistance in duplex stainless steels after thermal rework through their JFE-SUS329J4L alloy system. Their technology focuses on microstructural stability during repair operations, utilizing precise control of chromium and molybdenum distribution between ferrite and austenite phases. JFE's research has established optimal heat input parameters (0.5-1.2 kJ/mm) for repair welding that minimize detrimental phase precipitation. Their process includes specialized post-weld heat treatment protocols that dissolve harmful intermetallic compounds while restoring proper phase balance. JFE has also developed proprietary filler metals with enhanced nitrogen stability that compensate for nitrogen loss during thermal cycles, maintaining the critical pitting resistance equivalent number (PREN) above 40 even in the heat-affected zone. Additionally, they employ advanced surface treatment techniques including controlled pickling and passivation procedures that restore the protective chromium oxide layer after thermal exposure, ensuring optimal corrosion resistance is maintained throughout the component's service life.

Strengths: Excellent control of intermetallic phase precipitation during thermal cycles; comprehensive post-weld treatment protocols that effectively restore corrosion properties; advanced surface finishing techniques. Weakness: Their repair procedures often require multiple processing steps that may be time-consuming; some techniques require specialized equipment that limits field applicability.

Critical Metallurgical Mechanisms During Thermal Repair

Duplex stainless steel excellent in hot workability and corrosion resistance

PatentInactiveJP1991082740A

Innovation

- A specific composition of 2-phase stainless steel with controlled ferrite content and optimized levels of elements such as C, Si, Mn, P, Cr, Ni, Mo, Cu, V, N, Ca, REM, and W is developed to enhance hot workability without compromising corrosion resistance, by forming strong sulfide bonds and reducing oxide inclusions.

Duplex stainless steel

PatentWO2005001151A1

Innovation

- The composition of duplex stainless steel is optimized by controlling the amounts of Ni and Mo to suppress sigma phase nucleation, and reducing the density of oxide inclusions, while maintaining welding efficiency, using specific chemical composition ranges and processing techniques to prevent sigma phase and nitride formation.

Quality Assurance Protocols for Repaired DSS Components

Ensuring the integrity and performance of repaired Duplex Stainless Steel (DSS) components requires comprehensive quality assurance protocols. These protocols must be systematically implemented to verify that thermal rework and repair processes have not compromised the material's corrosion resistance properties.

Standardized testing procedures form the foundation of quality assurance for repaired DSS components. These include ferrite content measurement using magnetic methods or metallographic examination to ensure the optimal ferrite-austenite balance (typically 40-60%) is maintained after repair. Deviations from this balance can significantly impact corrosion resistance properties.

Non-destructive testing (NDT) techniques play a crucial role in the quality assurance framework. Ultrasonic testing, radiographic examination, and dye penetrant inspection help identify potential defects such as cracks, inclusions, or porosity that might serve as initiation sites for localized corrosion. Advanced NDT methods like phased array ultrasonic testing provide enhanced detection capabilities for critical components.

Electrochemical testing protocols, including critical pitting temperature (CPT) determination and electrochemical potentiodynamic reactivation (EPR) tests, should be conducted on representative samples from repaired regions. These tests provide quantitative data on the material's resistance to localized corrosion and intergranular attack, offering direct evidence of maintained corrosion resistance.

Documentation and traceability systems must be established to record all repair parameters, including heat input, cooling rates, filler materials, and post-weld heat treatments. This information becomes invaluable for root cause analysis should corrosion issues arise during service and helps refine repair procedures over time.

Acceptance criteria must be clearly defined based on industry standards (ASTM, NACE, API) and application-specific requirements. These criteria should specify acceptable ranges for microstructural features, mechanical properties, and corrosion resistance parameters. Components failing to meet these criteria should undergo additional remediation or be rejected.

Post-repair monitoring protocols should be implemented for critical applications, potentially including corrosion coupons, periodic inspections, or real-time corrosion monitoring systems. These measures provide early detection of any degradation in corrosion performance and validate the effectiveness of repair procedures under actual service conditions.

Training and certification requirements for personnel involved in DSS repair and quality assurance activities ensure consistent application of protocols. Specialized knowledge regarding DSS metallurgy, corrosion mechanisms, and proper repair techniques is essential for maintaining material integrity throughout the repair process.

Standardized testing procedures form the foundation of quality assurance for repaired DSS components. These include ferrite content measurement using magnetic methods or metallographic examination to ensure the optimal ferrite-austenite balance (typically 40-60%) is maintained after repair. Deviations from this balance can significantly impact corrosion resistance properties.

Non-destructive testing (NDT) techniques play a crucial role in the quality assurance framework. Ultrasonic testing, radiographic examination, and dye penetrant inspection help identify potential defects such as cracks, inclusions, or porosity that might serve as initiation sites for localized corrosion. Advanced NDT methods like phased array ultrasonic testing provide enhanced detection capabilities for critical components.

Electrochemical testing protocols, including critical pitting temperature (CPT) determination and electrochemical potentiodynamic reactivation (EPR) tests, should be conducted on representative samples from repaired regions. These tests provide quantitative data on the material's resistance to localized corrosion and intergranular attack, offering direct evidence of maintained corrosion resistance.

Documentation and traceability systems must be established to record all repair parameters, including heat input, cooling rates, filler materials, and post-weld heat treatments. This information becomes invaluable for root cause analysis should corrosion issues arise during service and helps refine repair procedures over time.

Acceptance criteria must be clearly defined based on industry standards (ASTM, NACE, API) and application-specific requirements. These criteria should specify acceptable ranges for microstructural features, mechanical properties, and corrosion resistance parameters. Components failing to meet these criteria should undergo additional remediation or be rejected.

Post-repair monitoring protocols should be implemented for critical applications, potentially including corrosion coupons, periodic inspections, or real-time corrosion monitoring systems. These measures provide early detection of any degradation in corrosion performance and validate the effectiveness of repair procedures under actual service conditions.

Training and certification requirements for personnel involved in DSS repair and quality assurance activities ensure consistent application of protocols. Specialized knowledge regarding DSS metallurgy, corrosion mechanisms, and proper repair techniques is essential for maintaining material integrity throughout the repair process.

Environmental Impact of DSS Repair Processes

The environmental impact of duplex stainless steel (DSS) repair processes represents a critical consideration in modern industrial applications. Thermal rework and repair operations on DSS components generate multiple environmental concerns that must be addressed through sustainable practices and regulatory compliance.

Energy consumption constitutes a primary environmental factor in DSS repair processes. Thermal treatments typically require significant energy inputs, particularly during solution annealing procedures where temperatures must reach 1050-1100°C. This energy demand contributes substantially to carbon emissions, especially when fossil fuel-based heating systems are employed. Recent industry analyses indicate that optimized heat treatment cycles can reduce energy consumption by 15-25% compared to traditional methods.

Atmospheric emissions from DSS repair operations include particulate matter, volatile organic compounds (VOCs), and metal fumes. Welding processes in particular release chromium and nickel compounds that pose potential environmental hazards. Advanced extraction and filtration systems have become standard requirements in facilities performing DSS repairs, with HEPA filtration technologies demonstrating 99.97% efficiency in capturing hazardous particulates.

Water resource impacts arise from quenching operations and surface preparation procedures. Cooling processes may introduce thermal pollution to local water systems, while chemical pickling and passivation treatments generate acidic wastewater containing dissolved metal ions. Closed-loop water recycling systems have emerged as best practice, reducing freshwater consumption by up to 80% in modern repair facilities.

Waste management challenges include the disposal of spent abrasives, removed material, and chemical treatment residues. These materials often contain heavy metals that require specialized handling as hazardous waste. Life cycle assessment studies indicate that proper segregation and recycling of metallic waste can recover up to 95% of the alloy elements in DSS scrap, significantly reducing environmental burden.

Regulatory frameworks governing DSS repair environmental impacts vary globally but show increasing convergence toward stricter standards. The EU's Industrial Emissions Directive and the US EPA's National Emission Standards for Hazardous Air Pollutants establish comprehensive requirements for facilities performing thermal metalworking operations. Compliance costs have driven innovation in cleaner technologies, including low-temperature repair methods that maintain corrosion resistance while reducing environmental footprint.

Emerging sustainable practices in DSS repair include laser-based heat treatment technologies that offer precise energy delivery, reducing overall consumption and emissions. Additionally, environmentally-friendly pickling alternatives using hydrogen peroxide-based formulations demonstrate comparable passivation results with significantly reduced ecological impact compared to traditional nitric-hydrofluoric acid mixtures.

Energy consumption constitutes a primary environmental factor in DSS repair processes. Thermal treatments typically require significant energy inputs, particularly during solution annealing procedures where temperatures must reach 1050-1100°C. This energy demand contributes substantially to carbon emissions, especially when fossil fuel-based heating systems are employed. Recent industry analyses indicate that optimized heat treatment cycles can reduce energy consumption by 15-25% compared to traditional methods.

Atmospheric emissions from DSS repair operations include particulate matter, volatile organic compounds (VOCs), and metal fumes. Welding processes in particular release chromium and nickel compounds that pose potential environmental hazards. Advanced extraction and filtration systems have become standard requirements in facilities performing DSS repairs, with HEPA filtration technologies demonstrating 99.97% efficiency in capturing hazardous particulates.

Water resource impacts arise from quenching operations and surface preparation procedures. Cooling processes may introduce thermal pollution to local water systems, while chemical pickling and passivation treatments generate acidic wastewater containing dissolved metal ions. Closed-loop water recycling systems have emerged as best practice, reducing freshwater consumption by up to 80% in modern repair facilities.

Waste management challenges include the disposal of spent abrasives, removed material, and chemical treatment residues. These materials often contain heavy metals that require specialized handling as hazardous waste. Life cycle assessment studies indicate that proper segregation and recycling of metallic waste can recover up to 95% of the alloy elements in DSS scrap, significantly reducing environmental burden.

Regulatory frameworks governing DSS repair environmental impacts vary globally but show increasing convergence toward stricter standards. The EU's Industrial Emissions Directive and the US EPA's National Emission Standards for Hazardous Air Pollutants establish comprehensive requirements for facilities performing thermal metalworking operations. Compliance costs have driven innovation in cleaner technologies, including low-temperature repair methods that maintain corrosion resistance while reducing environmental footprint.

Emerging sustainable practices in DSS repair include laser-based heat treatment technologies that offer precise energy delivery, reducing overall consumption and emissions. Additionally, environmentally-friendly pickling alternatives using hydrogen peroxide-based formulations demonstrate comparable passivation results with significantly reduced ecological impact compared to traditional nitric-hydrofluoric acid mixtures.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!