How Duplex Stainless Steel Controls Ferrite/Austenite Ratio After PWHT Or Service?

SEP 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Duplex Steel Phase Balance Background and Objectives

Duplex stainless steels (DSS) have emerged as a critical material class in industries requiring exceptional corrosion resistance combined with superior mechanical properties. These steels derive their unique characteristics from a balanced microstructure consisting of approximately equal proportions of ferrite and austenite phases. The evolution of DSS began in the early 1930s, with significant commercial development occurring in the 1970s and 1980s, driven by demands from offshore oil and gas, chemical processing, and marine applications.

The technical evolution of DSS has focused primarily on achieving and maintaining the optimal phase balance, typically 50% ferrite and 50% austenite. This balance represents the cornerstone of DSS performance, as it combines the corrosion resistance of austenitic stainless steels with the strength and stress corrosion cracking resistance of ferritic grades. Historical developments show a progressive refinement in alloying strategies, with modern super duplex grades incorporating precise additions of nitrogen, nickel, molybdenum, and chromium to stabilize the desired microstructure.

Post-weld heat treatment (PWHT) and high-temperature service conditions present significant challenges to maintaining this critical phase balance. When exposed to temperatures between 300°C and 1000°C, DSS can undergo microstructural transformations that alter the ferrite/austenite ratio, potentially compromising material properties. The precipitation of detrimental intermetallic phases, particularly sigma and chi phases, occurs predominantly in the ferrite phase, further complicating phase balance control.

Recent technological trends indicate growing interest in developing predictive models for phase transformation kinetics during thermal cycles. These models aim to establish processing windows that maintain optimal microstructures throughout the material's service life. Concurrently, advances in in-situ monitoring techniques are enabling real-time assessment of phase transformations during welding and heat treatment processes.

The primary technical objective in this field is to develop robust methodologies for controlling the ferrite/austenite ratio during manufacturing, welding, PWHT, and throughout service life. This includes establishing precise correlations between chemical composition, thermal history, and resultant microstructure. Secondary objectives involve understanding the influence of minor alloying elements on phase stability and developing non-destructive testing methods for phase balance verification in field applications.

Industry standards currently specify acceptable ferrite content ranges (typically 30-70%), but emerging applications in extreme environments demand narrower tolerances and greater predictability. The economic implications of phase balance control are substantial, as imbalances can lead to premature failure in critical components, resulting in costly downtime and safety concerns in sectors such as oil and gas, chemical processing, and power generation.

The technical evolution of DSS has focused primarily on achieving and maintaining the optimal phase balance, typically 50% ferrite and 50% austenite. This balance represents the cornerstone of DSS performance, as it combines the corrosion resistance of austenitic stainless steels with the strength and stress corrosion cracking resistance of ferritic grades. Historical developments show a progressive refinement in alloying strategies, with modern super duplex grades incorporating precise additions of nitrogen, nickel, molybdenum, and chromium to stabilize the desired microstructure.

Post-weld heat treatment (PWHT) and high-temperature service conditions present significant challenges to maintaining this critical phase balance. When exposed to temperatures between 300°C and 1000°C, DSS can undergo microstructural transformations that alter the ferrite/austenite ratio, potentially compromising material properties. The precipitation of detrimental intermetallic phases, particularly sigma and chi phases, occurs predominantly in the ferrite phase, further complicating phase balance control.

Recent technological trends indicate growing interest in developing predictive models for phase transformation kinetics during thermal cycles. These models aim to establish processing windows that maintain optimal microstructures throughout the material's service life. Concurrently, advances in in-situ monitoring techniques are enabling real-time assessment of phase transformations during welding and heat treatment processes.

The primary technical objective in this field is to develop robust methodologies for controlling the ferrite/austenite ratio during manufacturing, welding, PWHT, and throughout service life. This includes establishing precise correlations between chemical composition, thermal history, and resultant microstructure. Secondary objectives involve understanding the influence of minor alloying elements on phase stability and developing non-destructive testing methods for phase balance verification in field applications.

Industry standards currently specify acceptable ferrite content ranges (typically 30-70%), but emerging applications in extreme environments demand narrower tolerances and greater predictability. The economic implications of phase balance control are substantial, as imbalances can lead to premature failure in critical components, resulting in costly downtime and safety concerns in sectors such as oil and gas, chemical processing, and power generation.

Market Applications and Demand Analysis for Duplex Stainless Steel

The global market for duplex stainless steel continues to expand significantly, driven by increasing demand across multiple industries where corrosion resistance and mechanical strength are paramount. The oil and gas sector represents the largest application segment, accounting for approximately 30% of total duplex stainless steel consumption. This demand stems from the material's exceptional performance in offshore platforms, subsea equipment, and processing facilities where exposure to seawater and corrosive chemicals is common.

Chemical processing industries constitute another major market, particularly in applications involving aggressive media such as organic and inorganic acids, chlorides, and caustic solutions. The superior stress corrosion cracking resistance of duplex grades makes them ideal for chemical reactors, heat exchangers, and storage tanks where maintaining precise ferrite-austenite ratios is critical for operational safety and longevity.

Desalination plants worldwide have increasingly adopted duplex stainless steel for key components including high-pressure pumps, valves, and piping systems. The growing global water scarcity issues have accelerated investments in desalination infrastructure, creating sustained demand for materials that can withstand the highly corrosive seawater environment while maintaining structural integrity after post-weld heat treatment.

The power generation sector, particularly in waste-to-energy plants and biomass facilities, represents an emerging application area. These environments combine high temperatures with corrosive compounds, making the balanced microstructure of duplex stainless steel particularly valuable. Market analysts project this segment to grow at a compound annual growth rate of 6.8% through 2028.

Pulp and paper industries utilize duplex grades in digesters, bleaching equipment, and chemical recovery systems where the dual-phase microstructure provides resistance to both chloride-induced corrosion and mechanical stress. The ability to maintain optimal ferrite-austenite ratios after service exposure at elevated temperatures has made these materials increasingly preferred over traditional austenitic grades.

Regional market analysis reveals that Europe leads in duplex stainless steel consumption, followed by North America and Asia-Pacific. However, the fastest growth is occurring in emerging economies where infrastructure development and industrial expansion are creating new application opportunities. The Middle East region shows particularly strong demand growth due to extensive oil and gas operations and large-scale desalination projects.

Market trends indicate increasing interest in lean duplex grades that offer cost advantages while maintaining adequate performance in less severe environments. This development is expanding the application range into more price-sensitive sectors such as architecture, transportation infrastructure, and water distribution systems where controlling phase balance during fabrication and service remains essential.

Chemical processing industries constitute another major market, particularly in applications involving aggressive media such as organic and inorganic acids, chlorides, and caustic solutions. The superior stress corrosion cracking resistance of duplex grades makes them ideal for chemical reactors, heat exchangers, and storage tanks where maintaining precise ferrite-austenite ratios is critical for operational safety and longevity.

Desalination plants worldwide have increasingly adopted duplex stainless steel for key components including high-pressure pumps, valves, and piping systems. The growing global water scarcity issues have accelerated investments in desalination infrastructure, creating sustained demand for materials that can withstand the highly corrosive seawater environment while maintaining structural integrity after post-weld heat treatment.

The power generation sector, particularly in waste-to-energy plants and biomass facilities, represents an emerging application area. These environments combine high temperatures with corrosive compounds, making the balanced microstructure of duplex stainless steel particularly valuable. Market analysts project this segment to grow at a compound annual growth rate of 6.8% through 2028.

Pulp and paper industries utilize duplex grades in digesters, bleaching equipment, and chemical recovery systems where the dual-phase microstructure provides resistance to both chloride-induced corrosion and mechanical stress. The ability to maintain optimal ferrite-austenite ratios after service exposure at elevated temperatures has made these materials increasingly preferred over traditional austenitic grades.

Regional market analysis reveals that Europe leads in duplex stainless steel consumption, followed by North America and Asia-Pacific. However, the fastest growth is occurring in emerging economies where infrastructure development and industrial expansion are creating new application opportunities. The Middle East region shows particularly strong demand growth due to extensive oil and gas operations and large-scale desalination projects.

Market trends indicate increasing interest in lean duplex grades that offer cost advantages while maintaining adequate performance in less severe environments. This development is expanding the application range into more price-sensitive sectors such as architecture, transportation infrastructure, and water distribution systems where controlling phase balance during fabrication and service remains essential.

Current Challenges in Ferrite/Austenite Ratio Control

The control of ferrite/austenite ratio in duplex stainless steels (DSS) after post-weld heat treatment (PWHT) or during service presents significant technical challenges that continue to perplex metallurgists and engineers. The ideal balance of approximately 50:50 ferrite-to-austenite provides optimal mechanical and corrosion resistance properties, but maintaining this ratio throughout the material's lifecycle remains problematic.

Temperature sensitivity represents one of the most critical challenges, as the ferrite-austenite balance is highly dependent on thermal history. During PWHT or high-temperature service, the metastable microstructure of DSS undergoes continuous transformation. Even minor temperature fluctuations between 300-1000°C can trigger significant phase transformations, with ferrite decomposition accelerating dramatically above 600°C, leading to embrittlement and reduced corrosion resistance.

Compositional heterogeneity across welds and heat-affected zones further complicates ratio control. The partitioning of alloying elements during solidification and subsequent thermal cycles creates localized variations in chromium, nickel, nitrogen, and molybdenum concentrations. These variations directly influence phase stability, with nitrogen and nickel promoting austenite formation while chromium and molybdenum stabilize ferrite. The resulting chemical gradients make uniform phase distribution nearly impossible to achieve.

Cooling rate management presents another substantial challenge, particularly in thick sections or complex geometries. Rapid cooling tends to retain higher ferrite content, while slower cooling promotes austenite formation. The practical difficulties in ensuring consistent cooling rates throughout an entire component often result in microstructural variations and unpredictable mechanical properties.

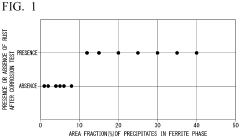

Secondary phase precipitation during PWHT or service represents perhaps the most insidious challenge. Sigma phase, chi phase, chromium nitrides, and various carbides can form at different temperature ranges, depleting the surrounding matrix of critical alloying elements. These precipitates not only alter the ferrite/austenite ratio but also create localized zones susceptible to corrosion and mechanical failure. The kinetics of these transformations are complex and highly dependent on both time and temperature.

Measurement and quality control methodologies add another layer of complexity. Current non-destructive testing techniques lack the precision needed for accurate phase quantification in field conditions. Magnetic measurements, while convenient, provide only approximate values and can be influenced by other microstructural features. This creates uncertainty in verification processes, making it difficult to ensure components maintain their optimal phase balance throughout their service life.

Temperature sensitivity represents one of the most critical challenges, as the ferrite-austenite balance is highly dependent on thermal history. During PWHT or high-temperature service, the metastable microstructure of DSS undergoes continuous transformation. Even minor temperature fluctuations between 300-1000°C can trigger significant phase transformations, with ferrite decomposition accelerating dramatically above 600°C, leading to embrittlement and reduced corrosion resistance.

Compositional heterogeneity across welds and heat-affected zones further complicates ratio control. The partitioning of alloying elements during solidification and subsequent thermal cycles creates localized variations in chromium, nickel, nitrogen, and molybdenum concentrations. These variations directly influence phase stability, with nitrogen and nickel promoting austenite formation while chromium and molybdenum stabilize ferrite. The resulting chemical gradients make uniform phase distribution nearly impossible to achieve.

Cooling rate management presents another substantial challenge, particularly in thick sections or complex geometries. Rapid cooling tends to retain higher ferrite content, while slower cooling promotes austenite formation. The practical difficulties in ensuring consistent cooling rates throughout an entire component often result in microstructural variations and unpredictable mechanical properties.

Secondary phase precipitation during PWHT or service represents perhaps the most insidious challenge. Sigma phase, chi phase, chromium nitrides, and various carbides can form at different temperature ranges, depleting the surrounding matrix of critical alloying elements. These precipitates not only alter the ferrite/austenite ratio but also create localized zones susceptible to corrosion and mechanical failure. The kinetics of these transformations are complex and highly dependent on both time and temperature.

Measurement and quality control methodologies add another layer of complexity. Current non-destructive testing techniques lack the precision needed for accurate phase quantification in field conditions. Magnetic measurements, while convenient, provide only approximate values and can be influenced by other microstructural features. This creates uncertainty in verification processes, making it difficult to ensure components maintain their optimal phase balance throughout their service life.

Established Methods for Phase Balance Control

01 Optimal ferrite/austenite ratio for duplex stainless steel properties

Duplex stainless steels typically aim for a balanced ferrite-to-austenite ratio of approximately 50:50 to achieve optimal mechanical properties and corrosion resistance. This balanced microstructure combines the strength of ferrite with the toughness and corrosion resistance of austenite. Controlling this ratio is critical as it directly affects the material's yield strength, tensile strength, ductility, and resistance to various forms of corrosion, particularly stress corrosion cracking and pitting.- Optimal ferrite/austenite ratio for duplex stainless steel properties: Duplex stainless steels typically aim for a balanced ferrite-to-austenite ratio of approximately 50:50 to achieve optimal mechanical properties and corrosion resistance. This balanced microstructure combines the strength of ferrite with the toughness and corrosion resistance of austenite. Controlling this ratio is critical as it directly affects the material's yield strength, tensile strength, ductility, and resistance to various forms of corrosion, particularly stress corrosion cracking and pitting corrosion.

- Heat treatment effects on ferrite/austenite phase balance: Heat treatment processes significantly influence the ferrite/austenite ratio in duplex stainless steels. Solution annealing followed by controlled cooling is commonly employed to achieve the desired phase balance. Improper heat treatment can lead to excessive ferrite formation or precipitation of detrimental intermetallic phases. The cooling rate from high temperatures particularly affects the transformation of ferrite to austenite, with slower cooling generally promoting more austenite formation while rapid quenching can preserve higher ferrite content.

- Alloying elements influence on phase ratio control: The ferrite/austenite ratio in duplex stainless steels is strongly influenced by alloying elements. Ferrite-promoting elements include chromium, molybdenum, and silicon, while austenite-promoting elements include nickel, nitrogen, manganese, and carbon. By carefully balancing these elements, manufacturers can achieve the desired microstructure. Nitrogen is particularly effective as an austenite stabilizer and provides additional benefits for corrosion resistance and mechanical properties without the cost associated with nickel additions.

- Manufacturing processes affecting phase distribution: Various manufacturing processes including hot rolling, forging, and welding significantly impact the ferrite/austenite ratio in duplex stainless steels. These processes introduce thermal cycles and deformation that can alter the microstructure. Welding is particularly critical as the heat-affected zone often experiences imbalanced phase ratios due to rapid heating and cooling. Post-weld heat treatments are frequently necessary to restore the optimal phase balance and maintain the desired properties throughout the component.

- Testing and measurement methods for phase ratio determination: Accurate measurement of the ferrite/austenite ratio is essential for quality control of duplex stainless steels. Common methods include metallographic examination with image analysis, magnetic measurement techniques (as ferrite is ferromagnetic while austenite is not), X-ray diffraction, and electron backscatter diffraction (EBSD). These techniques vary in accuracy, complexity, and applicability to different product forms. Standards typically require documentation of the phase balance as part of material certification, with acceptable ranges often specified as 30-70% ferrite, though 40-60% is generally preferred for optimal properties.

02 Heat treatment effects on phase balance

Heat treatment processes significantly influence the ferrite/austenite ratio in duplex stainless steels. Solution annealing followed by controlled cooling is commonly employed to achieve the desired phase balance. Improper heat treatment can lead to excessive ferrite formation or precipitation of detrimental intermetallic phases. The cooling rate from high temperatures particularly affects the transformation of ferrite to austenite, with slower cooling generally promoting more austenite formation while rapid quenching can preserve higher ferrite content.Expand Specific Solutions03 Alloying elements for phase ratio control

Specific alloying elements are used to control the ferrite/austenite ratio in duplex stainless steels. Nickel, nitrogen, manganese, and copper are austenite stabilizers that promote austenite formation, while chromium, molybdenum, and silicon promote ferrite formation. The precise balance of these elements is carefully controlled during steel production to achieve the target microstructure. Nitrogen is particularly effective as an austenite former and also enhances corrosion resistance and mechanical properties.Expand Specific Solutions04 Manufacturing processes affecting phase distribution

Various manufacturing processes including hot rolling, forging, and welding significantly impact the ferrite/austenite ratio in duplex stainless steels. These processes introduce thermal cycles and deformation that can alter the phase balance. Welding is particularly critical as the rapid heating and cooling can create heat-affected zones with excessive ferrite content. Controlled post-weld heat treatments are often necessary to restore the optimal phase balance. Processing parameters such as temperature, deformation degree, and cooling rate must be carefully controlled to maintain the desired microstructure.Expand Specific Solutions05 Testing and measurement methods for phase ratio

Various techniques are employed to measure and verify the ferrite/austenite ratio in duplex stainless steels. These include metallographic examination with image analysis, magnetic measurement methods (ferritescopes), X-ray diffraction, and electron backscatter diffraction (EBSD). Standardized testing procedures ensure consistent evaluation of the phase balance across different production batches. Accurate measurement is essential for quality control and ensuring that the material meets the specified properties for critical applications in chemical processing, oil and gas, and marine environments.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Duplex Steel

The duplex stainless steel market is currently in a mature growth phase, characterized by established manufacturing processes and widespread industrial applications. The global market size for duplex stainless steel is estimated at approximately $3 billion, with steady annual growth driven by demands in oil and gas, chemical processing, and marine applications. Leading companies like Outokumpu, NIPPON STEEL, and POSCO Holdings have developed sophisticated control mechanisms for maintaining optimal ferrite/austenite ratios after post-weld heat treatment (PWHT) and during service conditions. These companies employ precise alloying element balancing, controlled cooling rates, and advanced heat treatment protocols to prevent phase imbalances that could compromise corrosion resistance and mechanical properties. Research institutions such as Central Iron & Steel Research Institute and RIST are advancing new methodologies for predicting and controlling microstructural evolution during thermal cycles.

NIPPON STEEL CORP.

Technical Solution: NIPPON STEEL has developed advanced duplex stainless steel grades with optimized chemical compositions to control ferrite/austenite ratios after PWHT or service. Their approach involves precise balancing of ferrite-promoting elements (Cr, Mo, Si) and austenite-promoting elements (Ni, N, Mn) to achieve target phase ratios typically between 40-60% ferrite. They employ controlled cooling rates during manufacturing and have patented heat treatment protocols that minimize intermetallic phase precipitation while maintaining desired microstructure. Their research has shown that adding 0.14-0.32% nitrogen significantly improves phase stability during thermal cycles. NIPPON STEEL also utilizes computational models to predict phase transformations during PWHT, allowing them to tailor compositions for specific service conditions. Their latest super duplex grades maintain stable phase ratios even after exposure to temperatures up to 300°C for extended periods.

Strengths: Superior control of nitrogen content provides excellent phase stability during thermal cycling; proprietary computational models enable precise prediction of microstructural evolution. Weaknesses: Higher production costs due to tight compositional control requirements; some grades may show sensitivity to sigma phase formation during prolonged exposure at intermediate temperatures (600-900°C).

Outokumpu Oyj

Technical Solution: Outokumpu has pioneered a comprehensive approach to ferrite/austenite ratio control in duplex stainless steels through their proprietary "Balanced Duplex" technology. Their method involves precise control of both composition and processing parameters to maintain optimal phase balance after PWHT and during service. Outokumpu's technique includes carefully calibrated additions of nitrogen (typically 0.14-0.28%) combined with controlled nickel content to stabilize austenite, while managing chromium and molybdenum levels to prevent excessive ferrite formation. Their manufacturing process incorporates specialized solution annealing treatments with controlled cooling rates to establish the initial phase balance. For post-weld scenarios, Outokumpu has developed specific heat input guidelines and filler metal compositions that compensate for dilution effects and maintain phase balance in the heat-affected zone. Their research has demonstrated that maintaining ferrite content between 35-55% provides optimal corrosion resistance and mechanical properties across various service environments.

Strengths: Extensive experience with lean duplex grades that maintain phase balance while reducing costly alloying elements; sophisticated modeling capabilities for predicting phase transformations across various thermal cycles. Weaknesses: Some grades show sensitivity to intermetallic precipitation during prolonged exposure at temperatures between 650-950°C; requires tight control of cooling rates during manufacturing to achieve target microstructures.

Critical Patents and Research on Phase Stability

Welded structure and storage tank

PatentPendingEP4130321A1

Innovation

- A welded structure using duplex stainless steel with specific chemical compositions and controlled ferrite phase volume fractions in the weld metal, along with optimized alloying elements and welding conditions, to maintain a ferrite phase volume of 45-75% and minimize precipitate formation, ensuring a hardness ratio of 0.80-1.20 and proof stress of 440 MPa or more in the welded portion.

Corrosion Resistance Impact of Phase Imbalance

The phase balance between ferrite and austenite in duplex stainless steels (DSS) significantly impacts their corrosion resistance properties. When the optimal ratio of approximately 50:50 ferrite-to-austenite is disrupted following post-weld heat treatment (PWHT) or during service conditions, the material's ability to withstand various corrosive environments becomes compromised.

In chloride-containing environments, phase imbalance typically results in preferential corrosion attack. An excess of ferrite phase (>60%) reduces the overall chromium and nitrogen distribution in the microstructure, diminishing resistance to pitting and crevice corrosion. Studies have demonstrated that for every 10% increase in ferrite content above the optimal range, the pitting resistance equivalent number (PREN) decreases by approximately 2-3 points, directly correlating with reduced performance in chloride media.

Conversely, austenite-rich structures (>60%) exhibit decreased resistance to stress corrosion cracking (SCC), particularly in environments containing hydrogen sulfide. The austenite phase, with its face-centered cubic structure, provides less resistance to hydrogen embrittlement compared to the body-centered cubic structure of ferrite. This becomes especially problematic in sour service applications where hydrogen generation occurs at the metal surface.

Intergranular corrosion susceptibility increases dramatically with phase imbalance. The precipitation of chromium-rich phases at ferrite-austenite boundaries creates chromium-depleted zones that become preferential sites for corrosive attack. This phenomenon is exacerbated when improper PWHT procedures allow the formation of detrimental intermetallic phases such as sigma (σ) and chi (χ), which further disrupt the electrochemical homogeneity of the material.

General corrosion rates in acidic environments show a non-linear relationship with phase balance. Testing in sulfuric acid solutions reveals that DSS with optimal phase ratios exhibits corrosion rates 30-40% lower than those with significant imbalance. This performance differential becomes more pronounced as acid concentration increases, highlighting the importance of maintaining proper microstructure.

The localized corrosion resistance, particularly at weld heat-affected zones (HAZ), depends heavily on maintaining phase balance through controlled cooling rates. Rapid cooling that favors excessive ferrite retention or prolonged exposure to temperatures between 650-950°C that promotes intermetallic precipitation both result in reduced critical pitting temperatures (CPT) and critical crevice temperatures (CCT) by up to 20°C compared to properly balanced structures.

In high-temperature applications, phase imbalance accelerates the 475°C embrittlement phenomenon, where spinodal decomposition of ferrite into chromium-rich and chromium-depleted regions occurs. This microstructural change not only reduces mechanical properties but also creates electrochemical heterogeneity that significantly diminishes corrosion resistance in various media.

In chloride-containing environments, phase imbalance typically results in preferential corrosion attack. An excess of ferrite phase (>60%) reduces the overall chromium and nitrogen distribution in the microstructure, diminishing resistance to pitting and crevice corrosion. Studies have demonstrated that for every 10% increase in ferrite content above the optimal range, the pitting resistance equivalent number (PREN) decreases by approximately 2-3 points, directly correlating with reduced performance in chloride media.

Conversely, austenite-rich structures (>60%) exhibit decreased resistance to stress corrosion cracking (SCC), particularly in environments containing hydrogen sulfide. The austenite phase, with its face-centered cubic structure, provides less resistance to hydrogen embrittlement compared to the body-centered cubic structure of ferrite. This becomes especially problematic in sour service applications where hydrogen generation occurs at the metal surface.

Intergranular corrosion susceptibility increases dramatically with phase imbalance. The precipitation of chromium-rich phases at ferrite-austenite boundaries creates chromium-depleted zones that become preferential sites for corrosive attack. This phenomenon is exacerbated when improper PWHT procedures allow the formation of detrimental intermetallic phases such as sigma (σ) and chi (χ), which further disrupt the electrochemical homogeneity of the material.

General corrosion rates in acidic environments show a non-linear relationship with phase balance. Testing in sulfuric acid solutions reveals that DSS with optimal phase ratios exhibits corrosion rates 30-40% lower than those with significant imbalance. This performance differential becomes more pronounced as acid concentration increases, highlighting the importance of maintaining proper microstructure.

The localized corrosion resistance, particularly at weld heat-affected zones (HAZ), depends heavily on maintaining phase balance through controlled cooling rates. Rapid cooling that favors excessive ferrite retention or prolonged exposure to temperatures between 650-950°C that promotes intermetallic precipitation both result in reduced critical pitting temperatures (CPT) and critical crevice temperatures (CCT) by up to 20°C compared to properly balanced structures.

In high-temperature applications, phase imbalance accelerates the 475°C embrittlement phenomenon, where spinodal decomposition of ferrite into chromium-rich and chromium-depleted regions occurs. This microstructural change not only reduces mechanical properties but also creates electrochemical heterogeneity that significantly diminishes corrosion resistance in various media.

Mechanical Property Changes During Long-term Service

Duplex stainless steels (DSS) undergo significant mechanical property changes during long-term service, primarily due to alterations in the ferrite/austenite phase balance and microstructural transformations. These changes directly impact the material's performance characteristics and service life in industrial applications.

The tensile properties of DSS typically experience gradual degradation during extended service periods. Yield strength and ultimate tensile strength may decrease by 5-15% after 10-15 years in service at elevated temperatures (250-350°C), particularly in environments where the material is subjected to cyclic loading conditions. This reduction correlates strongly with the increase in austenite fraction that commonly occurs during service.

Toughness degradation represents one of the most critical concerns for DSS in long-term applications. Impact energy values can decrease by 30-50% after prolonged exposure at service temperatures, especially when the ferrite content increases beyond the optimal 45-55% range. The 475°C embrittlement phenomenon, characterized by the precipitation of α' phase within ferrite, significantly accelerates this toughness reduction when service temperatures approach this critical range.

Hardness evolution during service follows a non-linear pattern, initially increasing during the first 2-5 years due to precipitation hardening mechanisms, followed by a gradual decrease as microstructural coarsening occurs. The hardness differential between ferrite and austenite phases tends to increase with service time, creating localized stress concentration zones that can initiate cracking under certain loading conditions.

Fatigue resistance deterioration is another consequence of long-term service exposure. The fatigue limit may decrease by 10-20% after extended service, with crack initiation sites predominantly occurring at phase boundaries where compositional gradients exist. The cyclic stress-strain response becomes increasingly asymmetric as the phase balance shifts from the optimal ratio.

Creep resistance properties show notable sensitivity to phase balance changes. DSS with ferrite content exceeding 60% after service exposure typically exhibit accelerated creep rates and reduced rupture strength compared to materials maintaining the optimal phase balance. This behavior is attributed to the preferential diffusion pathways that develop along phase boundaries during service.

Corrosion resistance, while primarily a chemical property, directly influences mechanical integrity during service. Selective phase corrosion can create surface irregularities that act as stress concentrators, reducing effective load-bearing capacity and fatigue performance. The precipitation of intermetallic phases during service further compromises the material's ability to maintain mechanical properties in corrosive environments.

The tensile properties of DSS typically experience gradual degradation during extended service periods. Yield strength and ultimate tensile strength may decrease by 5-15% after 10-15 years in service at elevated temperatures (250-350°C), particularly in environments where the material is subjected to cyclic loading conditions. This reduction correlates strongly with the increase in austenite fraction that commonly occurs during service.

Toughness degradation represents one of the most critical concerns for DSS in long-term applications. Impact energy values can decrease by 30-50% after prolonged exposure at service temperatures, especially when the ferrite content increases beyond the optimal 45-55% range. The 475°C embrittlement phenomenon, characterized by the precipitation of α' phase within ferrite, significantly accelerates this toughness reduction when service temperatures approach this critical range.

Hardness evolution during service follows a non-linear pattern, initially increasing during the first 2-5 years due to precipitation hardening mechanisms, followed by a gradual decrease as microstructural coarsening occurs. The hardness differential between ferrite and austenite phases tends to increase with service time, creating localized stress concentration zones that can initiate cracking under certain loading conditions.

Fatigue resistance deterioration is another consequence of long-term service exposure. The fatigue limit may decrease by 10-20% after extended service, with crack initiation sites predominantly occurring at phase boundaries where compositional gradients exist. The cyclic stress-strain response becomes increasingly asymmetric as the phase balance shifts from the optimal ratio.

Creep resistance properties show notable sensitivity to phase balance changes. DSS with ferrite content exceeding 60% after service exposure typically exhibit accelerated creep rates and reduced rupture strength compared to materials maintaining the optimal phase balance. This behavior is attributed to the preferential diffusion pathways that develop along phase boundaries during service.

Corrosion resistance, while primarily a chemical property, directly influences mechanical integrity during service. Selective phase corrosion can create surface irregularities that act as stress concentrators, reducing effective load-bearing capacity and fatigue performance. The precipitation of intermetallic phases during service further compromises the material's ability to maintain mechanical properties in corrosive environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!