Duplex Stainless Steel Welding: Nitrogen Loss, Ferrite Control And HAZ Toughness

SEP 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DSS Welding Background and Objectives

Duplex stainless steels (DSS) have emerged as a critical material class in modern industrial applications, offering an exceptional combination of mechanical properties and corrosion resistance. The development of DSS began in the early 1930s, with significant advancements occurring in the 1970s and 1980s when the balanced microstructure of austenite and ferrite phases was optimized. This dual-phase structure provides DSS with higher strength than austenitic grades while maintaining excellent resistance to stress corrosion cracking and pitting.

The welding of DSS presents unique challenges that have been the focus of extensive research over the past four decades. The technical evolution in this field has been driven by the increasing demands of offshore oil and gas, chemical processing, and marine applications where material performance under extreme conditions is paramount. The historical progression of DSS welding technology reflects a continuous effort to maintain the delicate phase balance that gives these materials their distinctive properties.

Current trends in DSS welding technology are moving toward more precise control of heat input, filler metal composition, and shielding gas mixtures to address the three critical challenges identified: nitrogen loss during welding, ferrite content control, and heat-affected zone (HAZ) toughness. The industry has witnessed a shift from empirical approaches to science-based methodologies supported by advanced computational modeling and in-situ monitoring techniques.

The primary objective of current research in DSS welding is to develop robust processes that consistently produce welds with optimal phase balance (typically 35-65% ferrite) while preventing detrimental microstructural changes. Specifically, researchers aim to mitigate nitrogen loss during welding, which can lead to excessive ferrite formation and reduced corrosion resistance. Additionally, controlling ferrite content within acceptable ranges is crucial for maintaining mechanical properties and preventing embrittlement.

Another key goal is enhancing HAZ toughness, which is often compromised due to rapid thermal cycles during welding that can lead to undesirable phase transformations, precipitation of intermetallic compounds, and grain coarsening. The development of specialized heat treatment protocols and welding parameter optimization strategies represents a significant focus area for achieving this objective.

The technological trajectory suggests that future advancements will likely involve the integration of real-time monitoring systems with adaptive control algorithms to dynamically adjust welding parameters based on material response. This approach promises to overcome the inherent variability in welding processes and ensure consistent quality in DSS welded joints across diverse application environments.

The welding of DSS presents unique challenges that have been the focus of extensive research over the past four decades. The technical evolution in this field has been driven by the increasing demands of offshore oil and gas, chemical processing, and marine applications where material performance under extreme conditions is paramount. The historical progression of DSS welding technology reflects a continuous effort to maintain the delicate phase balance that gives these materials their distinctive properties.

Current trends in DSS welding technology are moving toward more precise control of heat input, filler metal composition, and shielding gas mixtures to address the three critical challenges identified: nitrogen loss during welding, ferrite content control, and heat-affected zone (HAZ) toughness. The industry has witnessed a shift from empirical approaches to science-based methodologies supported by advanced computational modeling and in-situ monitoring techniques.

The primary objective of current research in DSS welding is to develop robust processes that consistently produce welds with optimal phase balance (typically 35-65% ferrite) while preventing detrimental microstructural changes. Specifically, researchers aim to mitigate nitrogen loss during welding, which can lead to excessive ferrite formation and reduced corrosion resistance. Additionally, controlling ferrite content within acceptable ranges is crucial for maintaining mechanical properties and preventing embrittlement.

Another key goal is enhancing HAZ toughness, which is often compromised due to rapid thermal cycles during welding that can lead to undesirable phase transformations, precipitation of intermetallic compounds, and grain coarsening. The development of specialized heat treatment protocols and welding parameter optimization strategies represents a significant focus area for achieving this objective.

The technological trajectory suggests that future advancements will likely involve the integration of real-time monitoring systems with adaptive control algorithms to dynamically adjust welding parameters based on material response. This approach promises to overcome the inherent variability in welding processes and ensure consistent quality in DSS welded joints across diverse application environments.

Market Demand Analysis for DSS Welded Components

The global market for Duplex Stainless Steel (DSS) welded components has experienced significant growth over the past decade, driven primarily by increasing demand from oil and gas, chemical processing, and marine industries. The superior combination of strength and corrosion resistance makes DSS particularly valuable in harsh environments where traditional austenitic stainless steels would fail prematurely.

Recent market research indicates that the oil and gas sector remains the largest consumer of DSS welded components, accounting for approximately 40% of the total market share. This demand is particularly strong in offshore applications, subsea equipment, and pipeline systems where exposure to chloride-rich environments necessitates materials with exceptional corrosion resistance and mechanical properties.

The chemical processing industry represents the second-largest market segment, with growing applications in pressure vessels, heat exchangers, and storage tanks. The ability of properly welded DSS to withstand aggressive chemical environments while maintaining structural integrity has made it increasingly preferred over more expensive nickel-based alloys in many applications.

Marine and desalination sectors have also shown substantial growth in DSS welded component utilization. The increasing construction of desalination plants globally, particularly in water-scarce regions of the Middle East and North Africa, has created steady demand for corrosion-resistant piping systems and pressure vessels where DSS welding quality is critical.

Market analysis reveals a growing trend toward higher-grade DSS variants such as super and hyper duplex grades for more demanding applications. This shift has intensified the focus on advanced welding techniques that can maintain nitrogen content, control ferrite-austenite balance, and ensure HAZ toughness in these more complex alloys.

Regional market assessment shows that Europe currently leads in DSS welded component consumption, followed by North America and Asia-Pacific. However, the fastest growth is occurring in emerging markets, particularly in the Middle East and Southeast Asia, where infrastructure development and industrial expansion are creating new opportunities for high-performance materials.

Industry forecasts project the global market for DSS welded components to grow at a compound annual growth rate of 6.8% through 2028. This growth trajectory is supported by increasing investments in offshore oil and gas exploration, expansion of chemical processing facilities, and the development of advanced desalination technologies.

The market is also witnessing a shift toward value-added services, with customers increasingly demanding comprehensive welding procedure specifications, non-destructive testing, and quality assurance documentation to ensure the long-term performance of DSS welded components in critical applications.

Recent market research indicates that the oil and gas sector remains the largest consumer of DSS welded components, accounting for approximately 40% of the total market share. This demand is particularly strong in offshore applications, subsea equipment, and pipeline systems where exposure to chloride-rich environments necessitates materials with exceptional corrosion resistance and mechanical properties.

The chemical processing industry represents the second-largest market segment, with growing applications in pressure vessels, heat exchangers, and storage tanks. The ability of properly welded DSS to withstand aggressive chemical environments while maintaining structural integrity has made it increasingly preferred over more expensive nickel-based alloys in many applications.

Marine and desalination sectors have also shown substantial growth in DSS welded component utilization. The increasing construction of desalination plants globally, particularly in water-scarce regions of the Middle East and North Africa, has created steady demand for corrosion-resistant piping systems and pressure vessels where DSS welding quality is critical.

Market analysis reveals a growing trend toward higher-grade DSS variants such as super and hyper duplex grades for more demanding applications. This shift has intensified the focus on advanced welding techniques that can maintain nitrogen content, control ferrite-austenite balance, and ensure HAZ toughness in these more complex alloys.

Regional market assessment shows that Europe currently leads in DSS welded component consumption, followed by North America and Asia-Pacific. However, the fastest growth is occurring in emerging markets, particularly in the Middle East and Southeast Asia, where infrastructure development and industrial expansion are creating new opportunities for high-performance materials.

Industry forecasts project the global market for DSS welded components to grow at a compound annual growth rate of 6.8% through 2028. This growth trajectory is supported by increasing investments in offshore oil and gas exploration, expansion of chemical processing facilities, and the development of advanced desalination technologies.

The market is also witnessing a shift toward value-added services, with customers increasingly demanding comprehensive welding procedure specifications, non-destructive testing, and quality assurance documentation to ensure the long-term performance of DSS welded components in critical applications.

Current Challenges in DSS Welding Technology

Duplex stainless steel (DSS) welding technology currently faces several significant challenges that impede optimal performance and reliability in industrial applications. The most pressing issue is nitrogen loss during the welding process, which directly impacts the microstructure and mechanical properties of the weld metal. When DSS is subjected to high temperatures during welding, nitrogen—a critical austenite stabilizer—tends to escape from the molten pool, resulting in an imbalanced ferrite-austenite ratio that compromises corrosion resistance and mechanical integrity.

Ferrite control represents another major challenge in DSS welding. The ideal ferrite content in DSS welds typically ranges between 30-70%, with most applications targeting 40-60% for optimal performance. However, achieving and maintaining this balance is exceptionally difficult due to rapid cooling rates and variations in heat input. Excessive ferrite formation leads to reduced ductility and toughness, while insufficient ferrite content compromises strength and stress corrosion cracking resistance.

The heat-affected zone (HAZ) toughness degradation remains a persistent concern in DSS welding operations. The thermal cycles experienced during welding can trigger precipitation of detrimental intermetallic phases such as sigma (σ), chi (χ), and chromium nitrides, particularly when cooling rates are inappropriate. These precipitates significantly reduce impact toughness and corrosion resistance in the HAZ, creating potential failure points in welded structures.

Current welding procedures often struggle with heat input management, as DSS requires a delicate balance—sufficient heat to promote austenite formation but not excessive enough to cause grain growth or precipitate formation. This narrow processing window creates substantial challenges for welders, especially in field applications where environmental conditions may vary considerably.

Filler metal selection and composition optimization continue to challenge manufacturers, as standard filler materials may not adequately compensate for nitrogen loss or provide the necessary alloying elements to maintain phase balance. The industry lacks standardized approaches for different DSS grades, particularly for super and hyper duplex varieties with higher alloying content.

Post-weld heat treatment (PWHT) effectiveness remains questionable for DSS, unlike conventional stainless steels. While PWHT can relieve residual stresses, it may simultaneously promote detrimental phase precipitation if temperature and time parameters are not precisely controlled, creating a technical dilemma for fabricators.

The absence of real-time monitoring techniques for phase balance during welding operations forces manufacturers to rely on post-weld testing, which is both time-consuming and costly. This reactive approach to quality control increases production costs and can lead to significant material wastage when welds fail to meet specifications.

Ferrite control represents another major challenge in DSS welding. The ideal ferrite content in DSS welds typically ranges between 30-70%, with most applications targeting 40-60% for optimal performance. However, achieving and maintaining this balance is exceptionally difficult due to rapid cooling rates and variations in heat input. Excessive ferrite formation leads to reduced ductility and toughness, while insufficient ferrite content compromises strength and stress corrosion cracking resistance.

The heat-affected zone (HAZ) toughness degradation remains a persistent concern in DSS welding operations. The thermal cycles experienced during welding can trigger precipitation of detrimental intermetallic phases such as sigma (σ), chi (χ), and chromium nitrides, particularly when cooling rates are inappropriate. These precipitates significantly reduce impact toughness and corrosion resistance in the HAZ, creating potential failure points in welded structures.

Current welding procedures often struggle with heat input management, as DSS requires a delicate balance—sufficient heat to promote austenite formation but not excessive enough to cause grain growth or precipitate formation. This narrow processing window creates substantial challenges for welders, especially in field applications where environmental conditions may vary considerably.

Filler metal selection and composition optimization continue to challenge manufacturers, as standard filler materials may not adequately compensate for nitrogen loss or provide the necessary alloying elements to maintain phase balance. The industry lacks standardized approaches for different DSS grades, particularly for super and hyper duplex varieties with higher alloying content.

Post-weld heat treatment (PWHT) effectiveness remains questionable for DSS, unlike conventional stainless steels. While PWHT can relieve residual stresses, it may simultaneously promote detrimental phase precipitation if temperature and time parameters are not precisely controlled, creating a technical dilemma for fabricators.

The absence of real-time monitoring techniques for phase balance during welding operations forces manufacturers to rely on post-weld testing, which is both time-consuming and costly. This reactive approach to quality control increases production costs and can lead to significant material wastage when welds fail to meet specifications.

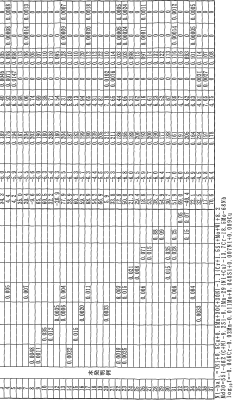

Current Solutions for Nitrogen Loss Prevention

01 Nitrogen addition techniques to prevent nitrogen loss during welding

Various techniques can be employed to prevent nitrogen loss during the welding of duplex stainless steel. These include using nitrogen-containing shielding gases, adding nitrogen-rich filler metals, or applying nitrogen-enriched flux. These methods help maintain the nitrogen content in the weld metal and heat-affected zone (HAZ), which is crucial for preserving the austenite-ferrite balance and ensuring optimal mechanical properties and corrosion resistance in the welded joint.- Nitrogen addition techniques to prevent nitrogen loss during welding: Various techniques can be employed to prevent nitrogen loss during duplex stainless steel welding, which is critical for maintaining corrosion resistance and mechanical properties. These methods include using nitrogen-containing shielding gases, nitrogen-enriched filler metals, and controlled welding parameters. By maintaining adequate nitrogen content in the weld metal, the austenite-ferrite balance can be preserved, which is essential for the desired properties of duplex stainless steel welds.

- Control of ferrite content in duplex stainless steel welds: Maintaining optimal ferrite content in duplex stainless steel welds is crucial for achieving the desired mechanical properties and corrosion resistance. The ferrite content can be controlled through proper selection of filler materials, welding parameters, and post-weld heat treatments. Excessive ferrite content can lead to reduced toughness and corrosion resistance, while insufficient ferrite may compromise strength. Balancing these factors is essential for producing high-quality duplex stainless steel welds.

- Heat-affected zone (HAZ) toughness improvement methods: Improving toughness in the heat-affected zone (HAZ) of duplex stainless steel welds is critical for preventing brittle fracture and ensuring structural integrity. This can be achieved through controlled heat input, proper interpass temperature management, post-weld heat treatment, and appropriate filler metal selection. These methods help maintain the optimal austenite-ferrite balance and minimize the formation of detrimental phases that could compromise the HAZ toughness.

- Welding parameter optimization for duplex stainless steel: Optimizing welding parameters is essential for successful duplex stainless steel welding. Key parameters include heat input, cooling rate, interpass temperature, and welding speed. Proper control of these parameters helps prevent nitrogen loss, maintain appropriate ferrite content, and ensure adequate HAZ toughness. Advanced welding techniques and monitoring systems can be employed to achieve consistent and high-quality welds in duplex stainless steel components.

- Post-weld heat treatment effects on microstructure and properties: Post-weld heat treatment significantly influences the microstructure and mechanical properties of duplex stainless steel welds. Appropriate heat treatment can help restore the austenite-ferrite balance, dissolve detrimental phases, relieve residual stresses, and improve overall weld quality. The temperature, duration, and cooling rate of the heat treatment must be carefully controlled to achieve optimal results and prevent the formation of unwanted phases that could compromise the weld's performance.

02 Control of ferrite content in duplex stainless steel welds

Controlling the ferrite content in duplex stainless steel welds is essential for achieving the desired mechanical properties and corrosion resistance. This can be accomplished through careful selection of welding parameters, filler materials, and post-weld heat treatments. The optimal ferrite content typically ranges between 30-70%, with excessive ferrite leading to reduced toughness and corrosion resistance, while insufficient ferrite can result in hot cracking susceptibility. Proper balance is critical for maintaining the characteristic properties of duplex stainless steel.Expand Specific Solutions03 Heat-affected zone (HAZ) toughness improvement methods

Improving the toughness of the heat-affected zone in duplex stainless steel welds can be achieved through several methods. These include controlling heat input during welding, implementing proper pre-heating and inter-pass temperature control, applying post-weld heat treatments, and using appropriate filler materials. These techniques help maintain the optimal microstructure in the HAZ, preventing excessive ferrite formation and ensuring adequate austenite reformation, which is crucial for maintaining toughness and corrosion resistance in the welded joint.Expand Specific Solutions04 Welding process optimization for duplex stainless steel

Optimizing the welding process for duplex stainless steel involves careful control of various parameters such as heat input, cooling rate, shielding gas composition, and welding speed. These factors significantly influence the microstructure, mechanical properties, and corrosion resistance of the welded joint. Advanced welding techniques like pulsed arc welding, controlled heat input processes, and specialized shielding gas mixtures can be employed to maintain the proper austenite-ferrite balance and prevent detrimental phase formations in the weld metal and heat-affected zone.Expand Specific Solutions05 Microstructure control and phase balance in duplex stainless steel welds

Maintaining the proper microstructure and phase balance in duplex stainless steel welds is critical for ensuring optimal mechanical properties and corrosion resistance. This involves controlling the cooling rate, chemical composition, and thermal cycles during welding to achieve the desired austenite-ferrite ratio. Techniques such as alloying element additions, controlled cooling, and post-weld heat treatments can be employed to promote austenite formation and prevent the precipitation of detrimental phases like sigma phase, chi phase, and chromium nitrides, which can compromise the performance of the welded joint.Expand Specific Solutions

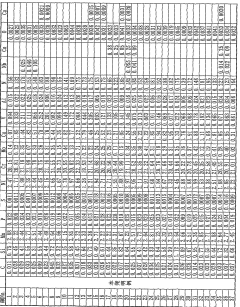

Major Industry Players in DSS Welding

Duplex stainless steel welding technology is currently in a mature development phase, with a global market size estimated at $2-3 billion annually and growing steadily at 5-7%. The competitive landscape is dominated by established steel manufacturers with advanced R&D capabilities, including NIPPON STEEL, Outokumpu Oyj, and POSCO Holdings. These companies have developed proprietary solutions addressing the key technical challenges of nitrogen loss prevention, ferrite content control, and heat-affected zone toughness improvement. Technical maturity varies, with Japanese and European manufacturers (JFE Steel, voestalpine BÖHLER) leading in specialized applications, while Chinese producers (Baoshan Iron & Steel, CNOOC) are rapidly advancing their capabilities through research partnerships with institutions like Central Iron & Steel Research Institute and Kunming University of Science & Technology.

NIPPON STEEL CORP.

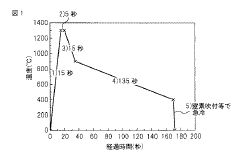

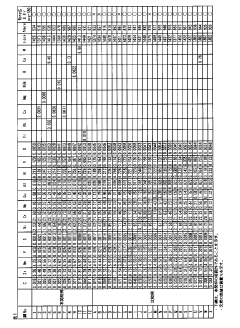

Technical Solution: NIPPON STEEL has developed advanced duplex stainless steel welding techniques focusing on nitrogen retention during welding processes. Their approach involves precise control of shielding gas compositions with optimized nitrogen content (typically 1-10%) to compensate for nitrogen loss in the weld metal. The company employs specialized filler metals with elevated nitrogen and nickel content to maintain phase balance in the weld zone. Their research has demonstrated that controlling heat input between 0.5-1.5 kJ/mm and implementing specific post-weld heat treatment protocols (typically at 1050-1150°C) significantly improves HAZ toughness. NIPPON STEEL has also pioneered pulsed arc welding techniques specifically calibrated for duplex grades, which creates controlled thermal cycles that minimize ferrite formation while ensuring adequate nitrogen retention. Their comprehensive approach includes real-time monitoring of ferrite content during welding using magnetic measurement devices to maintain the optimal ferrite-austenite ratio of approximately 50:50.

Strengths: Superior nitrogen retention technology resulting in consistent mechanical properties across weldments; excellent control of ferrite-austenite balance through specialized filler metals and shielding gas compositions. Weaknesses: Their techniques often require more sophisticated equipment and higher-grade consumables, potentially increasing production costs; some methods may be less suitable for field welding applications where environmental control is limited.

Outokumpu Oyj

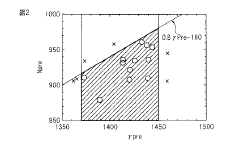

Technical Solution: Outokumpu has developed a comprehensive duplex stainless steel welding solution centered around their proprietary nitrogen-enriched shielding gas systems. Their technology utilizes precisely calibrated Ar-N2 gas mixtures (typically containing 2-5% nitrogen) that maintain nitrogen levels in the weld pool while preventing porosity issues. For thicker sections, they've pioneered multi-pass welding techniques with controlled interpass temperatures (maximum 150°C) to optimize ferrite-austenite transformation. Outokumpu's approach includes specialized heat input management protocols that maintain heat input between 0.5-2.0 kJ/mm, preventing excessive ferrite formation while ensuring adequate HAZ toughness. Their research has demonstrated that maintaining cooling rates between 800-500°C at 20-30°C/s provides optimal microstructural development. Additionally, they've developed specific filler metal compositions with elevated nitrogen content (0.14-0.20%) and nickel equivalents approximately 2-4% higher than the base metal to compensate for nitrogen loss and promote austenite formation in the weld metal and HAZ regions.

Strengths: Exceptional control of nitrogen content throughout the welding process; comprehensive approach addressing both consumable composition and process parameters; proven track record with super duplex grades in demanding applications. Weaknesses: Their solutions often require specialized training and equipment; some techniques may be less cost-effective for smaller scale operations or standard duplex grades where such precise control might be excessive.

Key Technologies for Ferrite Content Control

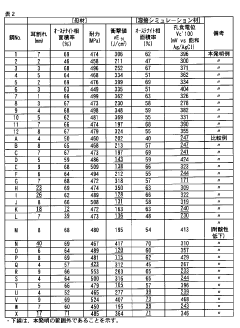

Low-alloy duplex stainless steel wherein weld heat-affected zones have good corrosion resistance and toughness

PatentWO2009119895A1

Innovation

- The composition of the alloy-saving duplex stainless steel is optimized by controlling the content of elements such as V, Nb, N, Ni, and Cu to minimize nitride precipitation and enhance the austenite phase ratio, thereby maintaining corrosion resistance and toughness. This is achieved by limiting the addition of V to a solid solution level and reducing N content in the ferrite phase, while adding Ni and Cu to improve toughness.

Duplex stainless steel of high-strength alloy-saving type having excellent corrosion resistance in weld heat-affected zone

PatentActiveJP2011068957A

Innovation

- The solution involves optimizing the composition and microstructure of the alloy-saving duplex stainless steel by controlling the addition of elements such as V, Nb, and B to suppress Cr nitride precipitation in the HAZ, maintaining a sufficient austenite phase ratio, and adhering to specific equilibrium precipitation temperature ranges to enhance corrosion resistance.

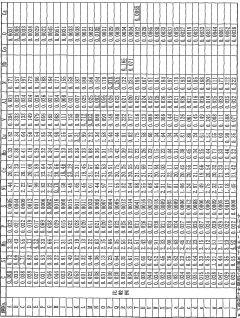

Corrosion Resistance Considerations in DSS Welds

Corrosion resistance is a critical property of duplex stainless steels (DSS) that must be maintained after welding operations. The balanced microstructure of austenite and ferrite phases in DSS provides superior resistance to various forms of corrosion, particularly pitting, crevice, and stress corrosion cracking. However, welding processes can significantly alter this balance and compromise corrosion performance.

The heat-affected zone (HAZ) represents a particularly vulnerable region where thermal cycles can lead to precipitation of detrimental intermetallic phases such as sigma, chi, and chromium nitrides. These precipitates deplete the surrounding matrix of chromium and molybdenum, creating localized areas susceptible to preferential corrosion attack. Research indicates that maintaining a ferrite content between 35-65% in the weld metal and HAZ is essential for optimal corrosion resistance.

Nitrogen loss during welding presents a significant challenge to corrosion resistance. As a strong austenite stabilizer and beneficial alloying element, nitrogen enhances pitting resistance in DSS. Studies have shown that up to 30% of nitrogen can be lost during certain welding processes, particularly in the root pass of gas tungsten arc welding (GTAW). This loss directly impacts the pitting resistance equivalent number (PREN), which can decrease by 2-3 points, significantly reducing corrosion performance.

Proper selection of filler metals with higher nickel and nitrogen content than the base metal helps compensate for nitrogen loss and maintains phase balance. Additionally, shielding gases containing nitrogen (typically 1-2% N₂ in Ar) have proven effective in minimizing nitrogen loss during welding. For super duplex grades, higher nitrogen contents in shielding gases (up to 5%) may be necessary to maintain corrosion properties.

Post-weld heat treatment (PWHT) considerations are also crucial for corrosion resistance. While PWHT can relieve residual stresses, improper temperature control can lead to formation of detrimental phases. Solution annealing followed by rapid cooling is sometimes recommended for critical applications to restore optimal microstructure and corrosion resistance.

Testing methodologies for evaluating corrosion resistance in DSS welds include ASTM G48 (ferric chloride pitting test), electrochemical critical pitting temperature (CPT) determination, and intergranular corrosion testing. These tests provide quantitative measures of how welding parameters affect corrosion performance and help establish acceptance criteria for welded components in corrosive environments.

The heat-affected zone (HAZ) represents a particularly vulnerable region where thermal cycles can lead to precipitation of detrimental intermetallic phases such as sigma, chi, and chromium nitrides. These precipitates deplete the surrounding matrix of chromium and molybdenum, creating localized areas susceptible to preferential corrosion attack. Research indicates that maintaining a ferrite content between 35-65% in the weld metal and HAZ is essential for optimal corrosion resistance.

Nitrogen loss during welding presents a significant challenge to corrosion resistance. As a strong austenite stabilizer and beneficial alloying element, nitrogen enhances pitting resistance in DSS. Studies have shown that up to 30% of nitrogen can be lost during certain welding processes, particularly in the root pass of gas tungsten arc welding (GTAW). This loss directly impacts the pitting resistance equivalent number (PREN), which can decrease by 2-3 points, significantly reducing corrosion performance.

Proper selection of filler metals with higher nickel and nitrogen content than the base metal helps compensate for nitrogen loss and maintains phase balance. Additionally, shielding gases containing nitrogen (typically 1-2% N₂ in Ar) have proven effective in minimizing nitrogen loss during welding. For super duplex grades, higher nitrogen contents in shielding gases (up to 5%) may be necessary to maintain corrosion properties.

Post-weld heat treatment (PWHT) considerations are also crucial for corrosion resistance. While PWHT can relieve residual stresses, improper temperature control can lead to formation of detrimental phases. Solution annealing followed by rapid cooling is sometimes recommended for critical applications to restore optimal microstructure and corrosion resistance.

Testing methodologies for evaluating corrosion resistance in DSS welds include ASTM G48 (ferric chloride pitting test), electrochemical critical pitting temperature (CPT) determination, and intergranular corrosion testing. These tests provide quantitative measures of how welding parameters affect corrosion performance and help establish acceptance criteria for welded components in corrosive environments.

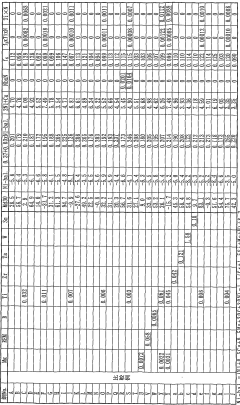

Quality Assurance and Testing Methods for DSS Welds

Quality assurance and testing methods for Duplex Stainless Steel (DSS) welds require comprehensive approaches to ensure structural integrity and performance. Non-destructive testing (NDT) techniques form the foundation of quality control, with radiographic testing (RT) being particularly effective for detecting internal defects such as porosity and inclusions. Ultrasonic testing (UT) complements RT by providing detailed information about weld penetration and fusion characteristics, especially critical in thick-section DSS components where nitrogen loss and ferrite control are paramount concerns.

Ferrite measurement represents a cornerstone of DSS weld quality assessment. Magnetic instruments like the Feritscope or Fischer Ferrite Test provide rapid on-site quantification of ferrite content, ensuring the optimal phase balance between austenite and ferrite is maintained. The target ferrite content typically ranges between 30-70%, with most specifications requiring 35-65% to achieve the desired combination of strength and corrosion resistance. Deviations outside these ranges often indicate nitrogen loss during welding or improper heat input control.

Corrosion testing methods are essential for validating the environmental performance of DSS welds. The ASTM G48 test (ferric chloride pitting test) serves as an industry standard for evaluating pitting resistance, while intergranular corrosion testing according to ASTM A262 helps identify sensitization in the heat-affected zone (HAZ). These tests are particularly relevant for assessing the impact of nitrogen loss on corrosion performance, as nitrogen depletion can significantly reduce pitting resistance.

Mechanical testing protocols focus on both strength and toughness properties. Tensile testing verifies the weld meets minimum strength requirements, while impact testing (particularly Charpy V-notch tests) at various temperatures evaluates HAZ toughness. For critical applications, fracture mechanics testing using CTOD (Crack Tip Opening Displacement) specimens provides more detailed assessment of fracture resistance, especially important in environments where hydrogen embrittlement may be a concern.

Microstructural examination through optical and electron microscopy represents the most detailed quality assessment method. Proper sample preparation, including etching techniques specific to DSS (such as Beraha's reagent), allows metallurgists to quantify phase balance, identify detrimental intermetallic phases like sigma or chi, and evaluate grain structure in both the weld metal and HAZ. Advanced techniques like EBSD (Electron Backscatter Diffraction) can provide crystallographic information to better understand phase transformations and their impact on mechanical properties.

Ferrite measurement represents a cornerstone of DSS weld quality assessment. Magnetic instruments like the Feritscope or Fischer Ferrite Test provide rapid on-site quantification of ferrite content, ensuring the optimal phase balance between austenite and ferrite is maintained. The target ferrite content typically ranges between 30-70%, with most specifications requiring 35-65% to achieve the desired combination of strength and corrosion resistance. Deviations outside these ranges often indicate nitrogen loss during welding or improper heat input control.

Corrosion testing methods are essential for validating the environmental performance of DSS welds. The ASTM G48 test (ferric chloride pitting test) serves as an industry standard for evaluating pitting resistance, while intergranular corrosion testing according to ASTM A262 helps identify sensitization in the heat-affected zone (HAZ). These tests are particularly relevant for assessing the impact of nitrogen loss on corrosion performance, as nitrogen depletion can significantly reduce pitting resistance.

Mechanical testing protocols focus on both strength and toughness properties. Tensile testing verifies the weld meets minimum strength requirements, while impact testing (particularly Charpy V-notch tests) at various temperatures evaluates HAZ toughness. For critical applications, fracture mechanics testing using CTOD (Crack Tip Opening Displacement) specimens provides more detailed assessment of fracture resistance, especially important in environments where hydrogen embrittlement may be a concern.

Microstructural examination through optical and electron microscopy represents the most detailed quality assessment method. Proper sample preparation, including etching techniques specific to DSS (such as Beraha's reagent), allows metallurgists to quantify phase balance, identify detrimental intermetallic phases like sigma or chi, and evaluate grain structure in both the weld metal and HAZ. Advanced techniques like EBSD (Electron Backscatter Diffraction) can provide crystallographic information to better understand phase transformations and their impact on mechanical properties.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!